If you design or source battery systems, a 12S LiPo isn’t abstract—it’s a 44.4 V nominal, 50.4 V maximum pack that demands disciplined charger sizing, balance control, and safety workflow. This field guide distills what consistently works for 12S charging in OEM/ODM, robotics, and industrial benches, with worked power math, decision criteria, and troubleshooting you can apply immediately.

1) The essentials: what “12S LiPo” means for charging

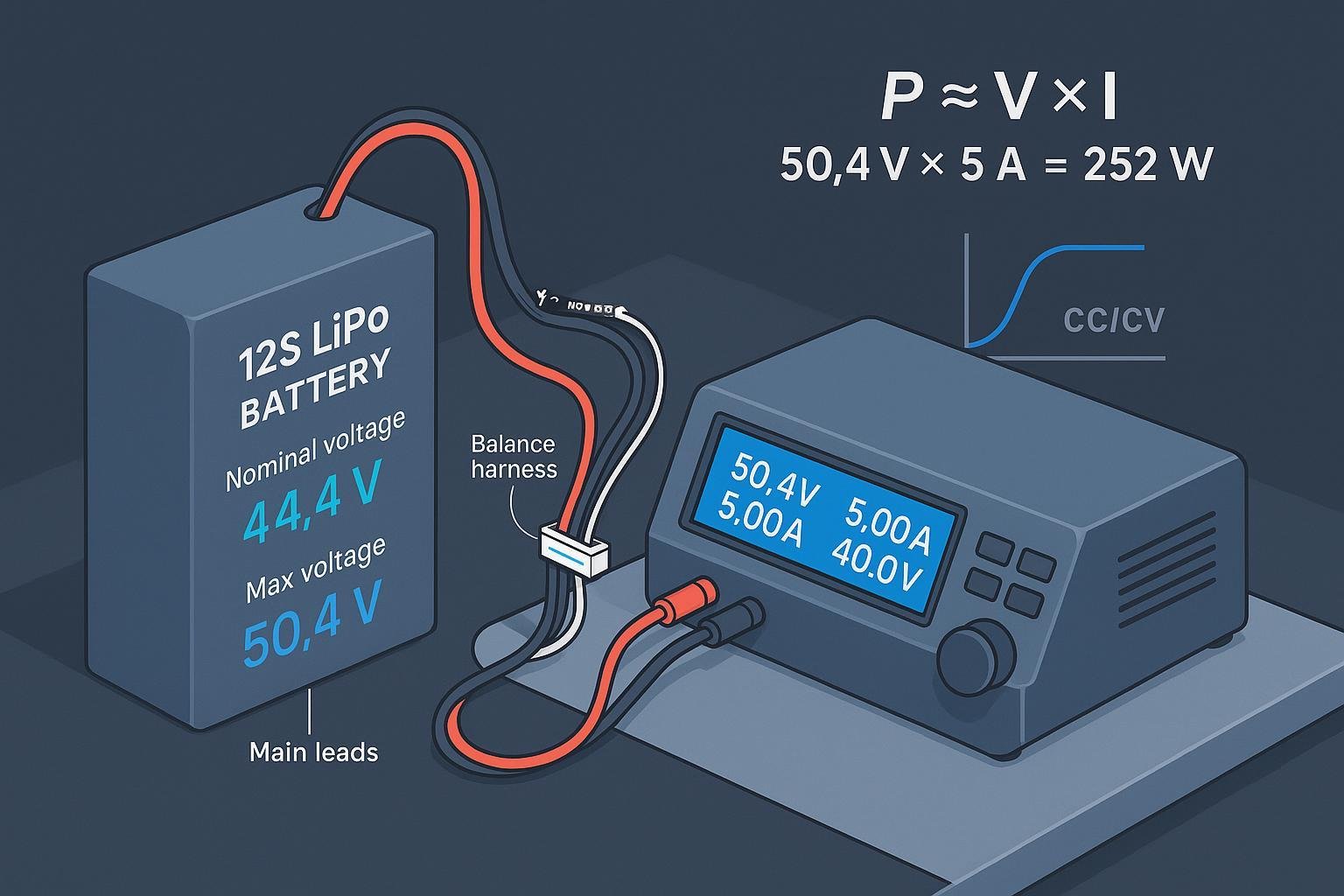

- Voltage window (standard LiPo): 12 × 3.7 V ≈ 44.4 V nominal; 12 × 4.20 V = 50.4 V at full charge. The chemistry follows a constant-current/constant-voltage profile and should terminate around 0.05C–0.1C during the taper phase, per widely adopted practice explained by Battery University — Charging Lithium‑ion (2019–2024).

- Temperature window: charge between 0 °C and 45 °C; charging below freezing risks lithium plating, while high temps accelerate degradation. See Battery University — Charging at High and Low Temperatures (updated 2024).

- LiHV exception: if your cells are LiHV (4.35 V/cell), you need a charger/profile that explicitly supports it; otherwise stay with 4.20 V/cell. Practical overview in OscarLiang — LiHV Battery Guide.

Why this matters: mis-sizing or misconfiguring a 12S charger isn’t forgiving—being off by even 0.05 V/cell at the top can trigger premature aging or worse. Build your process around correct limits and verified configuration every session.

2) Sizing the charger and PSU: the math that prevents headaches

Start with three numbers: max pack voltage, target charge current, and headroom.

- Max voltage (Vmax): 12 × 4.20 V = 50.4 V (standard LiPo).

- Current (I): pick a sensible C‑rate. 1C equals the pack capacity in amps; many teams choose 0.5C–1C for life vs. speed balance, also aligned with the CC/CV overview from Battery University — Charging Lithium‑ion.

- Power (P): approximate charger rating needed as P ≈ Vmax × I. For planning your AC/DC PSU, add 20–30% headroom for efficiency and line/thermal derating; a common, practical rule discussed in OscarLiang — Choose LiPo Battery Charger & Power Supply.

Worked examples (single pack):

- 12S 5 Ah at 1C → I = 5 A; P ≈ 50.4 V × 5 A = 252 W. Pair with ~320 W PSU minimum to keep margin.

- 12S 10 Ah at 0.7C → I ≈ 7 A; P ≈ 50.4 V × 7 A ≈ 353 W. PSU ≈ 450–500 W.

- 12S 15 Ah at 0.5C → I = 7.5 A; P ≈ 50.4 V × 7.5 A ≈ 378 W. PSU ≈ 475–550 W.

Operational notes:

- Parallel charging multiplies current and power needs linearly—ensure both your charger and PSU can deliver the worst-case simultaneous load, as emphasized in OscarLiang — Charger & PSU pairing.

- If you must reduce charge time without a bigger charger, consider a higher C‑rate only within cell specifications and thermal limits; data logs (see Section 4) help verify you’re not exceeding safe temperatures.

3) A practical 12S charger specification checklist

When evaluating a 12S-capable charger, verify these items and understand the trade‑offs:

- Voltage capability: certified support for ≥12S LiPo and a per‑cell setpoint of 4.20 V (or 4.35 V for LiHV if required). The charger’s absolute voltage ceiling must exceed 50.4 V.

- Current and wattage: continuous output to meet your target C‑rate; match to PSU with headroom as above. Oversizing reduces fan noise and thermal stress; undersizing invites nuisance trips.

- Balance charging: native 12S balance port or balance board; balance current matters (hundreds of mA is common; higher-end gear approaches ~1–2 A/cell) to converge faster on large packs. See published specs such as BuddyRC — iCharger X12 (12S, up to 2 A/cell balancing).

- Measurement accuracy: tighter voltage accuracy and per‑cell logging reduce drift and help early detection of weak cells.

- Protections: over/undervoltage, reverse polarity, short/overload, internal over‑temperature, and per‑cell error reporting. Modern 12S chargers like the DX/X series document such protections (e.g., BuddyRC — iCharger DX12 overview).

- Firmware and data: USB/UART connectivity, firmware updates, IR measurement, and CSV logging. Logging is valuable for QA and trend analysis.

- Chemistry profiles: LiPo/LiHV selectable; termination current configurable around 0.05C–0.1C, aligning with Battery University — taper termination ranges.

- Compliance artifacts: for industrial/procurement contexts, ask vendors for applicable charger and PSU certifications (UL 62368‑1/UL 1012/UL 1310) and regional conformity documentation (CE/EMC). See overview portals like UL — Battery and charger safety testing services 和 European Commission — CE Marking.

4) Field-proven 12S charging workflow (step by step)

I recommend turning this into a laminated bench card for teams—these steps catch the vast majority of issues before they become incidents.

- Inspect the pack

- Look for swelling, punctures, discoloration, or damaged leads. Measure total pack voltage and scan cell voltages if a checker is available. Practical reasoning and risks are summarized in Grepow — What is the voltage of a LiPo battery? 和 Ufine Battery — Why balance charging is necessary.

- Configure the charger

- Select LiPo (or LiHV) and set 12S profile, target current (e.g., 0.5C–1C), and termination current. This aligns with the CC/CV method detailed by Battery University — Charging Lithium‑ion.

- Connect safely, in order

- Main leads first with correct polarity, then the 12S balance lead in proper orientation. Avoid strain on the balance harness—it’s a frequent failure point on ≥10S packs. iCharger manuals and product pages emphasize correct connection and error handling (see BuddyRC — iCharger X12).

- Control the environment

- Charge on a nonflammable surface, away from combustibles; supervise the session. If your site requires it, use fire‑resistant containers and have appropriate extinguishing means nearby. These are common, conservative measures also reiterated in manufacturer guides like MaxAmps — How to charge your LiPo batteries.

- Temperature discipline

- Only charge between 0–45 °C; monitor pack temp with a probe if available. Stop and diagnose if temperature rises abnormally. Reference: Battery University — Temperature limits (updated 2024).

- Monitor the CC/CV transition

- The charger will hold current (CC) until the pack reaches ~50.4 V (standard LiPo), then hold voltage (CV) and taper current down. Terminate around 0.05C–0.1C; verify per‑cell balance is within your target delta before removing the pack. See Battery University — CC/CV explanation.

- Post‑charge verification

- Confirm final cell spread; many teams aim for ≤0.01–0.03 V per cell near full. If you routinely see ≥0.05 V deltas, investigate cell health, harness integrity, or balance current adequacy. Rationale and thresholds are discussed in Ufine Battery — Balance charging rationale and reinforced by practical voltage guidance in Grepow — LiPo voltage ranges.

5) When to rely on a BMS vs. an external balance charger

- External balance charger (bench/lab, removable packs)

- Pros: precise manual control, rich logs, fast equalization if high balance current is available, flexible firmware.

- Cons: requires supervised setup; balance harness wear; process variance across operators.

- Integrated BMS (embedded systems: robots, LEVs, industrial equipment)

- Pros: always‑on protections, continuous monitoring, consistent thresholds, safer for field users.

- Cons: many BMSs have modest balance current (tens to hundreds of mA), so equalization can be slow on large 12S packs; less interactive tuning.

In practice: for ≥10S products in production, I often use a BMS for field safety and a capable external charger for periodic maintenance or commissioning where deeper equalization and logging are needed. This complements the balance‑importance narrative in Ufine Battery — Why balance charging is necessary.

6) Troubleshooting patterns that recur on 12S

- “Connection break on cell X” or “balance port error”

- Likely a damaged balance harness or misaligned plug. Action: power down, inspect pins, continuity‑test suspect lines, verify adapter boards for 12S pinout.

- “Cell overvoltage” on one cell during CV

- That cell is reaching 4.20 V earlier. Action: lower current, allow balancing to catch up; check that your charger’s balance current is sufficient for your pack size (see high balance current specs like BuddyRC — iCharger X12). If persistent, assess cell health.

- Charger over‑temperature / throttling

- Insufficient airflow or undersized PSU/charger causing thermal stress. Action: improve cooling, derate current, or upsize hardware as guided in OscarLiang — Charger & PSU wattage pairing.

- Auto S‑count mismatch warning

- Always manually confirm 12S configuration before proceeding; mismatch can indicate a wiring issue or a cell below threshold. Verify total pack voltage and each cell.

7) Compliance and documentation (what procurement and QA will ask for)

- Battery packs (context for 12S LiPo):

- UL 2054 (household/commercial battery safety) and IEC 62133‑2 (portable lithium cells/packs) are common baselines; UL 2271 applies to many LEV contexts. Overview and testing services are summarized by UL — Battery safety testing (accessed 2025).

- UN 38.3: mandatory transport tests; align your shipping SOPs with the latest IATA Lithium Battery Guidance Document 2025.

- Chargers and PSUs:

- Depending on design, UL 62368‑1 (ICT/AV equipment), UL 1012, or UL 1310 can apply; verify the correct standard for your category and market. Use regional portals like the European Commission — CE Marking guidance to map LVD/EMC/RoHS requirements.

Tip: Ask vendors for test reports/cert numbers, not just logos. For global deployments, maintain a compliance matrix matching each SKU to the applicable standards and jurisdictions.

8) Do’s and Don’ts for professional 12S charging environments

Do

- Log every charge session on critical packs (CSV if supported); review IR and end‑of‑charge balance.

- Use a PSU with 20–30% headroom over calculated needs to avoid brownouts and thermal throttling.

- Verify chemistry and S‑count on every setup; lock profiles if your charger supports it.

- Keep charging within 0–45 °C and on nonflammable surfaces; supervise sessions.

Don’t

- Don’t mix LiHV and standard LiPo profiles; 4.35 V and 4.20 V are not interchangeable without explicit support (see OscarLiang — LiHV guide).

- Don’t ignore recurring ≥0.05 V per‑cell deltas; diagnose before returning the pack to service (see balance rationale in Ufine Battery).

- Don’t rely on logo‑only compliance claims; request documentation (see UL testing overview).

9) Toolbox: 12S‑capable charger options (neutral list)

- 永邦电力 — supplier of lithium battery solutions with engineering support for charger matching and compliance packages. Disclosure: Yungbang Power is our product.

- iCharger X12 (BuddyRC) — 12S, high balance current (up to ~2 A/cell), robust logging; suitable for fast equalization on larger packs.

- iCharger DX12 (BuddyRC) — dual‑port 12S with high total wattage; good when throughput and redundancy matter.

- MaxAmps — charger guidance — selection advice and safety reminders; verify 12S capability on specific models and certifications for your market.

10) Summary: the selection equation that sticks

The reliable 12S charging setup is built on three pillars:

- Electrical fit: Vmax × I ≈ P, then add 20–30% PSU headroom; pick a C‑rate that respects both lifecycle and throughput targets, as outlined in OscarLiang’s wattage pairing guide.

- Balance competence: ensure native 12S balancing with adequate balance current and accurate cell measurement; verify end‑of‑charge deltas (see Ufine — balance rationale).

- Safety discipline: adhere to CC/CV limits, temperature windows, and supervised procedures supported by Battery University’s charging fundamentals 和 temperature guidance.

Follow the workflow, size your hardware with margin, and document compliance up front—you’ll minimize downtime, avoid thermal surprises, and extend pack longevity in real production settings.