No—NiMH batteries are not lithium batteries. Nickel–metal hydride (NiMH) and lithium‑ion (Li‑ion) are different electrochemical systems with distinct materials, voltages, safety behaviors, and use cases. If you’ve ever wondered whether the AA NiMH in a camera or toy is “lithium,” the short answer is that it belongs to a nickel‑based family, while lithium‑ion powers most phones, laptops, and modern electric vehicles.

How the chemistries work (in plain English)

-

NiMH stores energy using a nickel hydroxide positive electrode and a hydrogen‑absorbing metal alloy negative electrode in an alkaline electrolyte. During charge and discharge, hydrogen moves in and out of the alloy while nickel compounds switch between oxidized and reduced forms—a robust, well‑understood system used for decades. An accessible overview of nickel’s role in batteries is provided by the Nickel Institute’s context page in the Nickel in batteries (Nickel Institute, 2018).

-

Lithium‑ion stores energy by moving lithium ions between host materials (commonly graphite at the negative electrode and various lithium metal oxides or phosphates at the positive electrode) in organic electrolyte. This “intercalation” mechanism enables high energy density in compact formats. A lay explanation of families and behavior appears in Battery University’s lithium‑based summary table (updated 2025).

In other words, NiMH uses nickel chemistry and hydrogen storage alloys; Li‑ion uses lithium compounds shuttling Li+ between layered materials.

Standard parameters: voltage, names, and why they matter

Each battery chemistry has a characteristic nominal voltage per cell—a core identifier used in datasheets and standards. The IEC 61960 series lays out how lithium rechargeable cells are designated and tested; the 2024 edition reiterates that “each electrochemical couple has a characteristic voltage range and a nominal voltage.” See IEC 61960‑4 overview (IEC, 2024).

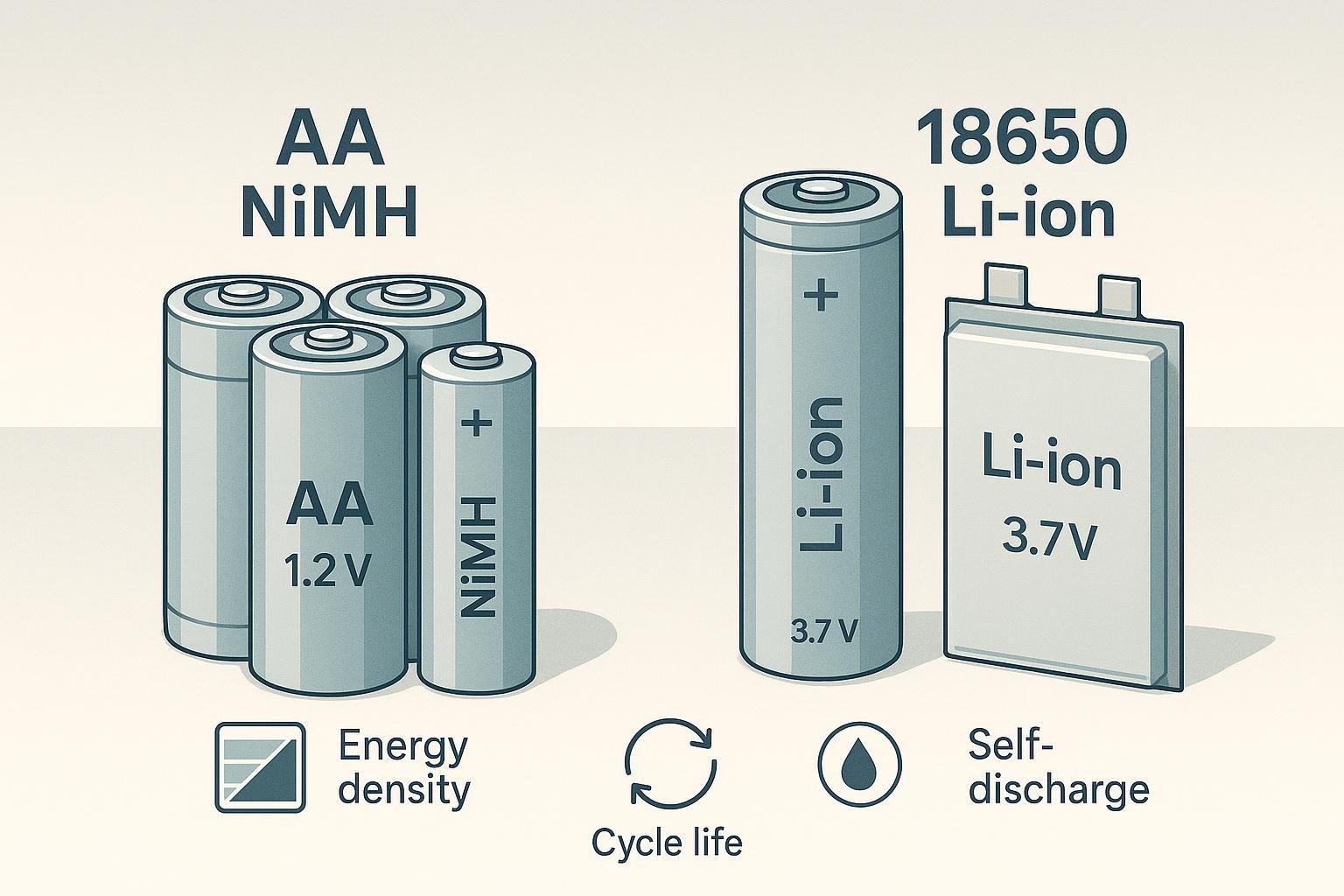

Typical single‑cell nominal voltages you’ll encounter:

- NiMH: about 1.2–1.25 V per cell

- Lithium‑ion (NMC/LCO): about 3.6–3.7 V per cell

- LiFePO4 (LFP, a lithium‑ion subtype): about 3.2–3.3 V per cell

These differences drive everything from how many cells you need in series to the charger design and the battery management system (BMS) requirements.

Side‑by‑side comparison (conservative ranges)

-

Nominal voltage per cell

- NiMH ≈ 1.2 V

- Li‑ion ≈ 3.6–3.7 V (LFP ≈ 3.2–3.3 V)

- Reference values compiled in Battery University’s lithium‑based summary (updated 2025) and aligned with the nominal‑voltage concept in IEC 61960‑4 (IEC, 2024).

-

Specific energy (energy per kilogram)

- NiMH ≈ 60–120 Wh/kg

- Li‑ion (typical NMC/LCO) ≈ 150–250 Wh/kg

-

Cycle life (highly dependent on depth of discharge, temperature, and charge limits)

- NiMH: often around 500–1,000 cycles in practical use

- Li‑ion: ranges widely; several hundred to a few thousand cycles are achievable under controlled conditions

-

Self‑discharge (capacity lost during storage)

- NiMH: relatively high; traditional cells can lose on the order of tens of percent per month, while “low‑self‑discharge” designs improve this

- Li‑ion: low; commonly a few percent per month

-

Charging and management

- NiMH: simpler charge control; often constant‑current with negative‑delta‑V detection and temperature monitoring

- Li‑ion: strictly managed CC/CV charging with precise voltage limits; requires protections for over/under‑voltage, over‑current, and temperature—typically via a BMS

-

Safety profile

- NiMH: generally tolerant and lower energy density, but still requires proper charging and thermal care

- Li‑ion: higher energy density; susceptible to thermal runaway under abuse or defect. Modern designs mitigate risk with cell selection, mechanical protections, BMS, and thermal management. A technical perspective on runaway mechanisms is discussed in ACS Energy Letters analysis (Jeevarajan et al., 2022).

-

Common formats and uses

- NiMH: AA/AAA rechargeable cells for consumer devices; historical and ongoing use in hybrid‑electric vehicles (HEVs)

- Li‑ion: cylindrical 18650/21700 cells, pouch/prismatic packs; dominant in smartphones, laptops, power tools, battery‑electric vehicles (BEVs) and plug‑in hybrids (PHEVs)

Numbers above are conservative industry ranges drawn from engineering references, including Battery University’s lithium‑based summary table (updated 2025).

Boundary clarifications to avoid confusion

- NiMH is nickel‑based; it is not a lithium chemistry.

- LiFePO4 (LFP) is a subtype of lithium‑ion—not a separate non‑lithium system. It trades some energy density for thermal stability and long cycle life.

- NiCd (nickel‑cadmium) is older and exhibits a pronounced “memory effect”; modern NiMH reduces cadmium concerns and improves energy density. Li‑ion does not suffer classic memory effect but ages faster at high voltage and temperature.

- NiZn exists as another nickel‑based system with higher per‑cell voltage (~1.6–1.8 V) but niche use and different longevity characteristics.

Choosing the right chemistry: practical guidance

Think in terms of application constraints:

-

Energy and weight budget

- If you need maximum energy in the smallest, lightest package (phones, laptops, drones), Li‑ion usually wins.

- For moderate energy with robust, simple systems (some handhelds, standby devices), NiMH can be a sensible choice.

-

Standby and storage behavior

- NiMH’s higher self‑discharge can be a drawback for infrequent use unless you select low‑self‑discharge variants.

- Li‑ion stores well with low self‑discharge, but prefers partial state‑of‑charge and cool temperatures.

-

Temperature and safety management

- Li‑ion requires disciplined charging and a BMS, especially in packs for tools, mobility, or energy storage.

- NiMH is generally more tolerant, though still benefits from temperature monitoring during charge.

-

Regulatory and logistics

- Lithium batteries are subject to UN 38.3 transport tests and specific air‑cargo handling rules; many certifications and standards (e.g., IEC 62133‑2 for lithium systems) govern design and safety.

- Nickel systems have their own safety standards (e.g., IEC 62133‑1), typically with fewer transport restrictions.

-

Market trends and availability

- As of 2025, lithium‑ion remains the prevailing technology for EV and portable electronics due to its energy density and scalability, as reflected in the U.S. Department of Energy’s overview in Batteries for Electric Vehicles (DOE AFDC, 2025).

Safety and charger FAQs

-

Can I use a Li‑ion charger on NiMH or vice versa?

- No. NiMH chargers typically use constant current with negative‑delta‑V termination and temperature checks; Li‑ion requires a constant‑current/constant‑voltage profile with strict voltage limits. Using the wrong charger risks damage or hazards.

-

Do these chemistries have “memory effect”?

- Classic memory effect is associated with NiCd. NiMH shows much less of it in modern cells. Li‑ion doesn’t have traditional memory effect, but prolonged high voltage and heat accelerate aging.

-

Any quick storage tips?

- NiMH: store cool; expect some capacity loss during long storage.

- Li‑ion: store at partial charge (around 30–50%) in a cool environment; avoid full charge at high temperature for extended periods.

Always consult the manufacturer’s datasheet for charger settings, temperature ranges, and safety notes before designing or purchasing packs.

Final thoughts and next steps

NiMH and lithium‑ion are complementary, not interchangeable. Start by defining your performance envelope (voltage, energy, weight, duty cycle), then factor in safety, charging, regulation, and logistics. Standards like IEC 61960 (performance/designations) and IEC 62133 (portable safety), along with transport rules under UN 38.3, form the backbone of compliant battery selection and system design.

If you’re exploring lithium‑ion packs for consumer, industrial, or smart‑home devices, Yungbang Power(永邦电源) offers design and manufacturing capabilities across Li‑ion formats, from custom packs to BMS integration. Disclosure: Yungbang Power is our product.

For deeper technical diving, consult standards and primary datasheets, and use conservative design margins when translating nominal specs into real‑world performance.