One Sentence Definition

Charge cut-off voltage is the maximum voltage limit to which a rechargeable battery cell or pack is charged; surpassing this threshold is prevented by the charger or battery management system (BMS) to ensure safety, performance, and cycle life preservation. (Battery University)

In-Depth Explanation

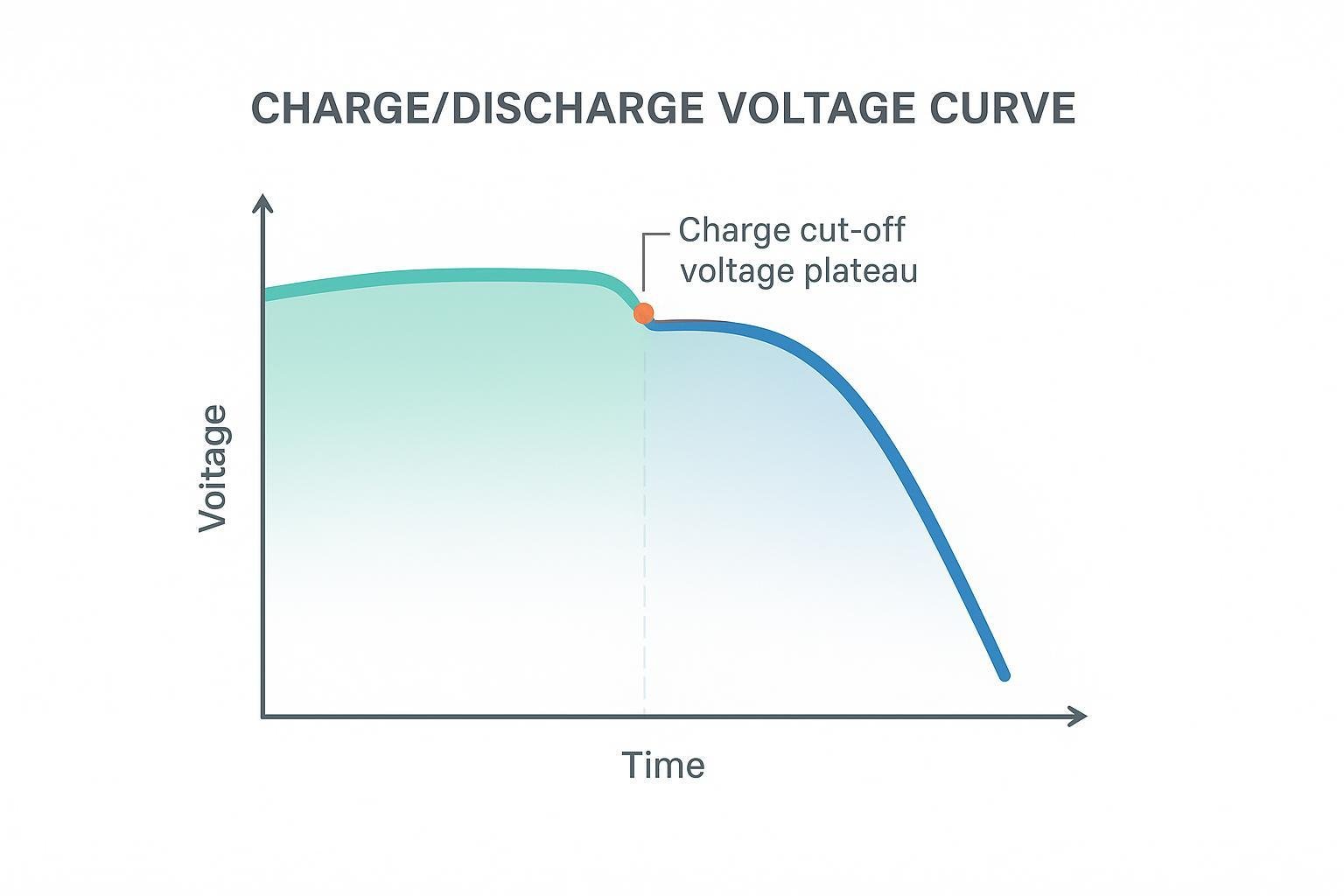

When a lithium-ion battery charges, its cell voltage rises under a constant current until it approaches the designated charge cut-off voltage—most commonly 4.2V per cell for traditional lithium-ion chemistries. The charger then switches to a constant voltage phase, maintaining this maximum until the charging current tapers to a minimal value, at which point charging stops entirely. This upper voltage limit is not arbitrary: it is determined by the cell’s electrochemistry and is fundamental to safe, reliable battery operation. Exceeding cut-off can cause electrolyte decomposition, lithium plating, or even thermal runaway, while charging to a lower limit reduces usable capacity but can significantly increase the number of available cycles.

Modern battery packs (for laptops, electric vehicles, or grid storage) rely on BMS units to monitor every cell. The BMS will disconnect charging if any cell exceeds the cut-off—protecting the system and abiding by industry safety standards.

Key Components and Trade-offs

- Chemistry-Specific Values:

- Li-ion (Cobalt-based): 4.20V (classic standard)

- High-voltage Li-ion/Polymer: up to 4.35V–4.40V (special applications)

- LiFePO₄ (LFP): 3.60V–3.65V

- Lithium Titanate (LTO): ~2.80V

- Cycle Life vs. Capacity: Lowering the charge cut-off voltage (e.g., charging a 4.20V cell only to 4.10V) can double or triple cycle life, but at the expense of approximately 10% less usable capacity.

- BMS Enforcement: Industrial BMSs precisely control cut-off during every cycle with voltage sensing and redundancy, especially in high-reliability markets (EVs, medical devices).

| Chimie | Typical Charge Cut-off (V/cell) |

|---|---|

| Li-ion (Cobalt, NMC) | 4.20 |

| High-Voltage Li-ion | 4.35–4.40 |

| LiFePO₄ | 3.60–3.65 |

| LTO | 2.70–2.80 |

Applications dans le monde réel

- Laptops and Smartphones: BMS limits each cell to the designated cut-off to meet warranty and safety requirements—malfunctioning BMS or accidental overcharging led to historic recalls in these sectors.

- Véhicules électriques : EV battery packs utilize complex BMSs to ensure no cell surpasses the cut-off, balancing consistent range with maximal lifespan and safety.

- Energy Storage Systems: Industrial-scale batteries for grid stabilization enforce cut-off voltages to prevent premature aging or catastrophic failure during rapid charge cycles.

Related Concepts and Further Reading

- Tension de coupure de la décharge : The minimum safe voltage at which battery use should stop to avoid damage. See discharge cut-off voltage for comparison.

- Système de gestion de la batterie (BMS) : The circuitry/software that monitors charge/discharge parameters, enforcing both voltage and current limits.

- Overcharge Protection: Broad safeguards (including both voltage and current cut-offs) against hazardous overcharging.

- Tension nominale : The average, not maximum, voltage at which the cell or pack operates during most use.

- Float Voltage: Typically relevant for standby lead-acid batteries, not lithium-ion.

By understanding and properly applying charge cut-off voltages per battery chemistry and use case, engineers and manufacturers can dramatically enhance product safety, reliability, and service life.