Lithium-ion battery assembly demands precision at every stage, from electrode manufacturing to cell assembly and finishing. This process supports a global market valued at $54.4 billion in 2023 and powers sectors such as electric vehicles, which saw nearly 14 million units sold last year. Safety remains paramount, as incidents like internal short circuits or overcharging can trigger thermal runaway. Automation and strict standard operating procedures help maintain battery assembly safety, technology advancement, and consistent lithium battery performance.

Ключевые компоненты

Электродные материалы

Lithium-ion battery performance starts with the right electrode materials. The cathode uses metal oxides such as lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate (LFP), and lithium nickel manganese cobalt oxide (NMC). Each type offers a different balance of energy density, safety, and cost. For example, LFP cathodes provide excellent safety and long cycle life, making them ideal for applications that need endurance. NMC cathodes deliver higher energy density and are common in electric vehicles and power tools. The anode usually contains graphite, which offers high electrical conductivity and stability at a low cost. Some lithium-ion batteries use silicon or silicon-graphite blends to increase energy density, but these can face issues with swelling and shorter cycle life. Cathode materials account for up to 40% of the cell cost, while anodes make up about 15%. The choice of electrode materials directly affects the lithium battery’s capacity, lifespan, and safety.

Separators and Electrolytes

The separator sits between the anode and cathode, preventing short circuits while allowing ions to pass. Most lithium-ion batteries use polyolefin-based separators like polyethylene (PE) and polypropylene (PP). These materials offer good mechanical strength and act as a thermal fuse by melting at high temperatures, which helps prevent overheating. Some advanced cells use cellulose-based separators, which improve electrolyte interaction and cycling performance, especially during fast charging. The table below compares common separator materials:

| Separator Type | Examples | Key Properties | Impact on Safety and Performance |

|---|---|---|---|

| Polyolefin-based | PE, PP | Strong, cost-effective, thermal fuse | Enhances safety, limits fast charging |

| Cellulose-based | CEL, CNF | High wettability, stable | Improves cycling, better for fast charging |

Electrolytes, usually liquid organic solvents with lithium salts, enable ion movement between electrodes. The right combination of separator and electrolyte ensures the cell operates safely and efficiently.

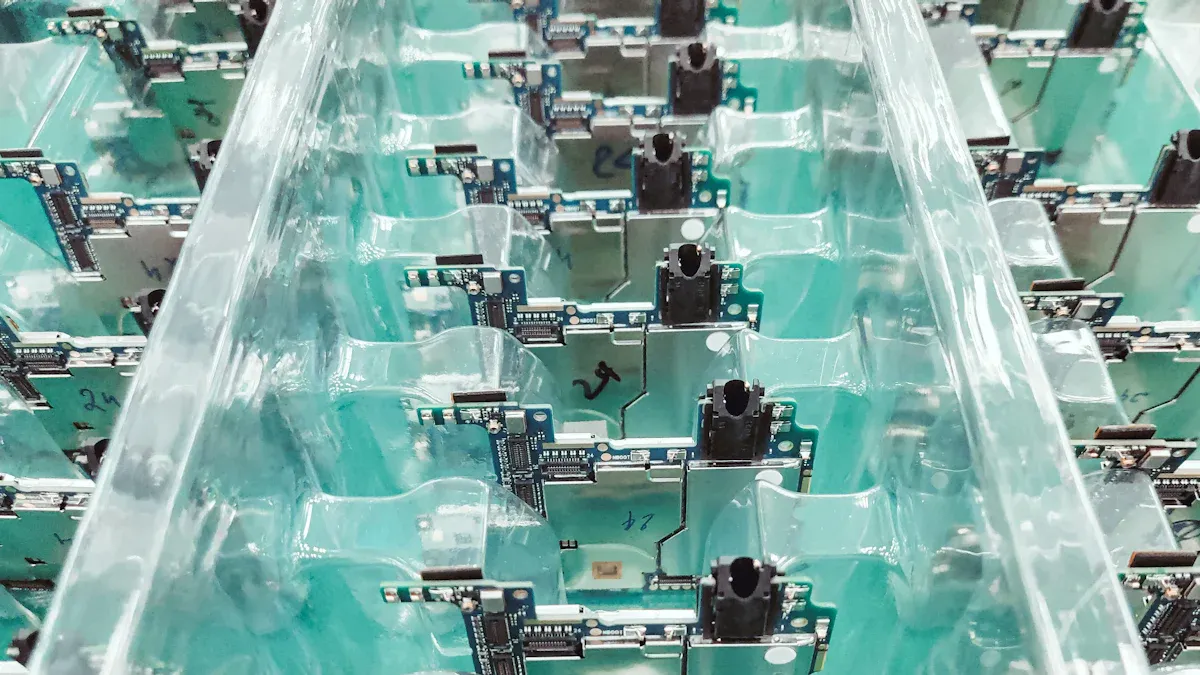

Casings and Terminals

The casing protects the lithium-ion battery’s internal components and manages heat. For small, embedded lithium battery packs, manufacturers often use shrink wrap or vacuum-formed plastics. Larger or high-impact applications, such as electric vehicles, use metal casings made from aluminum or steel. These materials resist heat and physical stress. Designers add features like vents, cooling channels, and bracing to handle cell swelling and heat. Terminals and current collectors use metals such as aluminum for the cathode and copper for the anode. These metals provide excellent conductivity and match the battery chemistry. Proper spacing and insulation prevent short circuits and thermal runaway. Advanced manufacturing, including 3D printing, allows for the integration of sensors and cooling systems directly into the casing, improving safety and performance for every lithium-ion battery cell.

Battery Assembly Process

Electrode Manufacturing

Electrode manufacturing forms the foundation of the lithium-ion battery assembly process. This stage begins with slurry mixing, where active materials, conductive additives, binders, and solvents blend together in large mixers. Operators maintain strict control over temperature, humidity, and vacuum levels to ensure a uniform mixture. After mixing, the slurry passes through sieves to remove large particles and ferromagnetic contaminants, which helps prevent defects in the final battery.

The next step involves coating the slurry onto metal foils—aluminum for the cathode and copper for the anode. Coating machines, such as slot dies and doctor blades, apply the slurry with high precision. The coated foils then enter drying ovens, where temperatures between 95°C and 120°C remove solvents and moisture. This drying process solidifies the electrode layer and prevents cracks or solvent drops.

Calendaring machines compress the dried electrodes, adjusting thickness and porosity to improve mechanical stability. This step ensures each electrode meets the strict requirements of the battery assembly process. Cutting machines then slit the wide rolls of coated electrodes into narrow strips, matching the dimensions needed for cell assembly. Vacuum ovens perform a final drying step, eliminating any residual moisture and ensuring optimal electrode quality.

Quality control plays a critical role throughout electrode manufacturing. Automated optical inspection and laser measurement systems monitor coating thickness, adhesion, and homogeneity. Imaging techniques, such as X-ray photography and CT scanning, detect internal defects and verify electrode integrity. Cleanroom environments with HEPA filtration minimize contamination risks, while inline laser profilometers measure coating thickness in real time. These measures ensure that only high-quality electrodes proceed to the next stage of lithium battery manufacturing.

Совет: Consistent electrode quality directly impacts the performance, safety, and lifespan of every lithium-ion battery.

| Шаг | Описание | Equipment Used |

|---|---|---|

| Slurry Mixing | Blend active materials, conductive additives, binder, and solvent to create uniform slurry. | Mixers (dry and wet mixing equipment) |

| Coating | Apply slurry onto metal foils using precise coating tools. | Coating machines (slot dies, doctor blades, anilox rollers) |

| Drying | Remove solvent from coated foils to solidify electrode layer. | Drying ovens |

| Calendaring | Compress coated electrodes to adjust thickness and porosity for mechanical stability. | Calendaring machines |

| Slitting | Cut wide coated electrode rolls into narrow strips matching battery cell dimensions. | Slitting/cutting machines |

Cell Assembly

Cell assembly transforms prepared electrodes into functional battery cells. This stage includes stacking, winding, or folding the electrodes and separators, depending on the cell design. Stacking involves layering individual anode, separator, and cathode sheets on top of each other. This method maximizes space in rectangular pouch or prismatic cells but requires precise alignment to avoid separator failure or short circuits. Z-folding uses a continuous separator, folding electrodes in a zigzag pattern. This approach ensures good separation but can introduce mechanical stress at the folds. Rolling, often used for cylindrical cells, stacks four sheets—anode, separator, cathode, separator—and rolls them into a spiral. This method provides strong separator integrity but is less space-efficient.

Automation plays a vital role in the cell assembly process. Precision guiding systems and robotic arms position electrode and separator layers with high accuracy, eliminating misalignment and improving battery uniformity. Unwind and rewind modules maintain tension during material feeding, preventing wrinkles or tears. Automated layer alignment systems use real-time feedback and AI-driven corrections to keep stacking precise and fast. These technologies increase production speed, reduce material waste, and enhance safety by minimizing human exposure to hazardous materials.

During cell assembly, operators continuously monitor electrode alignment and separator integrity. Cleanroom environments and optical guidance systems prevent contamination and misalignment errors. Automated X-ray diagnostics and advanced imaging systems detect micron-level defects, ensuring only compliant components move forward in the battery manufacturing process.

Примечание: Automation in cell assembly not only improves quality and consistency but also enables scalable production to meet growing market demands.

| Метод | Описание | Преимущества | Недостатки | Impact on Cell Design and Use |

|---|---|---|---|---|

| Stacking | Individual anode, cathode, and separator sheets are cut and layered one on top of another. | Maximizes space utilization in rectangular cells. | Risk of misalignment causing separator failure and short circuits; cutting imperfections possible. | Best for rectangular pouch or prismatic cells; maximizes active area. |

| Z-folding | Anode and cathode sheets are cut; separator remains continuous and electrodes are inserted via Z-folding. | Ensures good separation with continuous separator. | Mechanical stress at folds can cause separator rupture and short circuits. | Used where continuous separator integrity is critical; folding induces mechanical stress. |

| Rolling | Four sheets (anode, separator, cathode, separator) are stacked and rolled into cylindrical or oval shapes. | Good separator integrity due to continuous layers. | Less efficient volume use due to oval shape; mechanical stress at bending points risks rupture. | Common for cylindrical and prismatic cells; less space-efficient due to shape. |

Cell Finishing

Cell finishing completes the lithium-ion battery assembly process. This stage includes electrolyte filling, sealing, formation, and quality testing. Operators fill each cell with a precise amount of electrolyte, using vacuum filling systems to ensure thorough wetting of the electrodes. Accurate dosing and machine maintenance prevent over- or under-filling, which can affect battery capacity and cost.

Pre-treatment steps, such as thermal soaking at 40–60°C, improve electrolyte wetting and distribution. Electrical pre-treatment involves low-current charging to reduce copper foil corrosion and allow longer wetting times. The formation procedure begins with pre-charging the cell to release gas early, followed by main formation cycles that create the solid electrolyte interphase (SEI) and cathode electrolyte interphase (CEI). These layers are essential for battery stability and longevity.

Auxiliary steps include degassing, sealing, and, if needed, a second electrolyte filling. The cell then undergoes aging at room temperature, with continuous monitoring of open-circuit voltage. End-of-line testing evaluates capacity, internal resistance, weight, dimension, and voltage stability. Cells are graded based on quality, ensuring only those meeting strict standards proceed to battery pack assembly.

Common challenges in cell finishing include welding defects, moisture contamination, and electrolyte filling inaccuracies. Solutions involve precision welding control, strict environmental controls, and robust data management systems. Manufacturing Execution Systems (MES) track thousands of parameters, optimizing the battery manufacturing process and reducing scrap rates.

Тревога: Even a single defective cell can compromise the safety and performance of an entire lithium-ion battery pack. Thorough end-of-line testing and screening are essential.

| Категория шага | Key Steps and Processes | Critical Parameters to Monitor |

|---|---|---|

| Pre-treatment | – Thermal pre-treatment (high-temperature soaking at 40-60°C to improve electrolyte wetting) | – Wetting degree |

| – Mechanical pre-treatment | – Electrolyte distribution | |

| – Electrical pre-treatment (low current charging to reduce copper foil corrosion and allow longer wetting) | ||

| Formation Procedure | – Pre-charging (0.05 C, up to 20-30% SOC) to release gas early | – Voltage during aging |

| – Main formation cycles to form SEI (Solid Electrolyte Interphase) and CEI (Cathode Electrolyte Interphase) | – Gas release | |

| – Auxiliary steps: degassing, sealing, second electrolyte filling, aging | ||

| Quality Testing | – Room-temperature aging with monitoring of open circuit voltage | – Capacity |

| – End-of-Line (EoL) testing including capacity, internal resistance, weight, dimension, voltage stability | – Internal resistance | |

| – Grading based on quality level | – Weight, dimension, voltage stability |

The battery assembly process requires careful attention at every stage. Each step, from electrode manufacturing to cell assembly and cell finishing, uses advanced technology and automation to ensure safety, quality, and efficiency. By following best practices and maintaining strict quality control, manufacturers produce reliable lithium-ion batteries for a wide range of applications.

Steps in the Lithium Battery Assembly Process

Preparation and Handling

The first steps in the lithium battery assembly process focus on preparing and handling all components with care. Technicians follow a strict sequence to ensure each cell meets quality standards:

- Mix electrode slurry using active materials, binders, and conductive agents for a uniform blend.

- Coat the slurry onto metal foils, maintaining even thickness and strong adhesion.

- Dry the coated electrodes to remove solvents and moisture, preserving integrity.

- Compress electrodes through calendaring, which improves stability and conductivity.

- Clean electrodes to eliminate impurities.

- Cut electrodes to precise dimensions for each cell.

- Dry electrodes in a vacuum oven to remove any remaining moisture.

- Maintain a controlled environment, such as a dry room, during electrolyte filling and assembly to prevent contamination.

- Clean all metal parts, including cases and spacers, using acetone or alcohol and DI water in ultrasonic baths.

- Dry separators at low temperatures under vacuum, following manufacturer guidelines for new materials.

- Regularly check moisture content in solvents and electrolytes using advanced methods like Karl Fischer titration.

These steps in the lithium battery assembly process help prevent defects and ensure reliable battery performance.

Stacking and Winding

Stacking and winding represent two main techniques in battery assembly. Stacking involves cutting anode and cathode sheets, then layering them with separators in a Z-shaped pattern. This method suits square and pouch cells, offering высокая плотность энергии, better safety, and longer cycle life. Stacking also reduces material waste and improves thermal management.

Winding uses automated machines to roll electrodes and separators into a jelly roll structure. This process works best for cylindrical cells, providing high speed and reliability. However, winding may cause electrode deformation and uneven current distribution.

| Technique | Основные характеристики | Best Use Cases |

|---|---|---|

| Stacking | High energy density, better safety, less waste | Prismatic, pouch cells |

| Winding | Fast, cost-effective, mature process | Cylindrical cells |

Both methods play a vital role in battery pack assembly, depending on the cell design and application.

Electrolyte Filling and Sealing

Electrolyte filling and sealing are critical steps in the battery assembly process. Technicians clean cells and electrolyte before filling. They dispense the electrolyte with precision, ensuring each cell receives the correct amount. Weight checks confirm uniform filling. After filling, they inspect for leaks and verify seal tightness.

Sealing requires careful alignment of the case and cap. High pressure ensures a strong seal, while visual inspections and helium leak tests confirm integrity. Each battery receives a unique ID for traceability. Sealed cells are stored in humidity-controlled environments before moving to battery pack assembly.

Совет: Proper electrolyte filling and sealing prevent contamination and leakage, which can compromise battery safety and performance.

Initial Testing

Initial testing and validation ensure each cell meets safety and quality standards before further assembly. Technicians perform capacity testing to measure charge holding and delivery. Internal resistance testing evaluates energy conversion efficiency. Cycle life testing simulates real-world use to assess longevity. Temperature testing, including thermal runaway assessments, checks battery behavior under stress. Safety testing examines responses to overcharging, short circuits, and extreme temperatures.

Testing methods follow international standards such as IEC 62133 and UN 38.3. These steps in the lithium battery assembly process help manufacturers identify defects early and maintain high-quality battery production. Charge and discharge tests provide additional data on cell performance.

Regular testing and validation protect users and ensure reliable operation in every battery.

Safety and Quality

Safety Protocols

Safety considerations guide every step of the lithium-ion battery assembly process. Workers must follow standard operating procedures to prevent accidents and protect both people and equipment. The Lithium Battery Safety Program sets clear rules for handling, storage, and disposal. Department heads and supervisors train staff and enforce compliance with safety standards from organizations like OSHA and DOT.

Key safety protocols include:

- Always follow approved assembly procedures and manufacturer specifications.

- Ensure all wire connections are secure. Prevent exposed copper wires from touching to avoid short circuits.

- Never allow wires to short-circuit during installation. This protects the battery controller and the protection board.

- Monitor battery status indicators during wiring and charging to confirm normal operation.

- Source batteries from trusted manufacturers that meet safety standards such as UL 2054.

- Store batteries in cool, dry environments. Avoid charging beyond rated capacity or leaving batteries unattended while charging.

- Train workers to spot defects like bulging, leaking, or strange noises. Remove defective cells from the process and dispose of them safely.

- Prohibit battery disassembly due to fire and explosion risks. In emergencies, evacuate the area and call professionals.

Примечание: Strict safety protocols and safety considerations reduce the risk of burns, explosions, and other injuries during the battery assembly process.

Quality Control

Quality control measures ensure every battery meets strict standards for performance and reliability. The process starts with cell preparation and inspection, including cleaning, voltage checks, and visual inspections. Only high-quality cells move forward.

Manufacturers use several quality control tests to detect defects:

| Quality Control Test | Defects Detected / Issues Addressed |

|---|---|

| Cycle Life Testing | Capacity loss from repeated use |

| Voltage and Temperature Monitoring | Overcharging, overheating, or other faults |

| Internal Resistance Measurement | Battery health and efficiency problems |

| Non-Destructive Testing | Internal defects or structural issues |

| Accelerated Aging Testing | Long-term reliability and failure modes |

| Safety Testing | Battery response to abuse or short circuits |

Advanced methods like magnetic field imaging и Raman spectroscopy help detect hidden defects and chemical impurities. These tools support continuous improvement in quality.

Common pitfalls in battery assembly include separator failure, current collector damage, contamination, and mechanical failures. Manufacturers address these by using robust materials, improving cleanliness, and applying thermal management techniques. Quality control measures at every stage help prevent these issues and ensure each cell meets safety and quality requirements.

Regular quality control and safety considerations protect users and extend battery life.

Automation and Technology

Automated Assembly

Automated assembly has transformed the lithium battery manufacturing industry. Companies now use advanced machines and robotics to handle each step of the battery manufacturing process. These systems improve speed, accuracy, and safety. Flexible automation allows factories to adjust quickly to new battery technology and market needs.

Key advancements in automated battery assembly include:

- Flexible, scalable automation systems that use IoT-enabled machines and Industry 4.0 technology.

- Fully automated processes for cell sorting, stacking, high-precision spot welding, and real-time battery testing.

- Modular systems that let manufacturers upgrade or change production lines without major overhauls.

- Automation that reduces labor intensity and human error, while predictive maintenance keeps machines running smoothly.

- Increased throughput and zero-defect battery packs, which lower operational costs and boost efficiency.

Companies like Exicom have scaled their assembly lines to 1.2 GWh per year, improving throughput by 30% and achieving zero defects. SM Auto reduced labor by 60% while raising quality. These results show how automation gives manufacturers a strong advantage in the fast-changing battery market.

Innovations in Manufacturing

Lithium battery manufacturing continues to evolve with new technology and materials. Recent innovations in the battery manufacturing process bring better safety, higher energy density, and longer battery life. The table below highlights some of the most significant advances:

| Innovation Type | Преимущества |

|---|---|

| Solid-State Batteries | Improved safety by reducing overheating risks; enhanced energy density; longer cycle life |

| Silicon Anodes | Higher energy storage capacity; better performance at high discharge rates; compatible with existing manufacturing processes |

| Recycling Technologies | Sustainable battery production; recovery of valuable materials like lithium, cobalt, and nickel, reducing environmental impact |

Manufacturers now use artificial intelligence in battery management systems. AI monitors battery health, predicts failures, and improves charging efficiency. Nanomaterials, such as silicon nanoparticles, help batteries store more energy and last longer. Researchers are also exploring lithium-sulfur batteries, which could offer even higher energy density and lower costs in the future.

These advances in battery technology and the battery manufacturing process help companies produce safer, more powerful, and longer-lasting batteries. As technology improves, lithium battery manufacturing will continue to set new standards for quality and performance.

Best Practices for Lithium-Ion Battery Assembly

Storage and Handling

Proper storage and handling play a crucial role in lithium battery manufacturing. Companies must store lithium-ion battery components in cool, dry, and shaded environments. This approach prevents corrosion and reduces the risk of capacity loss. Batteries should remain at about 50% state of charge during storage to preserve material integrity. Workers avoid charging batteries above 80% to limit capacity degradation. Exposure to extreme temperatures or moisture can harm battery performance, so facilities use climate control systems.

Careful handling prevents physical damage that could impair function. Teams use lithium-specific chargers with intelligent charging logic to avoid overcharging and excessive heat. Following manufacturer charging instructions helps optimize battery lifespan. Regular maintenance, such as cleaning battery terminals and monitoring charge status, supports reliable operation. Companies also comply with transportation and disposal regulations to ensure safety and sustainability.

Tip: Always use proper personal protective equipment (PPE) and follow safety protocols during battery assembly to prevent accidents.

Maintenance and Longevity

Effective maintenance extends the operational life of lithium-ion batteries and supports sustainability in lithium battery manufacturing. Teams manage charging cycles by avoiding unnecessary full charge-discharge cycles. Partial discharges and recharges reduce battery wear. Most lithium-ion batteries last between 300 and 15,000 full cycles, depending on chemistry and usage.

Workers store batteries in temperature-controlled environments and avoid hot areas, such as inside vehicles on sunny days. Slow charging reduces heat generation and prevents cell damage. The use of a reliable Battery Management System (BMS) ensures safe operation by monitoring voltage, current, and temperature. Regular inspections help detect swelling, leaks, or other signs of failure.

Key maintenance practices include:

- Keeping battery charge between 20% and 80% to reduce strain.

- Using chargers recommended by the device manufacturer.

- Performing periodic cell balancing in multi-cell packs.

- Monitoring State of Health (SoH) to anticipate replacement needs.

- Updating software for devices like smartphones and laptops to use battery health features.

A robust approach to maintenance and assembly helps prevent common causes of premature failure, such as electrical abuse, thermal abuse, and mechanical damage. By following these best practices, companies in lithium battery manufacturing improve battery performance, safety, and sustainability.

Lithium-ion battery assembly requires careful attention to each step, from slurry mixing to packaging. Companies improve battery performance by using innovations like dry coating and robust packaging for safety. They follow strict SOPs and leverage automation to maintain quality and reduce errors. To extend battery lifespan, users should avoid deep discharges, keep batteries between 20% and 80% charge, and store them at moderate temperatures. Regular testing and maintenance help ensure reliable battery performance in real-world use.

Consistent focus on safety, quality, and best practices leads to safer, longer-lasting batteries.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the most important safety step in lithium-ion battery assembly?

Workers must always follow standard operating procedures. This step prevents accidents and ensures each battery meets safety standards. Proper training and protective equipment also help reduce risks during assembly.

Why do manufacturers use automation in battery assembly?

Automation increases precision and speed. Machines handle repetitive tasks, which reduces human error. Automated systems also improve product consistency and help companies meet high production demands.

How do separators improve battery safety?

Separators keep the anode and cathode apart. This barrier prevents short circuits. Many separators also melt at high temperatures, which stops dangerous reactions if the battery overheats.

What causes lithium-ion batteries to fail early?

Common causes include overcharging, deep discharges, and exposure to heat. Physical damage or contamination during assembly can also lead to early failure. Regular maintenance and careful handling extend battery life.

Can lithium-ion batteries be recycled?

Yes, recycling is possible. Specialized facilities recover valuable materials like lithium, cobalt, and nickel. Recycling helps reduce environmental impact and supports sustainable battery production.