You need the right lithium battery to bring your project to life. Your success depends on matching the correct energy source, a lithium battery, to your device’s needs. The first step is to define your power requirements. A lithium battery has three core specifications you must understand first.

- Capacity (mAh): How long the battery runs.

- Voltage (V): Ensures power compatibility.

- C-Rate: How it handles power demands.

Getting these details right for your lithium-ion li-ion battery pouch ensures you have the correct energy and capacity for a successful and safe lithium project.

Decoding Core Specifications

You must first understand the core numbers on a battery’s label. These specifications define the battery’s power, runtime, and limits. Getting them right is the most important step in your selection process.

Capacity (mAh/Ah)

Capacity measures how much energy a battery can hold. It is usually shown in milliamp-hours (mAh) or amp-hours (Ah). A higher capacity means your device will run longer on a single charge. You can calculate the capacity you need with a simple formula.

Required Capacity (mAh) = Device Current (mA) × Desired Runtime (hours)

Pro Tip: Add a 20% Buffer Always add at least a 20% buffer to your calculated capacity. For example, if you need 1000mAh, aim for a 1200mAh lithium battery. This buffer improves battery performance and longevity. Operating a lithium battery between a 20% and 80% state of charge can reduce degradation by almost half. This practice prevents stress on the battery’s internal parts and ensures you have reserve energy. It also helps avoid low-voltage shutdowns, which become more common as a lithium battery ages and its total capacity decreases.

Tensión nominal (V)

Nominal voltage is the average voltage of a lithium battery during its discharge cycle. You must match this voltage to your device’s requirements. A mismatch can damage your device or prevent it from working. Most single-cell lithium-ion pouch batteries use chemistries like Lithium Cobalt Oxide (LCO) or Lithium Nickel Manganese Cobalt Oxide (NMC).

A 3.7V lithium battery is very common. This rating refers to the nominal voltage. The battery’s actual voltage changes as it charges and discharges, typically operating between 3.0V and 4.2V.

| Química | Abbreviation | Tensión nominal |

|---|---|---|

| Lithium Cobalt Oxide | LCO | 3.60V |

| Lithium Nickel Manganese Cobalt Oxide | NMC | 3.60V (or 3.70V) |

Always check your device’s specifications to find the correct voltage. This ensures compatibility and safe operation.

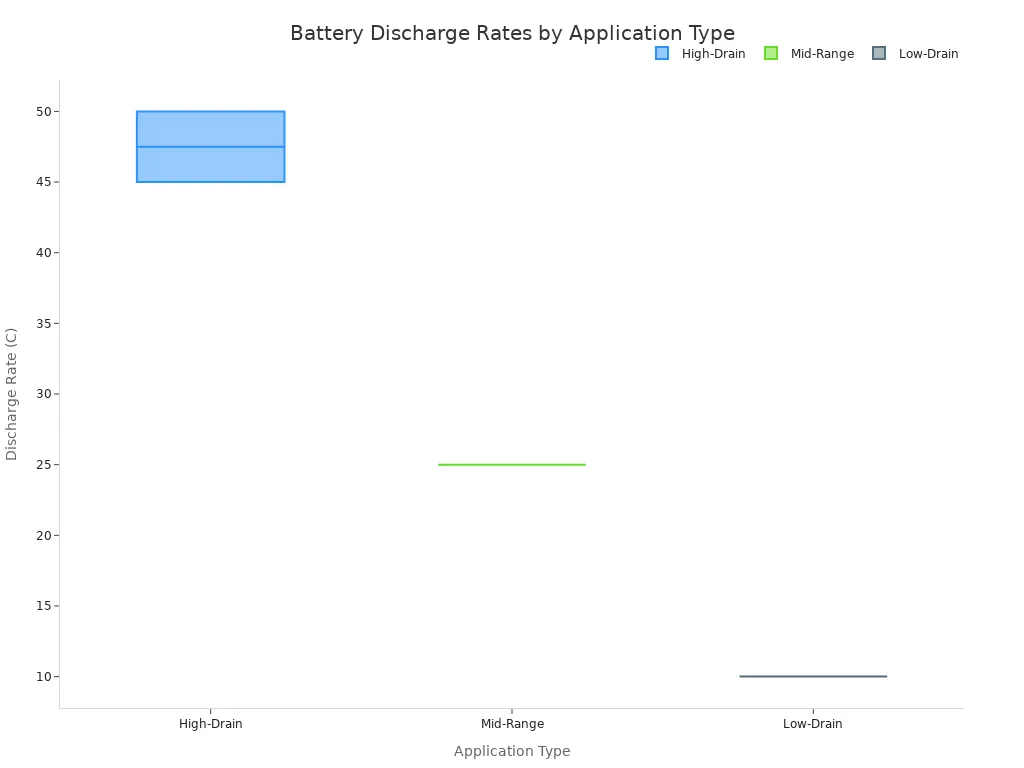

C-Rate (Discharge)

The C-rate tells you the maximum speed at which you can safely discharge a battery. It is a multiplier of the battery’s capacity. A higher C-rate means the battery can deliver a large amount of energy quickly. This is crucial for high-power applications.

You can calculate the maximum safe discharge current like this:

Max Current (A) = C-Rate × Capacity (Ah)

For example, a 2000mAh (2Ah) lithium battery with a 5C rating can provide a maximum current of 10 amps (2A * 5 = 10A).

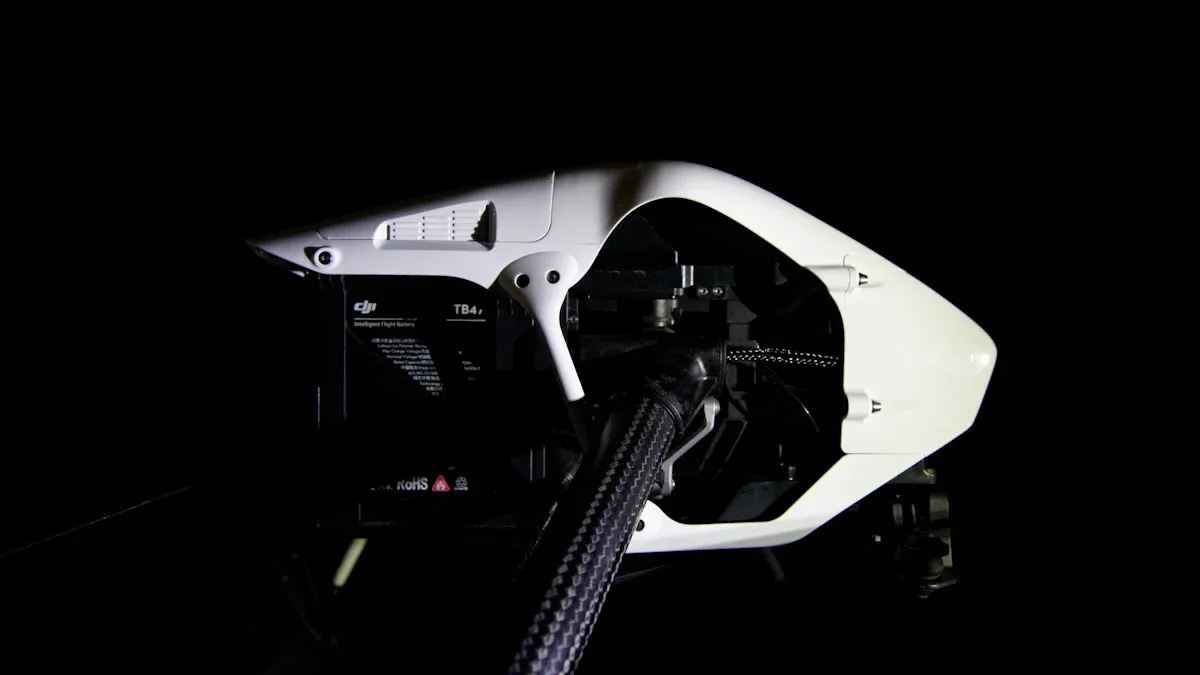

Different applications require different C-rates. A drone needs a high C-rate for its powerful motors, while a simple sensor needs a very low one.

The C-Rate Trade-Off Using a high C-rate generates more heat. This heat can reduce your battery’s lifespan. Operating a battery at 45°C (113°F) can cut its cycle life in half compared to using it at 20°C (68°F). High-rate discharging causes the battery’s temperature to rise quickly, which accelerates aging and hurts long-term battery performance. This makes proper thermal management essential for devices that demand high energy output.

Densidad energética

Energy density measures how much energy a battery can store for its size or weight. It is typically expressed in watt-hours per kilogram (Wh/kg). High energy density is a key advantage of lithium pouch cells. It allows for powerful, lightweight energy storage solutions.

In 2025, advanced lithium-ion pouch cells are pushing the limits of energy storage. While typical commercial batteries offer around 350 Wh/kg, research has produced lithium metal cells exceeding 600 Wh/kg. Future technologies like solid-state batteries promise even greater energy storage, with projections reaching 500 Wh/kg. These advancements provide more power in smaller packages, opening new possibilities for portable and compact devices. This makes the choice of lithium technology critical for efficient energy storage. The right battery provides the best capacity and energy for your project’s physical constraints.

Choosing Your Li-ion Battery Pouch

After defining your power needs, you must confirm the battery fits your device. The physical form factor is just as important as the electrical specifications. You need to check the dimensions, connector, and wire configuration to ensure a perfect match.

Physical Dimensions and Weight

You must measure your device’s battery compartment carefully. Get the length, width, and height. A li-ion battery pouch needs to fit correctly, but it also needs room to breathe and expand. A lithium battery can swell during its life due to internal chemical processes. This swelling creates mechanical stress. Good battery pack design accounts for this change.

Design for Swelling: Leave Extra Space Your design should leave about 10-15% extra space in the enclosure’s height. This buffer allows the lithium battery to expand without damaging itself or your device. Forcing a swollen lithium battery into a tight space can cause internal damage and safety risks. Proper space is essential for the longevity and safety of your lithium project.

Weight is also a factor, especially for portable devices like drones or wearables. The battery’s datasheet will list its weight, allowing you to balance runtime with portability.

Tipo de conector

The connector links your lithium battery to your device’s circuit board. You must choose a connector that matches your device and can handle the required electrical current. Using the wrong one can lead to a poor connection or even melting. Common connectors for a lithium battery include JST, Molex, and RCY.

| Tipo de conector | Corriente nominal típica | Common Use |

|---|---|---|

| JST-PH | 2A | Small, low-power electronics |

| JST-XH | 3A | Battery balancer cables |

| JST-RCY | 3A – 5A | RC cars, receivers |

| Molex Picoblade | 1A | Charging small 1S lithium packs |

Always check the pinout, as some connectors can have different polarities. A secure, correctly rated connector is vital for a reliable lithium power source.

Wire and Tab Configuration

The wires and tabs on a li-ion battery pouch are its positive and negative terminals. The tabs are typically made from aluminum or nickel. The material used affects performance and durability.

| Tab Material | Common Terminal | Key Benefit |

|---|---|---|

| Aluminum (Al) | Positive (+) | Lightweight and affordable |

| Nickel (Ni) | Negative (-) | Resists corrosion and is easy to weld |

Manufacturers often use aluminum for the positive tab and nickel or nickel-plated copper for the negative tab. This combination provides a good balance of cost, weight, and performance. Ensure the wire gauge (thickness) is also appropriate for the current your device will draw. A thicker wire can handle more current safely. This detail is crucial for a safe and efficient lithium battery setup.

Prioritizing Safety and Longevity

A lithium-ion pouch cell is a dense energy storage device. It packs a lot of power into a small space. This high energy concentration means you must prioritize safety. A cell failure can be severe, so understanding the built-in safety features is not optional. These features protect your device and ensure the long-term health of your lithium battery. Good safety considerations are key to a successful project.

Protection Circuit Module (PCM)

You should think of the Protection Circuit Module (PCM) as the brain of your lithium battery. It is a small electronic board that manages and protects the cell. For nearly all projects, a lithium battery with an integrated PCM is essential. It is the most important factor for battery safety. A more advanced version is called a battery management system (BMS), which is common in multi-cell packs. The PCM constantly monitors the lithium cell and keeps it within safe operating limits.

Key functions of a PCM include:

- Overcharge Protection: It stops charging if the voltage gets too high, typically above 4.25V. This prevents damage and dangerous conditions.

- Over-Discharge Protection: It disconnects the power if the voltage drops too low, usually around 2.5V. This protects the lithium battery from irreversible damage.

- Short Circuit Protection: It instantly cuts the power if it detects a short circuit, preventing a massive energy release.

- Temperature Monitoring: It uses sensors to watch the battery’s temperature and can shut it down if it gets too hot.

These safety considerations are vital. The PCM acts as a dedicated guard, ensuring the powerful energy inside the lithium-ion cell remains controlled and safe.

Lithium-ion Chemistry and Cycle Life

The chemical makeup of your lithium-ion battery determines its performance and longevity. The two most common chemistries for pouch cells are Lithium Cobalt Oxide (LCO) and Lithium Nickel Manganese Cobalt Oxide (NMC). Your choice affects how many times you can charge and discharge the battery before it needs replacement. This is known as its cycle life.

A battery’s “end of life” is typically when its maximum energy storage capacity drops to 80% of its original rating. A battery with a 1000mAh capacity is considered at its end of life when it can only hold 800mAh. Better longevity means your device will perform well for a longer time.

The chemistry you choose directly impacts this longevity.

| Característica | NMC Chemistry | LCO Chemistry |

|---|---|---|

| Ciclo de vida | Longer (1000+ cycles) | Shorter (500-1000 cycles) |

| Lo mejor para | Robotics, medical devices | Portable consumer electronics |

| Degradation | Slower and more stable | Faster due to its structure |

Choosing NMC can double your battery’s useful lifespan, making it a better investment for devices that need long-term reliability. These safety considerations help you plan for the future of your product.

Gestión térmica

Temperature is a critical factor for the health and longevity of a lithium-ion battery. Heat is the enemy of energy storage. Operating a lithium battery outside its recommended temperature range can cause permanent damage and create serious safety risks. Your battery’s datasheet will specify these limits.

Safe Operating Temperatures

- Charging: 0°C to 45°C (32°F to 113°F)

- Discharging: -20°C to 60°C (-4°F to 140°F)

Charging a lithium battery below freezing can cause a dangerous condition called lithium plating, which permanently damages the cell. High temperatures from rapid discharging also accelerate aging and reduce the battery’s total energy storage.

Proper thermal management is essential for devices that draw a lot of energy. Your design must have a way to dissipate heat.

- Passive Cooling: This method uses materials that absorb and spread heat, like heat sinks or phase change materials. It requires no extra energy.

- Active Cooling: This method uses fans or liquid systems to move heat away from the battery. It is more effective for high-power applications that generate significant energy.

Managing heat is one of the most important safety considerations for ensuring the longevity and safe operation of your lithium power source. Effective heat management protects your energy storage investment.

Sourcing and Verification

You have defined your needs. Now you must find the right lithium battery and verify its quality. This step ensures you get a safe and reliable power source. You will learn to read datasheets, evaluate suppliers, and understand the benefits of a complete lithium-ion battery pack.

Reading the Datasheet

The datasheet is the official report card for a lithium battery. You must review it carefully to confirm the battery meets your project’s needs. It contains all the performance data for the lithium cell.

Key Specs to Check on a Datasheet

- Rated Capacity (mAh): Confirms the total energy storage.

- Nominal Voltage (V): Must match your device’s operating voltage.

- Max Discharge Current (A): Ensures the lithium battery can handle your device’s power draw.

- Ciclo de vida: Tells you how many times you can charge the lithium battery before its capacity drops to 80%.

- Operating Temperatures: Defines the safe temperature ranges for charging and discharging.

The datasheet also includes discharge curve graphs. These graphs show how the voltage changes as the lithium battery is used. A flat curve means the voltage stays stable, which is good for many devices. A higher C-rate will cause the voltage to drop faster and reduce the usable capacity of your lithium-ion battery.

Evaluating Suppliers and Brands

You should choose your supplier and brand with care. Reputable brands like LG Chem, Panasonic, and Samsung SDI are known for quality and safety. A good supplier provides genuine products and complete datasheets. They also show proof of safety certifications.

Look for these key certifications to ensure your lithium-ion battery pack is safe:

- UL 1642: This standard tests lithium cells against hazards like short circuits and impact.

- IEC 62133: This is an international standard for the safety of portable rechargeable batteries.

- CE Marking: This mark shows the lithium-ion battery pack meets European Union safety standards.

These certifications mean the lithium-ion battery pack has passed strict safety tests.

Sourcing a Lithium-ion Battery Pack

For most projects, you should source a complete lithium-ion battery pack. A lithium-ion battery pack is more than just a single lithium cell. It is a fully assembled power solution that includes:

- The lithium cell itself.

- A Protection Circuit Module (PCM).

- Wires and a connector.

Buying a pre-assembled lithium-ion battery pack from a specialist ensures all parts are compatible and safely integrated. This is much safer than trying to build a lithium power source yourself. It guarantees your energy storage solution is reliable and protected.

You can confidently choose the right li-ion battery pouch for your project. Follow this final checklist to ensure your lithium power source is a perfect fit. This process helps you avoid common mistakes like overlooking thermal stability or cycle life.

- Define Power Needs: Calculate your required lithium battery capacity, voltage, and C-rate.

- Confirm Physical Fit: Check the dimensions and connector for your lithium device.

- Verify Safety Features: Ensure your lithium-ion battery has a PCM and proper thermal management.

- Choose a Reputable Supplier: Select a trusted source for your lithium-ion battery.

This structured approach guarantees your lithium battery provides safe, reliable energy and sufficient capacity for your 2025 project. A successful lithium project starts with the right li-ion battery pouch.

PREGUNTAS FRECUENTES

Can I use a battery with a higher mAh rating?

Yes. A higher mAh rating gives you a longer runtime. Your device only draws the current it needs. You must ensure the battery’s voltage and physical size are correct for your project. This is a common upgrade for a lithium battery.

What happens if I do not use a PCM?

You risk overcharging, over-discharging, or short circuits. These events can permanently damage the lithium cell. In the worst case, it can cause a fire. A PCM is a critical safety feature for any lithium project.

How should I store my lithium battery?

You should store your lithium battery in a cool, dry place. Aim for a 40-60% state of charge. Avoid storing a fully charged or fully depleted battery for long periods. Proper storage extends the life of your lithium power source.

Why is my new lithium battery not at full voltage?

Manufacturers ship batteries at a partial charge for safety during transport. This is a standard practice. You should fully charge your new battery before its first use. This step calibrates the battery and ensures you get its maximum performance.