Table of Contents

- Introduction

- Technology Overview: 3.7V Lithium Ion Chemistry

- Core Design Specifications

- Materials, Components, and Advanced BMS

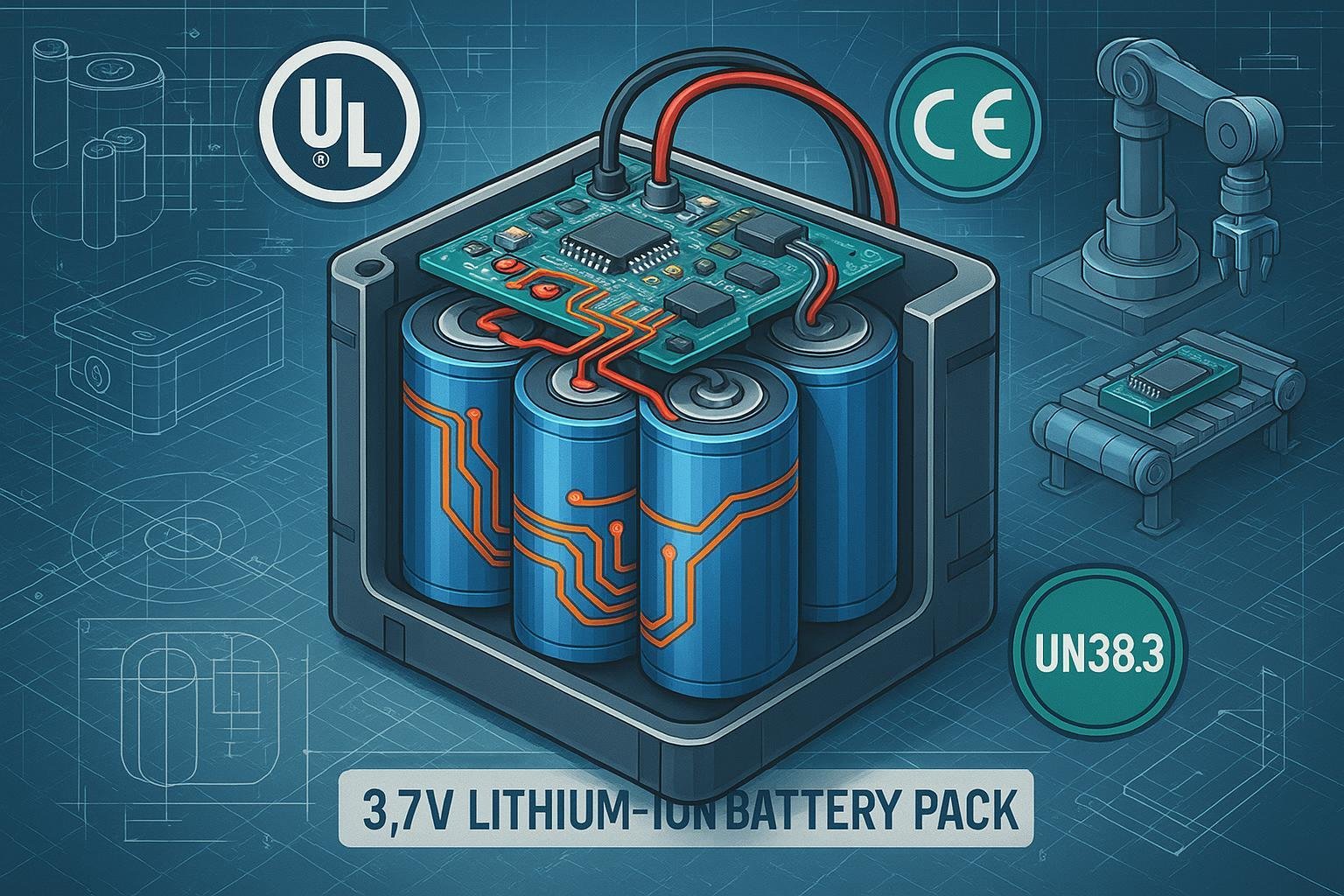

- Global Regulatory Standards and Certification

- Manufacturing Process: Stepwise Engineering

- Quality Control, Testing, and Failure Analysis

- Case Studies: Real-World Applications

- Glossary, Resources, and FAQs

- Downloadable Templates and Tools

Introduction

Custom rechargeable 3.7V lithium ion batteries have become the backbone for innovation across high-tech consumer electronics, industrial automation, medical devices, and emerging robotics. Whether you are a product designer, R&D engineer, procurement manager, or technical consultant, mastering the full workflow—from specification, to compliance, to mass manufacturing—is essential. This guide delivers the definitive end-to-end resource, blending authoritative data, actionable engineering steps, and insights from global manufacturing leaders.

Key takeaways:

- Complete coverage: design, certification, production, QC, and application.

- Based on latest industry standards (UN38.3, IEC 62133).

- Practical tools: design spec templates, process flowcharts, regulatory matrices.

Technology Overview: 3.7V Lithium Ion Chemistry

Chemistry and Voltages

3.7V lithium-ion packs typically use lithium cobalt oxide (LiCoO₂) cathodes and graphite anodes, establishing an optimal balance of energy density, cycle life, and safety. The 3.7V nominal voltage is industry-standard for single-cell applications, with packaged configurations expanding this baseline for custom needs (Motoma guide).

Key Chemistry Types: | Type | Energy Density (Wh/kg) | Cycle Life | Best Use Cases | |————-|———————–|————|———————–| | LiCoO₂ | 150–200 | 500+ | Consumer Electronics | | LiFePO₄ | 90–135 | 2000+ | Industrial, Safety | | NCM | 160–220 | 800+ | EV/Power Tools | | LTO | 70–110 | 7000+ | Extreme Temperature |

Why 3.7V?

- Standard for portable electronics.

- Simplifies BMS and IC integration.

- Flexible form factor for custom projects (cylindrical, pouch, prismatic).

Market & Trends

The global industrial lithium battery market continues to exhibit strong growth, driven by advances such as solid-state chemistries, AI-enabled BMS diagnostics, ultra-fast charging, and evolving regulatory mandates.

Core Design Specifications

Essential Parameters

Custom battery projects should begin with a thorough specification sheet:

- Capacity (mAh): Matched to energy profile.

- Tension nominale : Single cell at 3.7V, series for multi-cell designs.

- C-rate (Discharge/Charge): 0.5C–2.0C typical; higher requires thermal compensation.

- Durée du cycle : Minimum 500 cycles at ≥80% retention.

- Operating Temperature: -20°C to 60°C standard; wider for industrial/medical.

- Form Factor: Cylindrical (18650, 21700), pouch, prismatic—chosen for geometry, install constraints, and heat dissipation.

- Protection : Overcharge, over-discharge, short-circuit, temperature limit, ESD shielding.

- Connector/Enclosure: Custom headers, PCMs, waterproofing, shock-proof casings.

Sample Specification Table

| Paramètres | Value/Range | Notes |

|---|---|---|

| Capacité | 1000–10,000 mAh | Project/application specific |

| Max Discharge | 2.0C | For drones/robotics |

| Cycle de vie | >500 | 80%+ retention (QC required) |

| Plage de température | -20°C – +60°C | Special chemistries for extremes |

| Protection de l'environnement | PCM + BMS | Per IEC 62133 |

| Dimensions | Personnalisable | 18650: 18×65mm; pouch varies |

| Compliance | UN38.3, CE, IEC | Mandatory for transport/sale |

Critical Design Tradeoffs

- High energy density ↔ cycle lifetime ↔ safety requirements

- Physical constraints ↔ heat management ↔ integration cost

- BMS feature complexity ↔ regulatory compliance time/cost

Conseil : Always validate the application load profile and use engineering calculators to predict runtime, heat, and cycle degradation.

Materials, Components, and Advanced BMS

Key Material Selection

- Cathode : LiCoO₂ for energy, LiFePO₄ for safety/cycle endurance, NCM for hybrid applications

- Anode : Graphite or silicon composite

- Séparateur : Ceramic-polymer blends for high thermal resistance (Ufine Battery Datasheet)

- Électrolyte : Organic solvent blends tailored for voltage stability

- Collectionneurs actuels : Aluminum (cathode), Copper (anode)

Component Integration

- PCM (Protection Circuit Module): Manages overcharge/discharge, short prevention

- Tab/Weld Materials: Nickel/copper tabs, ultrasonic/laser welding for robust connections

- Enclosure Solutions: Waterproof (IP67+), anti-vibration, fire-retardant housing for industrial/medical

Système de gestion de la batterie (BMS)

BMS is the “brain” ensuring safe operation, health tracking, and pack protection.

- Functions:

- State-of-Charge (SoC) and Health (SoH) calculation

- Cell balancing (active/passive)

- Temperature/voltage safety cut-off

- Real-time communication (CAN, SMBus, BLE)

- Diagnostics (wireless, predictive analytics)

BMS Feature Comparison Table | Feature | Basic PCM | Advanced BMS | |——————-|———–|————–| | Overcurrent Prot. | ✔ | ✔ | | Cell Balancing | ✖ | ✔ | | Digital Health | ✖ | ✔ | | Thermal Control | Basic | AI-enabled | | Connectivity | None | CAN/BLE/WiFi | | Cost & Complexity | Low | Moderate-High|

Integration Best Practices

- Modularize for easy replacement

- Use high-durability tabs and connectors

- LEAN/MES systems for traceability

Global Regulatory Standards and Certification

Certifications are non-negotiable for legal sales, safe transport, and customer confidence.

Major Standards

| Standard | Coverage | Required For | Region/Scope |

|---|---|---|---|

| UN38.3 | Transportation | Air/sea/road shipment | Global (UN) |

| CE | EMC, safety | Sale in EU | L'Europe |

| IEC 62133 | Cell/battery safety | Global imports/exports | Europe, Asia, US |

| FCC | EMC | IT/devices, wireless | ÉTATS-UNIS |

| RoHS | Hazardous substances | EU compliance | L'Europe |

Certification Workflow

- Prototype pass in-house safety tests (short, overcharge, thermal run).

- Submit samples to accredited labs.

- Wait for report/dossier (typically several weeks depending on standard and lab throughput).

- Integrate required protection and labeling before production.

- Maintain traceable batch and process QC documentation.

Regulatory Cost & Time Matrix

| Région | Typical Testing Cost | Lead Time (weeks) |

|---|---|---|

| UN38.3 | $2,000–8,000 | 2–4 |

| CEI | $6,000–25,000 | 4–12 |

| CE/FCC | $2,000–10,000 | 2–8 |

| RoHS | $800–3,000 | 2–4 |

International Shipping Mandates

Battery packs must be packed, labeled, and documented per IATA and DG regulations.

- Use certified UN packaging

- Provide test summary and MSDS

- Markings for air shipment (Class 9)

Conseil : Always maintain a certification matrix for every project.

Manufacturing Process: Stepwise Engineering

End-to-End Workflow

Major manufacturers use automation-rich, digitally traceable systems:

Comprehensive Manufacturing Flowchart

- Raw Material Procurement: Audited suppliers, traceability.

- Electrode Mixing: Homogeneous slurries (cathode/anode).

- Coating & Calendering: Uniform thickness, automated QA.

- Slitting & Stacking/Winding: Precision dimensioning, layer alignment.

- Cell Assembly: Tab/lead welding, enclosure fit.

- Electrolyte Filling/Sealing: Controlled environment; vacuum fills.

- SEI Formation/Aging: Initial charge/discharge cycles, cell screening.

- Pack Integration: PCM/BMS install, connector/casing, modular assembly.

- Contrôle de la qualité : Inline HiPot, EIS, X-ray/CT vision, batch cell sorting.

- Packaging/Shipment: Certified labeling, compliance docs, warehouse traceability.

Note: Owing to an invalid link, the detailed manufacturing process image has been removed. For updated visual resources, consult reliable manufacturer websites or industry whitepapers.

Automation & Quality Management

- MES (Manufacturing Execution System) for end-to-end digital tracking

- Inline data capture at every step

- Lean/6Sigma for yield improvement

- Regular traceability audits

Common Pitfalls

- Inadequate tab welding (leads to cell failure)

- Poor solvent controls (affects cycle life)

- Insufficient formation aging (higher initial field failures)

Quality Control, Testing, and Failure Analysis

Modern QC Protocols

- Inline HiPot/insulation: Detect shorts/defects

- Electrochemical Impedance Spectroscopy (EIS): Assess cell internals

- X-ray/CT vision: Non-destructive inspection of weld/seal

- Cell Sorting/Binning: Capacity/IR matching

- Multi-stage QC: Pre-assembly, post-seal, pack finish, final batch (statistical sampling)

Key Performance Benchmarks

| Métrique | Best-in-class Value | Source |

|---|---|---|

| Yield Rate | >95% | Factory audit |

| Field Failure | 0.025–1ppm | OEM studies |

| Cycle Retention | 80–92% @ 500 cycles | Industry reports |

| Traceability | 100% batch digital | MES implementations |

Failure Analysis & Diagnostics

| Common Failure Mode | Diagnostic Approach | Corrective Action |

|---|---|---|

| Overcharge risk | Fused test, BMS log review | PCM/BMS re-design |

| Court-circuit interne | X-ray/CT, HiPot | Tab weld retraining |

| Rapid capacity loss | EIS, IR trending | Material validation |

| Thermal runaway | BMS thermal, review logs | Thermal pad/vent add-on |

Warranty, Returns, and Batch Testing

- Standard warranties: 12–24 months, 80% capacity minimum

- Returns: Immediate batch trace investigation; root-cause plus corrective implementation

Case Studies: Real-World Applications

Case 1: Wearable Medical Device

- Challenge: Ultra-compact, reliable 3.7V battery for round-the-clock vitals tracking

- Solution: Pouch cell, advanced BMS, dual redundant safety, IP67 housing

- Outcome: >800 cycles validated, UN38.3/IEC certified, field failure <0.03ppm

Case 2: Industrial Robotics Pack

- Challenge: Power spikes, rigorous charge/discharge, uptime-critical

- Solution: Cylindrical high-C-rate (2.0C), active balancing BMS, modular PCM

- Outcome: On-line cell sorting, batch QA, CE/UL approval, real-time process tracking

Case 3: Smart Home IoT Sensor Array

- Challenge: Ultra-low standby consumption, long life cycles

- Solution: Miniature LiCoO₂ cell, advanced sleep-mode BMS, sealed enclosure

- Outcome: Lifetime >3 years, >1,200 cycles tested, FCC/RoHS passed

Lessons Learned:

- Validate every custom in the field with real usage profile tests

- Early integration of certification reduces later redesign costs

- Advanced BMS and modular QC are critical for reliability

Glossary, Resources, and FAQs

Glossary of Terms

| Term | Définition |

|---|---|

| Taux C | Relative rate of charge/discharge to battery capacity |

| SoC/SoH | State of Charge / Health (BMS metrics) |

| UN38.3 | UN standard for battery transport safety |

| MES | Manufacturing Execution System |

| EIS | Electrochemical Impedance Spectroscopy |

| HiPot | High-potential insulation test |

| PCM/BMS | Protection Circuit Module / Battery Management System |

| IEC 62133 | International safety standard for battery cells |

Authoritative Resources

Frequently Asked Technical Questions

Q: What’s the safest chemistry for wearable/medical?

LiFePO₄; highest safety, long cycle life, moderate energy density.

Q: How long does certification take?

Typically 2–12 weeks, depending on standard and lab throughput. UN38.3 is usually the fastest; IEC may be more involved.

Q: Is advanced BMS mandatory for export?

For most industrial/medical—yes. For simple consumer, high-quality PCM suffices. Always check destination certification.

Downloadable Templates and Tools

Templates and checklists previously linked on this page have been removed due to invalid resource links. Please consult official regulatory websites or your battery supplier for the latest downloadable documents.

This guide is continuously updated to reflect the latest manufacturing best practices, industry standards, and technological innovations. Bookmark and share with your engineering colleagues and procurement teams for project success.