If you’ve upgraded to a DC balance charger (ISDT, iCharger, HOTA, etc.), picking the right power supply (PSU) is what lets the charger actually hit its advertised performance—safely. In this guide, you’ll calculate the PSU voltage, amperage, and wattage you need, match connectors and wire gauge, and verify the setup with quick checks. Expect 20–40 minutes to go from “not sure” to a safe, dialed‑in charging station.

- Difficulty: Intermediate (basic electricity: volts, amps, watts)

- What you’ll achieve: A PSU choice that matches your charger’s requirements with safety headroom, correct connectors/polarity, and verified performance

What You’ll Need

- Your charger’s manual/datasheet (for DC input voltage range, max input current, and output power)

- Your battery info: cell count (S) and permissible charge rate (C‑rate)

- A calculator (or phone) and a multimeter

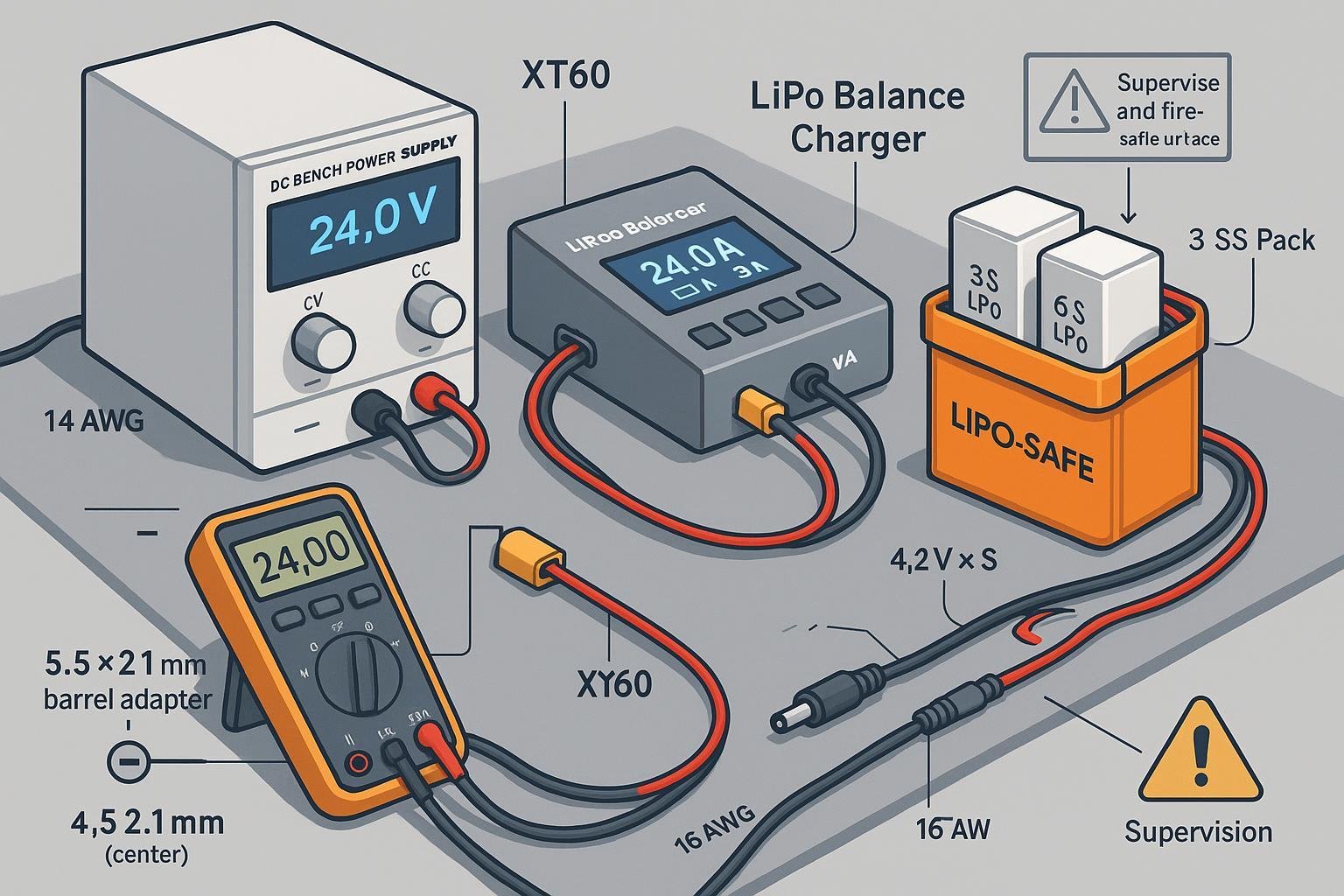

- Connectors/adapters: barrel (5.5×2.1 mm or 5.5×2.5 mm) or XT60, as your charger requires

- Safe charging setup: LiPo bag or fire‑resistant surface, and supervision guidance per hobby standards (see the 2024 guidance in Horizon Hobby’s LiPo charging basics)

Why this matters: Chargers deliver power to the pack, but the PSU feeds the charger. If the PSU is too weak or the voltage is mismatched, the charger will throttle, throw “input voltage/current” errors, or shut down under load. Experienced hobbyists commonly oversize PSU wattage for stability—as explained in Oscar Liang’s charger/power supply guide.

Step 1: Confirm Your Charger’s Input Specs

Find three numbers in your charger’s manual:

- DC input voltage range (e.g., 10–34 V)

- Max input current (e.g., 33 A)

- Max output power per channel and total (e.g., 200 W single‑channel; 2×100 W dual)

Why: Output power is capped by what the input can deliver. With a given input current limit, higher input voltage allows more available power (P ≈ Vin × Iin × η). For example, the ISDT Q8 Max lists 10–34 V input with a 33 A input limit; at 12 V that’s ≈396 W of input capacity, at 24 V ≈792 W before efficiency losses, illustrating why higher Vin lets a charger reach higher power where supported (see the ISDT Q8 Max manual on Manualslib).

Bonus corroboration: Some AC/DC chargers also show input‑voltage‑dependent power on AC. ISDT’s X16 specifies higher max power on 220 V than 110 V AC, demonstrating how input limits influence output capability (ISDT X16 power ratings, 2023).

Checkpoint

- Record Vin_min, Vin_max, Iin_max, and Wout_max.

- If your charger has dual channels, note the per‑channel and combined limits.

Step 2: Calculate Your Battery Charge Current and Pack Voltage

- Pack full‑charge voltage: Vpack_max = 4.2 × S (cells in series). For example, 3S → 12.6 V; 6S → 25.2 V. See the quick reference in Grepow’s LiPo voltage overview (2022).

- Charge current target: Ichg = Capacity (Ah) × C‑rate. If your battery datasheet doesn’t specify, use 1C as the conservative default per mainstream hobby guidance (e.g., Horizon Hobby’s charging guidance, 2023).

Note: Only exceed 1C if the battery datasheet explicitly allows it. Many LiPo packs list “standard” and “max” charge rates; respect the lower value for longevity, and never leave charging unattended.

Checkpoint

- Compute Ichg and Vpack_max for your most demanding pack(s).

- If using parallel boards or multi‑channel chargers, sum the simultaneous outputs you intend to run.

Step 3: Size PSU Wattage with Headroom

Formulas you’ll use:

- Battery‑side power demand: Wout ≈ Vpack_max × Ichg

- Charger input power: Win ≈ Wout / η (η = charger efficiency; plan with 0.85–0.90 to be conservative)

- PSU selection rule of thumb: Wpsu ≥ Win × 1.2–1.3 (20–30% headroom for transients and cooling)

Why: Real setups have losses and spikes. Seasoned builders oversize PSU wattage so the charger doesn’t sag or reboot under load—an approach consistent with the practice shown in Oscar Liang’s charger/PSU sizing examples (updated 2024).

Quick example: If your charger can output 200 W, choose Wpsu ≈ 200/0.9 × 1.3 ≈ 289 W → select a 300–350 W PSU class.

Checkpoint

- Decide your PSU wattage target using the rule above.

- If your charger has two channels, use the sum of simultaneous channel power for Wout.

Step 4: Choose Input Voltage (12 V vs 18–24 V)

Principle: With a finite Iin_max, higher Vin lets the charger deliver more output power before hitting limits: Pout_max ≲ Vin × Iin_max × η.

- If your charger supports up to ~24 V, running 18–24 V often unlocks higher charge rates before throttling. Many users see “input current/voltage limit” errors disappear when moving from a 12 V to a 24 V PSU, because the needed input current drops for the same output power.

- AC/DC examples show the same pattern: at higher input voltage, max output rises (e.g., ISDT X16 AC ratings, 2023). DC‑only listings also highlight large differences between AC vs DC capability on combo models, underscoring input choice importance; see GetFPV’s HOTA D6 Pro specs (2022).

Rule of thumb

- Up to ~100 W total: 12 V is usually fine.

- 150–300 W: Prefer 18–24 V to reduce input current and cabling stress.

- 300 W+: 24 V strongly recommended (if the charger allows it) to keep current manageable.

Checkpoint

- Pick Vin (12 V or ~24 V) within the charger’s rated range that best matches your power target.

Step 5: Match Connectors, Polarity, and Wire Gauge

Connector choice depends on current:

- Barrel connectors (common sizes: 5.5×2.1 mm, 5.5×2.5 mm). Typical continuous ratings are around 5 A for 5.5×2.1 and about 5–7 A for 5.5×2.5 depending on the exact part; check your part’s datasheet. For reference, see Switchcraft’s panel‑mount pages for the 5.5×2.1 mm 721AFMS 和 5.5×2.5 mm L712A.

- XT60 (polarized, robust) is rated around 60 A continuous with higher short peaks and is widely used for charger inputs and parallel boards; see the concise spec summary in the Cirkit Designer XT60 component page (2021).

Polarity

- Most RC chargers with a barrel jack are center‑positive; XT60 is keyed for polarity. Always confirm the icon on your charger or check the manual.

- Verify with a multimeter before first power‑up.

线规

- Keep voltage drop under control. For short PSU→charger leads (<1 m round trip):

- ≈5 A: 18 AWG

- ≈10 A: 16 AWG

- ≈15 A: 14 AWG

- ≈20 A: 12–14 AWG These fit within chassis‑wiring ampacity from the PowerStream AWG chart and you can confirm drop with the Southwire voltage drop calculator. At 12 V, even small drops matter; at 24 V, drop is proportionally less impactful.

Checkpoint

- Choose the connector type that safely handles your expected current.

- Confirm polarity and wire gauge before energizing.

Step 6: Verify Setup and Run a Safe Test Charge

Do a 2‑minute preflight before plugging into the charger:

- With the PSU unplugged from the charger, set voltage (e.g., 24.0 V) and confirm OVP/OCP/SCP/OTP protections are present (common on quality PSUs like Mean Well; verify on the specific datasheet).

- Measure PSU output with a multimeter: correct voltage, correct polarity.

- Inspect the connector fit (barrel size or XT60) and strain relief.

- Place the LiPo in a LiPo‑safe bag or on a fire‑resistant surface and ensure you can supervise the charge; mainstream hobby guidance emphasizes supervision and containment (see Horizon Hobby’s charging safety overview, 2024).

First charge test

- Start with a modest current (e.g., 1C or less) and watch the charger’s input voltage reading. If it sags or errors, your PSU/lead is under‑spec or too long/thin.

- Feel connectors and leads after a few minutes; they should be just warm at most. Overheating suggests undersized connectors/wire or poor crimps/solder joints.

Worked Examples (Follow These Patterns)

These examples show the math and the choices at each step. When a battery’s advertised charge rate exceeds 1C, only use it if the battery’s datasheet explicitly allows it.

Example A: 3S 1500 mAh at 1C on a 100 W Charger

- Battery: 3S (S=3), Capacity = 1.5 Ah, C‑rate = 1C → Ichg = 1.5 A

- Vpack_max = 4.2 × 3 = 12.6 V

- Wout ≈ 12.6 × 1.5 = 18.9 W (well below charger limit)

- Charger limit: 100 W → size to the charger (not the small pack)

- Win ≈ 100/0.90 ≈ 111 W; Wpsu ≈ 111 × 1.3 ≈ 144 W → choose a 150–200 W PSU

- Vin choice: 12 V is fine at this power level

- Connector: Barrel 5.5×2.1 or 5.5×2.5 is OK at ≤5 A; confirm center‑positive

- Wire: 18 AWG is ample

Example B: 6S 5000 mAh at 2C on a 200 W Charger (Compare 12 V vs 24 V)

- Battery: 6S (S=6), Capacity = 5.0 Ah, target C‑rate = 2C → Ichg_target = 10 A (Use 2C only if datasheet allows; otherwise fall back to 1C)

- Vpack_max = 4.2 × 6 = 25.2 V

- Wout_demand ≈ 25.2 × 10 ≈ 252 W → charger capped at 200 W → actual Ichg ≈ 200/25.2 ≈ 7.9 A

- Win ≈ 200/0.90 ≈ 222 W

- Wpsu ≈ 222 × 1.3 ≈ 289 W → choose a 300–350 W PSU

- Input current at 12 V: Iin ≈ 222/12 ≈ 18.5 A

- Input current at 24 V: Iin ≈ 222/24 ≈ 9.3 A

- Conclusion: 24 V input is preferred to avoid high current draw and potential “input limit” throttling (behavior aligned with how chargers scale power with Vin and Iin limits, as seen in the ISDT Q8 Max specs).

- Connector: XT60 recommended for this current level; barrel plugs are marginal

- Wire: 14 AWG (or 12 AWG for extra margin)

Example C: Dual‑Channel 2×100 W at 24 V

- Total Wout = 200 W (both channels simultaneously)

- Win ≈ 200/0.90 ≈ 222 W

- Wpsu ≈ 222 × 1.3 ≈ 289 W → select ~350 W PSU for transient headroom

- Iin at 24 V ≈ 222/24 ≈ 9.25 A → a 24 V, ≥15 A (≈360 W) PSU offers comfortable overhead for fans/spikes

- Connector: XT60 or dedicated high‑current input terminals

- Wire: 14 AWG

Troubleshooting: Common PSU ↔ Charger Issues

| 症状 | 可能的原因 | What to Do |

|---|---|---|

| Charger reboots or shows “input voltage/current error” when you start charging | PSU under‑powered, Vin too low, or input cable too thin/long | Increase PSU wattage and/or raise Vin to 18–24 V (if supported); shorten/thicken leads; confirm Iin_max in your manual (e.g., 33 A for ISDT Q8 Max per the manual). |

| Charge current won’t reach the setpoint | Hitting charger input limit at 12 V, PSU current limiting, or thermal derating | Use a higher Vin, choose a higher‑wattage PSU, improve airflow. AC/DC listings (like HOTA D6 Pro) illustrate how input constraints cap output. |

| Barrel connector gets hot | Over its current rating or poor connection | Switch to XT60, or use a 5.5×2.5 mm with verified rating; inspect soldering/crimps; keep current ≤ connector’s datasheet spec (see Switchcraft examples). |

| PSU shuts down mid‑charge | OCP/OTP triggered by overload or poor ventilation | Reduce charge power, add headroom, improve cooling, and ensure the PSU has proper OVP/OCP/SCP/OTP features. |

| Sparks or no power on first plug‑in | 极性相反 | Verify polarity marks; test with a multimeter; remember most barrels are center‑positive; XT60 is keyed. |

| Parallel charging triggers errors | Packs not matched (voltage/cell count) or board exceeds current rating | Only parallel same‑S packs within ~0.1 V of each other; ensure board current rating (many boards list 35–70 A and fuse protection, e.g., BuddyRC STRIX 70 A board). |

Tip: For large multi‑channel setups, iCharger DX‑series input limits (e.g., 65 A max input, 9–34 V) require robust PSUs and cabling—see the specs on ProgressiveRC’s iCharger DX6 page (2023).

Toolbox: Parts and References (Neutral, Vendor‑Agnostic)

- PSU brands/classes: Mean Well enclosed (LRS‑350‑24 for 24 V 350 W; RSP/SE series for higher power—verify OVP/OCP/OTP on the exact datasheet), Delta industrial PSUs, or adjustable bench PSUs with protections.

- Connectors/adapters: XT60 sets and quality barrel jacks; review current ratings and choose appropriately. XT60 overview: XT60 quick specs.

- Wire tools: Southwire voltage drop calculator 和 PowerStream AWG chart for selecting gauge vs current/distance.

- Charging best practices: Horizon Hobby’s LiPo charging basics 和 Oscar Liang’s charger/PSU guide.

- Battery spec sheet sources (for safe C‑rates and pack data): 永邦电力, Grepow/Tattu, and HobbyKing/Turnigy. Disclosure: Yungbang Power is our product.

Quick Reference: Decision Flow

- Gather charger specs: Vin range, Iin_max, Wout_max

- Gather battery specs: S, Ah, allowed C‑rate

- Compute: Vpack_max = 4.2 × S; Ichg = Ah × C

- Compute per‑channel Wout = Vpack_max × Ichg; cap by charger’s W/channel

- Sum simultaneous channels (or parallel) → Wout_total

- Choose Vin (12 V vs 18–24 V) within range to keep input current manageable

- Compute Win ≈ Wout_total/η (η ≈ 0.85–0.90) and select Wpsu ≥ Win × 1.2–1.3

- Select connectors (barrel vs XT60) and wire gauge (keep drop <~3% at 12 V)

- Verify polarity/voltage with a multimeter before first power‑up

- Test at modest current, check for droop/heat, then increase as needed

Pro Tips and Safety Reminders

- Don’t exceed 1C unless the pack’s datasheet explicitly allows it; many packs are happiest at 0.5–1C for longevity (a common theme in hobby references like Horizon Hobby’s guides).

- Keep PSU leads short and thick; at 12 V, a 0.3–0.5 V drop can trigger “input voltage” complaints. Use the calculator to right‑size AWG.

- Prefer 24 V for 200 W+ setups; it halves the input current vs 12 V for the same power.

- Parallel charging: only same‑S packs and within a tight voltage window; use boards with proper fusing and ratings (examples summarized by Oscar Liang on parallel charging, 2024).

- Never leave charging unattended; use a LiPo bag or fire‑resistant container and a clear surface—standard safety advice in the hobby community (see Horizon Hobby’s safety overview, 2024).

Next Steps

- Capture your numbers in a simple worksheet (charger Vin range, Iin_max, Wout; battery S/Ah/C; chosen Vin, Wpsu, connector and AWG). Print and tape it near your charging area.

- If you add a second charger or a parallel board, repeat the sizing math with the higher simultaneous load.

- Before buying, scan the PSU’s datasheet for protections (OVP/OCP/SCP/OTP) and adjustability. For higher power, active PFC improves AC side efficiency and line performance.

With the math, connectors, and safety checks in place, you’ll have a charging setup that runs efficiently and predictably—no surprises, no scorched plugs, and no mysterious throttling.