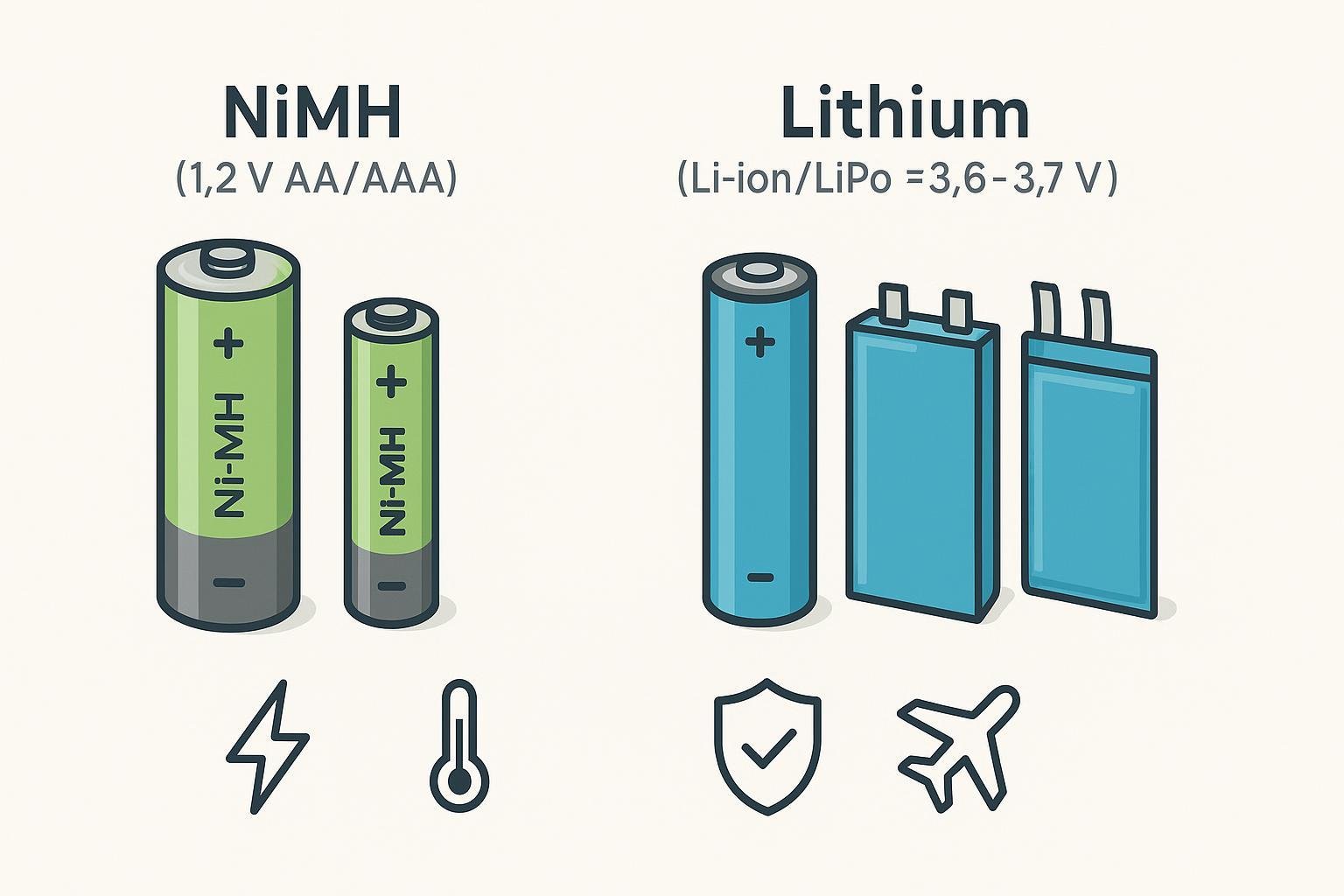

Whether you’re specifying a battery for an OEM device or deciding what to put in your camera flash, the “NiMH vs lithium” question is really about matching chemistry to use case. There isn’t a universal winner. Lithium-based batteries (Li‑ion and LiPo) dominate where energy density, compactness, and long life cycles matter. Nickel‑metal hydride (NiMH) shines in AA/AAA consumer formats, in cold weather at moderate loads, and where safety and logistics simplicity are priorities.

Below, we translate lab specs into real‑world behavior so you can choose the right chemistry for 2025 requirements.

Quick Comparison: Core Specs and Behaviors

| Dimension | NiMH (Nickel‑Metal Hydride) | Lithium (Li‑ion / LiPo) |

|---|---|---|

| Nominal cell voltage | ~1.2 V (AA/AAA, Sub‑C, etc.), defined in IEC 61951‑2; common in consumer devices. See IEC scope summary in OD ENEC 324 Annex A (2024). | ~3.6–3.7 V per cell (NMC/NCA); ~3.2–3.3 V (LFP); definitions in IEC 61960 per OD ENEC 324 Annex A (2024). |

| Energy density (typical ranges) | ~55–110 Wh/kg; ~140–300 Wh/L; consumer‑friendly but heavier/bulkier for the same energy. Summaries in Battery University’s nickel table. | ~100–300 Wh/kg; ~250–700 Wh/L depending on form factor and chemistry; favors compact devices and long runtimes. References consolidated across IEC 61960 and OEM data. |

| Power delivery (C‑rate) | Often ~1C–5C continuous; short pulse power possible in high‑drain cells. | Wide range by chemistry: NMC/NCA cells ~1C–3C continuous (cell‑dependent); LFP and RC LiPo packs can go much higher when designed for it. |

| Cycle life (to ~80% capacity) | ~500–1000 cycles typical under moderate use; LSD NiMH can maintain capacity well over years. | Highly chemistry‑dependent: NMC/NCA often ~1000–2000 cycles; LFP can reach ~3000–5000 cycles under controlled conditions. |

| Self‑discharge | Conventional NiMH is high (~15–30%/month). LSD NiMH (e.g., Eneloop) claims ~70% retention after 10 years (Panasonic global lineup, 2025) per Panasonic Eneloop lineup. | Typically ~2–3%/month, lower than conventional NiMH; varies with design and temperature. |

| Charging method | Smart chargers use −ΔV detection and temperature monitoring; typical charge 0.5C–1C. | Strict CC/CV with protection; charging below 0°C is generally prohibited per IEC 62133‑2 testing (e.g., IEC 62133‑2 TRF excerpt, 2025). |

| Temperature behavior | Discharge usability down to ~−20°C is common; charging typically recommended ~0–45°C. | Discharge often specified ~−20°C to +60°C (chemistry‑dependent). Do not charge below 0°C unless validated; lithium plating risk. |

| Safety & BMS | Inherently safer; lower specific energy; simpler protection (smart charging; occasional PTC/vent). | Requires robust BMS (OV/UV, over‑current, temp) and quality control to manage thermal risk. |

| Formats & availability | Very common in AA/AAA, Sub‑C, D. Easy drop‑in for many consumer devices. | Cylindrical (18650/21700), prismatic, pouch (LiPo). Common in phones, laptops, drones, tools, EVs. |

| Compliance & shipping | Non‑lithium: fewer restrictions; simpler packaging. | Must pass UN38.3; IATA Packing Instructions (PI 965–970), SoC limits, labeling, test summary—see IATA Lithium Battery Guidance (2025). |

| Cost/TCO | Lower $/cell; higher $/Wh at pack/device level; good value for AA/AAA convenience. | Higher upfront per pack but better $/Wh and lifetime value in energy‑dense applications; global pack averages were ~$115/kWh in 2024 per BloombergNEF survey. |

| Recycling & environment | Nickel/REE recovery pathways; consumer programs like Call2Recycle; EPA provides collection best practices—see US EPA battery collection best practices. | Complex material recovery (lithium, cobalt, nickel); EU Battery Regulation introduces recycled‑content targets—see Transport & Environment explainer. |

Notes on ranges: energy, cycles, and temperatures depend on exact models, depth of discharge, and operating profiles. Always consult the cell or pack datasheet for definitive limits.

How Those Specs Play Out in Real Devices

Energy and voltage profiles

- NiMH’s 1.2 V nominal fits many AA/AAA devices without regulators; serial stacks (2–4 cells) are common. Voltage sag under high load can be noticeable, but high‑drain NiMH cells mitigate this.

- Lithium’s ~3.6–3.7 V cells typically require regulation or are integrated into pack designs with built‑in protection and interface boards. The higher voltage enables efficient buck regulation for compact electronics.

Power delivery (C‑rate)

- NiMH supports respectable continuous discharge for consumer gear and flashes. For sustained high power (cordless tools, drones), lithium chemistries offer better thermal behavior and power density, especially LFP and RC LiPo packs.

Cycle life and TCO

- If your device cycles daily and you care about multi‑year longevity, lithium—particularly LFP—can deliver markedly higher cycle counts. Combined with falling pack prices (global average ~$115/kWh in 2024), lifetime cost per cycle often favors lithium in energy‑intensive applications.

- NiMH can reach ~500–1000 cycles in typical usage and remains economical for AA/AAA devices that don’t need high energy density.

Self‑discharge and storage

- Conventional NiMH loses charge faster in storage. Low‑self‑discharge NiMH (e.g., Eneloop) is a standout for household gear thanks to multi‑year retention claims from Panasonic’s lineup. Lithium’s low self‑discharge is excellent for standby and IoT devices, assuming proper BMS quiescent current management.

Temperature and charging limits

- NiMH is more forgiving on cold‑weather discharge at moderate loads; charging is generally recommended above 0°C.

- Lithium should not be charged below 0°C unless the system is explicitly validated (per IEC 62133‑2 test frameworks); heaters or pre‑conditioning are common solutions in cold climates.

Safety and system complexity

- NiMH’s lower specific energy reduces runaway risk and simplifies charger requirements.

- Lithium demands robust BMS and manufacturing quality. For OEMs, certification and pack‑level QA are not optional.

Compliance and Logistics (What It Means Operationally)

- Lithium batteries must comply with UN38.3 transportation tests and IATA rules (PI 965–970), including state‑of‑charge limits for certain shipments and documentation (test summary, labeling). See the 2025 guidance PDF from IATA Lithium Battery Guidance.

- NiMH is non‑lithium. It has fewer air‑transport restrictions; packaging and labeling requirements are generally simpler than lithium, though local regulations still apply.

Scenario‑Based Recommendations (2025)

Household AA/AAA devices (remotes, toys, LED lights, some camera flashes)

- Choose LSD NiMH. You get drop‑in compatibility, safer chemistry, robust cold‑weather discharge, and excellent long‑term retention (Panasonic Eneloop lineup claims ~70% after 10 years).

High‑drain, compact electronics (smartphones, laptops, drones, RC models)

- Choose lithium (NMC/NCA/LiPo). Superior energy/power density and pack integration. Respect charging temperature limits and ensure BMS protections.

Cordless power tools and e‑mobility micro‑packs (18650/21700 systems)

- Choose lithium. LFP for cycle longevity and safety; NMC/NCA where energy density is paramount. Thermal management and pack QA are decisive.

IoT sensors, backup/UPS, and systems prioritizing long life and safety

- Choose LFP lithium for long cycle life and stability. NiMH can be viable for small, simple backups where logistics simplicity matters and energy demands are modest.

Outdoor/cold‑weather moderate‑load applications

- Prefer NiMH, or use lithium systems with heaters/pre‑conditioning. Charging below freezing is the key constraint for lithium.

Chemistry Capsules: Pros and Cons

NiMH (Nickel‑Metal Hydride)

Pros

- AA/AAA ubiquity and simple replacement

- Inherently safer, simpler charging (−ΔV detection)

- Robust cold‑weather discharge at moderate loads

- Lower upfront $/cell; convenient for consumer formats

Contras

- Lower energy and power density → heavier/bulkier packs

- Higher self‑discharge unless using LSD variants

- Fewer high‑power system formats compared with lithium

Ideal for

- Household AA/AAA devices, intermittent use, cold environments

- Simple, low‑risk designs where BMS complexity isn’t desirable

Lithium (Li‑ion / LiPo)

Pros

- High energy and power density; broad form‑factor ecosystem (18650/21700/prismatic/pouch)

- Lower self‑discharge; strong options for long cycle life (especially LFP)

- Better $/Wh and TCO in energy‑intensive, compact applications

Contras

- Requires BMS/protection and strict charge management

- Thermal runaway risk if poorly designed or abused

- Stricter shipping/compliance requirements (UN38.3, IATA PI)

Ideal for

- High‑drain, space‑constrained devices (phones, laptops, drones, tools)

- Systems requiring thousands of cycles or very long runtimes

Cost and TCO Context

- Lithium pack pricing continues to trend down; global averages hit ~$115/kWh in 2024 according to the BloombergNEF pack price survey. At the device level, this often translates into superior lifetime cost for energy‑dense designs.

- NiMH per‑cell costs are low, but $/Wh is typically higher. For AA/AAA devices, convenience and safety can outweigh raw $/Wh comparisons.

Environmental and Recycling Pathways

- NiMH: Nickel and rare‑earth recovery is well established; consumer collection programs such as Call2Recycle operate widely in North America, and the US EPA’s 2023–2025 guidance outlines best practices for battery collection and labeling—see US EPA battery collection best practices.

- Lithium‑ion: Recycling is expanding via pyro‑ and hydro‑metallurgy, with policy momentum in the EU (mandatory recycled content for critical metals phased in over the 2030s). Overview of targets and context in the Transport & Environment recycling explainer.

Practical Safety Notes (Charging and Handling)

- Lithium charging below 0°C is generally prohibited unless explicitly validated; IEC 62133‑2 test frameworks and industry practice emphasize this control, as illustrated in accessible test report templates like the IEC 62133‑2 TRF excerpt (2025).

- For NiMH, use smart chargers with −ΔV detection and temperature monitoring to prevent heat damage; allow cooldown between fast‑charge cycles.

- Always follow the specific datasheet and safety standards for your chosen cells or packs.

How to Decide Quickly

Choose NiMH if:

- You need drop‑in AA/AAA reliability, simple logistics, and acceptable performance in cold environments.

Choose Lithium if:

- You need compact size, long runtime, high power, and long cycle life—and can implement proper BMS, charging controls, and compliance.

Also Consider (OEMs and Procurement)

Disclosure: Yungbang Power is our product.

If you’re sourcing lithium‑based packs, BMS integration, or custom designs for consumer/industrial devices, explore Yungbang Power(永邦电源). The company manufactures Li‑ion/LiPo packs with custom BMS and certification pathways (UL/CE), suitable for OEM programs.

Sources and Further Reading

- Energy density and nickel chemistry behavior: Battery University nickel summary table (2025)

- IEC definitions and scope for NiMH (61951‑2) and lithium (61960): OD ENEC 324 Annex A (2024)

- Lithium transport and shipping: IATA Lithium Battery Guidance (2025)

- Lithium pack price trends: BloombergNEF global pack price survey (2024)

- Consumer recycling and collection programs: US EPA battery collection best practices (2023–2025)

- EU recycling targets context: Transport & Environment battery recycling explainer (2024–2025)