If you get voltages right on LiPo (lithium‑ion polymer) packs, most other things get easier: longer cycle life, fewer field failures, and simpler compliance. This guide distills what consistently works in production and in the lab—voltage ranges that engineers actually set, the workflows we use to hit them, and the trade‑offs to consider.

- Scope: pouch‑type Li‑ion (aka LiPo) cells and packs in consumer and industrial devices

- Assumption: standard chemistry at 4.20 V/cell max unless a datasheet explicitly specifies a high‑voltage variant

Always validate against the specific cell or pack datasheet. High‑voltage chemistries (e.g., 4.35 V) are not interchangeable with 4.20 V cells, and thresholds must match the chemistry, as summarized by the practical CC‑CV guidance in the 2025 updates to Battery University’s charging overview.

Quick‑Reference Voltage Ranges (Per Cell)

| Mode | Target/Limit | Notes |

|---|---|---|

| Charging (standard LiPo) | Max 4.20 V | CC‑CV method; typical CC 0.5C–1C; terminate at ~0.05–0.1C per widely used practice summarized by Digi‑Key’s 2021 CC‑CV tutorial. |

| High‑voltage LiPo (if specified) | Up to 4.35 V | Only if datasheet allows; for example, Murata’s HV pouch US515569H5 specifies 4.35±0.05 V with CC‑CV parameters in the official Murata US515569H5 datasheet. |

| Discharge (longevity‑oriented) | Avoid <3.0–3.2 V | Under load, set BMS cutoff around 3.0–3.3 V/cell to prevent deep discharge; this aligns with common pack practices reflected in TI BQ40Z50 documentation (TRM, 2024). |

| Stockage | 3.70–3.85 V | ~40–60% SOC. This range minimizes calendar fade per storage guidance in Battery University BU‑702 (2024). |

Why these numbers: CC‑CV charging to 4.20 V is the mainstream standard, while storing near the mid‑SOC band reduces long‑term chemical stress. Deep discharge accelerates degradation; keeping the lower cutoff conservative pays back in cycle life, a trend documented in lab and field literature (see the cycle/calendar aging section below).

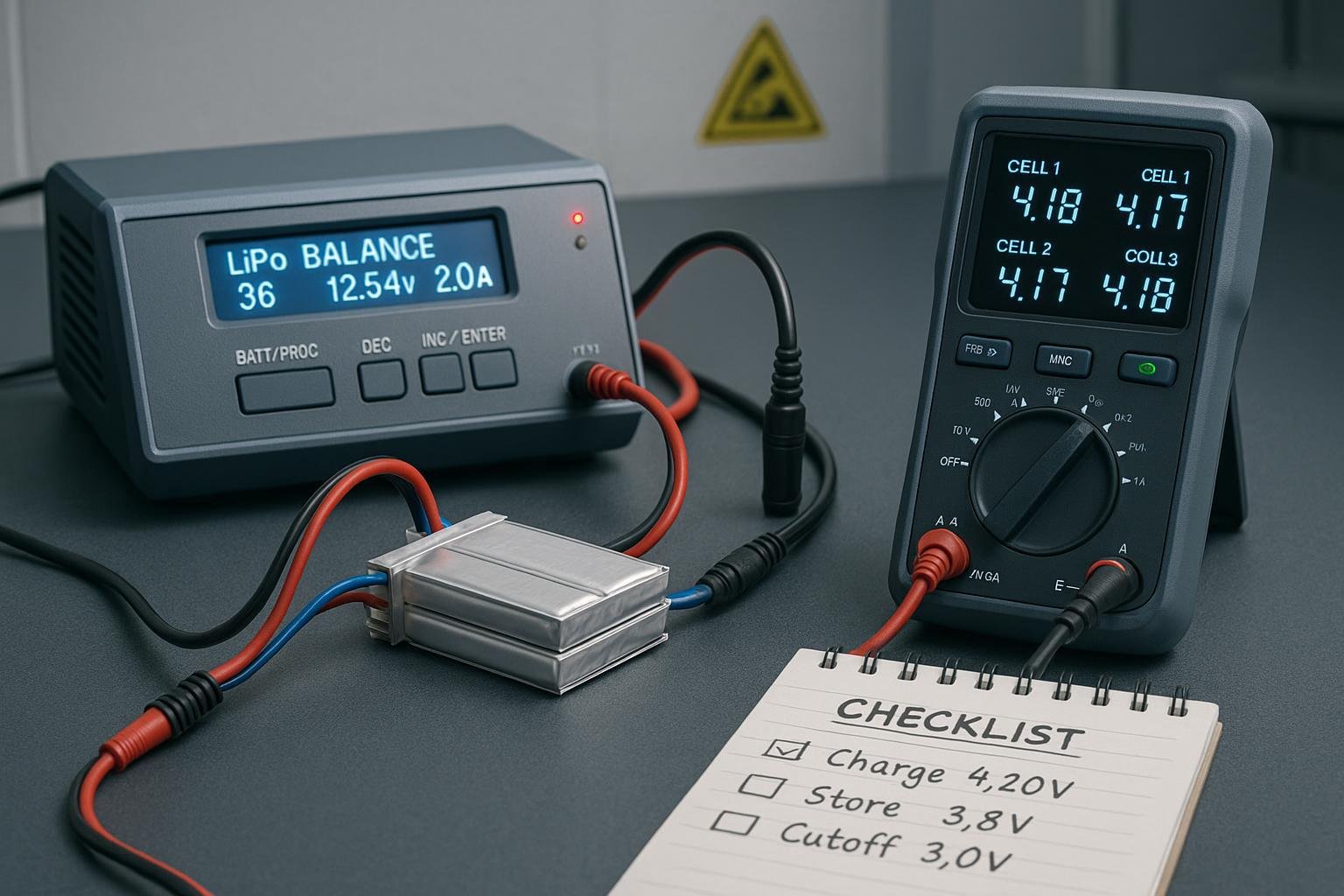

Charging Workflow That Protects Cells (CC‑CV Done Right)

This is the protocol we run on benches and production testers for standard 4.20 V/cell LiPo, adapted per datasheet.

Pre‑checks (2–3 minutes per pack)

- Visual inspection: no swelling, no odor, no shell damage.

- Measure open‑circuit voltage (OCV): reject or recondition packs <3.0 V/cell before standard charging.

- Temperature: ensure 10–30 °C if possible; do not charge below 0 °C to avoid lithium plating, as warned in Battery University’s temperature charging note (2024).

Instrument setup

- Charger mode: CC‑CV lithium‑ion.

- Voltage limit: 4.20 V/cell (or datasheet value for HV chemistries).

- Current limit: start at 0.5C for longevity; up to 1C if cycle‑time matters and the datasheet permits, consistent with CC‑CV summaries such as the Digi‑Key 2021 tutorial.

- Termination: 0.05–0.1C during the CV phase, validated per datasheet.

Balance charging for multi‑cell packs

- Use balance leads; initiate balancing when cell delta exceeds ~15–20 mV. This threshold aligns with common BMS practice found across pack managers such as TI’s BQ40Z50 family documentation.

Charge execution and monitoring

- CC phase: allow current to flow until the pack reaches the voltage setpoint.

- CV phase: hold 4.20 V/cell; terminate when current tapers to the programmed threshold.

- Temperature watch: stop and cool if you see abnormal rise beyond spec (e.g., internal >45 °C during charge).

Post‑charge checks

- Rest 30–60 minutes; verify per‑cell voltages are within ±50 mV of each other. This tolerance window is a widely cited practical target for maintaining balance, consistent with guidance in Battery University BU‑409 (2025).

Trade‑offs: Reducing the upper cutoff slightly can substantially extend cycle life. A commonly observed heuristic, summarized by Battery University BU‑808 (2024), is that dropping from 4.20 to ~4.10 V can markedly improve cycle life at the cost of ~10% peak capacity. Validate for your duty cycle.

Discharging Workflow: Performance Without Over‑Stress

Define cutoffs in the BMS or load profile

- For general longevity, set load or BMS cutoff ≈3.1–3.3 V/cell. This provides margin above deep‑discharge while accommodating load sag.

- For stricter energy use (e.g., RC), some designs run lower, but avoid allowing resting voltage to sit <3.0 V/cell.

Monitor under load

- Measure cell voltages during peak current events. If any cell dips rapidly below 3.2 V and rebounds significantly at rest, that cell may have higher internal resistance.

End of discharge procedure

- Stop the test when any cell hits the cutoff.

- Rest 30 minutes and record per‑cell OCV; investigate any imbalance >50 mV.

Reconditioning

- If packs were accidentally over‑discharged (e.g., <3.0 V/cell OCV), follow the manufacturer’s recovery instructions or quarantine. Do not fast‑charge a severely depleted pack.

Implementation note: UVP/OVP thresholds are programmable on mainstream pack ICs. For example, the TI BQ76940 monitor et BQ40Z50 pack manager (TRM) allow UVP around 2.8–3.0 V/cell and OVP around the chemistry limit; set conservatively and match the datasheet.

Storage Workflow That Minimizes Calendar Aging

Most avoidable capacity loss happens off‑duty—at high state of charge and high temperature. A simple routine prevents that.

Decide storage target per cell: 3.70–3.85 V (~40–60% SOC). This mid‑band is recommended in practical guidance like Battery University’s storage guide BU‑702 (2024).

Bring packs into range

- If >3.85 V/cell, discharge with a controlled load or your charger’s storage mode.

- If <3.70 V/cell, charge using CC‑CV to reach the band, then stop.

Temperature and environment

- Store ideally at 15–25 °C, dry conditions. Calendar fade accelerates with both SOC and heat; peer‑reviewed data (e.g., Keil & Jossen) show high‑SOC at 40 °C can roughly double or more the annual fade compared to mid‑SOC at 25 °C, as discussed in the 2016 J. Electrochem. Soc. study by Keil et al. and corroborated by a 2023 Frontiers Energy Research review by Ali et al..

Maintenance cadence

- Check voltage every 3–6 months; top up or bleed to stay in range.

- For long storage, cycle briefly (10–20% depth) annually to verify health.

Transport readiness

- For air shipments, prepare cells/packs at ≤30% SOC and follow packing instructions per the IATA Lithium Battery Guidance Document 2025. UN 38.3 test compliance is mandatory for transport, summarized in Intertek’s UN 38.3 overview.

Temperature Policy (Charge, Discharge, Store)

- Charge: 0–45 °C typical; optimal ~10–30 °C. Charging below 0 °C increases risk of lithium plating and long‑term damage, highlighted in Battery University BU‑410 (2024).

- Discharge: –20 to 60 °C typical, with pack‑specific limits; derate or stop above datasheet limits.

- Storage: Prefer 5–25 °C; avoid prolonged exposure above 40 °C. Manufacturer guidance such as the Renata Li‑poly rechargeable guidelines (2023) align with these ranges.

Practical tip: Put temperature gates into firmware along with voltage thresholds—charge enable 0–45 °C and discharge enable –20–60 °C are common defaults on pack managers like the TI BQ40Z50 family.

Cycle and Calendar Aging: What Voltage Windows Really Buy You

- Lowering the peak voltage reduces stress at the cathode/electrolyte interface, especially at elevated temperatures. Lab and field evidence show sharply higher degradation above ~4.10–4.20 V per cell. See the materials‑level perspective in Dose et al., ACS Applied Materials & Interfaces (2022).

- Heuristic for planning: according to the synthesis in Battery University BU‑808 (2024), dropping the charge limit by ~0.10 V can markedly extend cycle life, with roughly ~10% capacity trade‑off at 4.10 V vs 4.20 V.

- Calendar fade is dominated by high SOC and high temperature; datasets summarized in the 2016 Keil et al. JES paper et le 2023 Ali et al. review show mid‑SOC at room temperature can halve or better the yearly loss versus high‑SOC at elevated temperatures.

Design implication: If your product is longevity‑first (industrial sensors, medical wearables), consider 4.10–4.15 V upper limits and 3.1–3.3 V lower cutoffs, plus aggressive thermal management. Validate KPIs (runtime, power bursts) against the capacity you trade for significantly longer life.

BMS/Charger Settings That Map to Real Hardware

Typical starting points for standard 4.20 V/cell LiPo. Adjust per datasheet and validate with HALT/HASS.

- OVP (over‑voltage): 4.20 V/cell (or datasheet value for HV cells such as 4.35 V; see the Murata HV datasheet).

- UVP (under‑voltage): 2.8–3.0 V/cell hard cutoff; system‑level cutoff for longevity at 3.0–3.3 V/cell.

- Balance trigger: start when delta ≥15–20 mV, slow passive balancing until within tolerance.

- Charge current: 0.5C default; 1C if allowed.

- Termination current: 0.05–0.1C in CV.

- Temperature enables: charge 0–45 °C; discharge –20–60 °C.

These parameters are directly supported by mainstream pack ICs and monitors such as TI’s BQ40Z50/TRM, BQ76940 DS, and ADI’s stack monitors LTC6804 DS.

Troubleshooting Mini‑Guide (Field‑Proven Patterns)

Symptom: One cell consistently finishes at higher voltage after charge.

- Likely cause: Capacity mismatch or higher impedance in other cells.

- Action: Increase balancing time; cycle the pack with moderate C‑rates; if delta remains >50 mV after rest, evaluate replacement.

Symptom: Rapid voltage sag under load, then sharp rebound at rest.

- Likely cause: Elevated internal resistance or low SOC.

- Action: Verify SOC estimate; reduce current peaks; raise lower cutoff to 3.2–3.3 V/cell; check pack temperature.

Symptom: Pack warm during CV phase at normal current.

- Likely cause: Elevated impedance; possible incipient degradation.

- Action: Reduce termination current; check cell balance; run capacity and IR test to track trend.

Symptom: Storage puffing after months on shelf.

- Likely cause: Stored at high SOC and/or high temperature.

- Action: Institute storage policy at 3.7–3.85 V and 15–25 °C; audit warehouse climate; retest affected batch. Storage risks are emphasized in practical advisories like Reedy’s LiPo safety notes.

Symptom: Charger refuses to start on a deeply discharged pack.

- Likely cause: Safety lockout below UVP.

- Action: Follow manufacturer’s recovery protocol; some datasheets allow low‑current pre‑charge under supervision, but do not bypass protection without OEM approval.

Safety and Compliance Shortlist

- Handle and charge only on non‑flammable surfaces; use containment where appropriate—echoed across industry safety communications, including NBAA’s 2024 inflight Li‑ion safety article.

- Ensure UN 38.3 test reports and markings before transport; follow the IATA 2025 lithium battery guidance for packing and SOC limits.

- For market access, confirm IEC 62133‑2 compliance where applicable; see the Intertek overview of IEC 62133.

Why it matters: Incident histories in aviation and logistics show that improper charging/handling are recurring root causes. Conservative voltage windows and mid‑SOC storage significantly reduce risk profiles, as captured in safety roundups like Battery University’s lithium‑ion safety concerns.

Common Mistakes We Still See (and Fix Fast)

- Charging below 0 °C: hidden lithium plating that shows up later as swelling or capacity loss.

- Storing full: devices arrive at 100% SOC and bake in a hot warehouse—calendar fade skyrockets.

- Treating 4.35 V like “free capacity” on 4.20 V cells: it isn’t; only HV cells can go there, and they still trade life for capacity.

- Skipping balance on multi‑cell packs: the weak cell dictates safety; keep deltas tight.

- Using a single cutoff number: always specify both a hard UVP and a higher system cutoff for longevity.

Implementation Checklist (Put These Into Your SOPs)

- Define chemistry and max cell voltage from the datasheet; configure charger/BMS accordingly.

- Set CC‑CV: 0.5C–1C, 4.20 V/cell limit (or HV spec), termination 0.05–0.1C.

- Enable balancing at ≥15–20 mV delta; verify ≤50 mV spread after rest.

- Set UVP hard cutoff 2.8–3.0 V/cell; system cutoff 3.0–3.3 V/cell.

- Storage policy: 3.70–3.85 V/cell at 15–25 °C; check every 3–6 months.

- Temperature gates: charge 0–45 °C; discharge –20–60 °C.

- Shipping: prepare at ≤30% SOC; UN 38.3 documentation; follow latest IATA.

Supplier Toolbox (Neutral, Vetted Options)

Disclosure: The following supplier mentions include our own brand; recommendations remain vendor‑neutral and standards‑based.

- Yungbang Power — Custom LiPo design, BMS integration, and certified manufacturing capability across consumer and industrial packs. Scope includes UL/CE pathways and UN 38.3 testing support.

- Grepow — Broad LiPo portfolio including high‑rate and shaped cells; engineering support and application notes.

- PKnergy — LiPo cells and packs with clear voltage guidance resources; OEM/ODM engagement.

Selection criteria we apply in audits:

- Documentation quality (complete datasheets, safety files, UN 38.3/IEC 62133‑2)

- Process certifications (ISO 9001/14001), traceability, and incoming QC

- Application engineering depth (BMS tuning, pack testing, thermal design)

When to Deviate From the Defaults

- High‑voltage chemistry explicitly specified by the cell vendor (e.g., 4.35 V max): configure OVP, charger, and balancing to that spec and reassess cycle life.

- Ultra‑long‑life products: cap charge at 4.10–4.15 V and raise lower cutoff to 3.1–3.3 V/cell; log performance KPIs after change.

- Extreme temperature applications: prioritize thermal controls and derating; never charge below 0 °C.

Final reminder: Always reconcile these best‑practice ranges with the specific cell/pack datasheet and your device’s duty cycle. The bands above are what consistently deliver safe operation, predictable life, and smoother compliance across programs.