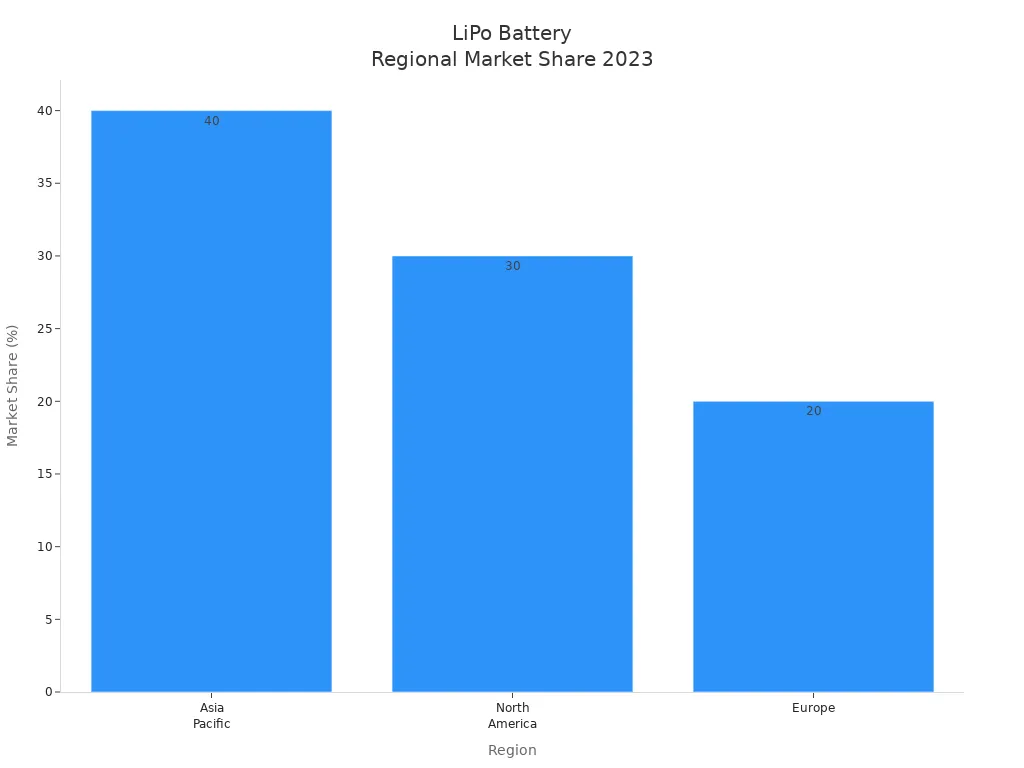

Battery contact designers drive innovation in LiPo connection systems, setting new standards for 2025. Compact, modular, and sustainable connections now enable advanced features in wearables, IoT, and renewable energy devices. The micro lithium polymer battery market stands at USD 4.5 billion in 2024, with strong growth expected due to rising demand for reliable and efficient power solutions. Asia Pacific leads with 40% market share, followed by North America and Europe.

Designer Impact

Battery Contact Designers’ Role

Battery Contact Designers shape the future of LiPo connection systems. They focus on creating reliable and efficient contacts that support new device requirements. These experts study how electricity flows through different materials. They select metals that resist corrosion and handle high currents. Their work ensures that batteries last longer and perform better in small devices.

Many designers use advanced simulation tools. These tools help them predict how contacts will behave under stress. They also test prototypes in real-world conditions. This process helps them find weak points and improve designs before mass production. Battery Contact Designers often lead the push for smaller, lighter, and safer battery connections.

Conseil : Battery Contact Designers often recommend gold-plated contacts for wearables. Gold resists sweat and moisture, which protects the battery from damage.

Industry Collaboration

Collaboration drives progress in battery technology. Battery Contact Designers work with engineers, manufacturers, and material scientists. Together, they solve problems and share new ideas. Teams often meet to discuss challenges like heat management and fast charging.

Industry groups set standards for safety and performance. Designers join these groups to help write new rules. They also attend conferences to learn about the latest trends. Many companies form partnerships to speed up innovation. For example, a battery company might team up with a wearable device maker to create a custom solution.

| Stakeholder | Role in Collaboration |

|---|---|

| Designers | Develop and test new contacts |

| Engineers | Integrate contacts into devices |

| Manufacturers | Produce at scale |

| Material Scientists | Suggest new materials |

Collaboration ensures that LiPo connections meet the needs of modern devices. It also helps the industry move forward quickly and safely.

2025 Trends

Compact and Modular Designs

Device manufacturers now demand smaller, lighter, and more adaptable power solutions. Compact LiPo batteries, including pouch cells and custom-shaped cells, fit tightly into limited spaces. This flexibility allows engineers to optimize device layouts and maximize space efficiency, which is critical for wearables and IoT devices. Modular LiPo battery packs enable stacking or connecting modules in series or parallel. This approach lets designers scale capacity and voltage to meet different power needs without redesigning the entire system. Modular designs also support easy upgrades and maintenance, which is essential for rapidly evolving applications.

Remarque : Modular battery packs with integrated Battery Management Systems (BMS) provide real-time monitoring, protection, and communication. These features ensure safe operation and reliable performance, which are vital for compact devices where safety and reliability directly impact user experience.

Smart and Custom Features

Modern LiPo connection systems now include smart features that enhance device functionality. Special-shaped batteries, such as ultra-thin, round, or cylindrical forms, allow integration into unique products like smartwatches, medical wearables, and foldable devices. This adaptability supports innovative designs that were not possible with standard battery shapes.

Smart LiPo battery packs often include advanced components like BMS and Protection Circuit Modules (PCM). The BMS manages charging and discharging, while the PCM protects against overcharge, over-discharge, and short circuits. These features enable real-time monitoring of battery status, health, and performance. Custom LiPo batteries can also include NTC sensors and specialized connectors, allowing precise control over discharge rates and power delivery. This level of customization supports specialized applications in robotics, drones, and medical devices.

Safety and Fast Charging

Safety and fast charging remain top priorities for Battery Contact Designers. Recent laboratory and field tests have validated new safety measures and charging protocols. Surface engineering of anode materials, such as coating graphite anodes with aluminum oxide, improves reversible capacity and supports fast charging at high rates. The use of spinel Li titanate as an anode material reduces lithium plating risks, enhancing safety during rapid charging.

Advanced battery management systems use sophisticated algorithms to control charging rates and monitor battery conditions. These systems minimize lithium plating and improve overall safety. Thermal management strategies, including advanced electrode and electrolyte designs, prevent overheating and thermal runaway. Optimized charging protocols and robust onboard detection methods further reduce risks, enabling faster and safer charging for all device types.

Sustainable Materials

Sustainability drives innovation in LiPo connection systems. Manufacturers now explore eco-friendly materials and processes to reduce environmental impact. The use of recyclable metals and non-toxic components supports greener production. Battery Contact Designers also focus on reducing waste by designing batteries with longer lifespans and improved recyclability.

Conseil : Choosing sustainable materials not only benefits the environment but also aligns with global regulations and consumer expectations for greener products.

Advanced Manufacturing

Advanced manufacturing methods have transformed LiPo battery production. Improved mixing technologies, efficient coating processes, and automated assembly lines ensure high-quality, structurally sound batteries. These innovations lead to enhanced performance and reliability, which benefit the connection systems by providing stable and consistent outputs.

Manufacturers like PKCELL use stringent quality control and advanced processes to produce durable LiPo cells with customized connectors. This approach ensures reliable performance and longer cycle life. New cooling technologies, such as carbon nanotube-coated micro heat pipes, improve thermal management by up to 71% compared to conventional methods. Better heat transfer prevents overheating and failure, supporting the performance and reliability of both batteries and their connection systems.

Key Innovations in 2025:

- 3D current collectors increase surface area for improved current flow.

- Enhanced current interfaces reduce resistance and boost efficiency.

- Automated assembly ensures consistency and reduces defects.

| Trend | Benefit for Applications |

|---|---|

| Miniaturization | Smaller, lighter devices |

| Modularity | Scalable, upgradable power |

| Smart Contacts | Real-time monitoring, safety |

| Fast Charging | Reduced downtime |

| Durabilité | Lower environmental impact |

| Advanced Manufacturing | Reliable, high-performance cells |

Wearables, IoT, and renewable energy devices all benefit from these trends. The result is safer, more efficient, and more adaptable products that meet the demands of modern users.

Real-World Impact

Performance Gains

New LiPo connection trends deliver clear performance improvements across many devices. Advanced Battery Management Systems (BMS) now monitor voltage, current, and temperature in real time. This technology balances each cell, prevents overcharging, and optimizes energy use. As a result, batteries last longer and work more efficiently. In portable medical devices, app-based monitoring systems track battery status and send safety alerts. These features help users rely on their devices for longer periods without frequent charging. Flexible and compact LiPo designs fit into small spaces, making them ideal for mobile healthcare and smart devices.

Safety Improvements

Safety remains a top priority for battery contact designers. Modern LiPo batteries include built-in protection against overcharge, over-discharge, and short circuits. These features reduce the risk of battery failure and extend battery life. Safety certifications and smart BMS systems add extra layers of protection. In electric vehicles and drones, these advancements prevent overheating and thermal runaway. Users can trust their devices to operate safely, even in demanding conditions.

Conseil : Always choose LiPo batteries with certified safety features for critical applications like medical wearables and electric vehicles.

User Experience

Users now enjoy simpler and more reliable battery systems. For example, the BetaFPV BT3.0 connector combines balance and power connections into one, reducing cable clutter. This design makes charging easier and keeps devices lighter. However, some users find the connector tight, which can make disconnection tricky. As more compatible batteries and chargers become available, these systems will offer even greater convenience. Overall, streamlined connectors and smart monitoring improve daily use and reduce maintenance.

Domaines d'application

Emerging LiPo connection trends benefit a wide range of industries. The table below highlights key sectors and their specific advantages:

| Domaine d'application | Benefits |

|---|---|

| Medical Devices & Wearables | Safety, compactness, flexibility; enables continuous monitoring and implantable devices |

| Véhicules électriques (VE) | High energy density, lightweight design; supports longer travel and improved efficiency |

| Électronique grand public | Lightweight, compact, custom shapes; allows thinner, lighter devices |

| Drones & Remote-Controlled | High capacity, lightweight; longer flight times, better performance |

| IoT Devices | Efficient, reliable energy; supports extended operation in smart environments |

LiPo batteries power fitness trackers, smartwatches, drones, and electric vehicles. Their flexibility and energy density support comfort, long use, and advanced features. These trends drive innovation and growth in each sector.

Future Outlook

Upcoming Standards

Industry leaders expect new standards for LiPo connection systems in 2025 and beyond. Companies like HobbyKing recognize that high energy density and strong performance require strict safety and transportation rules. They adapt their products to meet these regulations, ensuring safe handling and shipping. Many companies align their practices with airline carry-on restrictions and shipping laws. This approach combines certification, design improvements, and regulatory compliance.

- Most LiPo batteries now meet UL2054 certification. This standard requires tough electrical, mechanical, and safety tests.

- Protective circuits monitor and control charging voltages. These circuits prevent overcharge and over-discharge.

- Connectors use recessed terminals, keyed designs, or covers to stop accidental short-circuits.

- External connectors must use flame-retardant materials with V-2 or V-1 flame ratings.

- Battery pack enclosures have fewer openings to protect cells and circuits.

- Printed wiring boards must meet flame resistance standards.

- Protection circuits check each cell or block to keep voltage within safe limits.

- Testing includes forced-discharge and limited power source tests to ensure safety under fault conditions.

Leveraging Innovations

Battery Contact Designers continue to drive innovation by using new materials and smart designs. They adopt 3D current collectors and advanced manufacturing to improve current flow and reduce resistance. Many companies use automated assembly lines for consistent quality. Smart connectors and modular systems allow easy upgrades and repairs. These changes help companies stay ahead of industry trends and meet new standards.

Conseil : Companies that invest in research and development can quickly adapt to new rules and offer safer, more reliable products.

Preparing for Change

Companies prepare for future changes by training staff and updating their processes. They work with industry groups to learn about new standards early. Many teams test new designs before rules take effect. This proactive approach helps them avoid delays and stay competitive.

| Preparation Step | Bénéfice |

|---|---|

| Staff Training | Faster adoption of new rules |

| Early Testing | Fewer product recalls |

| Industry Collaboration | Access to latest information |

| Design Updates | Improved safety and compliance |

Battery Contact Designers play a key role in this process. They help companies understand new requirements and design products that meet or exceed standards. As the industry moves forward, companies that embrace change will lead the market.

Battery Contact Designers lead the way in shaping LiPo connection systems through innovation and sustainable practices. Their work brings safer, more efficient devices to users and industries. To stay ahead, experts suggest:

- Hands-on training and simulation tools for skill development

- Mentorship and regular updates from device manufacturers

- Continuing education and certification for high standards

Organizations can proactively leverage new trends by:

- Adopting advanced technologies and customizing user experiences

- Maintaining strict quality and safety standards

- Engaging communities and tracking performance for ongoing improvement

Staying informed and proactive ensures lasting success in this fast-evolving field.

FAQ

What makes modular LiPo battery designs important?

Modular LiPo batteries allow users to swap or upgrade cells easily. This design supports longer device life and simple repairs. Many industries choose modular systems for flexibility and cost savings.

How do smart connectors improve safety?

Smart connectors monitor battery status and prevent unsafe charging. They alert users to problems like overheating or overcharging. These features help protect both the device and the user.

Which industries benefit most from new LiPo connection trends?

| Industry | Key Benefit |

|---|---|

| Produits portables | Smaller, lighter devices |

| IoT | Reliable, long-lasting |

| Dispositifs médicaux | Enhanced safety |

| EVs | Fast charging, efficiency |

Why do designers use gold-plated contacts?

Gold-plated contacts resist corrosion and moisture. This material ensures a stable connection, especially in wearables. Devices last longer and work better with gold-plated contacts.

Can users recycle LiPo batteries safely?

Users should take LiPo batteries to certified recycling centers. These centers follow strict safety rules. Never throw LiPo batteries in regular trash, as they can cause fires or leaks.