Introduction: Why Battery Packaging Is Mission-Critical for EVs

Electric vehicle battery packaging is not only about encasing cells—it is the front line for passenger safety, system reliability, and regulatory market access. As the National Renewable Energy Laboratory (NREL) notes, battery fires and thermal incidents, though statistically rare, cause disproportionate recalls and reputational harm (NREL Energy Storage Safety). Only a holistic approach—balancing mechanical, thermal, and diagnostic engineering—can ensure robust EV performance and compliance in a fast-evolving risk landscape.

Key Challenges in Automotive Battery Packaging

- Thermal runaway & fire propagation: Lithium-ion chemistries are sensitive to overheating and can experience catastrophic failure without advanced mitigation layers.

- Mechanical trauma (crash, vibration, drop): Battery packs are often structural components and must survive severe impact and deformation.

- Regulatory compliance hurdles: Global shipping, market entry, and warranty require passing a gauntlet of safety and abuse tests (e.g., UN 38.3, IEC 62660).

- Field defects & counterfeit risk: Faulty cell/module assembly can remain latent until detected by inline diagnostics or after field failure (see BMW recall case below).

- Sustainability & lifecycle demands: New EU regulations mandate design for disassembly and recycling.

Global Safety & Performance Standards: At-a-Glance

| Standard | Champ d'application | Key Test Elements | Applicabilité |

|---|---|---|---|

| UN 38.3 | Transport safety | Altitude, thermal, vibration, shock, short-circuit | Mandatory for global shipping |

| IEC 62660 | In-vehicle cell/module performance | Electrical, cycling, mechanical, abuse tests | Industry/market entry |

| SAE J2464 | Abuse and safety | Physical/crash, fire/explosion, thermal, electrical | North America, global OEM |

| UL 2580 | Vehicle pack-level testing | Electrical, mechanical, environmental | US compliance, insurance |

| ISO 26262 | Functional safety (system level) | Diagnostics, control, risk management | Global, system integrators |

For detailed breakdowns, see Grepow: EV Battery Certifications

Best Practices for Automotive Battery Packaging Safety and Performance

1. Design for Compliance—Map Engineering to Each Standard

An effective packaging solution is engineered backwards from the most stringent regulatory hurdle. Integrate pass/fail criteria from UN 38.3, IEC 62660, SAE J2464, etc., into every design review and prototyping stage:

- Systematically document internal tests before third-party certification.

- Utiliser un “design → simulation → physical test → failure mode feedback” loop to catch issues before scale-up.

- Build compliance documentation in parallel with design iteration for faster market approval.

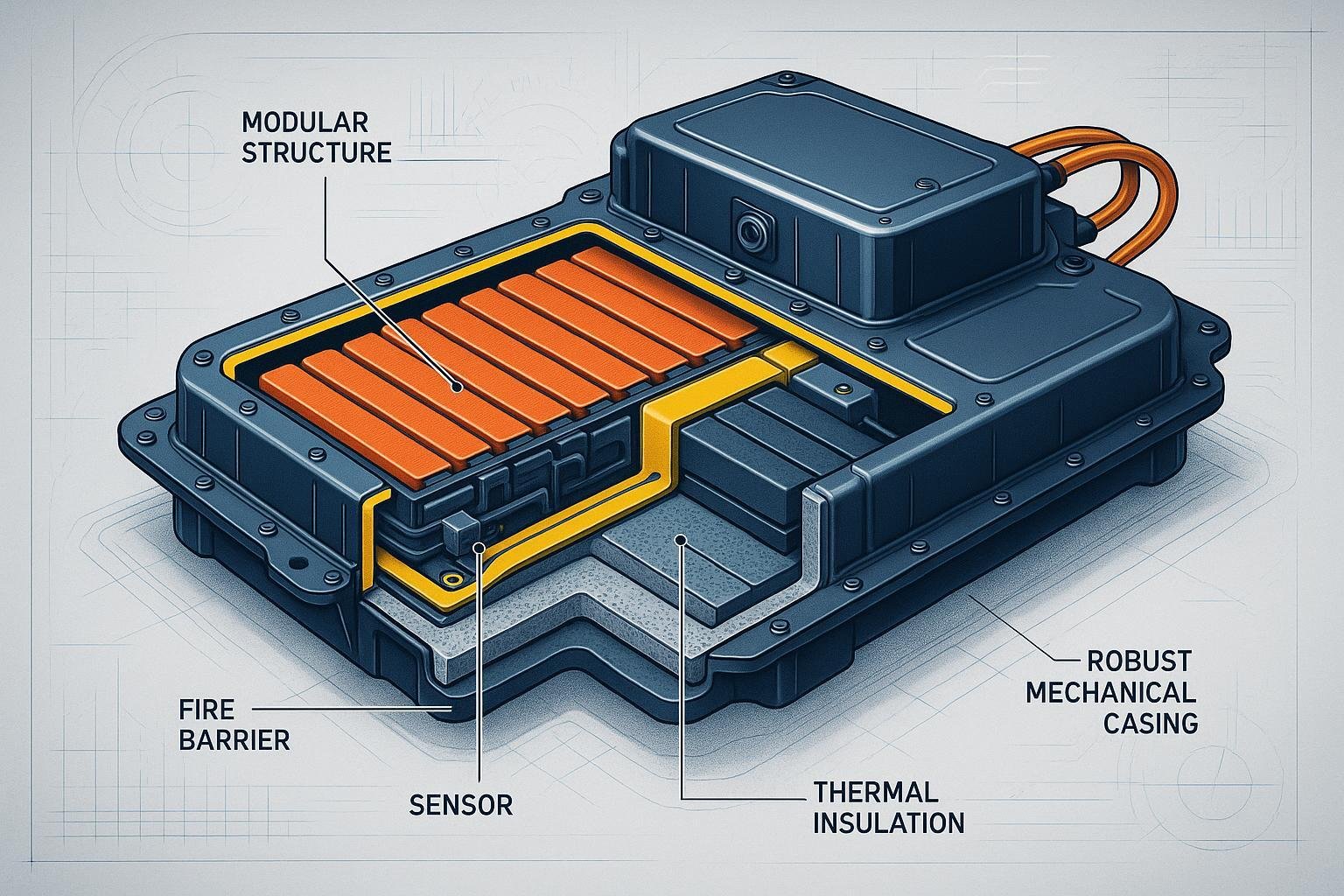

2. Advanced Thermal Management: Prevention, Containment, Diagnostics

Thermal runaway is the dominant catastrophic risk. Field and lab evidence show best-practice packaging involves:

- Integrated heat sinks, liquid cooling plates, or microchannel systems for even temperature management.

- Layers of thermal/fire barrier materials (e.g., intumescent coatings, fire-retardant foams, robust cell spacing) to limit propagation (NREL, 2023).

- Predictive modeling (CFD, FEA) to identify hotspots BEFORE physical build (Hexagon Simulation Suite).

- Embedded sensors and BMS with AI-driven analytics for early abnormality alerts.

3. Mechanical and Crash Robustness: Simulate, Validate, Protect

- Perform drop, crush, vibration, and penetration tests matching or exceeding SAE J2464/UL 2580 specs.

- Deploy crash rails, foam reinforcements, and deformable elements to manage impact energy away from cells.

- Use real field incident data (recalls/failures) to refine structure: statistical analyses show <0.01% OEM field failure can be achieved with rigorous validation (NTSB/NHTSA data).

4. Inline Quality Control & Diagnostic Integration

- Implement real-time X-ray/CT and EOL (end-of-line) electrical/thermal scans pre-delivery.

- Use defect tracking with AI/ML to spot process drift/counterfeit parts.

- Archive QC data for regulatory traceability in case of field incidents.

- Case in point: BMW i Series recall due to latent module damage from improper assembly—preventable with inline diagnostic feedback.

5. Lifecycle & Sustainability: Design for Disassembly & Recycling

- Comply with evolving EU Battery Directive and forthcoming UN guidelines on recyclability.

- Choose materials and fasteners supporting quick cell/module removal without damage.

- Label and document materials/components for downstream recycling chain.

6. Robust Testing Workflow and Validation Tools

- Use simulation suites such as MSC Nastran, Marc, Cradle CFD (Hexagon) ou GT-AutoLion for multi-physics modeling: thermal, electrical, and structural.

- Conduct abuse propagation studies in-lab and correlate with field/incident data.

- R&D teams: integrate XRD-CT, calorimetry, and high-fidelity diagnostic tools for state-of-the-art failure mode understanding (NREL, Embedded.com).

Case Studies: Recalls and Field Lessons

| Company/Case | Root Cause | Outcome | Mitigation Lesson |

|---|---|---|---|

| BMW i4/iX/i7 (2022-25) | Cell-to-module assembly defect | Recall, replacement | Inline diagnostics, improved process control |

| NREL Advanced Thermal Research | In-depth propagation studies/warnings | Updated safety protocols | Full lifecycle test-to-field validation |

| BYD, GM, Others | Crash/thermal propagation faults | Field recalls, safety redesigns | Stack abuse/thermal and crash protection |

(See BMW recall sources, NREL field reports)

Innovations & Future Trends

- Cell-to-pack/chassis architectures to increase energy density and structural integration

- Solid-state and new chemistry adoption for improved thermal stability

- Embedded AI/ML diagnostics for predictive failure prevention

- Lifecycle-focused recyclability and sustainability mandates

Expect compliance and performance thresholds to tighten with each regulatory update. Proactive adoption of forward-looking solutions can future-proof both safety and commercial viability.

Quick-Reference Best Practices Checklist

- [ ] Map design specs to each regulatory standard (UN 38.3, IEC 62660, SAE J2464, UL 2580)

- [ ] Integrate advanced thermal/fire barriers and active cooling

- [ ] Simulate and physically validate mechanical and crash protection

- [ ] Deploy inline QC tools (X-ray, AI diagnostics, EOL functional testing)

- [ ] Document lifecycle, recyclability, and component traceability

- [ ] Use multi-physics simulation to forecast and resolve complex packaging challenges

- [ ] Analyze real-world recall/failure data for continuous process refinement

- [ ] Stay updated with regulatory and technology shifts

Conclusion

Automotive battery packaging is a science defined by detail: it is not just about passing factory tests, but about achieving ultra-low field failure, maximizing EV safety, and staying ahead of regulatory and innovation curves. By embedding these best practices—grounded in international standards, field data, and engineering experience—every automotive battery project can deliver world-class safety and performance outcomes.

Further Reading/Resources: