If you’ve ever seen “25C” or “60C” on a LiPo pack and wondered what it really means for your drone, robot, or handheld device, this guide is for you. We’ll demystify C‑rate, show the simple math, and—more importantly—explain how voltage sag, heat, temperature, and aging really determine what your battery can deliver.

What is C‑rate (in plain English)?

C‑rate is a shorthand that expresses current as a multiple of a battery’s capacity. Formally: C = I (A) / Q (Ah). A 1C discharge means current equals the rated capacity; ideally, a 1C discharge would empty a full battery in about one hour, 0.5C in two hours, 2C in 30 minutes, and so on. This normalization is widely used in engineering references, such as the concise definition in the Battery University — BU‑402: What is C‑rate? (2021).

In other words, C‑rate tells you “how hard” you’re pulling relative to the battery’s size.

The math you’ll actually use

- Capacity in Ah = mAh ÷ 1000.

- Current at a given C = C × Ah.

- Time at constant current (idealized) ≈ 1/C hours.

Example: A 2200 mAh pack has 2.2 Ah. At 25C continuous, the advertised continuous current is 2.2 Ah × 25 = 55 A. At 10C, it would be 22 A; at 1C, 2.2 A.

Note: “Idealized” means ignoring voltage sag, efficiency, temperature, and protection limits. Real run time will differ.

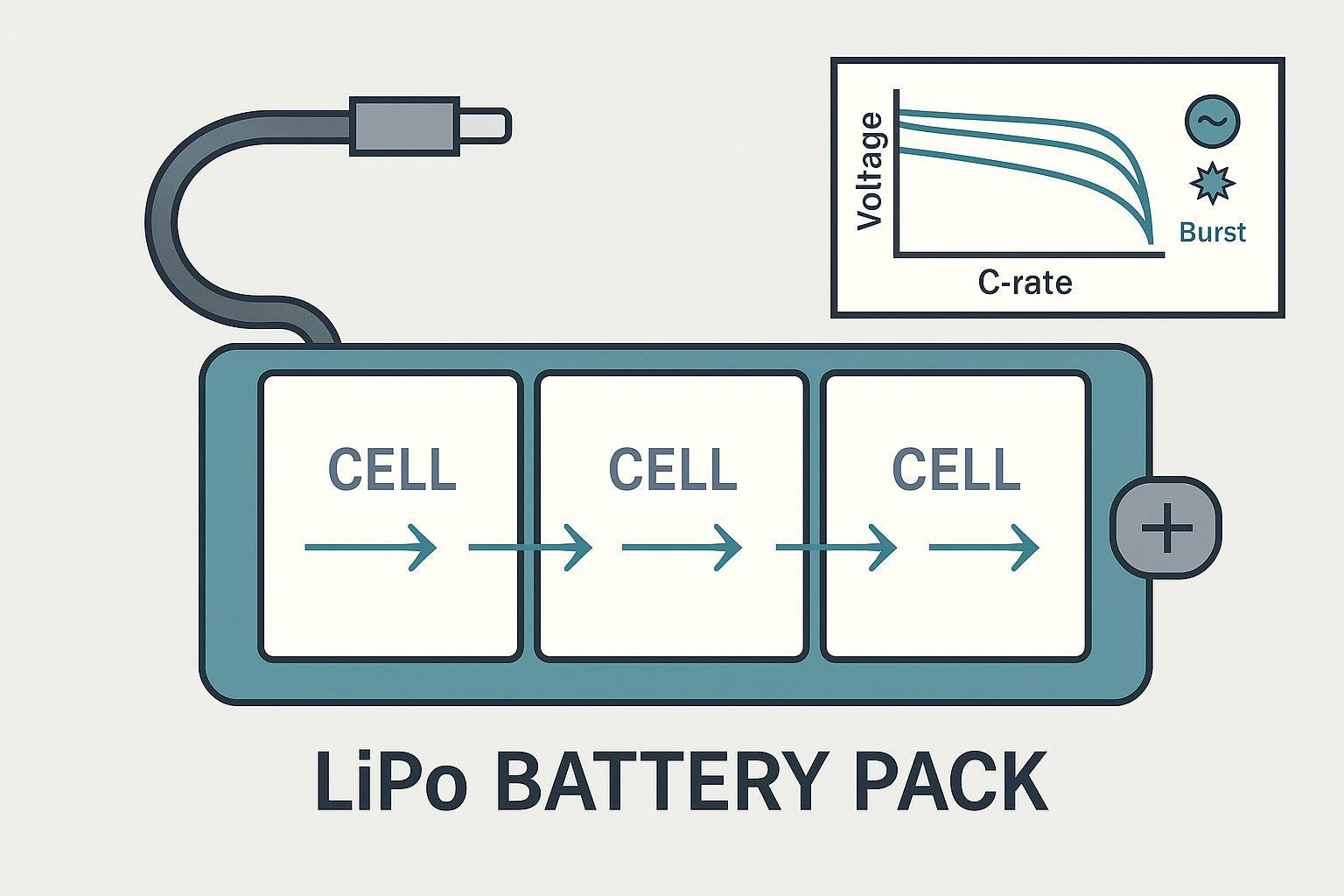

Continuous vs burst (and why “burst” is slippery)

Manufacturers sometimes provide two discharge ratings:

- Continuous C‑rate: Current the pack can sustain without exceeding temperature limits or causing damage under specified test conditions.

- Burst (or peak) C‑rate: A higher current allowed for a short time (often a few seconds) before heat and voltage sag become excessive.

Here’s the catch: burst isn’t standardized across the industry. Test duration, allowed voltage drop, starting state‑of‑charge, and ambient temperature vary by vendor. That’s why it’s safer to anchor on continuous ratings, and verify peaks in your own tests. This caution is consistent with practical overviews such as Battery University’s discharge behavior notes (2019–2021) and the pattern seen in OEM datasheets that emphasize continuous current within defined limits, for example the Molicel INR21700 P45B product datasheet (2024).

Why C‑rate alone doesn’t guarantee performance

Two physics facts explain most real‑world surprises:

- Voltage under load: V_load = V_open − I × R_internal

- Heat from resistive losses: P_loss ≈ I² × R_internal

As current (I) rises, voltage sags and heat climbs—both determined by the battery’s internal resistance (IR), which changes with temperature, state of charge (SoC), and aging. Extensive studies synthesize these relationships; for example, the NREL 2022 battery aging and performance report highlights how IR growth with age drives power fade, and low temperatures increase IR—worsening sag.

Practical implications:

- A “high C” label doesn’t ensure your motors won’t bog under throttle; IR and temperature dominate.

- High‑rate packs don’t increase energy; they help maintain voltage at higher currents. Run time still depends on capacity and load.

- Heat accelerates aging; operating hotter to meet peaks can shorten cycle life, as summarized in the Battery University — BU‑501: Basics about Discharging (2020).

A step‑by‑step sizing workflow

-

Define your load profile

- Measure or estimate worst‑case continuous current and short peaks. For motors/ESCs, use stall/maximum current data and likely duty cycles.

-

Add margin

- Add roughly 20–50% headroom to the worst‑case continuous current. Ensure peaks fit within the battery’s pulse capability—and within connector, wiring, and BMS limits.

-

Convert to required C

- C_required = I_required / Ah_nominal. Example: If your device needs 35 A continuous and you’re considering a 3000 mAh (3.0 Ah) pack, you need at least 35 A / 3.0 Ah ≈ 11.7C continuous.

-

Validate thermal limits

- Check that the pack can stay below its maximum cell temperature at your ambient while delivering the required current. Real‑world step‑load tests are essential (see “Verify with tests” below).

-

Check system limits (not just the battery)

- BMS protection thresholds, sense resistor sizing, connector ratings, and wire gauge must all exceed the absolute current in amps, not just the C‑rate. Guidance on setting BMS over‑current thresholds and measuring DC internal resistance by pulse appears in Texas Instruments’ TIDA‑00449 10‑series pack monitor reference (2019).

-

Re‑evaluate for conditions and aging

- Cold weather, low SoC, and aged packs have higher IR. Size with those worst cases in mind; if unsure, choose more margin.

Worked example

Goal: Power a small 2S FPV quad using a 2S 2200 mAh LiPo. The quad draws 30 A continuous with 55 A bursts on punch‑outs.

- Continuous requirement: 30 A. Required C ≈ 30 A / 2.2 Ah ≈ 13.6C.

- With 30% margin: 13.6C × 1.3 ≈ 17.7C minimum continuous rating.

- Bursts: 55 A corresponds to 55 / 2.2 ≈ 25C. Ensure the pack’s peak spec, connectors, wiring, and BMS can tolerate this for the brief duration, and validate with step‑load testing. If vendor gives no burst time, assume “very short” (a few seconds) and verify temperature/voltage sag.

Factors that change usable C in the real world

- Temperature: Cold significantly raises IR; expect more sag and less power when it’s cold. See cold‑performance highlights in the NREL low‑temperature behavior brief (2018).

- State of charge: Near empty, IR is higher and voltage drops faster; keep peaks short when SoC is low.

- Aging: IR increases with cycles and calendar time; power capability declines. The NREL 2022 durability/aging insights compilation summarizes these trends across chemistries and use cases.

Series/parallel, connectors, and BMS limits

- Series (S) adds voltage but not capacity; C stays the same. Parallel (P) adds capacity; C stays the same, but absolute current in amps increases at the same C.

- The pack’s safe current is limited by the weakest cell/string. Do not assume a pack can deliver more just because one sub‑string can.

- System elements must match: connectors (e.g., XT60/XT90 class), wire gauge, PCB copper width, and the BMS over‑current/short‑circuit thresholds. TI’s BQ77xx/BQ76xx families document how OCD/SCD thresholds are derived from sense resistor and comparators; see the TI BQ77915 protection IC datasheet (rev. 2023) for calculation examples relevant to practical limits.

Verify with tests (don’t just trust the label)

- Measure DC internal resistance (DCIR): Apply a known current step and record the instantaneous voltage drop; IR ≈ ΔV/ΔI. Use modest pulse widths and allow rest to avoid thermal confounds. Methodology and timing guidance are illustrated in Texas Instruments’ TIDA‑00449 reference (2019).

- Step‑load validation: Recreate your worst‑case load profile on the bench. Watch cell voltages, pack temperature, connector heating, and BMS behavior. Confirm you remain within datasheet current/temperature limits.

Safety, standards, and compliance context

- Transport: Lithium batteries must pass UN 38.3 tests for shipping. See the official UNECE UN 38.3 lithium battery test manual (latest materials, 2023–2024).

- Product safety for portable equipment: Many markets reference IEC 62133‑2:2017+A1:2021 (IEC Webstore) for construction and safety testing. While full texts are licensed, these standards frame safe operating windows that underpin responsible C‑rate usage in products.

Brief note on charge C‑rate

Charge C‑rate uses the same normalization but follows a CC/CV (constant current/constant voltage) profile, so actual full‑charge time exceeds 1/C. Many Li‑ion/LiPo cells recommend around 0.5C–1C standard charging unless the datasheet permits higher; see the overview in Battery University — BU‑409: Charging Lithium‑ion (2022) and an example 1C recommendation in the Molicel INR21700 P42A datasheet (V4). Fast‑charging raises heat and can accelerate aging; follow the exact limits of your specific cell/pack.

Practical myths and truths

- Myth: “Higher C is always better.” Truth: Higher‑C packs can be heavier and pricier. Choose enough margin for your load and conditions; beyond that, diminishing returns.

- Myth: “If the label says 100C, it will deliver 100C.” Truth: Without standardized burst definitions, marketing can overstate peaks. Validate with IR and step‑load tests.

- Myth: “C‑rate tells me run time.” Truth: Run time depends on capacity and your average current. C‑rate capability affects how well voltage holds at high loads, not energy stored.

Quick safety/usage checklist

- Size to the continuous current with 20–50% margin; treat burst conservatively and verify.

- Respect BMS, connector, and wiring limits in amps.

- Monitor temperature; keep cells within datasheet ranges. Elevated heat accelerates aging.

- Avoid deep discharges at high load—sag and stress are worst near empty.

- Periodically re‑check IR as packs age; retire swelling or high‑IR packs.

- Follow shipping/storage rules and charge with a balance charger appropriate for LiPo.

常见问题

- Is a higher C rating always better? Not necessarily. After you have adequate headroom, extra C often adds weight and cost without proportional benefit.

- Why does my pack sag even with a high C label? Internal resistance, temperature, SoC, and aging drive sag. Labels don’t override physics; measure DCIR and test under your load.

- Can I mix packs with different C ratings? Avoid series/parallel mixing of unlike packs; mismatches can cause imbalance and stress on the weaker pack.

- How long can I pull the burst rating? Only as per the vendor’s tested duration. If unspecified, assume very short (a few seconds) and verify with step‑load tests while monitoring temperature and voltage.

- Does C‑rate affect cycle life? Indirectly—higher discharge rates and higher operating temperatures accelerate aging, which reduces capacity and increases IR, as summarized in the Battery University life/aging overview (2022).

Key takeaway: Use C‑rate to translate your device’s current needs into battery requirements, but size and validate based on physics—internal resistance, temperature, SoC, aging—and on the limits of your entire system (BMS, connectors, wiring). Test, observe, and leave margin for safety and longevity.