You have a 3.7V lithium battery for your project. You might think it provides a steady voltage, but it does not. A battery’s output changes as it discharges.

💡 Did you know? A “3.7V” battery’s voltage actually ranges from a full 4.2V down to 3.0V. Connecting this unstable power directly to your 3.3V or 5V circuits can cause damage.

Proper voltage regulation is essential for reliable and safe operation. This guide helps you select the correct components for your specific needs.

Why Voltage Regulation is Essential

You need a steady and predictable power source for your electronics to work correctly. A battery’s output is anything but steady. This is why proper voltage regulation is a non-negotiable part of your project design. Let’s explore what happens inside your battery and why a direct connection is a bad idea.

The Lithium Battery Voltage Curve

Your lithium battery has a “nominal” or average voltage of 3.7V. However, its actual voltage changes depending on its charge level. A fully charged battery starts at 4.2V and drops as you use it.

| Battery State | Tension |

|---|---|

| Fully Charged | 4.2V |

| Nominal (Average) | 3.7V |

| Fully Discharged | ~3.0V |

This sliding scale of voltage is a major challenge. Your components expect a consistent power supply, not one that changes over time.

Stable vs. Unstable Voltage

Electronic components need stable voltage to function reliably. Microcontrollers like the ATmega328P (found in many Arduinos) operate between 1.8V and 5.5V. While this range seems wide, rapid voltage changes can cause problems. The battery’s voltage also drops instantly when your project demands more current, like when a motor starts. This instability is especially bad for analog sensors. An unstable power source can cause your sensor readings to fluctuate wildly, making your data useless. Effective voltage regulation transforms this unstable battery output into a clean, stable power source.

Risks of Direct Connection

Connecting a fully charged 4.2V battery directly to a 3.3V component is a recipe for disaster. You are feeding the component far more voltage than it was designed to handle.

⚠️ Avertissement : Never connect a lithium battery directly to a 3.3V microcontroller. The 4.2V from a full charge can permanently damage or destroy the chip.

This overvoltage condition can cause immediate failure. Even if the component survives initially, the stress can lead to a shorter lifespan and unreliable performance. Using voltage regulation is the only way to guarantee the safety and longevity of your project.

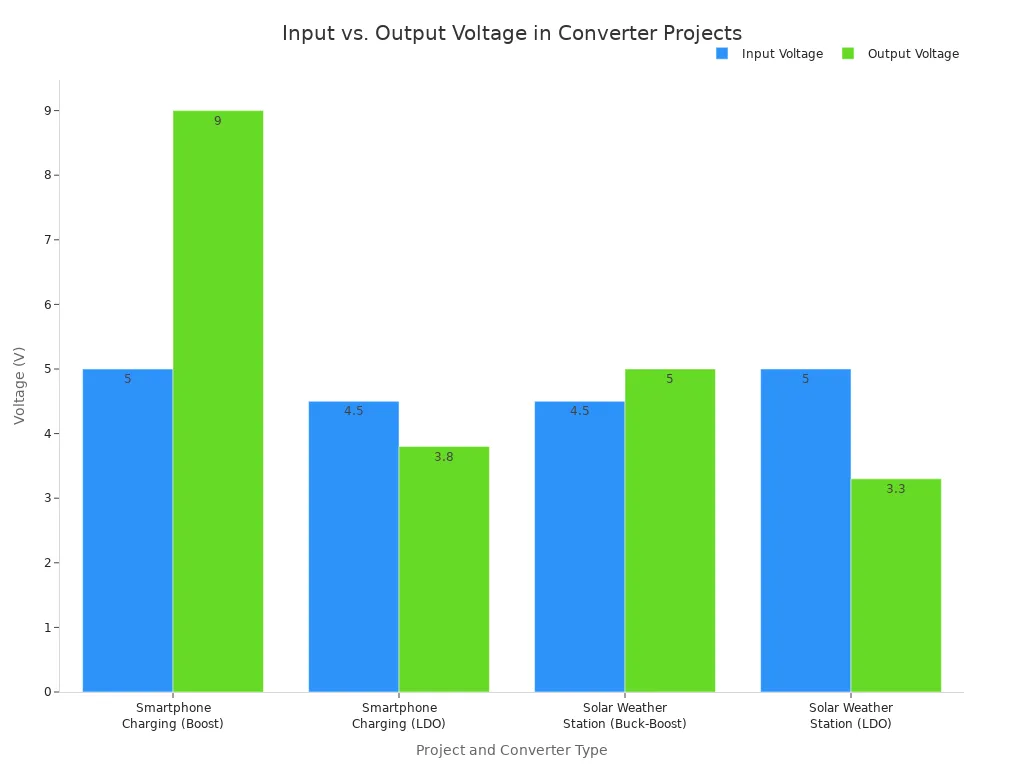

Step-Down: LDO Regulators

When your battery voltage is always higher than your target voltage, a Low-Dropout (LDO) regulator is a simple and effective solution. You can use an LDO to convert the battery’s 4.2V–3.0V range into a stable 3.3V supply for your microcontroller.

How LDOs Work

Think of an LDO as a smart, automated gatekeeper for electricity. It constantly checks the voltage going out to your circuit. Its main job is to maintain a steady output.

The LDO works using a negative feedback system:

- An internal component called an error amplifier compares the output voltage to a precise internal reference voltage.

- If your circuit’s voltage drops, the amplifier tells a pass transistor (the gatekeeper) to let more current through.

- If the voltage gets too high, it tells the transistor to restrict the flow.

This continuous adjustment happens thousands of times per second. It ensures your components receive a rock-solid voltage, even as the battery drains or the current demand changes.

When to Use an LDO

LDOs are perfect for projects that need clean, stable power. Their simple design produces very little electrical noise. This makes them ideal for sensitive applications.

✅ Pros vs. Cons of LDOs

- Use an LDO for:

- Low-power devices where simplicity is key.

- Analog sensors that need a quiet power source.

- RF projects (like radio transmitters) where noise can interfere with signals.

- Avoid an LDO for:

- High-current applications (e.g., driving many LEDs or motors).

- Projects where battery life is the top priority.

The main drawback of an LDO is its inefficiency. It works by burning off the extra voltage as heat. For example, powering a 3.3V circuit from a 4.2V battery means the LDO wastes the extra 0.9V as heat.

Practical Integration

Let’s build a practical circuit using a common LDO, the MCP1700-3302E. This component takes your battery voltage and outputs a fixed 3.3V. For stability, you only need two small capacitors.

You need a 1µF capacitor on the input and another 1µF capacitor on the output. These capacitors smooth out the voltage and keep the LDO stable.

Circuit Diagram:

+-----------------------+

| MCP1700 |

| |

BAT+ -----| VIN VOUT |----- 3.3V to Microcontroller

(4.2V-3V) | +--GND--+ |

| | | |

+------|-------|--------+

| |

--- ---

| | 1uF | | 1uF

--- ---

| |

GND -------------+-------+------------- GND

Once connected, you can power your 3.3V microcontroller. The following code for an Arduino board simply blinks the built-in LED. It confirms that the LDO is successfully powering your chip.

Example Code:

// This code runs on a microcontroller powered by the LDO.

// It doesn't control the LDO; it just shows the circuit is working.

void setup() {

// Initialize the digital pin LED_BUILTIN as an output.

pinMode(LED_BUILTIN, OUTPUT);

}

void loop() {

digitalWrite(LED_BUILTIN, HIGH); // Turn the LED on

delay(1000); // Wait for a second

digitalWrite(LED_BUILTIN, LOW); // Turn the LED off

delay(1000); // Wait for a second

}

Step-Down: Buck Converters

When efficiency is your top priority, a buck converter is the best choice. Unlike an LDO that burns off extra voltage as heat, a buck converter is a highly efficient switching regulator. It is ideal for getting the most life out of your battery.

How Buck Converters Work

You can think of a buck converter as a very fast electronic switch. It works by taking chunks of energy from the battery and delivering them to your circuit.

- An internal switch turns on, allowing energy to build up in an inductor.

- The switch then turns off. The stored energy in the inductor is released to your circuit at a lower voltage.

- This on-off cycle happens thousands of times per second.

A controller chip adjusts how long the switch stays on to keep the output voltage perfectly stable. This method is much more efficient than the LDO’s approach of resisting current.

When to Use a Buck Converter

You should use a buck converter when your project demands significant power or needs to maximize battery life. For a load of 500mA, a buck converter is far more efficient than an LDO. Buck converters can maintain an efficiency of 85-95%, even with a large difference between the input and output voltage. An LDO’s efficiency drops as the voltage difference increases, wasting power as heat.

🚀 Choose a buck converter for high-power tasks like:

- Driving motors or powerful LEDs

- Powering Single Board Computers (SBCs)

- Running data logger boards with multiple sensors

If your project requires more than 500mA of current, a buck converter is almost always the right solution.

Practical Integration

Using a buck converter is simple when you use a pre-made module. A module based on the PAM2306 chip is a great, low-cost option for providing a stable 3.3V from your battery. These modules are perfect for applications needing 500mA to 1000mA of current.

Connecting it is straightforward. You just need to connect your battery to the input pins and your microcontroller to the output pins.

Circuit Diagram:

+-----------------------+

| PAM2306 Module |

| |

BAT+ -----| VIN VOUT |----- 3.3V to Microcontroller

(4.2V-3V) | |

| |

GND ------| GND GND |----- GND

+-----------------------+

This setup gives you a highly efficient and stable power source. It ensures your high-current components get the power they need without quickly draining your battery.

Step-Up: Boost Converters

Sometimes your project needs a higher voltage than your battery can provide. For example, you might need 5V to power a standard Arduino Uno or a USB device. In these situations, you need a boost converter to “step up” the voltage.

How Boost Converters Work

A boost converter works like an energy slingshot. It takes the lower voltage from your battery and boosts it to a higher, stable voltage.

It uses an inductor and a fast-switching component.

- The switch connects the inductor to the battery, storing energy in the inductor’s magnetic field.

- The switch then disconnects. This action forces the stored energy to release at a higher voltage.

This process repeats thousands of times per second. A controller chip carefully manages the switching to ensure the output remains a constant 5V, even as the battery’s voltage drops from 4.2V to 3.0V.

When to Use a Boost Converter

You should use a boost converter whenever your components require a voltage higher than your battery’s output. This is a very common need in portable electronics.

💡 Use a boost converter to power 5V electronics, such as:

- Standard Arduino boards (like the Uno or Nano).

- USB-powered devices or peripherals.

- Sensors and modules that specifically require a 5V supply.

Boost converters make it possible to use a single 3.7V lithium-ion cell for projects that would otherwise need a bulkier power source.

Practical Integration

Using a boost converter module is the easiest way to get a stable 5V source. A module built with a chip like the PAM2401 is a fantastic choice. These tiny boards are designed to efficiently convert your battery’s voltage up to 5V.

You can connect your 3.7V battery to the module’s input. The output will provide a steady 5V, perfect for powering an Arduino Uno. A great way to do this is to connect the module’s output to a USB cable and plug it directly into the Arduino’s USB port.

Circuit Diagram:

+-----------------------+

| Boost Module |

| (PAM2401) |

BAT+ -----| VIN VOUT |----- 5V to Arduino/USB Device

(4.2V-3V) | |

| |

GND ------| GND GND |----- GND

+-----------------------+

This simple setup unlocks the ability to power a wide range of 5V electronics from a compact, rechargeable battery, making your projects truly portable.

Battery Protection and Management

Proper voltage regulation gives your project a stable power supply. However, you also need to protect the battery itself. A Battery Management System (BMS), or protection circuit, is a vital safety feature for any lithium battery project. It acts as a bodyguard for your battery cell.

Understanding Protection Circuits

A protection circuit prevents conditions that could permanently damage your battery. It constantly monitors the battery and will disconnect it if it detects a problem. You should always use a battery with a built-in protection circuit.

- Overcharge Protection: The circuit stops charging when the battery voltage gets too high (e.g., above 4.2V). This prevents damage from too much power.

- Over-discharge Protection: It disconnects the battery if its voltage drops too low. This is crucial because letting a lithium battery’s voltage fall below a certain point, often around 2.5V to 2.8V, can ruin it forever.

- Short-circuit Protection: If your wires accidentally touch, the circuit instantly cuts the power. This protects both the battery and your electronics from a dangerous surge of current.

Low Quiescent Current (Iq)

Your project might spend most of its time in a low-power sleep mode. During this time, your voltage regulator still uses a small amount of power. This standby power is called quiescent current, or Iq. A high Iq can drain your battery even when your project is doing nothing.

Choosing a regulator with a low Iq is essential for long battery life. For example, the MCP1700 regulator has a very low quiescent current. Some specialized components, like the TPL5110 power timer, have an incredibly small Iq of just 35nA. A low Iq can extend your device’s battery life from a few hours to several days.

All-in-One Power Modules

You can simplify your project by using an all-in-one power module. These boards combine several key functions onto a single circuit. They are a fantastic option for beginners and experts alike.

A typical module includes:

- A charging circuit (often with a USB port).

- A full battery protection circuit.

- A boost or buck converter for stable 5V or 3.3V output.

These modules handle all the complexities of power management for you. You simply connect your battery and your project. This gives you a safe, reliable, and rechargeable power source in one convenient package.

You now have three great tools for powering your projects.

- LDOs offer simple, low-noise power for sensitive parts.

- Buck converters give you efficient step-down power for high-current needs.

- Boost converters step up your battery voltage to power 5V devices.

🚀 Your Next Step: Analyze your project’s voltage and current needs. Correct voltage regulation and battery protection are fundamental to success. You can now confidently choose the right components for your next build.

FAQ

What is “dropout voltage” in an LDO?

Dropout voltage is the smallest difference needed between the input and output voltage for the LDO to work. Your battery’s voltage must always stay above the LDO’s output voltage plus its dropout voltage. For example, a 3.3V LDO with a 0.2V dropout needs at least 3.5V input.

Why can’t I just use resistors to lower voltage?

Resistors are not regulators. They cannot provide a stable voltage. The output voltage will change as your circuit’s current demand changes. This instability can cause your project to fail or behave unpredictably. You should always use a proper regulator for a stable power supply.

Can I use a buck and a boost converter at the same time?

✅ Yes, you can. Many projects need both 3.3V and 5V. You can connect your battery to a buck converter for a stable 3.3V output and also to a boost converter for a 5V output. This allows you to power different components from a single battery.

Should I use a module or a bare chip?

💡 For most projects, you should start with a module. Modules include all the necessary extra components, like capacitors and inductors. They are easier to use and more reliable for beginners. You can use bare chips later to make your designs smaller and more custom.