Introduction: The Next Generation of 18650 Battery Packaging

In a world where high-performance 18650 lithium-ion packs power electric vehicles, industrial robotics, medical devices, and smart homes, the bar for safety, efficiency, and longevity has never been higher. With regulatory standards like UL 1487 and IEC 62133 rapidly becoming mandatory worldwide, battery engineers are challenged not just to meet compliance—but to attain exceptional reliability, manufacturability, and advanced thermal control. This article distills the most innovative, field-tested solutions for designing battery packaging that delivers maximum protection, energy efficiency, and best-in-class thermal management.

Quick Checklist: 18650 Battery Packaging Best Practices

- Comply with latest global standards (UL 1487, IEC 62133) for safety and thermal stability.

- Select enclosure materials (preferably aluminum or steel) for heat dissipation, strength, and EMI/fire protection.

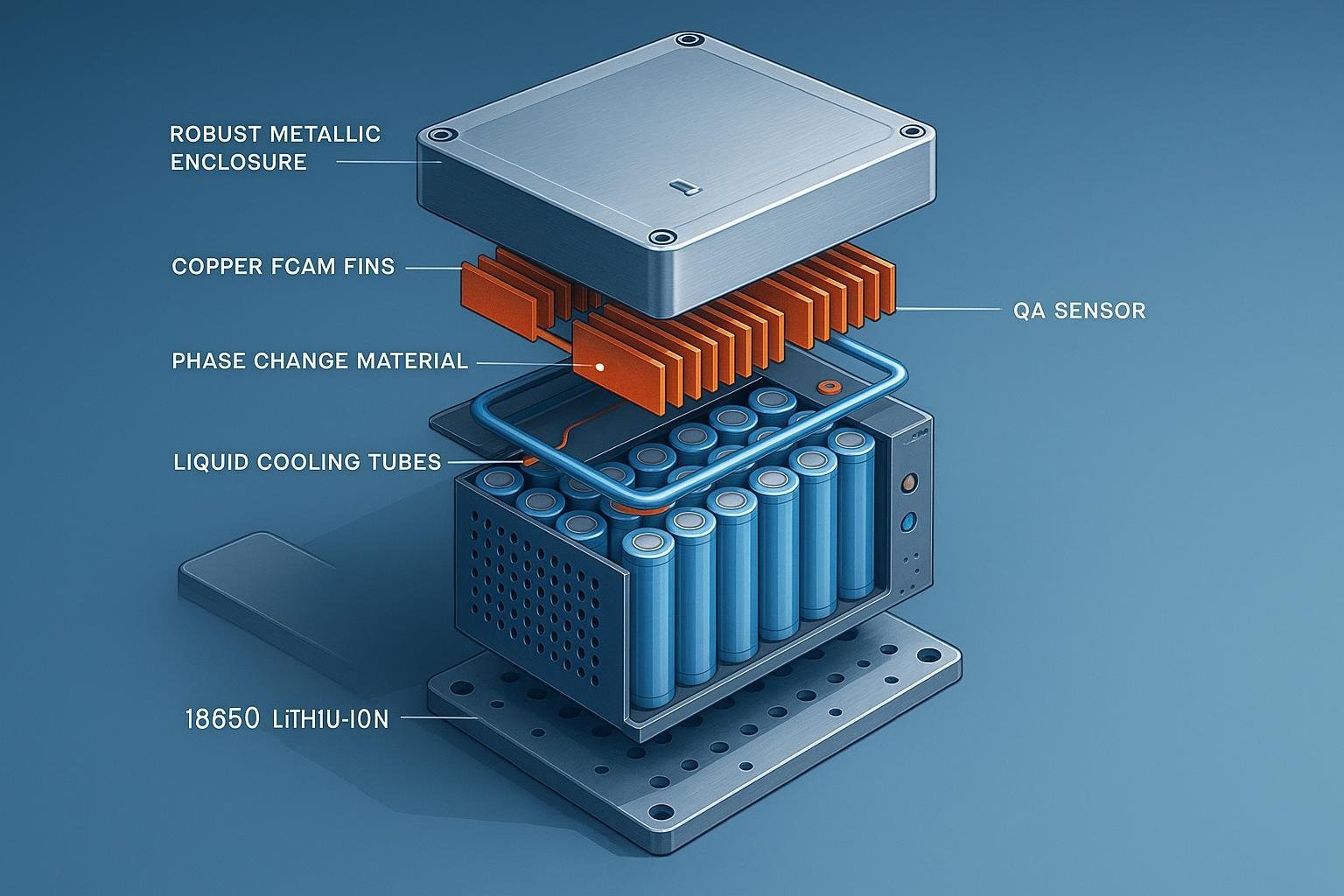

- Integrate advanced hybrid thermal management (PCM + copper foam fins + liquid cooling when feasible).

- Automate assembly and QA to reduce defects and ensure reproducibility.

- Use modular, scalable pack designs for maintenance and adaptability.

- Validate every stage with simulation software (e.g., ANSYS, MATLAB) and rigorous lab testing.

1. Mechanical & Electrical Protection Strategies

a. Material Selection: Metals vs Advanced Polymers

- Aluminum and Steel Enclosures: Offer industry-leading thermal conductivity, fire resistance, and mechanical protection (источник). They are the gold standard for high-density or mission-critical packs.

- Advanced Polymers: Suitable for weight-sensitive or highly corrosive environments but require extensive flame-retardation, EMI shielding, and additional QA verification.

| Property | Aluminum | Steel | Advanced Polymer |

|---|---|---|---|

| Теплопроводность | Высокий | Умеренный | Низкий |

| Strength | Высокий | Very High | Умеренный |

| Огнестойкость | Превосходно | Превосходно | Переменная |

| EMI Shielding | Превосходно | Превосходно | Needs Additive |

b. Design for Impact & Fire Protection

- Reinforce corners/edges and add internal padding to absorb mechanical shock.

- Integrate fire-resistant barriers (ceramics, mica tapes) between cells.

- Ensure containment for single-cell failures (per UL 1487 guidelines: UL Battery Enclosure).

c. Electrical Safety Features

- Add robust BMS (Battery Management System) with short-circuit, overcharge, and thermal runaway protection.

- Design for fail-safe isolation: Each cell module should be electrically and thermally partitioned.

2. Maximizing Manufacturing and Design Efficiency

a. Automation for Quality and Consistency

- Utilize automated assembly lines with laser/ultrasonic welding for precise, repeatable connections (assembly guide).

- Employ in-line QA sensors—vision systems, resistance testers, and thermal scanners—to catch defects early.

- Implement track-and-trace systems to monitor every cell/module through production.

Tool Spotlight:

- Automated Precision Welders (industry-standard in top-tier OEMs)

- Simulation Software (e.g., ANSYS, SimScale, MATLAB) for DFM and virtual validation

b. Modular, Scalable Packaging

- Design packs as modular blocks for easier assembly, servicing, and future capacity upgrades.

c. Defect Reduction Protocols and FMEA

- Run Failure Mode and Effect Analysis (FMEA) at each stage.

- Integrate stress and environmental validation (thermal cycling, humidity exposure) per IEC/UL demands.

3. Advanced Thermal Management Innovations

a. Hybrid Thermal Management Systems (HBTMS)

- Combine Phase Change Materials (PCM), Porous Copper Foam Fins, and Liquid Cooling.

- Производительность: Lab studies (ScienceDirect) show packages using PCM + copper foam fins reduce max cell temperatures by as much as 9.18 K at 5C discharge, maintaining uniformity to within 1K—crucial for longevity and safety.

- Плотность энергии: Up to 25% improvement over traditional fin-only cooling designs.

b. Simulation-Driven Design

- Use CFD/FEA tools (e.g., ANSYS, MATLAB) to model airflow, heat flux, and identify hotspots before physical prototyping.

- Validate simulated results with full-scale environmental lab testing for certification.

c. Real-World Implementation Tips

- Proper PCM encapsulation is essential—avoid thermal leaks and ensure physical separation from electronics.

- Copper foam fin porosity should target balance between thermal conductivity and energy density.

4. Certification and Standards Compliance

- UL 1487 и IEC 62133: Certification is rapidly moving from “desirable” to essential for entry into global automotive, medical, and industrial battery markets.

- Контрольный список: Independent lab thermal runaway testing, short-circuit simulation, and fire containment verification.

- BMS Compliance: Ensure all electronics meet FCC/CE for EMI and communications safety.

- Reference authoritative test services: UL Battery Enclosure Testing Service

5. Case Study & Industry Benchmarks

Benchmark: Hybrid Thermal Systems in High-Power Packs

- Peer-reviewed data confirm HBTMS (PCM + copper foam) achieves up to 9.18 K lower peak cell temperatures and tighter uniformity under high loads (ScienceDirect).

Market Trend:

- Automated QA and modular, certified designs are now baseline at top global OEMs (Panasonic, LG Chem, Tesla), resulting in 15–30% fewer defects and measurable improvements in pack cycle life.

6. Actionable Engineering Checklist for Your 18650 Pack

- [ ] Select enclosure type (aluminum/steel for most applications)

- [ ] Plan mechanical/fire barriers (ceramic, mica, reinforced corners)

- [ ] Integrate robust BMS and partitioning

- [ ] Design modular blocks for assembly/service

- [ ] Automate welding and QA (vision, electrical, thermal sensors)

- [ ] Simulate and validate thermal management (PCM + copper foam + optional liquid channels)

- [ ] Conduct full IEC/UL/FCC pre-certification testing

- [ ] Maintain full documentation for traceability and certification

Further Reading & Tools

- UL Battery Enclosure Testing

- Comprehensive Assembly Guide

- Thermal Management Case Study

- Simulation tools: ANSYS, MATLAB (ANSYS Overview)

Примечание: For the latest technical updates, refer to recognized standards bodies like UL, IEC, and authoritative engineering resources.