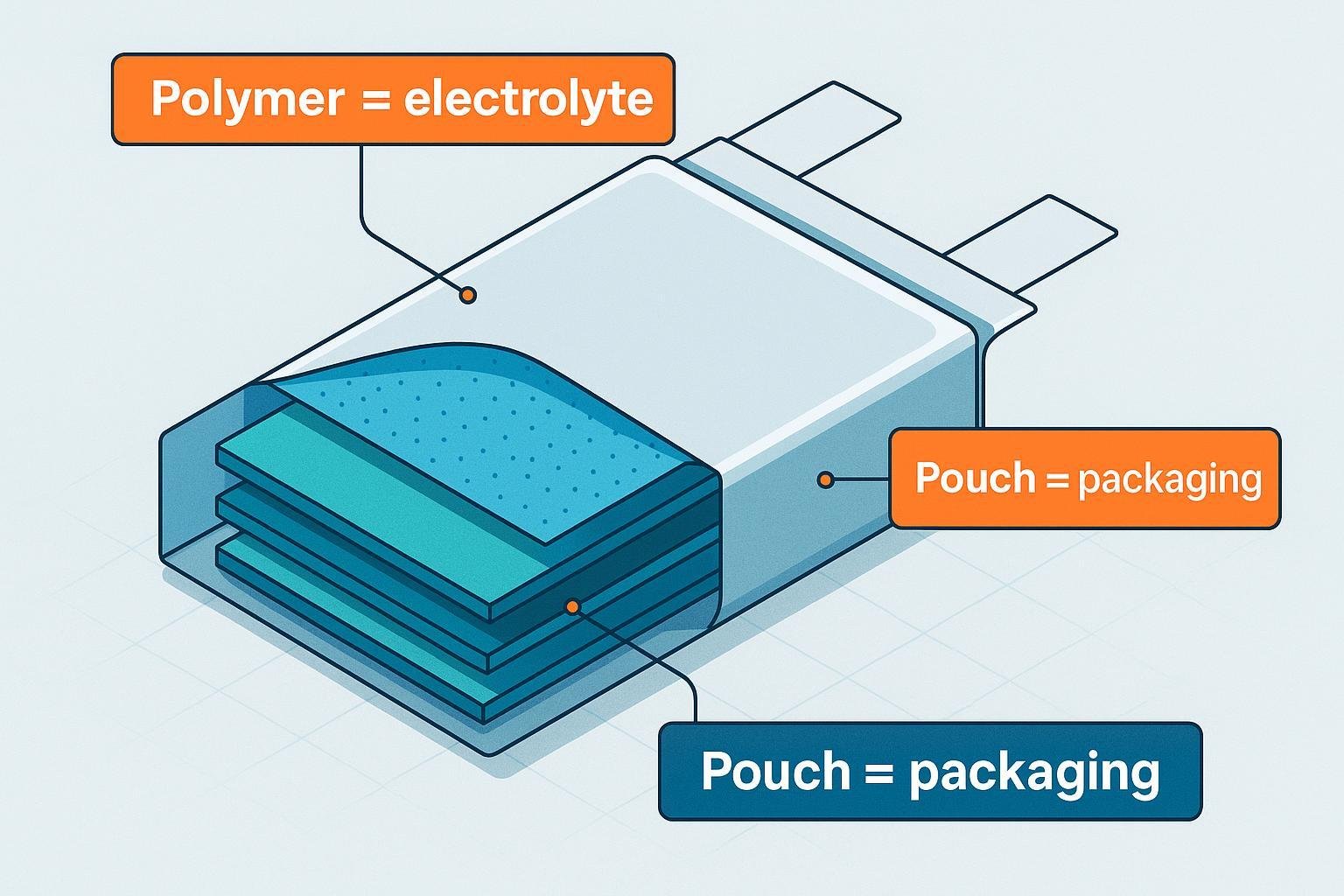

If you’ve ever wondered what the “Po” in “LiPo” means, here’s the short, definitive answer: Po stands for polymer. LiPo is shorthand for lithium‑ion polymer, a lithium‑ion system that uses a polymer‑based electrolyte matrix (solid or gel) rather than only a free‑flowing liquid electrolyte. Just as important: “Po” does not mean pouch. Pouch is a packaging format—a flexible laminated foil envelope—that can be used for various lithium‑ion cells, whether they use polymer gel electrolytes or conventional liquid electrolytes.

Think of it like this: the polymer is the filling; the pouch is the wrapping. You can have polymer filling in different wrappings, and you can also have non‑polymer fillings inside the same pouch wrapping.

Polymer ≠ Pouch: Why the Confusion?

The hobbyist and consumer electronics markets popularized thin, flexible batteries packaged in soft foil “pouches,” and many of those cells also used polymer gel electrolytes. Over time, people started treating “polymer” and “pouch” as synonyms. In manufacturing reality, pouch is simply a mechanical format. Major cell makers describe pouch assembly as inserting the electrode stack into a laminated film case and heat‑sealing it—independent of electrolyte chemistry, as illustrated by LG Energy Solution’s pouch assembly explainers from 2023 in How to make a battery: Step 2 — Cell assembly, Pouch battery (Part 1) and (Part 2) (LG Energy Solution 2023 — Part 1, Part 2).

For a quick format overview—cylindrical, prismatic, and pouch—see the “Cell formats” section in the encyclopedic Lithium‑ion battery entry, which summarizes mechanical differences without tying them to a single electrolyte type (Wikipedia — Lithium‑ion battery: Cell formats).

What Makes a Battery “Polymer”? SPE vs GPE

“Polymer” refers to the electrolyte architecture:

- Solid Polymer Electrolyte (SPE): A solid polymer host (such as PEO) carries the lithium salt with little to no free liquid. Room‑temperature ionic conductivity is typically limited and improves at higher temperature; this remains an active R&D area.

- Gel Polymer Electrolyte (GPE): A polymer matrix swells with a liquid electrolyte (organic solvent + Li salt), giving solid‑like handling with liquid‑like ion transport. This approach dominates commercial “LiPo” today because it achieves practical room‑temperature performance.

In other words, most batteries marketed as “lithium‑ion polymer” in 2025 use gel polymer electrolytes or quasi‑solid matrices rather than truly solid polymer electrolytes. An accessible industry explainer that aligns with this practical view is Cadex’s overview of cell types, which describes pouch and other formats alongside polymer usage in commercial products (Battery University — BU‑301a: Types of Battery Cells).

Where Packaging Fits: Pouch vs Cylindrical vs Prismatic

- Pouch: Flexible laminated foil case; excellent for thin, lightweight, shape‑conforming designs. Can contain polymer‑gel systems or classic liquid electrolytes. See the manufacturing steps in LG Energy Solution’s pouch assembly articles (2023) (LGES — Pouch assembly Part 1).

- Cylindrical (e.g., 18650/21700): Rigid metal can; mechanically robust, standardized sizes, good heat paths. Widely used across consumer and industrial products. High manufacturing scale.

- Prismatic: Rigid rectangular can; space‑efficient in packs, common in automotive and large devices.

Key point: Format is about mechanics and integration, not the electrolyte definition. A “pouch cell” can be a conventional liquid‑electrolyte Li‑ion, a gel polymer Li‑ion, or even a different lithium chemistry. Format alone does not make a battery “polymer.” For a neutral overview of formats, see the Cell formats discussion in the lithium‑ion battery encyclopedia entry (Wikipedia — Lithium‑ion battery: Cell formats).

What Standards and Regulators Actually Say (Naming and Compliance)

International safety standards and transport regulations do not create a separate “LiPo” class. They focus on safety performance and testing, not on whether a cell is polymer vs liquid or pouch vs cylindrical/prismatic.

- Portable device safety: IEC 62133‑2 covers portable sealed secondary lithium cells and batteries “containing non‑acid electrolyte,” and applies regardless of format or electrolyte subtype. See the official scope for IEC 62133‑2:2017 with Amendment 1:2021 on the IEC Webstore (IEC 62133‑2 scope (2017+A1:2021)).

- Industrial batteries: IEC 62619 addresses secondary lithium cells and batteries for industrial applications, again format‑ and electrolyte‑agnostic by scope (IEC 62619:2022 scope).

- UL standards: UL 1642 (cells) and UL 2054 (packs) specify abuse and safety tests for lithium batteries without segregating by pouch/cylindrical or polymer/liquid in the categorization; the 2022 catalog entries outline these scopes (UL 1642 — Lithium Batteries (2022 catalog); UL 2054 — Household and Commercial Batteries (2022 catalog)).

- Transport rules: The UN Manual of Tests and Criteria, subsection 38.3 (UN 38.3), applies to all lithium‑ion and lithium‑ion polymer cells and batteries. IATA’s 2025 Lithium Battery Guidance consolidates the air‑transport requirements, including the manufacturer’s UN 38.3 test summary and state‑of‑charge limits (IATA — Lithium Battery Guidance Document 2025).

Bottom line: For compliance, “LiPo” is a commercial label. Your obligations do not change simply because the datasheet says “polymer.” What matters is the cell’s performance in standardized tests and following the correct shipping/marking rules.

Practical Differences and Trade‑offs

- Form factor flexibility: Pouch and some polymer‑based cells enable thin, custom shapes—useful in wearables, drones, and handhelds.

- Packing efficiency vs robustness: Pouch improves volumetric packing at the module level but may need more mechanical protection than rigid cans.

- Thermal pathways: Rigid cans offer predictable heat paths and crush resistance; pouches rely on external structures and can be sensitive to swelling.

- Energy density: Depends on chemistry and design. Pouch modules can reduce inactive material and thus boost pack‑level efficiency, but the electrolyte being “polymer” does not guarantee higher energy density.

- Cost and scale: Cylindrical formats benefit from massive scale; custom pouch shapes can raise tooling and qualification costs.

Safety and Handling: Myths vs Reality

- Charging method: Lithium‑ion cells—including polymer variants—use constant current/constant voltage (CC/CV) charging. Overvoltage risks include lithium plating and gas generation. Cadex provides a clear primer in BU‑409: Charging Lithium‑ion (Battery University — BU‑409).

- Thermal runaway can still occur: Polymer matrices can reduce free‑liquid leakage, but abuse, defects, or thermal events can trigger runaway. The FAA’s 2020 technical report documents runaway initiation methods for lithium batteries and underscores the hazards of overcharge/overheat (FAA — TC‑20/12 Thermal Runaway Initiation (2020)).

- Standards test for abuse: Safety standards include short‑circuit, overcharge, crush, and temperature tests to mitigate hazards regardless of format or electrolyte type (see the IEC 62133‑2 scope and UL 1642/2054 catalogs for test families: IEC 62133‑2 scope (2017+A1:2021); UL 1642 catalog (2022)).

Practical tips:

- Use the specified CC/CV charge profile and the correct charger.

- Integrate a proper protection circuit or BMS; don’t rely on “polymer” to imply safety.

- Watch for swelling or unusual heat; isolate and dispose of compromised cells per local regulations.

- Follow transport SoC and packaging rules; for air cargo, IATA reiterates a ≤30% state of charge for cells/batteries shipped alone, with 2025 guidance summarizing current and upcoming rules (IATA Lithium Batteries — Fact Sheet, June 2025).

Quick Myth‑Busting

- “Po = pouch.” Incorrect. Pouch is a wrapping, not the electrolyte. See LG Energy Solution’s pouch assembly overview (2023) for the mechanical process (LGES — Pouch assembly Part 2).

- “All LiPo are solid‑state.” Overstated. Most commercial “LiPo” today use gel polymer electrolytes at room temperature (Battery University — BU‑301a).

- “LiPo are inherently safer than Li‑ion.” Misleading. Safety depends on design, protection circuits, chargers, and operating conditions; thermal runaway is still possible (FAA — TC‑20/12 (2020)).

- “Standards treat LiPo as a separate class.” No. IEC/UL safety scopes and IATA/UN 38.3 transport rules are format‑ and chemistry‑agnostic (IEC 62619:2022 scope; IATA 2025 Guidance).

Buyer/Spec Checklist (What to Verify)

- Electrolyte type: Does the datasheet state a gel polymer electrolyte (GPE), a solid polymer electrolyte (SPE), or a conventional liquid electrolyte in a pouch? Don’t infer from “pouch” alone.

- Format choice: Pouch vs cylindrical vs prismatic based on mechanical constraints, thermal management, and robustness.

- Compliance evidence: Request the UN 38.3 test summary and applicable safety reports (e.g., IEC 62133‑2 for portable, IEC 62619 for industrial; UL 1642/2054 where relevant). See the IEC 62133‑2 and IEC 62619 scope pages for applicability (IEC 62133‑2 scope; IEC 62619:2022 scope).

- Charging and protection: Confirm CC/CV limits, protection circuit/BMS features, and pack‑level safety design.

- Shipping and labeling: Check Wh rating marking and IATA packing instructions; consult the current IATA Lithium Battery Guidance (2025) for air transport (IATA — Guidance 2025).

How to Use the Term Correctly in 2025

- Say “Li‑ion polymer (LiPo)” when you want to highlight the polymer‑based electrolyte architecture (most commonly a gel polymer at room temperature).

- Say “pouch cell” when you mean a laminated foil package form factor—regardless of whether the electrolyte is polymer‑based or liquid.

- For compliance and documentation, reference the applicable safety and transport standards by number (IEC 62133‑2, IEC 62619, UL 1642/2054, UN 38.3/IATA), because regulators don’t classify “LiPo” as a separate category.

In short: Po = polymer. Pouch is packaging. Keep those two ideas separate, and your designs, documentation, and sourcing conversations will be clearer—and safer—every time.