Custom lithium polymer batteries use a gel-like polymer electrolyte, which helps improve safety and reduce leakage risks. These batteries stand out in modern technology because they offer lightweight, flexible, and energy-dense power for slim devices. Many industries seek custom battery solutions for unique device shapes and higher performance.

- Сайт shift to compact, high-performance devices drives demand for custom lithium polymer batteries.

- These batteries support healthcare, IoT, drones, wearables, and robotics where space and weight matter most.

- Advances in material science keep improving efficiency and safety.

What Are Custom Lithium Polymer Batteries

Основные характеристики

Custom lithium polymer batteries use advanced lithium battery technology to deliver power in a flexible and lightweight form. These batteries stand out because they can be made extremely thin—sometimes less than 1mm. They use a полимерный электролит instead of a liquid one, which allows for unique shapes and sizes. Manufacturers can design these batteries to fit almost any device, making them ideal for products where space and weight matter.

Some important features include:

- High energy density, which means more power in a smaller space.

- Lightweight design due to the lack of a metal casing.

- Flexible aluminum-plastic packaging that increases safety and reduces the risk of explosion or leakage.

- Low self-discharge rate, so they hold their charge longer when not in use.

- No memory effect, so users can recharge them at any time without reducing battery life.

- Environmentally friendly materials, as they do not contain harmful metals.

Custom lithium polymer batteries also require careful charging and protection. A battery management system (BMS) helps prevent overcharging, overheating, and swelling. This makes them safer for use in sensitive devices.

Custom vs Standard Batteries

Custom lithium battery solutions offer several advantages over standard lithium-ion batteries. Standard batteries come in fixed shapes and sizes, which can limit device design. In contrast, custom lithium polymer batteries can be shaped to fit the exact needs of a device. This flexibility supports the development of thinner, lighter, and more compact products.

The table below highlights key differences:

| Характеристика | Custom Lithium Polymer Batteries | Standard Lithium-Ion Batteries |

|---|---|---|

| Shape & Size | Any shape or size | Fixed shapes (cylindrical, prismatic) |

| Вес | Lighter, no metal casing | Heavier, metal casing |

| Плотность энергии | Higher for same size | Lower for same size |

| Packaging | Flexible pouch | Rigid metal case |

| Безопасность | Less risk of explosion/leakage | More robust but heavier |

| Application Fit | Tailored to device | Limited by standard sizes |

Custom lithium battery packs often power wearables, medical devices, and drones. These applications benefit from the unique shapes and high performance that custom lithium polymer batteries provide. However, they may have a shorter lifespan and higher cost compared to some lithium-ion batteries. Careful handling and proper battery management help ensure safe and reliable operation.

Benefits of Custom Lithium Polymer Batteries

Flexibility and Form Factor

Custom lithium polymer batteries offer unmatched flexibility in size, shape, and capacity. Manufacturers can design these batteries to fit almost any device, which supports innovation in many industries.

- Engineers can tailor the battery’s form factor to maximize space and energy density.

- Devices in consumer electronics, medical equipment, electric vehicles, and renewable energy systems benefit from this flexibility.

- Custom batteries allow for advanced features like smart battery management systems and wireless charging.

- Designers can create batteries for harsh environments, such as extreme temperatures or vibrations, ensuring durability and optimal battery performance.

- This flexibility encourages innovation, letting companies build sleek, compact, and efficient products.

Note: Custom lithium polymer batteries support innovation by enabling unique product designs and efficient energy storage solutions.

Performance and Safety

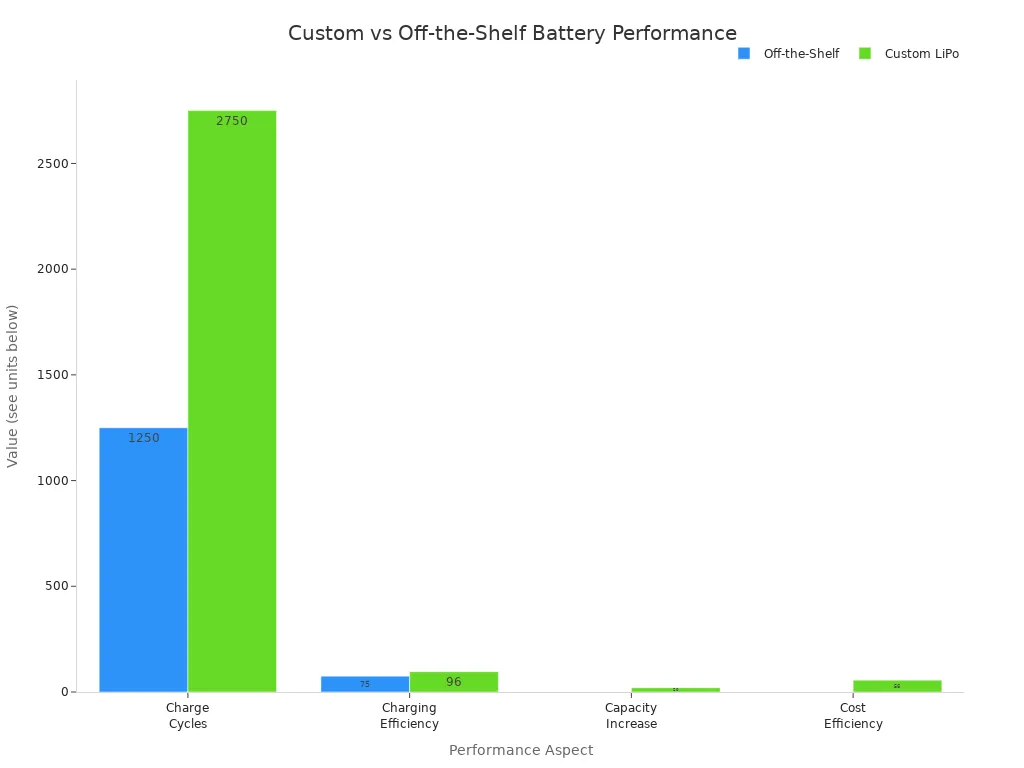

High-quality lithium batteries deliver strong performance benchmarks compared to standard lithium-ion batteries. The table below shows key improvements:

| Performance Aspect | Off-the-Shelf Battery Packs | Custom Lithium Polymer Battery Packs |

|---|---|---|

| Charge Cycles | 1,000 – 1,500 cycles | 2,000 – 3,500 cycles |

| Charging Efficiency | Approximately 75% | Approximately 96% |

| Capacity Increase | Fixed form factors | 15-25% higher capacity within same size |

| Система управления аккумулятором | Basic protection, limited monitoring | Advanced real-time monitoring, programmable profiles |

| Lifespan and Maintenance | Shorter lifespan, more frequent replacements | Longer lifespan, reduced maintenance and replacement frequency |

| Cost Efficiency (8-year) | Higher replacement costs | Up to 56% reduction in total battery costs despite higher initial cost |

| Form Factor Flexibility | Limited to standard shapes | Custom shapes (curved, L-shaped, ultra-thin) for better space utilization |

| Cell Chemistry Options | Standard graphite anodes | Advanced chemistries like silicon anodes for increased capacity |

Custom lithium polymer batteries use advanced cell chemistries and smart battery management systems. These features improve charge and discharge performance, safety, and reliability. Safety features include thermal monitoring, shock resistance, and international certifications, which ensure high quality and long service life.

Application-Specific Advantages

Custom lithium polymer batteries provide unique benefits for specialized devices.

- Flexible pouch construction allows batteries to fit into thin, curved, or irregular spaces, which is essential for wearables and medical devices.

- High-quality lithium batteries can deliver fast charging and operate in tough conditions, such as high temperatures or vibrations.

- Custom packs meet exact power and energy needs, supporting innovation in device design.

- Advanced safety features and smart management systems ensure quality and reliability, especially in critical applications.

- These batteries enable long service life and reduce the need for frequent replacements.

- Fast charging and compatibility with predictive maintenance systems improve user experience and device competitiveness.

Custom lithium polymer batteries drive innovation by allowing engineers to optimize form, fit, and function for each application. This approach ensures high quality, safety, and performance in every cell, supporting the demands of modern technology.

Design Process

Custom battery design for lithium polymer batteries involves teamwork, careful planning, and a focus on safety and performance. Engineering, manufacturing, and quality teams work together to create batteries that fit each device perfectly. This process supports innovation and ensures every battery meets strict standards.

Requirement Gathering

The first step in the design process is requirement gathering. Teams start by talking with clients to understand what the battery must do. They ask questions about the device’s power needs, size, and shape. They also look at how much energy the battery should store and how long it should last.

Key steps in requirement gathering:

- Define what the battery must power, including voltage, capacity, and current.

- Decide how many charge cycles the battery should last.

- Measure the space available for the battery inside the device.

- Think about the weight, especially for portable products.

- Plan for thermal management, such as cooling or heat sinks.

- Add safety features like overcharge and short-circuit protection.

- Make sure the battery will meet rules and standards, such as UL or CE.

- Check the environment where the battery will work, like temperature or humidity.

- Choose connectors that fit the device.

- Pick high-quality cells for a long battery life.

Note: Good requirement gathering helps teams avoid mistakes and supports innovation in battery-powered devices.

Cell Selection

Choosing the right cell is a key part of custom battery design. The cell type affects how much energy the battery can hold, how fast it can charge, and how safe it will be. Teams look at the device’s needs and pick cells that match.

- Teams calculate the voltage by counting the number of cells and checking each cell’s voltage.

- They use only new, matching cells to keep the battery safe and reliable.

- Each cell must have the right C rating to handle the device’s power needs.

- Teams check cells for damage before using them.

- They use chargers made for lithium polymer cells and set safe charging limits.

- Cell balancing keeps all cells at the same voltage, which helps the battery last longer.

- Teams remove the load when the cell voltage drops to a safe level to prevent damage.

A table can help compare cell choices:

| Cell Feature | Importance in Design |

|---|---|

| Напряжение | Matches device needs |

| Вместимость | Decides how long battery lasts |

| Рейтинг C | Handles power demands |

| Size and Weight | Fits device form factor |

| Химия | Affects safety and lifespan |

| Quality | Ensures reliability |

Selecting the right cell supports innovation and helps the battery perform well in any application.

BMS and Safety Integration

A Battery Management System (BMS) is vital for lithium battery safety. The BMS monitors each cell, controls charging and discharging, and protects the battery from harm. Teams design the BMS to fit the battery’s size, chemistry, and use case.

Main steps for BMS and safety integration:

- Pick a BMS that matches the battery’s voltage and cell count.

- Add sensors to watch voltage, current, and temperature.

- Use protection circuits to stop overcharging, over-discharging, and short circuits.

- Design thermal management, such as fans or heat sinks, to keep cells cool.

- Build strong enclosures to protect against shocks and moisture.

- Follow safety standards like UL 1642 and IEC 62133.

- Add fire-resistant materials and fire suppression if needed.

- Test the BMS and safety features often.

Совет: Custom BMS design allows teams to add special features, like fast charging or advanced data monitoring, which supports innovation and improves battery performance.

Prototyping and Testing

Prototyping and testing help teams find and fix problems before mass production. Teams build a sample battery and run many tests to check safety, performance, and durability.

Typical testing protocols:

- Altitude simulation checks battery safety at low air pressure.

- Thermal cycling tests how the battery handles hot and cold.

- Vibration testing simulates shaking during transport or use.

- Mechanical shock testing checks if the battery survives drops or impacts.

- Short-circuit testing ensures the battery stays safe if wires touch by accident.

- Impact testing checks for damage from hits.

- Overcharge testing makes sure the battery stops charging at the right time.

- Forced discharge testing checks how the battery reacts to unusual use.

Teams use these tests to make sure the battery does not leak, break, or catch fire. They also check that the battery keeps most of its voltage after testing. Quality teams and engineers work together during this phase, sharing results and making changes to improve the design.

Prototyping and testing are key steps in lithium battery manufacturing. They help teams deliver safe, reliable, and high-performing batteries for modern devices.

Battery Development Process

Concurrent Engineering

Concurrent engineering plays a key role in the battery development process. Teams from design, engineering, and lithium battery manufacturing work together from the start. This approach helps meet strict energy density, safety, and performance goals.

- Battery manufacturers and clients share ideas early to match the cell design with device needs.

- Companies like AeroVironment and Emerging Power used this method to create a drone battery pack that fit exact power needs.

- Emerging Power and THALES worked together to build a lithium battery pack that could survive submersion and tough field tests.

- Early teamwork helps select the right cell, improve reliability, and make lithium battery manufacturing more efficient.

This process ensures the cell, battery management system, and safety features all work together. Teams can solve problems before they reach the production line.

Prototyping

Prototyping stands as a vital step in the battery development process. Engineers build sample batteries based on design plans. They test each cell for capacity, voltage, temperature resistance, and cycle life. This step helps find and fix problems before mass lithium battery manufacturing begins. Additive manufacturing, like 3D printing, allows fast changes to cell shapes and battery parts. Teams can add sensors or change the cell layout quickly. Prototyping lets engineers check if the battery meets all design needs and works safely. This step reduces the risk of failure and improves the final product.

Prototyping helps teams refine the cell design and ensures the lithium battery manufacturing process produces safe, reliable batteries.

Certification and Compliance

Custom lithium polymer batteries must meet strict safety certifications and rules. These standards protect users and allow batteries to enter global markets. The table below shows key certifications for lithium battery manufacturing:

| Сертификация | Назначение | Main Market | Applies To |

|---|---|---|---|

| UN38.3 | Safe transport of lithium batteries | Глобальная | All lithium batteries |

| IEC 62133 | Safety of rechargeable cells | Глобальная | Rechargeable lithium batteries |

| CE | EU health, safety, and environment | ЕС | Battery packs |

| UL (e.g., UL 1642, UL 2054) | U.S. safety for cells and packs | США | Consumer, industrial batteries |

| RoHS | Limits hazardous substances | EU, UK | Electronics |

| MSDS / SDS | Chemical safety info | Глобальная | All battery products |

Manufacturers must test each cell and battery pack for shock, vibration, and temperature changes. They follow rules for each country, such as UL in the US or CE in Europe. Meeting these safety certifications ensures lithium battery manufacturing produces batteries that are safe, legal, and ready for use in many devices.

Battery Manufacturing Process

Lithium Battery Manufacturing Steps

Сайт lithium battery manufacturing process for custom lithium polymer batteries follows a series of precise steps. Each step ensures the battery meets strict quality and safety standards. The process starts with raw materials and ends with a finished battery pack ready for use.

Electrode Manufacturing

Workers mix powders and liquids to create a slurry. They coat this slurry onto metal foils, using copper for the anode and aluminum for the cathode. The coated foils dry in special ovens. Machines press the foils to adjust thickness and porosity. Workers then cut the foils into strips and clean them to remove dust.Cell Assembly

Technicians stack or wind the anode, cathode, and separator layers. They fix the stack and weld terminals to the electrode foils. The stack goes into a pouch cell housing. Machines seal three sides of the pouch to keep out air and moisture.Electrolyte Filling

The cell moves to a dry room. Workers fill the cell with electrolyte under vacuum. They repeat vacuum evacuation and filling to make sure the electrolyte wets all parts of the cell.Final Sealing and Pressing

Machines seal the last side of the pouch under vacuum. Some cells go through a pressing step to spread the electrolyte evenly.Formation and Maturation

The cell receives its first charge and discharge cycles. This step forms a stable layer inside the cell called the SEI. The cell ages under controlled conditions to check for stable performance.Quality Control and Testing

Workers measure internal resistance, check for leaks, and inspect the cell visually. Machines test the cell for capacity, safety, and temperature cycling. Only cells that pass all tests move to the next stage.Battery Pack Assembly

Workers arrange cells in series or parallel to reach the desired voltage and capacity. They add a Battery Management System (BMS) and connect wires and sensors. The finished battery pack receives a label and passes a final inspection.

Note: Each step in lithium battery manufacturing requires careful control to ensure high-quality lithium batteries.

Assembly and Integration

Assembly and integration of custom battery packs present unique challenges. Teams must arrange cells with precision. They use spot welding and laser welding to connect cells and terminals. The BMS must fit perfectly and work with the battery’s shape and size.

Common challenges include:

- Designing automated assembly systems for custom shapes.

- Meeting strict deadlines for delivery.

- Ensuring precision in welding and sealing.

- Keeping the assembly area ultra-dry to prevent moisture damage.

| Challenge Category | Specific Challenges | Solutions |

|---|---|---|

| Technical | Precise cell arrangement, spot welding, BMS fit | Training, advanced welding machines |

| Safety and Testing | Preventing thermal runaway, crush/fire resistance | Strict safety protocols, regular testing |

| Workforce and Training | Skilled labor shortage | Staff training, on-site engineering support |

| Инфраструктура | Need for clean rooms, humidity control | Investment in clean rooms |

| Regulatory and Certification | Certification delays, compliance | Work with consultants, early planning |

| Production Timelines | Meeting aggressive deadlines | Streamlined processes, parallel development |

Teams often use clean rooms with controlled dew points. They embed engineering support on-site to solve problems quickly. These steps help ensure flawless assembly and safe operation of custom lithium ion battery packs.

Quality Control

Quality control stands at the heart of lithium battery manufacturing. Every cell and battery pack must meet strict standards for safety and performance. Workers and machines check each step for defects.

- Heat control systems and insulation tests prevent overheating.

- The BMS monitors power and temperature with sensors on every cell.

- Communication boards allow remote monitoring and rapid recharging.

- Batteries go through safety tests like UN38.3 and abuse tests such as the Nail Penetration Test.

- Performance tests check if the battery meets its specifications.

Material purity is critical. Factories use advanced tools like WDXRF and Raman spectroscopy to detect impurities. Electrode manufacturing uses twin-screw compounding for better reproducibility. Real-time metrology checks electrode mass and coating quality. These steps reduce scrap rates and improve the quality of lithium-ion battery packs.

Tip: Quality control at every stage ensures reliable, high-quality lithium batteries for demanding applications.

Lifecycle Support

Manufacturers of custom lithium ion battery packs offer full lifecycle support. This support covers every stage, from design to recycling.

- Design and engineering teams help select the best cell for each application.

- The BMS provides multi-level protections, firmware updates, and detailed data logging.

- Communication protocols like SMBus, CANBus, Bluetooth, and cloud dashboards allow remote monitoring.

- Quality assurance includes testing at every assembly stage and cycle testing.

- Safety and regulatory certifications ensure compliance with UL, IEC, and UN standards.

- Custom charger design matches the battery’s chemistry and environmental needs.

- Mechanical design protects against vibration, shock, and thermal stress.

- End-to-end solutions include delivery, product training, implementation support, and recycling.

These services help users get the most from their custom battery packs. They ensure the battery remains safe, reliable, and compliant throughout its life.

Manufacturers who provide strong lifecycle support help customers achieve long-term success with their custom lithium ion battery packs.

Приложения

Бытовая электроника

Custom lithium polymer batteries power many devices people use every day. These batteries appear in smartphones, tablets, laptops, and wearable devices. Their high energy density and compact size help designers create slim, lightweight products.

- Medical devices

- Wearables

- Wireless controllers

- Communication devices

These examples show how the applications of custom lithium polymer batteries support the needs of modern consumer electronics. Their customizable form and strong performance make them a top choice for device makers.

Медицинские приборы

Medical devices need safe, reliable, and compact power sources. Custom lithium polymer batteries offer a low-profile size and flexible packaging. This design fits into small medical tools and equipment. Manufacturers follow strict standards like ISO 13485 and FDA registration. They use smart battery management systems with features such as cell balancing and health monitoring. These batteries undergo tests for safety and reliability. They protect patients by preventing overcharge, overheating, and mechanical damage. Custom lithium polymer batteries improve device performance and user safety in critical healthcare settings.

Носимые устройства и IoT

Wearables and IoT devices require batteries that are small, light, and powerful. Custom lithium polymer batteries meet these needs with high energy density and flexible shapes.

- They support long cycle life for daily use.

- Fast charging reduces downtime.

- Flexible designs fit smart rings, watches, and clothing.

- Stable power delivery keeps sensors running for health tracking.

- Batteries come in ultra-thin, curved, or polygonal shapes.

- They work in temperatures from -50°C to +80°C.

- Advanced charge management chips help monitor and protect the battery.

These features allow wearables and IoT devices to offer more functions, such as GPS and health monitoring, without sacrificing comfort or style.

Drones and Robotics

Drones and robotics rely on custom lithium polymer batteries for power and performance. These batteries have низкое внутреннее сопротивление, which reduces power loss and extends standby time.

- Custom shapes maximize space and capacity.

- Stable discharge and fast charging support long missions.

- Flexible packaging improves safety by preventing explosions.

- Advanced battery management systems monitor health and protect against damage.

- Modular designs make upgrades and repairs easier.

Custom lithium polymer batteries help drones fly longer and robots work harder. They also meet safety and environmental standards, making them suitable for industrial applications.

Specialized and Emerging Uses

The applications of custom lithium polymer batteries continue to grow. New uses include electric vehicles, renewable energy storage solutions, power tools, wireless sensors, asset tracking, and military equipment.

- Designers use modular and flexible packs for easy customization.

- Advanced battery management systems add real-time monitoring and predictive maintenance.

- Compact, energy-dense designs support smaller and lighter devices.

- Integration of sensors and wireless features enables smart analytics.

These trends show how custom lithium polymer batteries drive innovation in many fields, meeting the changing needs of modern technology.

How to Specify a Custom Lithium Battery

Основные параметры

When specifying a custom lithium battery, engineers must define several important parameters. These details help ensure the battery matches the device’s needs and works safely.

- Power requirements include voltage, capacity (mAh), and energy density.

- Discharge rates (C-rate) show how quickly the battery can deliver power.

- Charging protocols and charge rates affect how fast the battery can recharge.

- Safety features such as a battery management system (BMS), overvoltage and undervoltage cutoffs, and cell balancing protect the battery.

- Material choices for the enclosure, like aluminum alloys or thermoplastics, improve durability and heat control.

- Certification standards such as UN38.3 or UL 2580 ensure compliance with safety rules.

- Size, weight, and cell selection impact how well the battery fits the device.

- Protection circuitry and wire harness selection add extra safety and reliability.

- The working environment, including temperature, vibration, and humidity, must be considered.

A well-defined set of parameters leads to better custom battery solutions and safer products.

Working with Manufacturers

Developing a custom lithium battery involves close teamwork with the manufacturer. The process usually follows these steps:

- Free consultation to discuss the project and gather requirements.

- Technical analysis to check if the design is possible and safe.

- Sourcing materials that match the design and safety needs.

- Creating the battery design based on the client’s specifications.

- Manufacturing the battery according to the approved plan.

- Delivering and installing the finished battery.

This structured approach helps ensure the custom lithium battery meets all performance and safety goals. Regular communication between the client and manufacturer supports a smooth process from start to finish.

Common Pitfalls

Mistakes in specifying a custom lithium battery can lead to poor performance or safety risks.

Tip: Avoid these common pitfalls to achieve the best results.

- Failing to define all key parameters, such as voltage or capacity.

- Overlooking the need for proper safety features and certifications.

- Ignoring the working environment, which can cause battery failure.

- Choosing the wrong cell chemistry or size for the application.

- Not planning for future changes in device design or power needs.

Careful planning and clear communication help prevent these issues. Teams that focus on detail and safety create reliable custom battery solutions.

Custom lithium polymer batteries offer many advantages for modern technology.

- Lightweight designs reduce system weight, which helps drones and electric vehicles.

- Flexible shapes fit unique device needs.

- High energy density and stable voltage provide reliable power.

- Low self-discharge rates keep batteries ready for use.

- Safety features protect devices and users.

Proper design, manufacturing, and compliance ensure safe and efficient batteries. Companies should work with experts to create the best solution. Those interested in custom batteries can start by defining their device’s needs and reaching out to trusted manufacturers.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What makes lithium polymer batteries different from lithium-ion batteries?

Lithium polymer batteries use a flexible pouch and a gel-like electrolyte. Lithium-ion batteries use a rigid metal case and a liquid electrolyte. Lithium polymer batteries weigh less and fit more shapes. They work well in slim or curved devices.

How long do custom lithium polymer batteries last?

Most custom lithium polymer batteries last between 2 and 5 years. The lifespan depends on charge cycles, usage, and care. Good battery management and safe charging help extend battery life.

Are custom lithium polymer batteries safe?

Custom lithium polymer batteries include safety features like a battery management system (BMS). This system protects against overcharging, overheating, and short circuits. Manufacturers test each battery to meet safety standards.

Can custom lithium polymer batteries be recycled?

Yes, recycling centers accept lithium polymer batteries. Users should never throw them in the trash. Recycling helps recover valuable materials and protects the environment.

What devices use custom lithium polymer batteries?

Custom lithium polymer batteries power many devices. Examples include smartphones, medical tools, wearables, drones, and robots. Their flexible design supports many shapes and sizes.