Definition (in One Sentence)

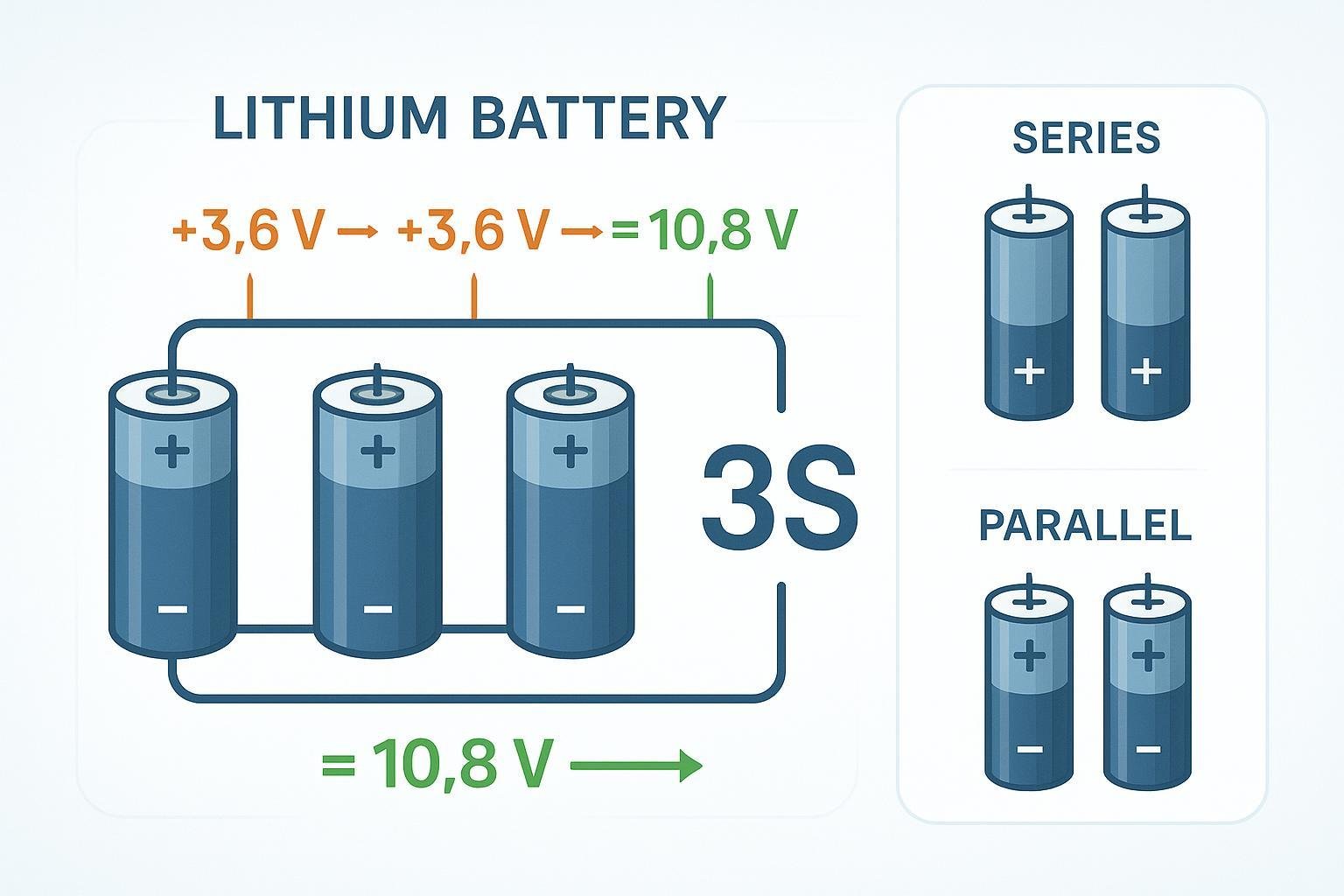

A series connection (S) in lithium battery manufacturing refers to wiring battery cells end-to-end—positive to negative—so that their individual voltages are summed, resulting in a higher total pack voltage while keeping capacity unchanged.

Explication détaillée

In a series connection, the positive terminal of one cell is connected to the negative terminal of the next. This forms a continuous “chain” where current flows sequentially through all cells. The primary goal of a series arrangement is to increase the output voltage to match the requirements of specific applications, such as electric vehicles, consumer electronics, or energy storage systems. For example, connecting four 3.7V lithium-ion cells in series—a 4S configuration—yields a total voltage of 14.8V (3.7V × 4).

Key Formula:

- Pack Voltage (V) = Number of Series Cells (S) × Single Cell Voltage

- Pack Capacity (Ah) = Capacity of One Cell

Notation Example:

- “3S2P” means three cells in series, with two such strings connected in parallel—a common format for larger packs (Université de la batterie).

Key Components and Technical Considerations

- Voltage Additivity: Each cell’s voltage adds up, while current capacity remains the same as one cell.

- Consistent Current: All cells carry the same current during operation.

- Critical Balancing: Lithium-based series packs must be managed for cell voltage balance to avoid overcharge or overdischarge; this is achieved using a Battery Management System (BMS).

- Safety Standards: Well-designed packs follow UL and IEC safety requirements with cell balancing features and protective circuits (Cell Saviors).

Applications dans le monde réel

- Véhicules électriques (VE) : Modules with 10S or higher are typical, taking the total voltage above 36V, 72V, or more for propulsion.

- Energy Storage: Home backup units or grid storage solutions (such as Powerwall) often use 14S configurations or higher to meet inverter voltage criteria.

- Électronique grand public : Laptop batteries commonly use 3S or 4S series arrangements for optimal voltage and efficiency.

Calculation Example

Let’s say you want to build a battery pack for a device requiring ~11.1V. You use three 3.7V, 2500mAh cells:

- Tension : 3 cells × 3.7V = 11.1V

- Capacité : 2500mAh (not increased unless more cells are added in parallel)

For higher capacity at the same voltage, you would use parallel connection in combination with series (see 3S2P example below).

Related Concepts and See Also

- Parallel Connection (P): Cells connected so all positives and all negatives are linked, increasing capacity—voltage stays the same.

- Battery Pack: An assembly of multiple battery cells in a configuration (series, parallel, or both) for required voltage/capacity.

- Tension nominale : The standard voltage per cell, usually 3.6V or 3.7V for lithium-ion.

- Capacity (mAh/Ah): Total charge a cell or pack can deliver; for series, this remains as a single cell’s rating.

- BMS (Battery Management System): Essential for protecting and balancing cells in series, preventing failures.

Safety, Balancing, and BMS Roles

When batteries are connected in series, tiny differences between cells can lead to one cell charging or discharging faster than others. Over time, this can cause dangerous imbalance, risking overcharge, thermal runaway, or capacity loss. A quality BMS monitors individual cell voltages, manages balancing, and disconnects cells if unsafe conditions are detected—an absolute necessity for lithium-based series packs, particularly in demanding applications like EVs or large energy storage.

Summary Table: Series vs. Parallel Connections

| Propriété | Series (S) | Parallel (P) |

|---|---|---|

| Tension | Adds up (S × cell V) | Same as single cell |

| Capacité | Same as single cell | Adds up (P × cell Ah) |

| Current flow | Same in all cells | Divided among branches |

| Example Notation | 4S | 2P |

| Main Use Case | Higher voltage systems | Higher capacity systems |

Glossaire

- Series (S): Cells are chained positive to negative, increasing voltage.

- Parallel (P): Cells are linked by all positives and all negatives, increasing capacity.

- BMS: Battery Management System for monitoring, balancing, and protecting cells.

- Cell Balancing: The process of equalizing charge/discharge states in all series-connected cells.

For further reading and technical diagrams, see Battery University’s guide on series and parallel battery configurations et Cell Saviors’ article on series lithium batteries.