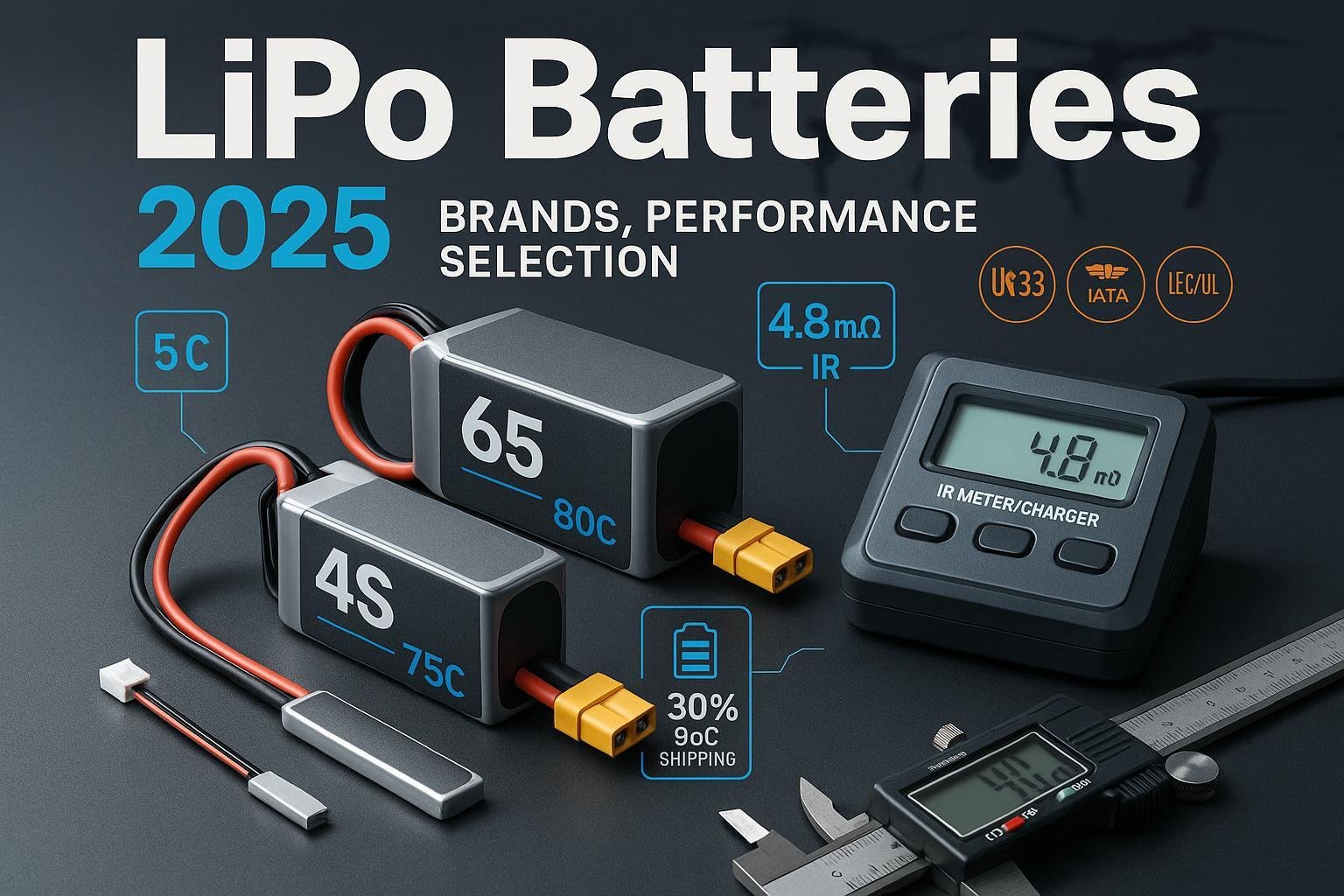

If you fly FPV, spec a drone, build robots, or ship consumer devices, 2025 is a pivotal year for LiPo batteries. The market has matured, brand quality gaps are clearer, and transport rules are tightening (hello, ≤30% state-of-charge rules). This guide distills what actually matters—real performance beyond marketing C-ratings, how to choose the right pack for your application, and what you must know about safety and shipping to stay compliant.

What you’ll take away:

- Shortlists of reputable brands (with realistic expectations).

- The metrics that predict performance: IR, voltage sag, energy density, and cycle life.

- Step-by-step selection playbooks for FPV/RC, drones, robotics, and consumer products.

- 2025 rules on UN38.3, IEC/UL safety, and IATA air shipping.

- Practical checklists you can print and use today.

1) LiPo fundamentals in 60 seconds

- Chemistry: “LiPo” packs for RC/drone use are lithium-ion cells in polymer pouches. Same core intercalation chemistry as other Li-ion, different packaging.

- Nominal voltage: 3.7 V per cell; full charge ≈4.2 V. LiHV variants charge to ≈4.35 V per cell for slightly higher energy, often with some trade-off in cycle life.

- Cell count defines pack voltage: 1S=3.7 V, 4S≈14.8 V, 6S≈22.2 V (nominal).

- Capacity (mAh) × voltage (V) ≈ energy (Wh). Weight is your hidden cost—more Wh improves runtime but can wreck handling.

- C-rating is a claimed current multiple. A 1300 mAh pack labeled 100C implies 130 A continuous, but in practice real, sustainable current is often far lower. Treat C-ratings as relative within a brand.

For newcomers, Oscar Liang’s evergreen explainer remains a practical on-ramp, including storage, voltage limits, and care, updated through 2024–2025 in his LiPo battery guide.

2) The performance metrics that actually predict how your pack flies or drives

Skip the label hype. Here’s what correlates with on-field performance.

2.1 Internal resistance (IR)

- What it is: The inherent opposition to current flow inside a cell/pack. Lower IR means less heat and less voltage sag under load.

- Why it matters: Voltage sag under throttle is roughly proportional to load current and IR: Vdrop ≈ I × IR.

- How to measure:

- Most modern RC chargers can estimate per-cell IR, but readings depend on temperature and state-of-charge (SOC). Measure at consistent ≈25°C and mid-SOC for comparisons. Practical technique and caveats are outlined in the hobby community, such as RC Helicopter Fun’s IR explainer and Oscar Liang’s IR guidance.

- A pulse method gives IR from a short current step: IR ≈ ΔV/ΔI; vendor technical briefs describe this approach, e.g., Ufine’s 2024 IR measurement guide.

- Practical ranges: Fresh, high-performance FPV cells often show ≈2–5 mΩ per cell; if your per-cell IR rises 30–50% from baseline or one cell drifts higher than the rest, expect noticeable sag and shorter useful bursts, consistent with 2024–2025 field guidance in the sources above.

2.2 Voltage sag under load

- What it is: The drop from open-circuit voltage when you punch the throttle or load the drivetrain.

- How to assess:

- Bench dischargers (e.g., 350–600 W units) or ESC telemetry can capture sag at your target current profile. Independent 2024 FPV bench tests for 4S packs show sag and heat rising sharply as you approach the practical current ceiling, far below label C-claims; see the skkyFPV/AOS RC 4S sub-250 g battery test PDF for example curves.

- Rules of thumb: Healthy FPV packs show ≈0.1–0.2 V per cell transient sag at typical bursts; sustained sag above ≈0.3 V per cell signals elevated IR/aging—advice echoed in community practice such as Oscar Liang’s whoop/FPV notes.

2.3 Energy density and weight

- Energy density (Wh/kg) = (Capacity in Ah × Nominal V) / mass in kg. Commercial LiPo for drones/RC commonly lands around ≈150–220 Wh/kg; the highest densities often trade off peak power and cycle life, as summarized in Ufine’s 2024 drone battery overview.

2.4 Cycle life and temperature behavior

- Cycle life is typically defined to 80% of original capacity. Expect ≈300–500 cycles at moderate rates and temperatures, fewer for race-grade abuse; again see the 2024 vendor technical overviews synthesized above.

- Temperature matters: cold increases IR and reduces power; heat accelerates aging and gas formation. Recent materials reviews detail the low-temperature limitations and high-temperature degradation mechanisms in Li-ion systems, e.g., an ACS Omega 2024 review on low-temperature performance (ACS Omega 2024 low-temp mechanisms) and a 2024 Advanced Energy Materials perspective on degradation pathways (Advanced Energy Materials 2024 review).

3) 2025 brand and manufacturer landscape (with realistic expectations)

No brand is perfect across every line and batch. The goal is to shortlist reliable options and then verify with your own IR and sag checks on arrival.

What the community and retailers converge on in 2025:

- Gens Ace / Tattu (by Grepow): Premium lines with strong QC reputation, broad distribution, and readily available documentation (UN38.3 test summaries on request). Community and retailer coverage remains consistently positive; see ongoing hobby guidance in Oscar Liang’s battery guide.

- ChinaHobbyLine (CNHL): Strong price-to-performance and accessible educational posts (e.g., CNHL’s 2025 IR explainer); occasional batch variability reported in forums.

- GNB (Gaoneng): Popular for micro FPV and whoops; widely stocked by FPV retailers.

- Turnigy (HobbyKing): Budget-friendly with a wide range; mixed QC historically.

- Thunder Power: Long-time pro-grade brand with premium pricing.

- SMC, Ovonic, Acehe, Dogcom: Value and race-focused options with improving QC and strong followings in 2024–2025; browse reputable FPV retailers like Pyrodrone’s battery catalogs and brand shops such as Ovonic’s US store for the latest lines and weights.

Independent, standardized 2025 head-to-head data is still limited. Where available, reviewers like AOS RC demonstrate on-rig testing and telemetry interpretation (example 2024 methodology in an AOS testing video). Treat C-ratings as brand-relative, use weight and per-cell IR to compare, and keep receipts/documentation for returns if your measurements diverge from expectations.

4) How to translate specs into the right battery for your application

We’ll keep this practical. Start with voltage (cell count), then size capacity around weight and current needs, then vet with IR and sag.

Key formulas and rules:

- Peak current estimate: Ipeak ≈ power / voltage. For prop/motor setups, look up thrust stand data or ESC logs.

- “C math”: I (A) ≈ Capacity (Ah) × C. If you truly needed 100 A continuous, a 1300 mAh “100C” label would claim to cover it—but real-world continuous capability will usually be well below the label.

- Sag check: Vdrop ≈ I × IR (pack). Pack IR ≈ sum of cell IRs plus interconnects.

4.1 FPV drones

- 5-inch freestyle/race (most common)

- 4S builds: 1300–1500 mAh, ≈150–180 g, XT60. Good for traditional 4S ecosystems.

- 6S builds: 1000–1300 mAh (up to ≈1480 mAh), ≈200–240 g, XT60. Lower current at the same power reduces sag/heat. For reference on a popular 6S pack weight targeting, see the listing for a Tattu R-Line V5 1480 mAh 6S ≈237 g at NewBeeDrone’s product page.

- Targets: Favor packs with per-cell IR in the low single milliohms when new; aim for transient sag ≈0.1–0.2 V/cell on your rig.

- Micro whoops/toothpicks (1S–3S)

- 1S: Weight dominates; choose by actual sag under 10–30 A bursts and connectors that minimize loss.

- LiHV: Consider for flight time pop; monitor long-term cycle life.

- Long-range/cinema rigs

- Higher capacity 4S/6S (or parallel packs) for endurance; manage thermal load and don’t pull race-level peaks from endurance packs.

Connectors and wiring: Size the connector/wire for your current. XT60 is standard for 5-inch; XT30 for micro. A concise manufacturer overview of connector types and use cases is provided by Grepow’s 2024 connector guide.

4.2 RC cars, helis, and boats

- RC cars (1/10, 1/8 scale): Duty cycles include frequent bursts and high peak currents; weight is less constrained than in quads. Look for packs with robust leads, low IR, and heat tolerance. Land before sustained per-cell voltage sags past ≈3.5 V under load to protect cycle life—guidance aligned with the FPV community best practices above.

- Helis/boats: Continuous high power demand; prioritize conservative C-ratings (relative) and cooling airflow. Consider two smaller packs in series/parallel where packaging allows to distribute heat.

4.3 Robotics and embedded devices

- Duty cycle first: Are loads spiky (actuators) or steady (compute, sensors)? Choose capacity for average draw and ensure burst headroom for spikes.

- BMS and protection: Many robotics/consumer applications require a pack-level BMS and additional protection circuits; IEC/UL safety compliance matters here (see Section 6). If you’re integrating into a product, evaluate cells/packs certified to IEC 62133-2 and consider UL 2054 for pack compliance.

4.4 Consumer electronics and custom devices

- Mechanical fit is king: Pouch sizes, lead routing, and connector strain relief often drive selection.

- Compliance and documentation: You will need UN38.3 Test Summary for shipping, and often IEC 62133-2 certification for market access. Some markets and retailers increasingly expect UL certification at the pack or system level—see Section 6 for details and links to the primary standards catalogs.

5) C-rating inflation: what the data and 2024–2025 tests actually show

- Community testers consistently find that the practical continuous current is well below label C-claims. The 2024 skkyFPV/AOS RC side-by-side 4S test measured per-cell IR in the ~3–5 mΩ range for new packs and showed that around ≈60–90 A loads, sags and temperatures indicated the practical limits—even when labels suggested “100C” capabilities.

- Experienced reviewers (e.g., AOS RC/Chris Rosser) recommend comparing weight and IR within and across brands, and evaluating voltage hold at your target current rather than trusting the label; see an example 2024 methodology overview in the AOS testing video.

- Practical takeaway for buyers: Treat C-ratings as relative within a brand series; compare weight, measure per-cell IR on arrival, and validate with short burst tests while monitoring temperature.

6) Safety, compliance, and air-shipping in 2025 (what changed and what to do)

This is where 2025 is truly different: the IATA Dangerous Goods Regulations (DGR) 66th Edition are in force, with lithium-battery guidance updated, and the industry is moving to stricter state-of-charge rules.

6.1 UN numbers and IATA packing instructions

- UN3480: Lithium-ion batteries shipped alone — IATA Packing Instruction PI965.

- UN3481: Lithium-ion batteries packed with equipment (PI966) or contained in equipment (PI967).

- The official reference is IATA’s 2025 Lithium Battery Guidance Document, which summarizes classification, marking, and documentation for shippers; consult the current PDF on IATA’s site: IATA Lithium Battery Guidance 2025 PDF.

6.2 Section IA/IB/II distinctions and quantity/packaging

- Section IA/IB shipments require a Shipper’s Declaration; Section II provides limited quantity relief for small cells/batteries. Specific net quantity limits and package counts depend on Wh ratings and configuration; see IATA’s DGR 66th Edition summary of significant changes: IATA DGR 66 Significant Changes (2025).

6.3 State-of-charge (SoC) policy for air transport

- In 2025, IATA and ICAO continue to guide shippers toward ≤30% SoC for lithium-ion batteries to reduce thermal runaway risk during transport; updates signal a 2026 mandate for ≤30% SoC for certain categories, with State approvals for exceptions. See IATA’s Knowledge Hub note on dangerous goods manual updates (IATA Knowledge Hub update, 2025) and the 2025 press release on manual revisions (IATA press release, 2025-02-03).

6.4 Marking and labeling

- Lithium battery marks and Class 9 hazard labels apply; the 66th Edition updates incorporate a broader “Battery mark” concept that also captures sodium-ion within the Battery Shipping Regulations framework. For exact artwork/specs and adoption timelines, refer to the IATA DGR significant changes document linked above.

6.5 UN38.3 testing and the Test Summary you must have

- UN38.3 (UN Manual of Tests and Criteria, Rev.7 Amd.2) defines the transport safety sequence: altitude, thermal, vibration, shock, external short, impact (cells), overcharge, forced discharge. The 2025 session notes confirm scope continuity; see the UNECE committee information note: UN/SCETDG/66/INF.12 (April 2025).

- Since 2020, a Lithium Battery Test Summary (TS) under 38.3.5 must be made available by manufacturers or distributors. Ensure your supplier provides this TS for each cell/pack you ship.

6.6 Product safety standards (IEC/UL) most buyers should know

- IEC 62133-2: The globally referenced safety standard for rechargeable lithium cells and batteries (portable applications). The current base edition is 2017 with Amendment 1:2020. Check the official IEC webstore entries for scope and details: IEC 62133-2 Ed.2.0 (2017) et IEC 62133-2 Amd1:2020.

- UL 1642 (cells) and UL 2054 (battery packs): Widely requested in North America. To verify current editions and applicability to your product category, use UL’s standards catalog entries: UL 1642 catalog page et UL 2054 catalog page.

6.7 Recall and incident lessons

- Real-world safety issues often stem from poor chargers or uncertified packs. The U.S. CPSC in 2024 urged consumers to stop using certain aftermarket e-bike packs lacking UL certification due to fires (CPSC warning on UPP e-bike batteries, 2024). Charger defects can also pose risks; see the 2024 CPSC recall of HTRC C240 battery chargers for fire/burn hazards (CPSC recall listing, 2024). The takeaway: buy certified gear where applicable, monitor temperatures, and retire damaged or swelling packs.

7) Care, maintenance, and when to retire a pack

- Charging: For longevity, charge at ≤1C unless the manufacturer specifies higher and you can control pack temperature. Balance-charge routinely.

- Voltage limits: In flight/drive, try to land before sustained <3.5 V/cell under load; avoid dipping below ≈3.3 V/cell. For storage, set to 3.75–3.85 V/cell.

- Temperature: Operate around 20–40°C; avoid charging hot packs. Cold weather? Pre-warm packs and avoid full-throttle punches when cells are cold, aligning with the low-temperature performance limitations discussed in literature like the ACS Omega 2024 review.

- Health monitoring: Track per-cell IR at a consistent SOC and ≈25°C. Retire packs that show >30–50% IR rise from baseline, persistent swelling, or one-cell drift/imbalance you cannot correct.

- Disposal: Follow local e-waste and hazardous waste rules; fully discharge to a safe level before disposal if required by your facility.

8) Step-by-step selection playbooks (printable)

Use these as field cards. They reflect the 80/20 of good choices.

8.1 Universal 5-step LiPo selection

- Define voltage (S-count) for your system and performance goal.

- Estimate peak and average current; size capacity for desired runtime and weight limit.

- Shortlist by weight and dimensions that fit your frame/enclosure.

- Choose by brand line and community track record; plan to verify IR and sag on arrival.

- Confirm compliance needs (UN38.3 TS, IEC/UL for products) and shipping plan (IATA rules, ≤30% SoC when shipping by air).

8.2 FPV quick picks (guidelines)

- 5-inch 6S freestyle: 1100–1300 mAh; target ≤240 g; XT60; low per-cell IR when new (≈2–5 mΩ); verify transient sag.

- 5-inch 4S race: 1300–1500 mAh; ≤180 g; XT60; prioritize weight and cooling.

- Micro whoop 1S: prioritize grams and measured sag under 10–30 A bursts; connector and lead resistance matter as much as the cell.

8.3 RC car/heli/boat

- Match pack form factor to tray; ensure leads/connector can handle bursts; favor lower IR and robust build. Log temps after runs and gear down if packs exceed ≈60°C.

8.4 Robotics/consumer devices

- Map duty cycle and thermal envelope; define certification targets (IEC 62133-2, UL 2054) early; choose BMS-equipped packs when needed; collect UN38.3 Test Summaries for logistics.

9) Buying checklist (clip and save)

- Application

- [ ] Voltage (S): __; Peak current: __ A; Average: __ A; Target runtime: __ min

- [ ] Max battery weight: __ g; Space (L×W×H): __ mm; Connector: __

- Shortlist

- [ ] Candidates A/B/C: capacity, weight, price noted

- [ ] Verify brand line reputation via recent community tests/reviews

- On arrival

- [ ] Measure per-cell IR at ≈25°C, mid-SOC; record baseline (mΩ)

- [ ] Perform short burst tests at target current while monitoring sag and temperature

- [ ] Inspect build quality (leads, connector, shrink, balance lead strain relief)

- Compliance & docs

- [ ] UN38.3 Test Summary obtained (matches exact model)

- [ ] Safety certifications needed? IEC 62133-2 (cells/packs), UL 1642/2054 (as applicable)

- [ ] For air shipping: plan ≤30% SoC, correct marks/labels, and declarations per IATA DGR 66

10) Troubleshooting and failure signs

- One cell drops faster: Likely higher IR in that cell; confirm with IR readings; retire if persistent.

- Puffing/swelling: Gas generation from electrolyte decomposition—often from heat/overdischarge. Retire safely.

- Hot after modest use: Check current draw versus pack capability; consider a higher-voltage or higher-capacity pack (heavier) or reduce throttle/gear.

- Balance issues: If repeated balancing is needed and drift continues, the pack is aging out.

11) Reference cards (at-a-glance)

- Storage: 3.75–3.85 V/cell at 15–25°C in a fire-resistant container.

- Charge: ≤1C for longevity; balance charge; stop if any cell behaves abnormally.

- Land: ≈3.5 V/cell under load for longevity; earlier in cold weather.

- Retire: >30–50% IR increase from baseline or persistent swelling/imbalance.

- Ship: UN3480/3481 per IATA PI965–967; prepare UN38.3 Test Summary; plan ≤30% SoC on air shipments in line with 2025 guidance and 2026 mandates.

12) Source notes and where to verify details

- Performance and care fundamentals are well-documented in hobbyist technical guides like Oscar Liang’s updated LiPo battery guide and RC Helicopter Fun’s IR explainer. Use these for practical technique, not regulatory compliance.

- For discharge capability vs. label, examine independent test datasets such as the 2024 skkyFPV/AOS RC 4S sub-250 g battery test PDF and methodology videos like an AOS RC testing walkthrough.

- For connectors and pack build considerations, vendor explainers like Grepow’s 2024 connector overview are useful.

- For transport and safety requirements, consult primary standards and official documents: IATA’s 2025 Lithium Battery Guidance PDF et DGR 66 Significant Changes; the UNECE 2025 information note on the UN Manual of Tests and Criteria sequence UN/SCETDG/66/INF.12; IEC 62133-2 webstore entries (2017 edition, 2020 amendment); and UL standards catalog entries for UL 1642 et UL 2054.

- Recall awareness sharpens safety judgment: review incidents like the U.S. CPSC’s 2024 UPP e-bike battery warning and the 2024 HTRC charger recall listing.

Dernières réflexions

Your best LiPo in 2025 is the one that matches your voltage and weight constraints, holds voltage at your target current, and arrives with the right paperwork. Measure IR, watch sag and temperature, and don’t let a marketing C-number decide your build. If you ship or sell products, align early with UN38.3, IEC 62133-2, UL, and the IATA DGR 66th Edition to avoid costly delays.

Fly safer, ship smarter, and enjoy longer-lasting packs by making data—not labels—your guide.