Definición en una frase

A pouch cell is a rechargeable lithium-ion battery that uses a flexible, laminated foil pouch for its casing (instead of a rigid metal shell), maximizing energy density, weight savings, and design flexibility—crucial advantages over prismatic and cylindrical cell types.

Explicación detallada

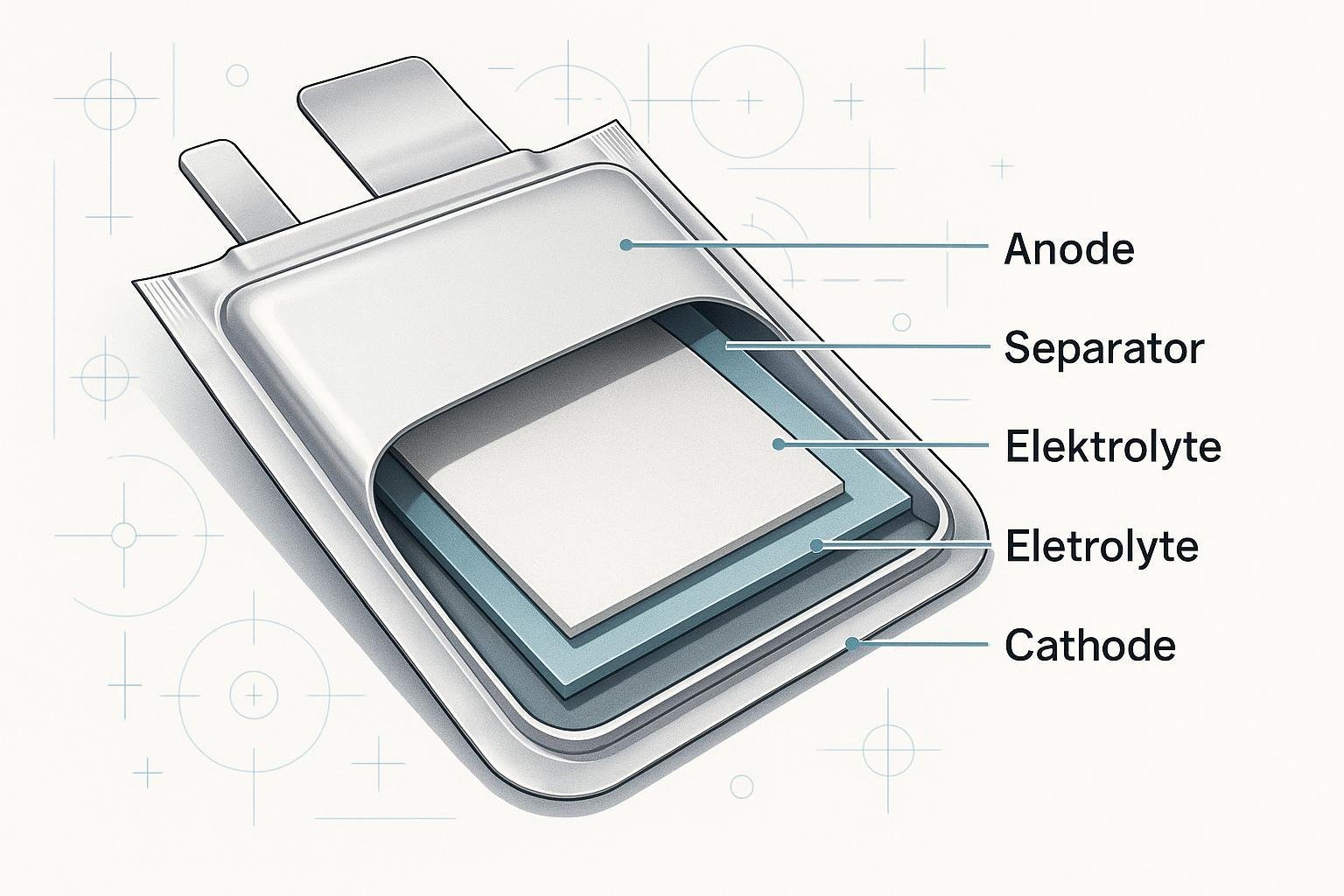

In a pouch cell, stacked layers of anode (often graphite), cathode (such as lithium cobalt oxide, manganese, or iron phosphate), a separator, and a liquid or gel electrolyte are sealed within a thin, heat-sealed aluminum-laminated plastic pouch. Unlike the rigid cans of cylindrical or prismatic cells, this soft pouch adapts to different sizes and shapes, minimizing unused space and enabling 90–95% packaging efficiency (see Grepow comparison). The outer pouch provides minimal physical protection, making careful external support structure and battery management (BMS) integration essential.

During battery operation, lithium ions shuttle between anode and cathode through the electrolyte, while electrons travel through external circuits between the tabs—thin, conductive terminals welded to the cell’s internal current collectors.

Key Components and Features

- Active Materials: Graphite anode, various lithium-based cathodes

- Separador: Microporous polymer, preventing short circuits

- Electrolito: Liquid or gel, sometimes polymer-based for higher safety

- Laminated Pouch Casing: Multi-layer foil/plastic laminate with precise heat sealing

- Tabs: Welded aluminum/copper connectors for power flow

Technical Highlights:

- High energy density: 150–250 Wh/kg typical

- Superior packaging efficiency: up to 95%

- Lightweight, flat, or custom-shaped designs

- Requires careful swelling/thermal management and robust module support

Visual Comparison Table

| Característica | Pouch Cell | Prismatic Cell | Cylindrical Cell |

|---|---|---|---|

| Casing Material | Flexible laminate | Rigid metal/plastic shell | Rigid metal can |

| Shape | Flat/customizable | Rectangular/blocky | Round |

| Typical Energy Density (Wh/kg) | 150-250 | 120-200 | 110-180 |

| Packaging Efficiency | 90-95% | 80-90% | 60-75% |

| Mechanical Strength | Low (needs support) | Alta | Very high |

| Swelling Risk | Moderate-high (requires management) | Moderado | Bajo |

| Aplicaciones comunes | EV, smartphones, drones, ESS | EV, storage, industrial | Power tools, consumer devices |

Aplicaciones comunes

- Electrónica de consumo: Smartphones, tablets, and laptops favor pouch cells for slim form factors and high energy density.

- Electric Vehicles (EVs): Used in models like the Nissan Leaf, Chevrolet Bolt, and some Tesla and Mercedes-Benz vehicles for large-format battery packs (Battery University).

- Energy Storage Systems (ESS): Home and grid batteries utilize pouch cells for space-constrained installations.

- Drones and Robotics: Lightweight and efficient power sources.

Related and Confusing Concepts

- Prismatic Cell: Rigid, rectangular battery format with strong protection but less packaging efficiency.

- Cylindrical Cell: Traditional round metal can batteries; mature, reliable, cost-effective but bulkier.

- Lithium Polymer Battery (LiPo): Sometimes confused with pouch cell; actually refers to the use of a polymer-based electrolyte, regardless of shape. Not all lithium polymer batteries use pouch construction, and not all pouch cells use polymer electrolytes.

- Sistema de gestión de baterías (BMS): Essential for all types, but especially important for pouch cells due to swelling and thermal considerations.

Why Choose a Pouch Cell?

Pouch cells enable higher energy density, greater design freedom, and lower weight—ideal for modern devices and EVs where compactness matters. However, they must be engineered with robust packaging and advanced BMS for safety and longevity. For more technical insight, see ScanTech’s analysis.