⚡️ Safety First! Read Before You Start

Avertissement : Lithium-ion cells can catch fire or explode if mishandled! Faulty assembly is a leading cause of battery fires (source). Always work in a ventilated, fire-safe area with Personal Protective Equipment (PPE), insulated tools, and a working fire extinguisher ready. If you are unsure about any step, pause and seek expert guidance!

What You’ll Achieve: A rock-solid, safe, and well-insulated 18650 battery pack matched to your needs, with proven methods for alignment, spot-welding, wiring, insulation, and troubleshooting.

🛠️ Preparation: Tools, Materials & Pre-Build Checklist

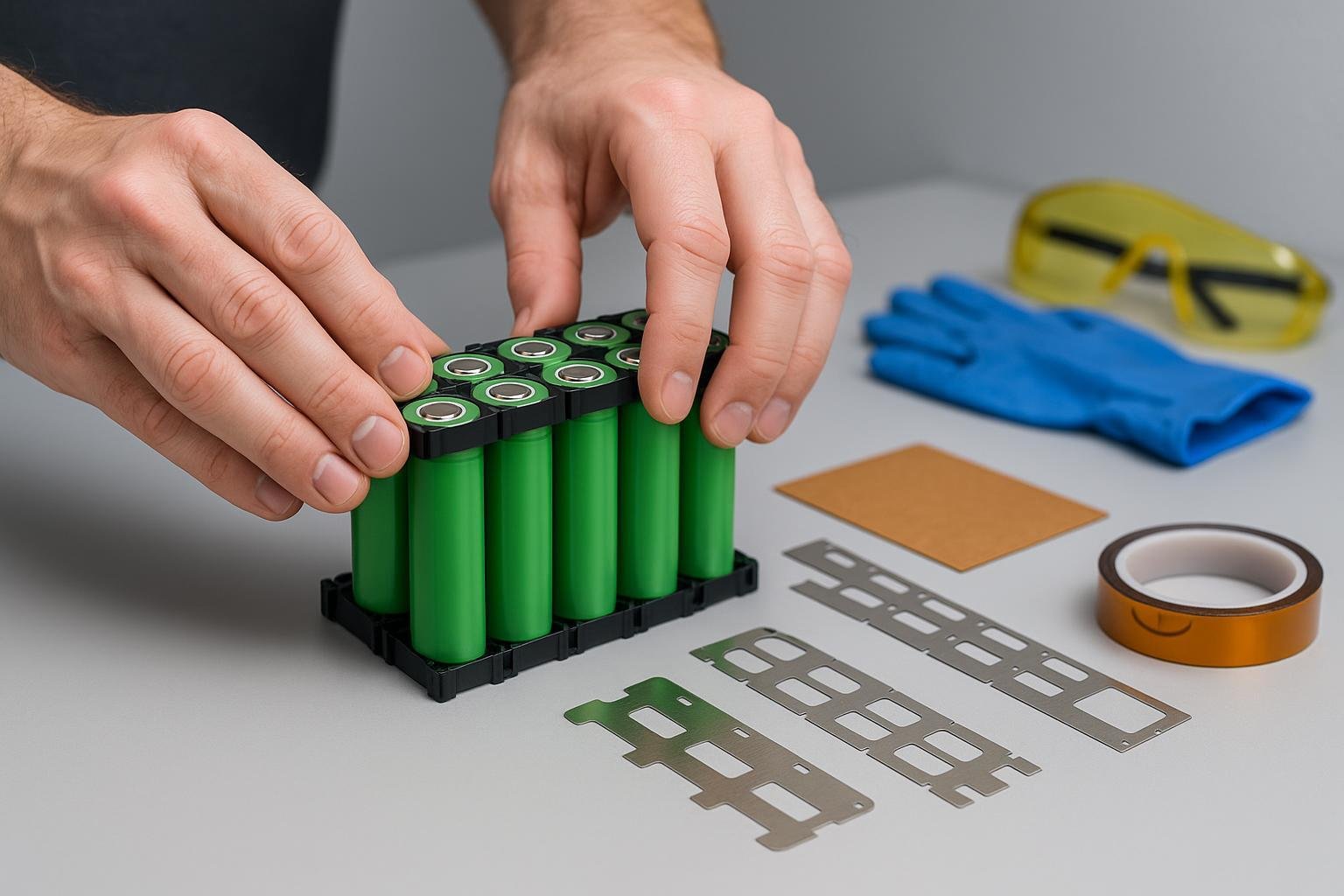

Before building, gather all required items and clear your workspace for safety and organization. Print or reference the following checklist for smooth execution:

Downloadable Preparation Checklist

| ✅ | Item/Action | Notes/Links |

|---|---|---|

| Insulated gloves & safety goggles | Mandatory for all assembly | |

| Spot welder (preferred) or battery-safe soldering iron | Spot welder highly recommended (Guide) | |

| Nickel strips (pure, battery-grade) | For cell interconnects | |

| Multimeter | For voltage/continuity checks | |

| Cell holders/spacers | Prevent stress, maintain alignment | |

| Fish paper rings & Kapton tape | Insulate positive terminals/all contacts | |

| Heat shrink tubing | For final pack insulation | |

| Fire extinguisher (ABC/CO2) / no metal clutter | Must be immediately accessible | |

| Ventilated, non-flammable workspace | No flammable surfaces! | |

| Pre-tested, matched 18650 cells (voltage/capacity/IR) | Test every cell—log results (Cell Guide) |

(For a printable version and wiring templates, see Resource Section.)

🔋 Step 1. Planning Your Pack: Configuration & Cell Selection

Define your goal:

- Target Voltage:

- Series cells = voltage (e.g., 4 cells in series × 3.7V = 14.8V)

- Target Capacity:

- Parallel cells = amp-hour capacity (e.g., 3 cells parallel × 2.5Ah = 7.5Ah)

- Utiliser un Pack Planner or simple table to visualize configuration.

- Target Voltage:

Test & Match Each Cell:

- Measure voltage: All should be within 0.05V of each other.

- Check internal resistance: Remove high-resistance cells.

- Log results: Label/stage cells to avoid mix-ups.

Pre-Visual Layout:

- Dry-fit all cells into holders/spacers matching your diagram (see layout templates).

- TIP: Alternate orientation (flip every other row) for easier wiring and balance leads.

🏗️ Step 2. Arranging & Aligning Cells Safely

Arrange cells in holders/spacers:

- Use plastic cell holders or 3D-printed frames for neat, stable alignment and airflow. This dramatically reduces shorts and cell movement issues (visual example).

Install fish paper rings:

- Place an insulating ring (fish paper/Kapton) over each cell’s positive end—never skip (this prevents accidental shorting by nickel strips).

Dry-fit full configuration:

- All positives/non-positives must face as per your wiring diagram! Double-check orientation before any welding/soldering.

Common Mistake Callout:

- Misaligned cells cause stress and shorts—always re-check layout!

🔗 Step 3. Electrical Connections: Spot Welding or Soldering

Spot Welding (Preferred Method)

- Set up spot welder: Adjust settings for clean, solid welds on nickel strips—practice on dummy cells first.

- Weld parallel groups:

- Lay nickel strips across cells in each parallel row. Tap two or more welder spots per terminal.

- Weld series connections:

- Bridge parallel groups with nickel, keeping wiring as short and straight as possible.

- Check connections: Each weld should:

- Be shiny and solid;

- Withstand a gentle tug (pull test);

- Have no burned spots or weak bridges.

Soldering (Only if Absolutely Necessary & With Care!)

- Use a powerful iron (60W+), battery-safe solder, work quickly (<2s per joint). Direct heat damages cells!

- NEVER solder directly to positive terminal top.

- Allow cells to cool frequently.

Troubleshooting Tip:

- Cold welds? Re-weld after cleaning surface and adjusting welder settings (technique source).

- Loose wires? Respot or carefully resolder, ensuring nickel is flat and tight.

🧰 Step 4. BMS, Insulation & Final Securing

Attach BMS (Battery Management System)

- Solder balance leads in sequence (B-, B1, B2, … B+, as per diagram)—follow manufacturer manual exactly! (Guide BMS)

- Double-check polarity before connecting main leads—mistakes can destroy pack/BMS.

Insulate everything:

- Wrap exposed metal and connections with Kapton tape or fish paper.

- Slide on tight heat-shrink tubing for whole pack, shrink with hot air.

Final mechanical securing:

- Hot glue between cell groups or to holder as needed to prevent movement.

- Place completed block in a non-conductive, robust outer case if desired.

✅ Step 5. Quality Checks & Final Inspection (QA)

Essential Pass/Fail Checklist

- [ ] No exposed nickel/wires visible

- [ ] All cells firmly locked, no movement

- [ ] Measured pack voltage matches design

- [ ] All parallel groups within 0.05V

- [ ] All insulation intact, with no exposed terminals

- [ ] BMS connections verified by continuity test

- [ ] No abnormal heat, arcing, or sparks

Functional test: Briefly apply a moderate load with a tester (e.g., light bulb, resistor bank) and measure voltage drop/temperature.

🩺 Troubleshooting Table: Fast Fixes for Common Problems

| Symptôme | Likely Cause | Solution |

|---|---|---|

| Cells not aligned | Wrong spacers/layout | Realign, use holders or re-stage layout |

| Cold/weak welds | Low power/unprepared surface | Clean tabs, increase welder output, retry |

| Loose wires/parallels | Weak solder or weld | Re-solder/re-weld, reinforce/wrap |

| BMS doesn’t turn on | Wrong balance lead order | Review diagram, resolder in correct sequence |

| Exposed tabs after shrink | Incomplete wrap | Add tape/fish paper, reheat-shrink |

| Excess temperature | Bad contact, solder overheat | Check all joints, replace damaged cells |

(For a printable troubleshooting flowchart, see recommended template.)

📥 Resources & Downloadables

- Cell and Pack Layout Planner (online visual tool)

- Wiring Diagrams: Typical Configurations

- Printable Preparation & QA Checklist

- Spot Welding Tips & Repairs

- Regulatory & Safety Codes: UN 38.3, IEC 62133

❓ Frequently Asked Questions (FAQ)

Q1: Is spot welding always better than soldering for 18650 packs?

A: Yes, spot welding produces lower resistance, safer connections, and less thermal damage (in-depth explanation).

Q2: My pack doesn’t charge—what should I check?

Verify all BMS leads in the right order, ensure no wires are loose or reversed, and check for matching cell voltages.

Q3: Can I safely repair a cold weld after pack assembly?

Yes, carefully re-spot or re-solder after isolating the affected group—and always re-insulate. If damage is suspected, replace the cell.

Q4: How long does a DIY 18650 pack last?

With quality cells, proper welding, and balanced charge/discharge, expect 300–800 cycles—lifespan varies by use and maintenance.

🚨 Final Safety Reminders

- Never build packs with mismatched, old, or unknown cells.

- Toujours utiliser dedicated spot-welders for main cell interconnects.

- Double-insulate every exposed terminal and tab.

- Test pack outside, away from people/flames, during first charge/discharge.

📚 Further Learning & References

Takeaway: With patience, respect for safety, and this stepwise workflow, you can build a durable, safe 18650 battery pack. Print the checklists, double-check every stage, and never cut corners on insulation or testing. Happy building—and stay safe!