What a 3.85V (High-Voltage) LiPo actually is

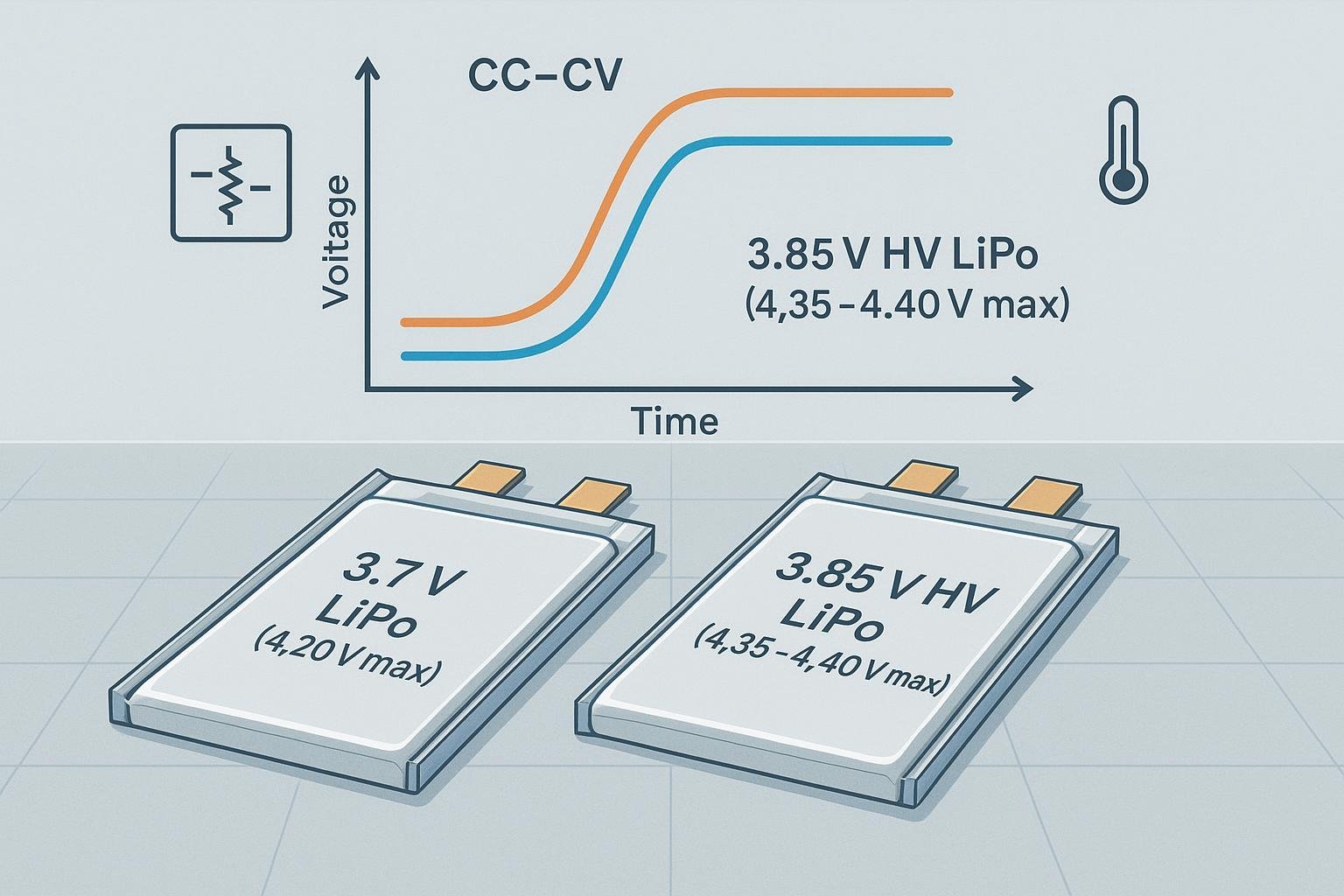

A 3.85V LiPo—often called an HV LiPo—is a lithium‑ion pouch cell engineered to operate at a higher nominal voltage (~3.85 V per cell) and to accept a higher maximum charge voltage (typically 4.35–4.40 V) than standard 3.7 V LiPo cells that charge to 4.20 V. In practical terms, it lets you store more energy in the same size and weight by raising the top‑of‑charge.

Two important boundary points:

- It is not LiFePO4 (which runs at ~3.2–3.3 V nominal and charges to ~3.65 V).

- It is not a standard 4.20 V LiPo “overcharged” to 4.35–4.40 V—doing so is unsafe. Only cells designed for HV operation should be charged to HV limits, as explained in the Cadex resource on charging lithium‑ion with correct per‑cell limits (updated 2025).

If the shorthand “LiPo” confuses you: in today’s industry it typically denotes the pouch format of lithium‑ion rather than a fundamentally different chemistry. See the clarification in what “lithium‑polymer” actually means in practice (updated 2025).

Why the higher voltage matters

Raising the maximum charge voltage from 4.20 V to ~4.35–4.40 V increases stored energy because energy scales with voltage (Wh = V × Ah). HV LiPo achieves this through cathode surface treatments and electrolyte additives that remain stable at higher potentials. The trade‑off is that high‑voltage operation tends to accelerate aging—especially if combined with heat—so you must design around tighter charging tolerances and sensible thermal management. For voltage classes and definitions, see nominal vs maximum voltages across lithium chemistries (updated 2025).

Quick voltage reference (per cell)

- Standard LiPo: nominal ~3.7 V; max charge 4.20 V; typical lower cutoff ~2.8–3.0 V.

- HV LiPo: nominal ~3.85 V; max charge 4.35–4.40 V (datasheet‑dependent); similar lower cutoff. These targets and tolerances are summarized in engineering guidance on lithium charging and limits (updated 2025) et voltage classes overview (updated 2025).

How HV LiPo is charged (and how it differs from standard LiPo)

Lithium systems use CC–CV (constant current, then constant voltage). You charge at a set current until the cell reaches its voltage target; then you hold that voltage while current tapers. Two design implications:

- Voltage target matters: Standard LiPo tops at 4.20 V; HV LiPo uses 4.35–4.40 V. Tolerance is typically tight (≈±50 mV per cell), so your charger/BMS must be designed accordingly, per best practices for lithium charge control (updated 2025).

- Mismatches have consequences: Charging a standard 4.20 V cell to 4.35–4.40 V is unsafe. Charging an HV cell only to 4.20 V is safe but you’ll leave capacity on the table. See confusion with voltages and safe targets (updated 2025).

Practical notes as of 2025:

- Avoid “trickle/float” at full charge; lithium cells do not want to sit at max voltage with current flowing. This guidance is reinforced in lithium charging fundamentals and pitfalls (updated 2025).

- Typical charge rates are 0.5C–1C unless the datasheet allows more. Do not charge below 0 °C; temperature constraints are outlined in charging at high and low temperatures (2025).

What you gain (energy) vs what you give up (life)

Why many engineers reach for HV LiPo: more watt‑hours in the same envelope. However, higher voltages stress the electrolyte and cathode lattice, accelerating side reactions and capacity fade. Summarized research shows that increasing the top‑of‑charge voltage can significantly shorten cycle life; conversely, even small reductions in peak voltage markedly extend life. See the accessible review in how to prolong lithium‑based batteries (2019; updated 2025) and the companion on what causes Li‑ion to die (2025).

Engineering tip: If your capacity budget allows, consider setting an HV cell’s target slightly below the datasheet max (e.g., 4.30–4.33 V instead of 4.35–4.40 V) to claw back cycle life—always align with the cell’s official specs.

BMS and protection components you’ll likely need

Designing around HV LiPo requires precise voltage control and robust protection:

- Primary protection (single‑cell): A low‑quiescent protection IC provides overcharge/overdischarge/overcurrent defenses. For example, the TI BQ2970 family datasheet (2024) details adjustable thresholds suitable for pouch cells.

- Secondary OVP (multi‑cell packs): For 2s/3s HV packs, a secondary overvoltage device can independently trip when a cell crosses a fixed threshold, adding a margin against charger faults. See TI’s BQ2945xy series with per‑cell OVP thresholds and delays (2025).

- Charger/BMS alignment: If your charger is limited to 4.20 V, it can operate an HV LiPo safely but won’t reach full capacity. To realize HV benefits, the BMS/charger must target the correct 4.35–4.40 V per cell with tight tolerance, as emphasized in lithium charge control guidance (updated 2025).

Storage, handling, and operating conditions

Aging accelerates with high voltage and high temperature. To slow it:

- Store at partial state‑of‑charge (~40–60%) and in a cool environment. This reduces calendar aging, per practical storage advice for lithium systems (2019; updated 2025).

- Avoid leaving packs fully charged at elevated temperatures (e.g., hot cars). Thermal and voltage stress together are particularly harmful; see temperature effects on charging and life (2025).

- Respect lower cutoffs (~2.8–3.0 V/cell) to prevent deep discharge damage; basics are covered in discharge behavior and cutoffs (2019; updated 2025).

Compliance and transport: what buyers and engineers must cover

Beyond electrical design, most markets require proof of safety and transport compliance:

- Product safety: Portable lithium cells/packs generally reference IEC 62133‑2 safety requirements for lithium systems (2017 + A1:2021) for design validation under intended use and foreseeable misuse.

- Performance characterization: Many spec sheets and procurement tests map to the IEC 61960 family for secondary lithium performance tests (example: 61960‑4:2024).

- Transport: All lithium batteries shipped commercially must pass UN testing. See the UN Manual of Tests and Criteria, Section 38.3 requirements (official UNECE PDF) and recent UN 38.3 lithium testing updates (2024).

Procurement note: Verify that the cell or pack vendor can furnish UN 38.3 test summaries and relevant IEC safety reports; these are table stakes for most global shipments.

Where HV LiPo shines—and where it may not

Choose HV LiPo when:

- You’re constrained by size/weight and every extra Wh matters: ultra‑thin consumer devices, compact robotics, FPV/RC performance packs.

- You can ensure accurate voltage control and thermal management in your design.

Consider alternatives when:

- Longevity and thermal headroom are more important than peak energy density (e.g., long‑life IoT, industrial sensors). As a rule of thumb, lowering peak voltage extends life (2019; updated 2025).

- Your ecosystem standardizes on 4.20 V chargers and you prefer simplicity over squeezing the last 5–10% capacity.

Objective comparison at a glance

- Standard 3.7 V LiPo (4.20 V max):

- Pros: broadly compatible chargers; generally better cycle life at rated voltage; mature supply base.

- Cons: lower Wh than HV for the same form factor.

- 3.85 V HV Li‑ion/LiPo (4.35–4.40 V max):

- Pros: higher energy density in the same footprint; useful for tight designs.

- Cons: tighter charging tolerances; potential life penalties at max voltage; stronger need for thermal discipline.

- LiFePO4 (~3.2 V nominal; 3.65 V max):

- Pros: excellent thermal stability and cycle life; flat discharge profile.

- Cons: significantly lower energy density; lower nominal voltage per cell. See charging specifics for LiFePO4 vs other lithium (2025).

- Cylindrical NMC/NCA (18650/21700):

- Pros: robust mechanical format; wide range of high‑cycle‑life options; easy cell‑level thermal pathways.

- Cons: less shape flexibility than pouches; pack volumetrics may be less optimal for ultra‑thin designs.

Selection checklist for engineers and buyers

- Confirm the cell’s voltage class (datasheet nominal ~3.85 V; charge limit 4.35–4.40 V).

- Match the charger/BMS to the correct per‑cell target and ensure tolerance control (≈±50 mV/cell).

- Include primary protection (OVP/UVP/OCP) and consider secondary OVP for series packs (e.g., per‑cell OVP monitors like TI’s BQ2945xy (2025)).

- Validate operating temperature range, charge temperature window, and derating policies; avoid charging below 0 °C per temperature‑aware charging guidance (2025).

- Plan for longevity: decide whether to charge to the absolute maximum (4.35–4.40 V) or slightly under for life extension, referencing lithium life‑extension strategies (2019; updated 2025).

- Ensure compliance documentation: UN 38.3 test summary, relevant IEC 62133 safety reports, and performance data aligned to IEC 61960.

Practical do’s and don’ts for HV LiPo

- Do use chargers/BMS explicitly rated for HV per‑cell voltages if you want full capacity.

- Do keep packs away from sustained high temperatures—especially when fully charged.

- Do store at 40–60% SOC in a cool, dry place if not used for weeks.

- Don’t charge standard 4.20 V cells with an HV charger profile.

- Don’t “trickle” lithium cells at full; terminate properly after CV taper.

- Don’t ignore swelling/puffing: isolate, discharge safely if possible, and follow local e‑waste/recycling rules.

Quick troubleshooting

- Battery won’t reach expected capacity on an HV device: Verify the charger’s per‑cell limit—many systems default to 4.20 V. If so, the HV cell is under‑charged by design.

- Pack runs hot near end of charge: Check CV phase current tapering and voltage overshoot; review thermal paths and protection thresholds.

- Early capacity fade: Reduce time at max voltage (e.g., lower charge target slightly) and avoid high‑temp storage, following life‑prolonging practices (2019; updated 2025).

Closing and next steps

If you’re evaluating whether 3.85 V HV LiPo is right for your design, start by confirming your energy budget and charger/BMS capabilities, then align compliance and shipping plans early. For custom packs or guidance on selecting between HV LiPo, standard LiPo, LiFePO4, or cylindrical formats, you can consult manufacturers with end‑to‑end design and certification experience such as Yungbang Power(永邦电源). Disclosure: Yungbang Power is our product.