Selecting the right 3.7V battery is crucial for your project’s success. The market for the rechargeable 3.7V lithium-ion battery is expanding rapidly, making selecting the right battery more important than ever. Your choice for a successful project balances four key pillars.

- Capacité (mAh) for runtime

- Discharge Rate (C-Rate) for power

- Size & Form Factor for physical fit

- Chemistry & Safety for reliability and safety

This guide helps you understand these factors for your rechargeable 3.7V lithium battery. A proper rechargeable battery ensures your project performs well.

Understanding Your 3.7V Rechargeable Lithium Ion Battery

To choose the best 3.7V rechargeable lithium ion battery, you first need to understand its key specifications. These details on a battery’s datasheet are not just numbers; they define its performance, lifespan, and safety. Let’s decode what they mean for your project.

Capacity (mAh): Project Runtime

Capacity measures the total energy a battery can hold. You will see this listed in milliampere-hours (mAh). A higher mAh rating generally means a longer runtime for your device. Think of it as the size of your battery’s fuel tank. The relationship between capacity and runtime is direct.

- What is mAh? A 1000mAh battery can theoretically provide 1000 milliamps (mA) of current for one hour. It could also provide 100mA for ten hours.

- Estimating Runtime: You can estimate your project’s runtime with a simple formula.

Runtime (Hours) = Battery Capacity (mAh) / Device's Average Current Draw (mA) - Beyond the Numbers: Factors like device efficiency and operating temperature also affect the actual runtime you will achieve. A high capacity battery is great, but it is often larger and heavier.

Discharge Rate (C-Rate): Power Delivery

Les C-rate acts like a speed limit for your battery. It tells you how fast the battery can safely deliver its energy. This is critical for high-power applications that need quick bursts of energy. A low C-rate battery in a high-draw device can lead to poor performance, overheating, and damage.

What is C-Rate? The C-rate is calculated by dividing the current being drawn (in Amps) by the battery’s capacity (in Amp-hours).

C-Rate = Current Draw (A) / Battery Capacity (Ah)For example, drawing 4 amps from a 2Ah (2000mAh) battery is a 2C discharge.

High-power devices like racing drones or power tools require a battery with a high C-rate. A racing drone might pull 60 amps from a 2Ah battery, resulting in a 30C draw. You must ensure your battery’s C-rating can handle your project’s peak power demands for optimal performance and safety. For many low-power electronics, the C-rate is less of a concern.

Voltage: Nominal vs. Charged

You will see “3.7V” printed on many lithium-ion cells, but this is the nominal voltage, not the full charge voltage.

- Nominal Voltage (3.7V): This is the average voltage of the battery during its discharge cycle. It is a standard reference point.

- Fully Charged Voltage (4.2V): A fully rechargeable 3.7V lithium battery actually starts at around 4.2V. As you use the device, the voltage will gradually drop from this peak.

- Cut-off Voltage (~3.0V): The battery is considered fully discharged when its voltage drops to its cut-off point, typically around 3.0V.

Your project’s electronics must be able to handle this entire voltage range, from 4.2V down to 3.0V, to function correctly.

Cycle Life: Battery Lifespan

Cycle life tells you how many times you can charge and discharge a rechargeable battery before its performance degrades significantly. One cycle is a full charge and discharge. Most manufacturers consider a battery’s life ended when its capacity drops below 80% of its original rating. A standard lithium-ion battery typically offers 2,000 to 3,000 charge cycles with proper care, giving you a service life of around five years. Choosing a battery with a higher cycle life means it will last longer, saving you money and reducing waste.

Form Factor: Pouch, Prismatic, and Cylindrical

Lithium-ion cells come in three primary shapes, each with unique benefits. The right shape depends on the physical space available in your project and your durability requirements.

- Cylindrical Cells: These look like traditional AA batteries. Their rigid metal case offers excellent durability and protection, making them ideal for power tools and electric vehicles. Their round shape helps distribute internal pressure evenly.

- Prismatic Cells: These are flat, rectangular cells in a rigid metal case. Their box-like shape allows them to be packed together very efficiently, making them great for battery banks where space is tight.

- Pouch Cells: These use a flexible, foil-like wrapper instead of a hard case. This makes them lightweight and allows for custom shapes, perfect for compact devices like smartphones, tablets, and some drones. However, their soft shell makes them more vulnerable to punctures.

Common Cell Sizes: 18650, 21700, and More

Within the cylindrical form factor, you will find standardized sizes. The name tells you the dimensions: the first two digits are the diameter in millimeters, and the next two are the length.

| Cell Size | Dimensions (Diameter x Length) | Typical Capacity | Common Applications of 3.7v batteries |

|---|---|---|---|

| 14500 | 14mm x 50mm | ~1,000 mAh | LED flashlights, wireless speakers, solar lights |

| 18650 | 18mm x 65mm | 2,300 – 3,600 mAh | Laptops, power tools, robotics, medical devices |

| 21700 | 21mm x 70mm | 4,000 – 5,000 mAh | Electric vehicles, high-power drones, industrial gear |

The 21700 cell was designed as a higher-energy replacement for the popular 18650, offering more power in a slightly larger package.

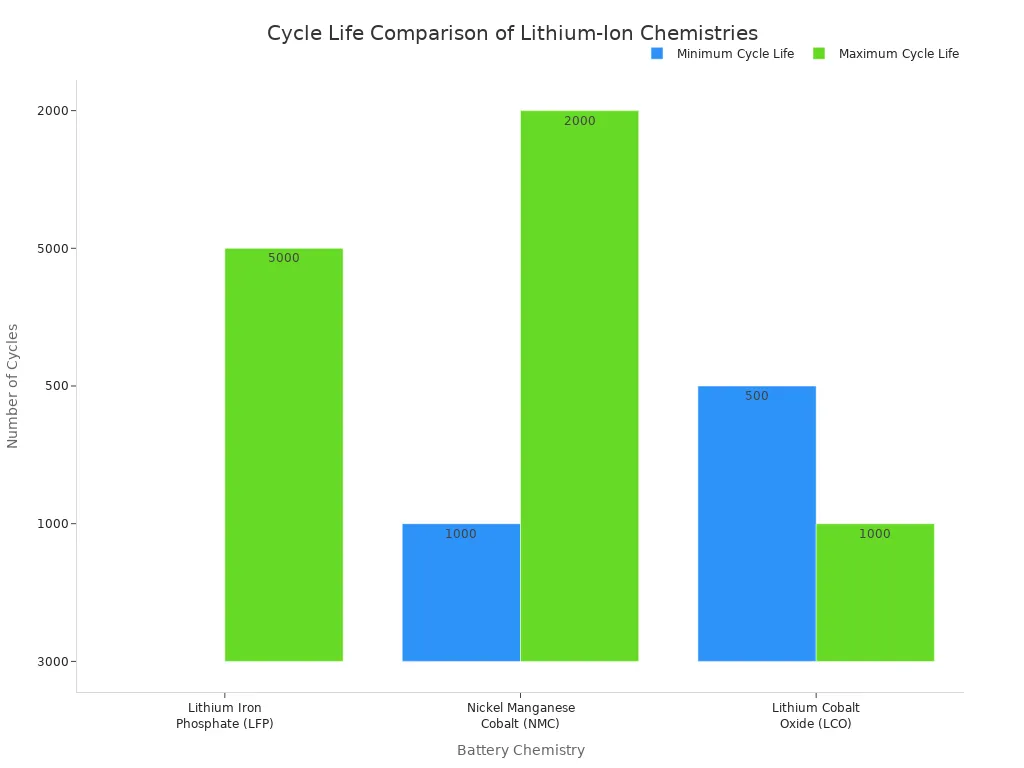

Comparing Li-ion Chemistries: LFP, NMC, LCO

Not all 3.7V rechargeable lithium ion battery cells are the same on the inside. The internal chemistry affects safety, lifespan, and performance. While most have a nominal voltage around 3.7V, some chemistries like Lithium Iron Phosphate (LFP) are nominally 3.2V but are often grouped with them. Here’s a comparison of common lithium-ion types:

| Chimie | Cycle Life (to 80% Capacity) | Safety & Thermal Stability | Meilleur pour |

|---|---|---|---|

| LFP (Lithium Iron Phosphate) | 3,000 – 5,000+ | Excellent | Projects where safety and longevity are top priorities. |

| NMC (Nickel Manganese Cobalt) | 1,000 – 2,000 | Good | Balancing energy density and performance, like in EVs. |

| LCO (Lithium Cobalt Oxide) | 500 – 1,000 | Fair | High energy density in small devices like phones. |

LFP chemistry stands out for its exceptional safety and long cycle life. Its stable molecular structure makes it highly resistant to overheating. For any project where reliability and safety are paramount, an LFP battery is an outstanding choice.

Creating Your Custom Lithium Battery Profile

Now you understand the specifications. It is time to define the perfect battery for your needs. You will create a custom lithium battery profile by answering four key questions about your project. This profile acts as your blueprint for selecting the ideal custom lithium battery pack.

Step 1: Calculate Required Capacity

First, you need to determine how long your device must run on a single charge. This helps you calculate the necessary battery capacity. You can find this with a simple calculation.

Formula for Capacity:

Required Capacity (mAh) = Desired Runtime (Hours) × Average Current Draw (mA)

Let’s say you are building a custom device that needs to run for 5 hours. You estimate it will draw an average of 400mA.

5 Hours × 400 mA = 2000 mAh

You would need a rechargeable battery with at least 2000mAh capacity. It is always a good idea to add a 20% buffer for safety and to account for efficiency losses. A 2400mAh custom lithium battery would be a safer choice.

Step 2: Determine Current Draw

Next, you must understand how much electrical current your project will use. You need to identify two types of current draw: continuous and peak. This is a vital step in your custom lithium battery pack design.

- Continuous Draw: This is the steady current your components use while the device is running normally.

- Peak Draw: This is a short burst of high current. A motor starting up is a perfect example.

To find your total continuous draw, you will list all components and add up their current needs. You can find this information in the component’s datasheet.

Let’s design a simple custom lithium battery pack for a small robot:

- Microcontroller: 50 mA (continuous)

- Sensors (x2): 20 mA each = 40 mA (continuous)

- Small DC Motor: 300 mA (continuous)

- Motor Peak Draw: 900 mA (for 1 second on startup)

Calculating Total Continuous Draw:

50 mA + 40 mA + 300 mA = 390 mAYour project has a continuous draw of 390mA. You would use this number for your capacity calculation in Step 1. The peak draw of 900mA helps you choose a battery with the right C-Rate.

Step 3: Measure Physical Constraints

A powerful battery is useless if it does not fit. You must measure the physical space available inside your project’s enclosure. This measurement will guide your choice of a custom lithium battery form factor.

- Measure the Space: Use a ruler or digital calipers to get the exact length, width, and height of the battery compartment.

- Account for Extras: Remember to leave extra room for wires, connectors, and a Battery Management System (BMS). A tight fit can damage the battery or wires.

- Choose a Shape: Your measurements will tell you if a cylindrical cell like an 18650, a flat prismatic cell, or a flexible pouch cell is the best custom option. A custom lithium battery pack can be built to fit nearly any space.

This step ensures your custom lithium ion battery fits perfectly and safely.

Step 4: Assess Operating Environment

Finally, consider where your device will operate. The environment, especially temperature, dramatically affects a rechargeable battery’s performance and lifespan. A 3.7v battery is sensitive to extreme heat and cold.

Hot temperatures cause a lithium-ion battery to age faster. Heat forces the internal chemistry of the lithium ion battery to work too hard, which can permanently reduce its capacity. Cold temperatures have a different effect. The internal resistance of the battery increases, which can reduce available capacity and cause the voltage to drop.

The ideal operating temperature for a 3.7v rechargeable lithium ion battery is between 15°C and 35°C (59°F to 95°F). You should only charge your rechargeable lithium battery between 0°C and 45°C (32°F to 113°F).

| Plage de température | Impact on Your Battery |

|---|---|

| Below 0°C (32°F) | Significant capacity loss; risk of internal damage. |

| 15°C à 35°C (59°F à 95°F) | Optimal performance and maximum efficiency. |

| Above 45°C (113°F) | Faster aging and reduced lifespan. |

| Au-dessus de 60°C (140°F) | High risk of overheating and permanent damage. |

If your project will be in the sun or a hot car, you may need a larger capacity battery to compensate for performance loss. You might also need to add ventilation. This makes your custom lithium battery safer and more reliable.

Battery Safety and Protection Circuits

A powerful battery is only useful if it is safe. You must include protection circuits to ensure your project is reliable and does not pose a danger. These systems are non-negotiable for safety.

The Role of a Battery Management System (BMS)

Think of a Battery Management System (BMS) as the brain of your battery pack. It is a smart circuit that provides total protection and optimization. A BMS is essential for complex or high-power projects. Its main jobs include:

- Monitoring the battery’s temperature and state of charge.

- Balancing the charge across all cells to maximize lifespan.

- Providing advanced battery pack protection from electrical and thermal faults.

- Communicating real-time data about battery health for maximum safety.

Understanding Protection Circuit Modules (PCM)

A Protection Circuit Module (PCM) offers fundamental safety features. It is simpler than a BMS but provides critical protection for single-cell applications. A PCM focuses on preventing immediate damage. Its core safety features include:

- Protection contre les surcharges: Stops charging when the battery is full.

- Protection contre la surcharge: Prevents the battery from draining too low.

- Protection contre les surintensités: Cuts power if the device draws too much current.

While a PCM provides basic protection, a BMS offers these safety features plus advanced management like cell balancing.

Safe Charging Protocols

Proper charging is the most important part of battery safety. You should always follow safe charging practices. Most lithium batteries use a charging method called Constant Current/Constant Voltage (CC/CV). Improper charging can cause overheating and fires.

Important Charging Tip 💡 Always use a charger designed for your specific battery. Look for chargers with safety certifications. Never leave a charging battery unattended. Following these safe charging practices is key to preventing accidents.

Your charging setup needs robust protection. Good safe charging practices ensure the long-term health and safety of your battery.

Proper Storage and Disposal

How you store and dispose of your battery matters for safety.

- Storage: Store your battery at about 50% charge in a cool, dry place. Avoid extreme temperatures.

- Disposal: Never throw a lithium battery in the regular trash. This creates a fire hazard. Take it to a designated battery recycling center. You should tape the terminals before recycling to prevent short circuits.

How to Spot a Damaged Battery

You should regularly inspect your battery for signs of damage. Stop using a battery immediately if you see any of these issues:

- Swelling or Bulging: This is a clear sign of internal failure.

- Discoloration or Corrosion: Look for strange colors or powdery buildup on the terminals.

- Leaks or Strange Smells: Any fluid or odd odor means the battery is compromised.

A damaged battery is a major safety risk. Proper handling and protection are essential.

Making the Final Selection: A Checklist

You have defined your project’s needs. Now you are ready for the final steps in selecting the right battery. This checklist will guide you through reading datasheets, finding a good supplier, and performing final safety checks.

How to Read a Battery Datasheet

A battery datasheet is the official report card for a battery. You must review it to confirm the battery meets your custom profile. It contains all the critical performance and safety information.

Look for these key values:

| Paramètres | What It Means for You |

|---|---|

| Rated Capacity (mAh) | Confirms the battery’s runtime potential. |

| Tension nominale (V) | Should be 3.7V for your project. |

| Discharge Rates (C) | Ensures the battery can safely power your device. |

| Operating Temperature | Tells you the safe temperature range for charging and use. |

| Cycle de vie | Estimates how many charging cycles the battery will last. |

The datasheet also includes safety features, like built-in protection. A good datasheet provides confidence in your choice.

Choosing a Reputable Supplier

Selecting the right supplier is as important as selecting the right 3.7v battery. A reputable supplier ensures you get a safe, high-quality product. Look for suppliers with a long history and positive customer reviews.

Supplier Tip 💡 A good supplier provides batteries with key safety certifications like UN38.3 for safe shipping et UL for safety standards. These certifications show a commitment to quality and protection.

They should offer strong technical support and clear warranty information. This ensures you have help if you need it and protection for your purchase.

Verifying Connectors and Polarity

You must check the battery connector and its polarity before you plug anything in. Many small lithium batteries use JST-PH or JST-XH connectors.

- Check the Connector: Make sure the battery connector matches the one on your device.

- Verify Polarity: Use a multimeter to confirm the positive (+) and negative (-) wires. Red is usually positive, and black is negative, but you should always verify.

Never assume the polarity is correct. Connecting a battery backward can instantly damage your device. Measure twice, plug once.

Your Final Selection Checklist

Use this final checklist to make your decision:

- [ ] Capacité : Does the mAh meet your calculated runtime needs?

- [ ] C-Rate: Can the battery handle your project’s peak current draw?

- [ ] Taille : Does the battery fit safely inside your enclosure?

- [ ] La sécurité : Does it have a protection circuit and proper certifications?

- [ ] Supplier: Is the supplier reputable and trustworthy?

Following this process helps you choose a safe and effective custom battery for your project.

You now have the tools for selecting the right battery. A successful project depends on a methodical approach, not guesswork. Your process provides total protection. You understand specs for knowledge protection. You calculate needs for performance protection. You prioritize a BMS for electrical protection and thermal protection. This protection is vital. A datasheet offers another layer of protection. This protection ensures quality. Your final project has the best protection and power. This is smart protection.

FAQ

Can I use a 3.7V battery in a 3.3V device?

You should not connect it directly. A 3.7V battery’s voltage ranges from 4.2V to 3.0V. This high voltage can damage a 3.3V component. You must use a 3.3V voltage regulator between the battery and your device for safe operation.

What happens if I don’t use a BMS or PCM?

You remove a critical layer of safety. Without a protection circuit, you risk overcharging, over-discharging, and short circuits. These events can cause the battery to overheat, swell, or even catch fire. A BMS provides essential electrical and thermal protection.

How do I connect multiple 3.7V batteries together?

You can connect batteries in two ways:

- Series: Connect positive to negative to increase voltage.

- Parallel: Connect positive to positive and negative to negative to increase capacity.

Important : Always use identical cells and a proper BMS when building a battery pack.

Is a higher mAh rating always better?

Not necessarily. A higher mAh rating gives you a longer runtime. However, it also means a larger, heavier, and more expensive battery. You should choose a capacity that balances your project’s runtime needs with its size and weight constraints.