If you’ve ever stared at a LiPo label that reads “2200 mAh 20C” and wondered what that really means for your motors or device, this guide is for you. We’ll translate C rating into usable current, clarify “continuous” vs “burst,” and show practical ways to verify claims—without risking your pack.

What the C rating actually means

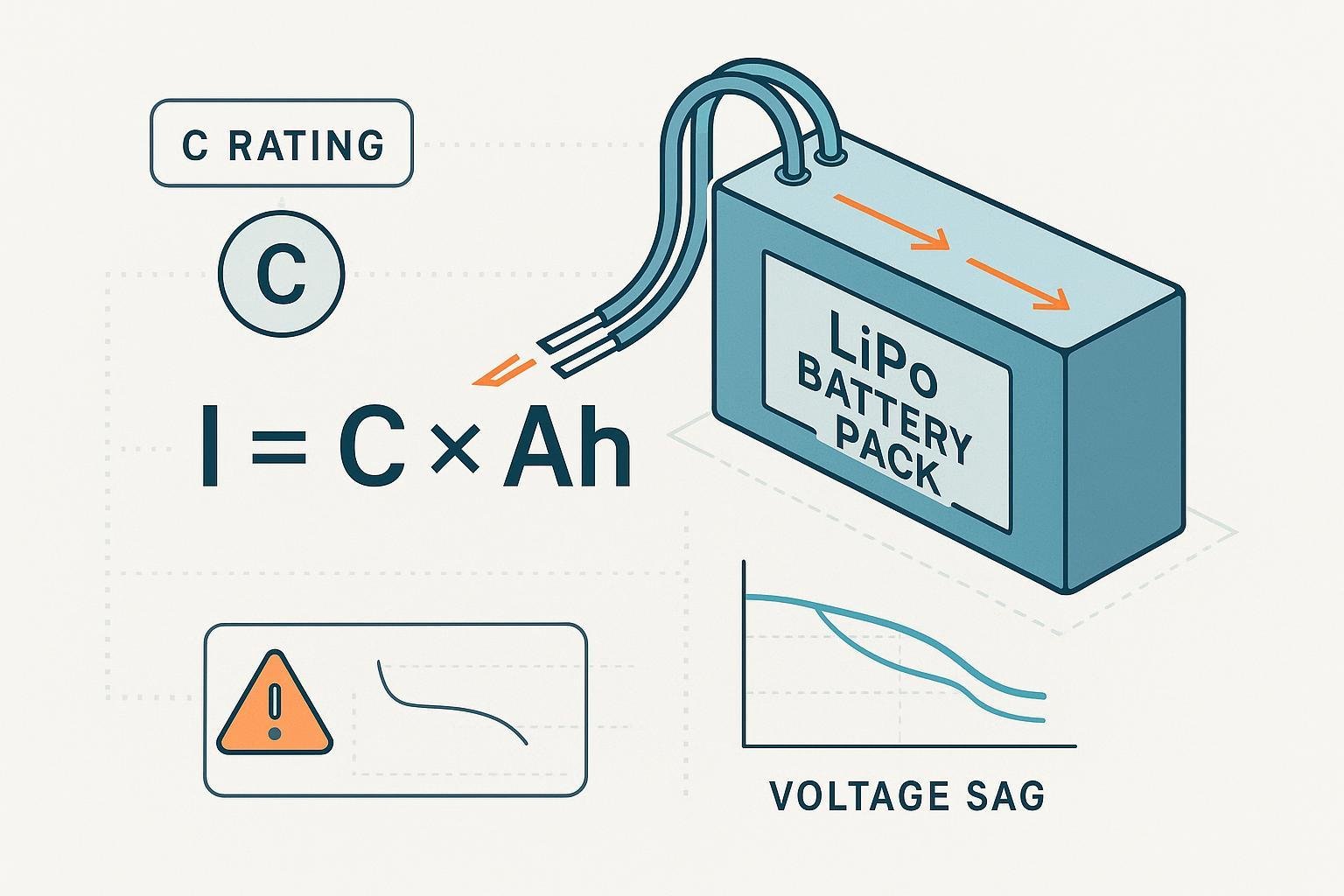

- Plain definition: The C rating is a multiplier that tells you how much current a battery can safely deliver relative to its rated capacity. In simple math, I = C × Ah. A 1C discharge empties a pack in about one hour; 2C in about half an hour.

- A quick technical note: In formal terms, C has units of h⁻¹, but in everyday use you can treat it as a dimensionless multiplier. This convention is widely used in industry and explained in Battery University’s 2024 update on C‑rate usage in the Cadex piece “BU‑605: Calibrating Smart Batteries” (Cadex, 2024). The same definition underpins IEC’s portable Li‑ion standards family, the “IEC 61960 系列” (IEC, 2023+).

Think of C rating like the width of a pipe: the wider the pipe (higher C), the more current (water) it can deliver for a given “tank size” (capacity in Ah). But making the pipe too wide for your plumbing can cause leaks—heat and stress—so sizing matters.

How to convert mAh and C into amps (with examples)

- Convert mAh to Ah: 2200 mAh = 2.2 Ah.

- Multiply by the C rating to get current in amps.

- Example A (continuous): 2.2 Ah × 20C ≈ 44 A continuous.

- Example B (larger pack): 5.0 Ah × 30C ≈ 150 A continuous.

- If a manufacturer specifies a burst rating and duration, say 40C for 10 s on the same 2.2 Ah pack: 2.2 × 40 ≈ 88 A for up to 10 s. If no burst duration is stated in a datasheet, do not assume one.

Continuous vs. burst: what’s the real difference?

- Continuous C rating is intended to be sustained without exceeding the manufacturer’s limits for temperature, voltage, and capacity retention.

- Burst (or peak) C rating allows short spikes above the continuous level for transient demands—but only for a stated duration and conditions. Many reputable cell datasheets do not publish a “10‑second” burst number at all; for instance, Murata’s high‑power US21700VTC6A datasheet defines continuous discharge conditions but does not specify a formal “burst seconds” rating, highlighting that such claims are not universal (see Murata’s “US21700VTC6A product datasheet” accessed 2025).

Bottom line: Treat burst numbers on retail labels cautiously unless the manufacturer’s datasheet spells out duration and test conditions.

What really limits the C rating: internal resistance, voltage sag, and heat

- Internal resistance (IR) causes voltage sag (ΔV = I × R). Higher current means more sag and more heat (I²R). As cells warm up or age, IR generally rises, which reduces the practical current you can pull.

- Measurement frameworks: Portable Li‑ion performance, including impedance/IR methods, is addressed in the “IEC 61960‑3” family (IEC, 2023). Labs often use a DC step method at 25 °C around mid‑SoC to estimate DCIR; EIS tools characterize impedance over frequency. See Hioki’s instrumentation overview for context on impedance testing in the “BT4560 Battery Impedance Meter” page (Hioki, 2023+).

Practical takeaways:

- Expect less usable C at low temperature, low state of charge, and with aged packs.

- If your pack gets too hot or sags to cutoff voltage early, your effective continuous C is lower than the label suggests.

Typical ranges and market reality (use as context, not promises)

- Consumer LiPo packs often claim roughly 10–20C continuous and 20–30C burst.

- RC/FPV packs may claim 20–60C continuous and 30–100C burst.

These are broad, marketing‑influenced ranges and not standardized across brands. There’s no single enforceable global rule for “what test defines C on the label.” Because of that, many engineers design with margin—planning loads at roughly 60–80% of the advertised continuous C—unless they have trustworthy discharge curves and thermal data validating the claim. This is conservative practice, not a formal standard.

How to select the right C rating for your application

- Start from the load: Estimate your continuous current and peak current. For RC, check motor/ESC specs and typical throttle duty cycles. For products, analyze your load profile.

- Calculate current from capacity × C and compare to your needs. Add margin for temperature and aging.

- Check wiring and connectors: Ensure your leads, connector type, and ESC/controller are rated for the same current.

- Consider pack configuration: In series you raise voltage; in parallel you increase Ah, which raises absolute current at a given C. Ensure balance leads and BMS are appropriate.

- Plan for ambient conditions: Cold weather reduces effective C; high ambient or poor airflow increases thermal stress.

Can you verify a C claim yourself? A practical method

If you have access to a constant‑current electronic load and basic instrumentation:

- Set the load to the claimed continuous current (C × Ah) at 25 °C and mid‑SoC. Log voltage and temperature from start to cutoff.

- Pass criteria: The pack should deliver expected capacity without exceeding the manufacturer’s temperature limit (many Li‑ion datasheets target case temps below roughly 60–70 °C during operation unless specified otherwise). Overheating or severe sag indicates the real continuous capability is lower.

- For “burst” claims with a specified duration (e.g., 5–10 s): Test pulses at the stated current and duty cycle while watching temperature. If no duration is specified, don’t assume one.

- Track internal resistance over time with a controlled current step around 1 s after rest; rising IR is a sign to lower your current expectations. While exact protocols sit within the IEC 61960‑3 family, this outline reflects common lab practice.

Safety and compliance: what the rules actually cover (and what they don’t)

- Transport: Lithium packs must pass the UN Manual of Tests and Criteria Part III, subsection 38.3 before shipping. See the official “UN 38.3 test suite” (UNECE, 2023) covering altitude, thermal, vibration, shock, short, impact, overcharge, and forced discharge.

- Product safety standards for portable Li‑ion: “IEC 62133-2” (2017+) and North American counterparts UL 1642 (cells) and UL 2054 (packs) define safety requirements and tests. These improve baseline safety but don’t standardize marketing C labels.

- EU Battery Regulation: Regulation (EU) 2023/1542 phases in comprehensive rules on labeling, safety, and traceability from 2023 onward; several milestones land in 2025. See the official “EU 2023/1542 text” (Official Journal L 191, 2023).

- China CCC inclusion: Certain Li‑ion batteries entered mandatory CCC certification starting Aug 1, 2024 after a 2023 transition. See UL’s regulatory brief “CCC certification for Li‑ion batteries around the corner” (UL, 2023) and 2024 follow‑up in the “Global Market Access newsletter Q3 2024” (UL, 2024).

Important: None of these frameworks define how to advertise C rating on a label. They govern safety and compliance. For performance claims, your best sources are manufacturer datasheets and validated test data.

Related but different: charge C vs. discharge C

Charging limits are usually lower than discharge limits. Many Li‑ion/LiPo cells specify 0.5C–1C for standard charging under a CC‑CV profile within a defined temperature window. Always follow the specific datasheet for charge current and temperature limits.

Common misconceptions (and quick fixes)

- “Higher C is always better.” Not necessarily. Higher‑C packs can be heavier and may trade energy density for power capability. Pick the C that meets your load with margin; don’t overspec blindly.

- “Burst C can be used continuously.” False. Burst is for short transients at specified durations, if defined at all.

- “Label C equals real‑world C in all conditions.” No. Cold, high ambient heat, low SoC, aging, and poor airflow all reduce usable current.

Quick checklist you can use today

- What is my continuous and peak current demand?

- What capacity (Ah) and C rating meet that current with margin at my ambient temperature?

- Do the wiring, connectors, and ESC/controller match the current?

- Do I have the manufacturer’s datasheet curves and temperature limits? If not, design conservatively.

- Have I planned a verification test (constant‑current discharge with temperature logging)?

- What compliance requirements apply (UN 38.3 for transport, IEC 62133‑2/UL for safety, EU 2023/1542 labeling, CCC in China)?

Key sources for deeper understanding

- Definition and usage of C‑rate in practice: “BU‑605: Calibrating Smart Batteries” (Cadex/Battery University, 2024)

- Standards context for capacity/C‑rate and impedance methods: “IEC 61960 系列” and “IEC 62133-2” (IEC, 2017–2023+)

- Impedance measurement instrumentation overview: “Hioki BT4560 Battery Impedance Meter” (Hioki, 2023+)

- Transport testing requirements: “UN 38.3 test suite” (UNECE, 2023)

- EU Battery Regulation: “Regulation (EU) 2023/1542” (European Union, 2023)

- Datasheet example illustrating lack of burst spec: “Murata US21700VTC6A product datasheet” (Murata, accessed 2025)

In short: Use C rating as a starting point, not gospel. Convert C × Ah into amps, confirm that meets your load, then validate with temperature‑aware testing and trustworthy datasheets. That approach keeps performance strong and batteries safe.