Choosing the better battery depends on your specific needs. A lithium polymer (lipo) battery is perfect for a lightweight application. The flexible li-po is a great battery technology for custom shapes. Your application’s needs will decide if a lipo battery is right. The lipo market shows steady growth, though the lithium polymer (lipo) market is smaller than the li-ion market.

2026 Market Projections at a Glance 📈

| Tipo de batería | 2024/2025 Market Size | CAGR (2026-2033) |

|---|---|---|

| Iones de litio | USD 68.66 billion | 21.1% |

| Lithium-polymer | USD 12.5 billion | 14.2% |

This guide helps you choose the right lipo battery.

Core Differences: Lithium Polymer vs. Lithium-Ion Batteries

Understanding the core differences between a lithium polymer (lipo) battery and a lithium ion battery is key to choosing the right power source. While both are rechargeable batteries based on lithium chemistry, their internal construction creates significant trade-offs in performance, safety, and application.

The main distinction lies in the electrolyte—the medium that allows ions to flow between the battery‘s positive and negative ends. A standard lithium ion battery uses a liquid electrolyte. In contrast, baterías de polímero de litio use a electrolito polimérico gelatinoso o sólido. This fundamental difference impacts everything from shape to safety profile.

| Característica | Lithium-ion Batteries | Lithium-polymer Batteries |

|---|---|---|

| Electrolyte Type | Liquid (Organic Liquid Electrolyte) | Gel or Solid Polymer Electrolyte |

| Composition | Solvent, lithium salts, additives | Polymer compounds, lithium salts, polar organic solvents |

| Key Trait | High conductivity but requires a rigid case | Flexible form factor, improved thermal stability |

Energy Density and Power Capacity

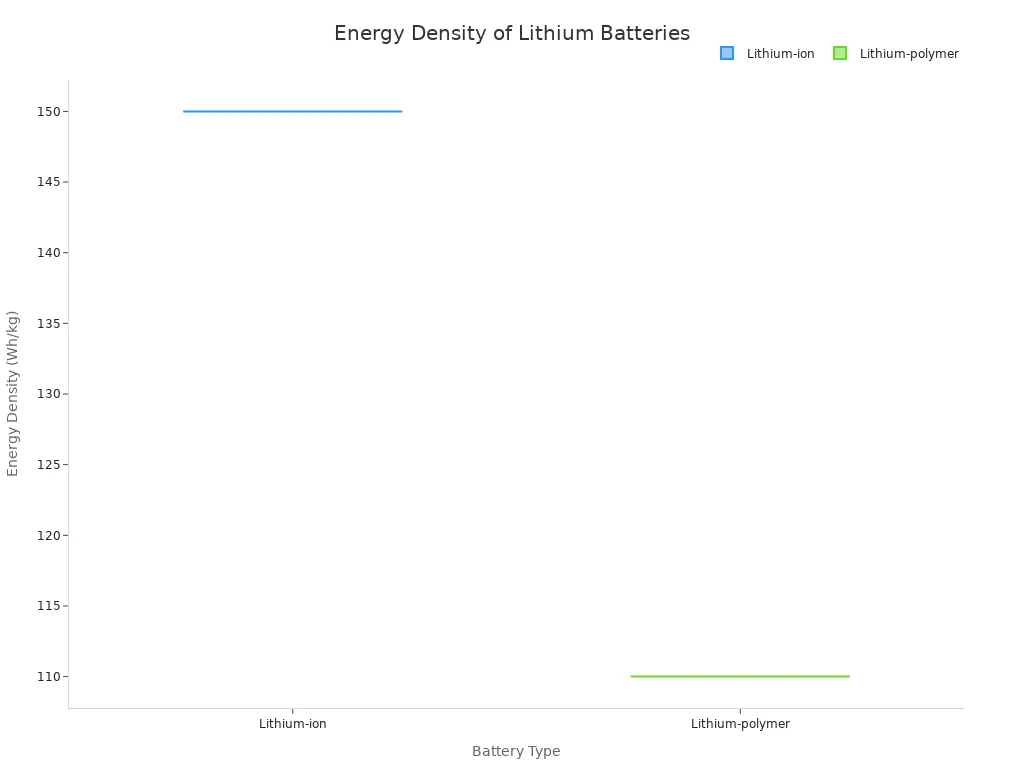

Energy density measures how much power a battery can store relative to its size or weight. This is where baterías de iones de litio have a distinct advantage.

A higher densidad energética means a lithium ion battery can hold more charge in the same amount of space. This makes it the ideal choice for applications demanding long battery life from a compact source. The alta densidad energética of these batteries is why they dominate markets like electric vehicles and high-end laptops. A lithium polymer battery typically has a lower densidad energética.

Power capacity also involves the discharge rate, or C-rate. This number tells you how quickly a battery can release its energy. High-performance lipo batteries, like those in racing drones, often boast a very high discharge rate. This allows them to deliver intense bursts of power. However, these advertised C-rates can be optimistic. For real-world performance, it’s wise to expect about one-quarter of the advertised rate for a lipo and half for a batería de iones de litio. The alta densidad energética of baterías de iones de litio often comes with a lower C-rate compared to a specialized lipo battery.

Form Factor and Weight

The flexibility of baterías de polímero de ión-litio is their standout feature. The gel electrolyte in a lipo does not require a heavy, pressurized metal casing. Instead, baterías de polímero de litio are housed in a flexible foil pouch. This design allows a lithium polymer battery to be made in nearly any custom shape or size.

Design Freedom with Li-Po 💡 The malleable nature of a

lithium polymerbatterymakes it perfect for modern, slim devices. Think of the thin smartphones, wearables, and compact medical devices where every millimeter counts. Thelipocan be molded to fit snugly into unconventional spaces.

In contrast, baterías de iones de litio are typically produced in standard cylindrical (like 18650 cells) or prismatic (rectangular) formats. Their rigid metal shell adds weight and restricts design possibilities, but it also provides structural protection. For this reason, a lipo is almost always lighter than a lithium ion battery of the same capacity.

Safety Characteristics and Risks

Seguridad is a critical concern for any battery technology. Both baterías de polímero de ión-litio y baterías de iones de litio have unique risks. The primary safety concern for a lithium ion battery is thermal runaway. This dangerous event can be triggered by several factors:

- Sobrecarga: Using an incorrect charger or a faulty battery management system (BMS).

- Internal Failure: Manufacturing defects that compromise the internal separator.

- Mechanical Damage: Dropping, crushing, or puncturing the rigid case.

- Extreme Temperatures: Operating the

batteryin very hot or cold conditions.

A lithium polymer battery has a different safety profile. Its flexible pouch makes it more vulnerable to puncture. A puncture can cause a short circuit and a fire. The most common issue with a lipo is hinchazón. Overcharging or deep discharging can cause the electrolyte to break down and release gas. This gas gets trapped inside the pouch, causing the lipo battery to bloat. A swollen lipo is permanently damaged and poses a significant safety risk. You should stop using it immediately. While the rigid case of baterías de iones de litio makes them feel safer, the gel electrolyte in a lipo is less flammable, which improves its overall safety profile.

Lifespan and Cost of a LiPo Battery

When it comes to lifespan and cost, baterías de iones de litio generally come out ahead. A typical lithium ion battery can endure between 300 and 800 charge cycles before its capacity significantly degrades. Modern smartphone batteries often exceed 800 cycles. The lifespan of a polymer battery is often similar, typically rated for De 300 a 500 ciclos. However, their greater sensitivity to overcharging and deep discharging can sometimes shorten their operational lifespan.

Cost Comparison: A Clear Winner 💰 Manufacturing costs for

baterías de iones de litioare lower due to mature, high-volume production processes. Alithium polymerbatterycan be nearly twice as expensive as alithium ion batterywith the samecapacity, making thelithium ion batterythe more economical choice for many products.

Good charging efficiency and lifespan depend heavily on proper care for both battery types. Avoiding extreme temperatures and using the correct charger are essential for maximizing lifespan.

Climate Resilience and Performance

Temperature has a major impact on battery performance y safety. Both lithium polymer y lithium ion technologies degrade faster in extreme heat. High temperatures accelerate internal chemical reactions, reducing lifespan and increasing the risk of thermal runaway. This degradation affects performance by increasing internal resistance, which means the battery has to work harder to deliver power.

Extreme cold is also a problem.

- Reduced Efficiency: Chemical reactions slow down, lowering the

battery‘s power output. - Voltage Drop: Internal resistance increases, causing a noticeable drop in voltage under load.

- Charging Risks: Charging any lithium

batterybelow freezing (0°C / 32°F) can cause permanent damage and createsafetyhazards.

While both are sensitive, the rigid structure and established chemistry of baterías de iones de litio often give them a slight edge in predictable performance across a wider temperature range. The lipo battery, with its delicate pouch, can be more susceptible to physical stress caused by temperature-induced expansion and contraction.

Application Guide: Choosing a Lithium Polymer Battery or Li-Ion

The best battery technology is the one that fits the job. Your specific application needs will guide your choice between a lithium polymer (lipo) battery and a lithium ion battery. This guide breaks down the ideal use cases for each, helping you understand where each battery shines. The right battery ensures optimal performance and safety for your device.

Use Cases for High Portability

When a device must be as small and light as possible, the lithium polymer (lipo) battery is the clear winner. Its lightweight and flexible design gives it a major advantage in portability. The absence of a heavy metal case means a lipo is perfect for products where every gram matters.

This is especially true in modern consumer electronics.

- Wearable Technology: Devices like smartwatches, smart rings, and wireless earbuds need a power source that fits into a tiny, ergonomic space. A lithium polymer battery can be made ultra-thin (1-4 mm) and molded into custom shapes (round, curved) to fit these designs. Most smartwatches use a small 3.7V lipo battery.

- Drones and RC Hobbies: The high power-to-weight ratio of a lipo is essential for radio-controlled aircraft. A lighter battery means longer flight times and better agility. The high discharge rate of a lipo also provides the necessary bursts of power for quick maneuvers.

- Ultra-Slim Smartphones: Flagship smartphones get thinner every year. A lithium polymer battery enables these slim profiles. The flexible foil pouch can be shaped to fill every bit of internal space, allowing for a large capacity battery without making the phone bulky. This gives the lipo a superior energy density by volume.

A Closer Look at a Typical Li-Po Cell 🔬 The specifications for a common lithium polymer cell show why it’s built for compact devices. The low weight and customizable features are key. This specific lipo battery is designed for a high-performance application.

| Specification | LP402025 (LiPo) |

|---|---|

| Química | Lithium Polymer (LiPo) |

| Capacidad | 140~160mAh (typical) |

| Dimensions (mm) | 4.0 × 20 × 25 |

| Densidad energética | ~350 Wh/L |

| Ciclo de vida | 300–500 cycles (to 80%) |

Use Cases for Maximum Endurance

When an application needs maximum endurance, durability, and cost-efficiency, lithium-ion batteries are the industry standard. Their superior high energy density by weight means they can store more power for longer, making them the go-to choice for demanding jobs. The long lifespan of these batteries also makes them more economical over time.

- Electric Vehicles (EVs): All Tesla vehicles use lithium-ion battery packs. These packs need to store huge amounts of energy to provide a long driving range. Tesla uses two main types of lithium-ion batteries. Nickel-based batteries offer a higher energy density for more range. Lithium-Iron-Phosphate (LFP) batteries have a longer lifespan, improved safety, and are more affordable, making them ideal for standard-range models. The resilience of LFP batteries also makes them a great choice for varied climates.

- Laptops and Power Tools: High-performance laptops and cordless power tools draw a lot of power. A lithium ion battery provides the sustained energy needed. Laptop batteries are designed to retain about 80% of their capacity after 500 charge cycles, typically lasting 2 to 5 years. Their rigid case also provides the durability required for these applications.

- Portable Power Stations: For off-grid power and emergency backup, power stations rely on the high energy density and long lifespan of lithium-ion batteries. Their predictable performance and safety features are critical for storing and delivering large amounts of electricity reliably.

The Advantage of a Polymer Battery in Custom Designs

The most unique feature of a lithium polymer battery is its design flexibility. This is where the technology has no competition. Because the gel electrolyte is housed in a soft pouch, a lipo can be manufactured in almost any shape or size imaginable. This ability solves design challenges that a rigid lithium ion battery cannot.

This flexibility is critical for innovation in specialized fields.

- Advanced Medical Devices: Many modern healthcare technologies require compact and reliable power solutions. A custom-shaped lithium polymer battery can be designed to fit inside portable medical monitors, drug delivery systems, and surgical tools where space is extremely limited. The battery must meet the specific needs of the medical application.

- Mission-Critical Applications: Military and aerospace equipment often demands batteries that fit into unconventional spaces. A flexible lipo can be integrated into soldier-worn gear, communication devices, and unmanned systems. The safety and performance of the battery are paramount in this application.

Innovation Through Flexibility 💡 The malleable nature of a lithium polymer (lipo) battery allows engineers to create next-generation products. This technology is essential for developing flexible displays, smart clothing with integrated sensors, and other Internet of Things (IoT) devices. The battery can bend, twist, and conform to the human body, enabling a new class of seamless electronics. This application requires a very specific battery design.

The 2026 Outlook and Future Trends

The battle between the lithium polymer lipo and the lithium ion battery is not standing still. The future trends in battery technology show exciting progress for both types. Researchers are pushing the limits of performance and safety. This progress will shape the devices we use in 2026 and beyond. A better battery is always on the horizon.

Evolution of the Polymer Battery

The lithium polymer battery is getting a major upgrade. Scientists are improving the gel electrolyte inside a lipo. These improvements boost the performance and safety of lithium polymer batteries. The new lipo battery technology focuses on several key areas.

- Better ionic conductivity for faster charging.

- Longer battery life by reducing harmful reactions.

- Improved safety with less flammable materials.

- Greater stability, especially at higher voltages.

These advancements make the lithium polymer lipo safer and more powerful. The improved safety of a lipo is a top priority. This evolution helps the lithium polymer lipo compete in more applications. The enhanced safety and performance of a lipo are critical. The future for the lithium polymer is bright.

Innovations in Lithium-Ion Technology

The lithium ion battery is also seeing huge innovations. A major breakthrough is the use of silicon anodes. Silicon can theoretically hold ten times more energy than the graphite used in a current lithium ion battery. This could dramatically increase battery capacity and performance. Fast charging is another area of rapid improvement.

Charging in Minutes, Not Hours ⚡ By 2026, new EVs like the Lucid Gravity will gain nearly 200 miles of range in just 15 minutes. This incredible performance is possible through advanced battery management and new lithium-ion polymer batteries chemistry. This leap in battery technology makes electric vehicles more convenient than ever.

The Challenge from Solid-State Batteries

A new challenger is emerging: the solid-state battery. These batteries replace the liquid or gel electrolyte with a solid material. This change promises higher energy density and much better safety. A solid-state battery could store more power than both lithium-ion polymer batteries and a standard lithium ion battery. However, there are big challenges to overcome.

Mass production is difficult. The solid electrolyte is very thin and hard to make without defects. These tiny flaws can cause the battery to fail, creating a safety risk. Companies like Factorial Energy and Toyota are racing to solve these problems. They hope to have solid-state batteries in luxury EVs around 2026 or 2027. These next-generation batteries could redefine performance and safety, but the lipo and lithium polymer batteries will remain dominant for now due to their proven reliability and lower cost. The safety of these new batteries is still being tested.

The right battery depends on your needs. The lithium polymer lipo battery is for form, while the other battery is for function. You trade the flexibility of a li-po lithium polymer lipo battery for higher density and durability. The future of this battery technology is dynamic. The li-po lithium polymer lipo battery faces new rivals. A li-po lithium polymer lipo battery is not the only option.

The Next Wave of Power 🌊 Researchers are already exploring what comes next:

- Lithium-air: A potential future lithium polymer lipo battery.

- Sodium: A cheaper lithium polymer lipo battery alternative.

PREGUNTAS FRECUENTES

Which battery is better for a drone?

A lipo battery is the best choice for drones. The high power-to-weight ratio of a lipo is essential for flight. This special battery gives drones agility and speed. For this reason, the lipo is the standard battery for most RC hobbies.

Can I use any charger for my lipo battery?

Important Safety Note ⚠️ No, you must use a specific charger designed for a lipo. Using the wrong charger can permanently damage the lipo battery. This mistake creates a serious fire risk for the lipo battery.

Why does my lipo battery swell up?

A lipo battery swells when gas builds up inside. This often happens from overcharging, physical damage, or age. A swollen lipo is a dangerous battery. You should safely dispose of the damaged lipo battery and replace it.

Is a lipo a type of lithium-ion battery?

Yes, a lipo is a subtype of lithium-ion battery. The core difference is the electrolyte. A standard lithium-ion battery uses a liquid. A lipo uses a flexible gel polymer. This makes the lipo battery a very adaptable power source. Every battery has a specific design.