Charging lithium-ion batteries without overcharge protection is a critical safety issue. An overcharge pushes the lithium-ion battery cell voltage too high. This overcharging destroys the battery capacity. The li-ion battery voltage climbs, causing the battery to swell and enter thermal runaway. This dangerous charge destroys the li-ion battery.

These safety considerations are predictable. The li-ion battery needs protection. All batteries need voltage protection for safety. The li-ion battery capacity depends on safe charging. The voltage of all batteries must be controlled. The li-ion battery capacity is at stake. A safe charge for any li-ion battery is a must. All batteries need this safety. The voltage during charging is key. The charging must be monitored. The charging voltage is important. The charging process needs protection. The battery capacity is vital. The batteries need care. The voltage is a key metric. The battery capacity is reduced. The batteries swell. The batteries are a risk. This charging is dangerous. This charging must stop. The li-ion battery is a risk without protection. The battery capacity is lost. The batteries need safe charging. The voltage is high. The li-ion battery is a risk. All batteries need this protection. The voltage is high. The charging is dangerous. The li-ion battery capacity is lost. The batteries need a safe charge. The voltage is high. The li-ion battery capacity is lost. The batteries need a safe charge. The voltage is high. The battery capacity is lost. The battery capacity is lost. The li-ion battery has no capacity. The battery has no capacity. The overcharge is bad. The overcharge is bad.

The Critical 4.2V Charging Threshold

The 4.2-volt mark is a fundamental limit in the world of li-ion batteries. For most common lithium-cobalt oxide cells, this number represents the full charge voltage. Les lithium-ion battery cell voltage should not exceed this point. Manufacturers build in a small tolerance, typically around +/- 50 millivolts (mV). Pushing the voltage beyond this precise ceiling begins a destructive process. The nominal voltage of a li-ion battery is lower, around 3.7V, representing its average voltage pendant décharge. The safe voltage range of a li-ion battery cell exists between its discharge cutoff voltage and its full charge voltage. Exceeding these voltage thresholds compromises battery safety and longevity.

Understanding Li-ion Chemistry

Not all li-ion batteries share the same chemistry or voltage limits. The 4.2V standard applies to specific types. Other chemistries require different charging protocols for optimal safety et efficiency.

| Chimie | Maximum Charging Voltage |

|---|---|

| Phosphate de fer lithié (LiFePO4) | 3.65V/cell |

| Titanate de lithium (LTO) | 2.85V/cell |

Un overcharge event triggers harmful chemical reactions inside a li-ion battery. When the lithium-ion battery cell voltage is too high, the anode becomes saturated. Excess lithium ions can no longer integrate into the anode’s structure. Instead, they deposit on the surface as metallic lithium. This process, known as lithium plating, permanently reduces battery capacity et efficiency.

Simultaneously, the high voltage destabilizes other components.

- The electrolyte begins to oxidize, or break down, at high potentials. This reaction produces gases like carbon dioxide (CO2).

- The cathode material releases reactive oxygen. This oxygen then attacks the electrolyte, creating more gas and even water.

- These harmful byproducts can travel to the anode. They damage the protective Solid Electrolyte Interphase (SEI) layer, consuming active lithium and further reducing

capacity.

This chain reaction degrades battery performance and is a primary reason why a proper charge cycle is critical for li-ion battery safety. Les charging process must respect these chemical boundaries.

The Path to Thermal Runaway

Thermal runaway is a li-ion battery‘s most dangerous failure mode. It is a rapid, self-sustaining cycle of overheating. An overcharge is a direct path to this catastrophic event. The process unfolds in distinct stages.

- Initial Damage: High-current

chargingfirst damages the internal structure of thebattery. - Slow Heating: Les

battery‘s internal resistance increases. This increased resistance generates significant heat duringcharging, even as the flow of lithium ions slows. - Gas Production: Internal electrochemical reactions accelerate. These reactions start producing volatile gases, causing the

batteryto swell. - Accelerated Heating: Les

chargingcontinues to generate immense heat. The internal temperature and pressure build rapidly. - Rapid Failure: Heat generation overwhelms the

battery‘s ability to cool itself. The temperature spikes, leading to a violent venting of hot gases, fire, or explosion.

Remarque : This dangerous cycle happens because the rate of heat generation exceeds the rate of heat dissipation. Rising temperatures speed up chemical reactions, which in turn generate more heat. This positive feedback loop makes the progression of thermal

runawayextremely quick and violent. Thedéchargeprocess also generates heat, butsurchargecreates a much more hazardous situation.

Signs of Battery Damage

A li-ion battery damaged by surcharge often provides clear warning signs. Recognizing these signals is essential for safety. You should immediately stop charging and safely isolate any batteries showing these symptoms.

Physical Signs:

- Swelling or Bulging: This is the most common sign. Gas buildup from internal reactions causes the

batterycasing to puff up or deform. - Surchauffe : Les

batteryfeels unusually hot to the touch during or aftercharging. - Discoloration: Les

batterywrapper or case may show burn marks, stains, or other discoloration. - Strange Odors: A sharp, chemical, or burnt smell indicates that the electrolyte is venting.

- Hissing Sounds: Audible hissing or crackling means gas is escaping from the cell.

Performance-Related Signs:

Even a single overcharge event can permanently damage battery capacity et efficiency. Les lithium-ion battery cell voltage may seem normal, but the damage is done. After an overcharge, a li-ion battery will exhibit poor performance. It will lose its charge much faster, and its overall capacity will be significantly lower. The décharge cycle will be much shorter. The nominal voltage of a li-ion battery may drop quicker during décharge. Its efficiency plummets, and its lifespan is drastically shortened. Les voltage range of a li-ion battery cell is compromised, affecting both charging et décharge. This loss of capacity is irreversible. Continued use of such batteries poses a serious safety risk.

Fonctionnement de la protection contre les surcharges

Modern electronics prevent the dangers of an overcharge using sophisticated safety circuits. These circuits act as vigilant guardians for every li-ion battery. They ensure the charging process remains within safe limits. This protection is not an optional feature; it is a fundamental requirement for li-ion battery safety. Without this essential management, the risk of failure increases dramatically.

The Role of the PCM and BMS

A Protection Circuit Module (PCM) is the first line of defense for a li-ion battery. This small electronic board provides critical safety functions. A PCM constantly monitors the battery to prevent dangerous conditions. Its primary job is to protect the battery during both charging and discharging. This protection extends the battery’s operational life and preserves its capacity.

A PCM offers several layers of safety:

- Protection contre les surcharges: It stops the charging process if the voltage goes above the safe limit, preventing an overcharge.

- Over-discharge Protection: It disconnects the battery if the voltage drops too low, which would cause permanent damage to the battery capacity.

- Overcurrent and Short-Circuit Protection: It cuts power instantly if the current is too high or if a short circuit occurs, preventing catastrophic failure.

For more complex applications with multiple batteries, a more advanced system is necessary. A système de gestion de la batterie (BMS) provides comprehensive oversight. A BMS is an intelligent system that performs advanced battery management. It uses microcontrollers and sensors for precise monitoring of each individual li-ion cell. This system analyzes the battery’s State of Health (SoH) to evaluate its overall condition and aging. A key function of this management system is cell balancing. It ensures all cells in a pack have a consistent voltage, which maximizes the usable capacity and lifespan of the entire pack of batteries.

Halting the Charging Process

Smart chargers and protection circuits use a specific method to stop charging at the perfect moment. They follow a process called Constant Current/Constant Voltage (CC/CV). The TP4056 is a common integrated circuit (IC) that shows how this works. This chip is a great example of effective overcharge protection in action.

The charging process unfolds in two main stages.

- Constant Current (CC) Phase: Initially, the charger supplies a steady current to the li-ion battery. During this phase, the battery voltage rises steadily. The charger continues this constant current charging until the voltage approaches the

full charge voltageof 4.2V. - Constant Voltage (CV) Phase: Once the

lithium-ion battery cell voltagenears 4.2V, the charger switches modes. It holds the voltage steady at thefull charge voltagelimit. An internal comparator continuously checks the battery’s voltage. In this phase, the charging current naturally begins to decrease as the battery becomes full.

How does it know when to stop? The charging cycle is complete when the charging current drops below a set level. For the TP4056, this termination happens when the current falls to one-tenth of the initial charge rate. At that point, the circuit cuts off the power completely. This two-step process ensures the battery reaches its maximum capacity without the risk of an overcharge. This precise management is vital for the long-term health and safety of all li-ion batteries.

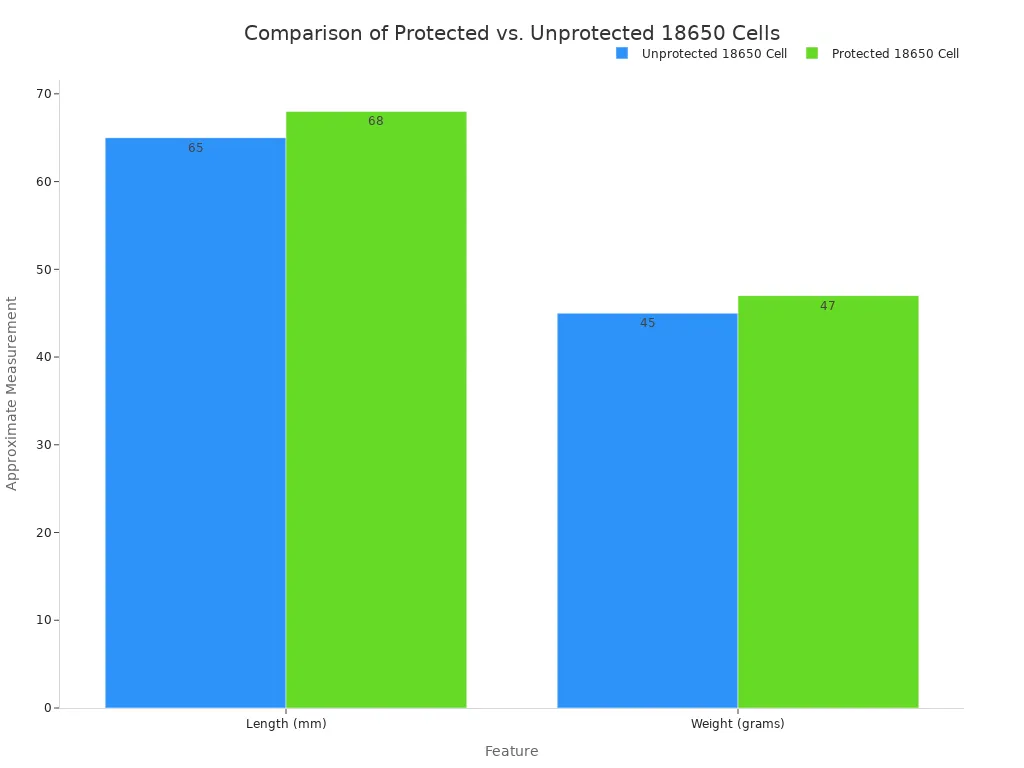

Protected vs. Unprotected Cells

Users can often identify whether a li-ion battery has built-in protection. A “protected” battery has a small electronic circuit, the PCM, physically attached to it. This circuit provides full-time monitoring and safety. An “unprotected” battery is a bare cell without this integrated safety board. These unprotected batteries rely entirely on the charger or the device for overcharge protection. Using unprotected batteries without a separate management system is extremely risky. Failures in devices like hoverboards and laptops have been linked to unprotected cells or inadequate battery management, leading to recalls and safety alerts.

Visually, there are several clues to tell these batteries apart. A protected li-ion battery is slightly longer and heavier to accommodate the extra circuit. The protection circuit is usually a small disc located at one end of the battery, hidden underneath the plastic wrapper.

The table below summarizes the key differences for a standard 18650 li-ion cell.

| Fonctionnalité | Unprotected 18650 Cell | Protected 18650 Cell |

|---|---|---|

| Length | ~65mm | ~68-70mm |

| Wrapper | Single, smooth layer | May have a second layer covering the circuit |

| Appearance | Flat top and bottom terminals | May have a “button top” positive terminal |

| Labeling | Varies | Often explicitly states “protected” |

This added protection is a non-negotiable safety feature for consumer use. It ensures the battery operates within its designed voltage limits, preserving its capacity and preventing dangerous failures. Always choose batteries with proper protection for any project or device.

Essential Li-ion Safety Rules

Following proper safety rules is crucial for handling any li-ion battery. These guidelines help prevent accidents and prolong battery life. Correct charging and daily use habits are key safety considerations for every user. These practices protect the battery and ensure better battery performance.

Using the Correct Charger

Using the right charger is the most important step for li-ion battery safety. A li-ion battery requires a charger with a specific Constant Current/Constant Voltage (CC/CV) charging profile. Generic DC power adapters lack this essential feature and can cause a dangerous overcharge.

The CC/CV charging process works in two stages:

- Constant Current: The charger supplies a steady current, causing the battery voltage to rise.

- Constant Voltage: When the voltage nears the 4.2V limit, the charger holds the voltage constant. The charging current then slowly drops. The charging stops completely when the current is very low.

⚠️ Avertissement : Never use a charger not designed for your specific li-ion batteries. A mismatched charger cannot communicate with the battery. This can lead to overheating, fire, and a total loss of capacity. Always check the charger’s label to confirm its voltage matches the battery’s requirements.

Best Practices for Daily Use

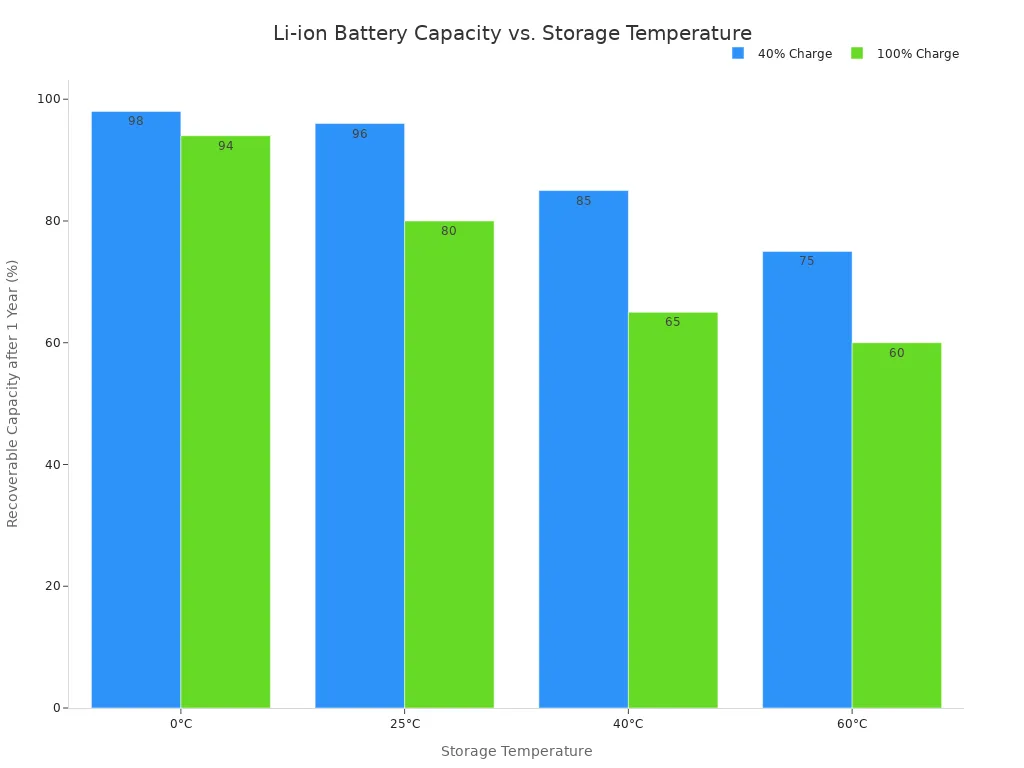

Proper daily habits can significantly prolong battery life and maintain its efficiency. For maximum longevity, it is best to keep the li-ion battery charge between 20% and 80%. This “sweet spot” reduces stress on the battery components. Avoiding full 100% charging and deep discharging below the discharge cutoff voltage helps prolong battery life. This simple habit can greatly prolong battery life.

Storing batteries correctly also helps prolong battery life. For long-term storage, a li-ion battery should be kept at a 40-50% charge. The ideal storage temperature is around 15°C (59°F). Storing a fully charged battery, especially in warm conditions, permanently reduces its capacity and efficiency. This practice will prolong battery life. Following this tip will prolong battery life and improve battery performance. This is the best way to prolong battery life.

When to Stop Charging Immediately

A damaged li-ion battery often gives clear warning signs. Recognizing these signals is vital for safety. You must stop charging immediately if a battery shows any of these symptoms:

If you notice any of these signs, unplug the device from the charger. Carefully move the battery to a non-flammable surface like concrete, away from anything that can burn. Do not try to use or continue charging the damaged battery. This immediate action is a critical safety measure to prevent a fire. This helps maintain overall safety.

An overcharge event is a direct path to destroying a li-ion battery. Pushing the lithium-ion battery cell voltage too high during charging causes a total loss of battery capacity and creates a severe safety hazard. Overcharge protection is a non-negotiable safety feature, not an optional add-on. This charging protection is essential for all li-ion batteries. Industry safety standards mandate this protection for every li-ion battery.

- UL 1642 & UL 2054

- UL 2595

- IEC 62133

Respecting the charging voltage of every li-ion battery is fundamental to safety. This protection preserves battery capacity. The charging voltage for each li-ion battery needs this protection. The battery capacity and safety of all batteries depend on this charging protection. The li-ion battery voltage and capacity need this charging protection. The battery voltage and capacity need this charging protection. The li-ion battery voltage and capacity need this charging protection. The battery voltage and capacity need this charging protection. The li-ion battery voltage and capacity need this charging protection.

FAQ

What happens if a li-ion battery is overcharged?

An overcharge pushes the li-ion battery voltage too high. This dangerous charging destroys the battery capacity. The li-ion battery can swell or enter thermal runaway. This unsafe charging process is a major risk. The high voltage from this charging permanently damages the li-ion battery.

Why is a specific charger needed for li-ion batteries?

Li-ion batteries need a special CC/CV charging process. The charger must control the charging voltage precisely. A generic power supply provides a constant voltage that will overcharge the battery. This incorrect charging ruins the battery capacity. Proper charging is essential for all li-ion batteries.

How does storage affect li-ion battery capacity?

Storing a li-ion battery at 100% charge degrades its capacity. The sustained high voltage stresses the battery. For long-term storage, a 40-50% charge is ideal. This lower voltage state helps preserve the battery capacity. This rule applies to most li-ion batteries.

Is partial charging better for li-ion batteries?

Yes, partial charging is better for li-ion batteries. Keeping the charge between 20% and 80% reduces stress. This practice maximizes the battery capacity and lifespan. The battery avoids the strain of very high or low voltage levels. This charging habit helps all batteries.