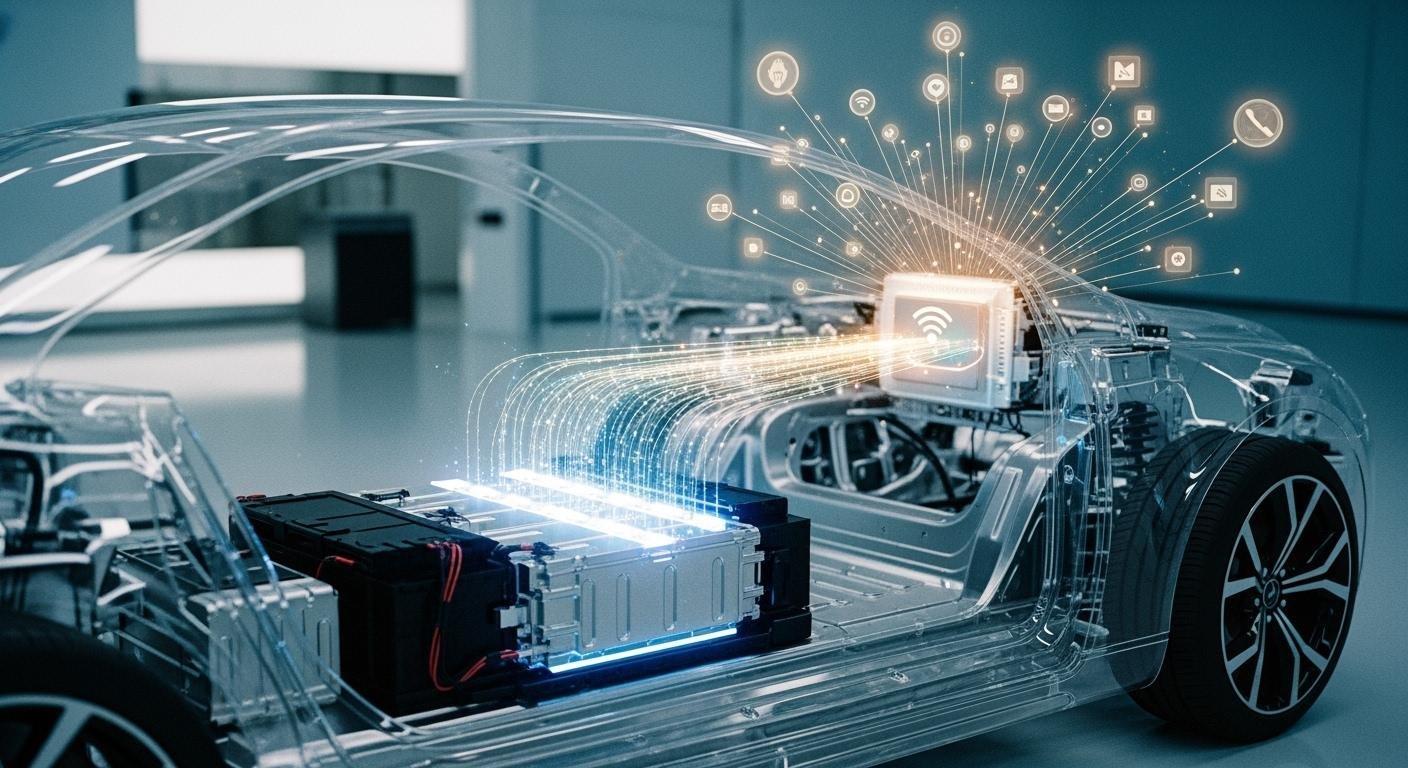

Lithium Iron Phosphate (LiFePO4) lithium batteries are the premier choice for modern telematics and fleet management systems. This specific lithium battery chemistry provides key advantages for reliable device operation.

Key Benefits of LiFePO4:

- Superior safety profile

- Exceptional battery lifespan

- Wide temperature tolerance

- Excellent long-term performance

Understanding these factors is essential when choosing the right battery. A quality lithium battery ensures dependable telematics operations.

Why LiFePO4 Excels for Telematics

LiFePO4 chemistry offers distinct advantages for demanding applications like fleet management and eCall systems. Its unique properties directly address the challenges of safety, longevity, and environmental exposure common in telematics.

Unmatched Thermal Safety

Safety is the most critical factor for any component installed in a vehicle. LiFePO4 lithium batteries provide exceptional thermal stability, greatly reducing the risk of fire. This safety comes from their fundamental chemistry.

- Stable Crystal Structure: A LiFePO4 battery uses a very stable olivine crystal structure.

- Strong Chemical Bonds: The phosphate group in the battery contains a powerful covalent bond. This bond resists breaking down and releasing oxygen, even at high temperatures. Oxygen release is a key factor that fuels thermal runaway in other lithium chemistries.

- High Decomposition Temperature: LiFePO4 chemistry maintains its structure up to very high temperatures. It resists thermal runaway until it reaches about 270°C. This provides a huge safety margin compared to other common battery types.

This table shows how LiFePO4 compares to another common lithium chemistry.

| Química de la batería | Approximate Thermal Runaway Onset Temperature |

|---|---|

| Lithium Iron Phosphate (LiFePO4) | ~230-270°C |

| Nickel Manganese Cobalt (NMC) | ~160-210°C |

The higher temperature threshold makes LiFePO4 the inherently safer choice for in-vehicle electronics.

Superior Cycle Life & TCO

A battery’s true cost extends beyond its purchase price. Total Cost of Ownership (TCO) includes replacements, maintenance, and operational costs over its entire lifespan. While LiFePO4 batteries have a higher initial cost, they deliver a much lower TCO.

A longer battery lifespan means fewer replacements. Fewer replacements lead to lower costs for new parts and labor. LiFePO4 technology offers a superior cycle life, often lasting 4,000 cycles or more. This is a massive improvement over traditional lead-acid batteries, which may only last 300-500 cycles. Over a ten-year period, a single LiFePO4 battery can do the work of 6 to 11 lead-acid units. This durability makes it a smarter long-term investment.

The chart below illustrates the significant TCO difference over a decade.

Nota: Over 10 years, the TCO for a LiFePO4 battery can be 64% to 75% lower than its lead-acid counterparts. This is due to zero replacement costs and higher charging efficiency.

Extreme Temperature Resilience

Telematics devices operate in vehicles that face extreme heat and cold. A LiFePO4 battery performs reliably across a wide operational temperature range, typically from -20°C to 60°C (-4°F to 140°F).

However, extreme temperatures do affect performance.

- In the Cold: At low temperatures, a battery’s internal resistance increases. This makes it harder to deliver power. While performance returns when the battery warms up, charging below 0°C (32°F) can cause permanent damage.

- In the Heat: High temperatures primarily shorten the battery’s lifespan. Consistent operation above its ideal range accelerates the degradation of internal components. For every 10°C increase, the battery lifespan can be cut in half.

The table below shows how cold affects available capacity.

| Temperatura | Approximate Available Capacity |

|---|---|

| 25°C (77°F) | 100% |

| 0°C (32°F) | 80-90% |

| -10°C (14°F) | 70-80% |

| -20°C (-4°F) | 50-60% |

Despite these effects, the robust nature of LiFePO4 chemistry ensures it functions more reliably in harsh vehicle environments than many alternatives.

LiFePO4 vs. Other Lithium Batteries

Not all lithium batteries are created equal. While LiFePO4 is a type of lithium-ion battery, its chemistry creates important differences when compared to other common lithium-ion batteries like Lithium Cobalt Oxide (LCO). These differences involve a direct trade-off between energy density, stability, and voltage.

Energy Density vs. Stability

Other lithium-ion batteries often provide higher energy density. This means they can store more energy in a smaller, lighter package. A higher density is useful for consumer electronics. However, this benefit comes at the cost of stability.

A LiFePO4 lithium-ion battery has a very strong crystal structure. The powerful bonds in its chemistry resist breaking down under stress from overcharging or physical impact. This makes the battery inherently safer. A standard lithium-ion battery is more likely to have a violent reaction during a puncture or crush event. The superior safety of a LiFePO4 battery makes it the clear choice for vehicle applications.

Charging Speed and Efficiency

A LiFePO4 lithium-ion battery excels in charging performance. Many of these lithium-ion batteries can handle a standard charge rate of 1C. This allows the battery to charge from empty to full in about one hour.

High Efficiency: LiFePO4 technology is also highly efficient. It has a round-trip efficiency of about 92%. This means very little energy is lost as heat during charging and discharging, making the entire system more effective.

Voltage and Cell Balancing

Different lithium chemistries operate at different voltages. A LiFePO4 lithium-ion battery has a nominal voltage of 3.2V per cell. This differs from other lithium-ion batteries, which often have a nominal voltage of 3.6V or 3.7V.

| Química | Nominal Cell Voltage |

|---|---|

| LiFePO4 | 3.2V |

| Cobalt-based Li-ion | 3.6V – 3.85V |

While many simple GPS trackers use a 3.7V lithium-ion battery, professional telematics systems require greater robustness. The enhanced safety and long-term stability of the 3.2V LiFePO4 lithium-ion battery make it the more reliable and professional choice for demanding fleet operations. Proper cell balancing within the battery pack ensures every lithium cell works together for optimal health and longevity.

Key Specifications for Your Battery

Selecting the right LiFePO4 battery involves more than just choosing a brand. Fleet managers must evaluate key technical specifications. These details determine the battery’s performance, reliability, and suitability for a specific telematics application.

Capacity (Ah) and Physical Size

A battery’s capacity, measured in Amp-hours (Ah), defines how much energy it can store. A higher Ah rating means a longer runtime for the telematics device. You can estimate the required capacity with a simple formula.

Calculating Runtime:

Runtime (in hours) = Battery Capacity (Ah) / Device Current (Amps)For example, a telematics device drawing 500mA (0.5A) will run for approximately 8 hours on a 4Ah battery (4Ah / 0.5A = 8 hours).

This calculation provides a baseline. Real-world conditions significantly impact a battery’s effective capacity.

- Temperature: Extreme cold reduces a battery’s available capacity. Extreme heat can accelerate wear and shorten its overall lifespan.

- Discharge Rate: Drawing power too quickly (a high C-rate) reduces the total energy a battery can deliver. A 100Ah battery might only provide 80Ah if discharged very rapidly.

- Depth of Discharge (DoD): LiFePO4 chemistry maintains high efficiency even at a deep 90% DoD. This is a major advantage over other chemistries that lose efficiency with deep discharges.

Fleet managers must consider these factors to choose a battery with enough capacity for worst-case scenarios, ensuring the device stays online when needed most.

Low Self-Discharge Rate

A battery naturally loses some charge over time, even when not in use. This process is called self-discharge. A low self-discharge rate is crucial for telematics devices, as vehicles can remain parked for days or weeks. LiFePO4 lithium batteries excel in this area.

| Tipo de batería | Typical Monthly Self-Discharge Rate |

|---|---|

| LiFePO4 | 1-3% |

| Lead-acid | ~10% |

The low rate of LiFePO4 ensures the battery retains its charge for extended periods. This readiness is vital for emergency functions and consistent tracking. However, temperature affects this rate. High storage temperatures accelerate internal chemical reactions. The self-discharge rate can double for every 10°C increase, so a battery stored at 35°C will lose charge faster than one at 25°C. This makes proper installation location important for optimal performance.

The Role of the BMS

A Battery Management System (BMS) is the intelligent control center of a modern lithium battery pack. It is not an optional feature; it is essential for safety, longevity, and performance. The BMS continuously monitors and manages all aspects of the battery’s operation. Effective battery management is its core purpose.

Key functions of a BMS include:

- Voltage Protection: It prevents damage from overcharging or over-discharging by cutting off the circuit if cell voltage goes outside a safe range.

- Current Protection: The system shuts down the load during an over-current event or a short circuit, protecting both the battery and the telematics device.

- Temperature Monitoring: It uses sensors to track the battery’s temperature. The BMS will stop charging or discharging if temperatures become dangerously high or low.

- Equilibrio celular: This critical battery management function ensures all individual lithium cells in the pack maintain an equal voltage. It prevents small imbalances from growing over time, which maximizes the pack’s cycle life.

The integration of a bms with telematics creates a powerful system for remote battery data management. This allows fleet operators to monitor battery health, state of charge, and usage patterns from a central dashboard. This proactive approach to battery management helps prevent failures and reduces vehicle downtime.

Verifying Quality and Performance

A battery’s specifications only tell part of the story. Fleet managers must also verify a manufacturer’s commitment to quality through certifications and production standards. These credentials ensure the battery will deliver safe, reliable performance in the field.

Essential Safety Certifications

International safety certifications are non-negotiable. They prove a battery has passed rigorous testing for safety and transport. Look for these key standards:

- UN 38.3: This certification is mandatory for shipping any lithium battery. It involves a series of eight tests that simulate transportation conditions like vibration, shock, and extreme temperatures to prevent hazards.

- IEC 62133: This is a global standard for the safety of portable batteries. It covers potential issues like overcharging and external short circuits, ensuring the battery is safe for its intended application.

- UL 2054 / UL 1642: These Underwriters Laboratories (UL) standards are common in the U.S. market. They involve extensive electrical and mechanical tests to validate the safety of the battery pack and its internal cells.

A quality battery will have these certifications clearly documented.

Automotive-Grade Standards

For any component installed in a vehicle, automotive-grade manufacturing is a key indicator of quality. The most important standard is IATF 16949. A manufacturer with this certification follows strict quality management processes.

IATF 16949 requires:

- A focus on defect prevention, not just detection.

- Continuous improvement across all production stages.

- Detailed record-keeping and strict process controls.

This standard ensures every battery is built to a consistently high level of quality, which is essential for long-term reliability and effective battery management.

Custom Battery Solutions

Off-the-shelf batteries may not always meet the specific needs of a telematics device. A custom-designed battery ensures perfect integration and peak performance. A custom solution is ideal when:

- The device has a unique shape or size constraint.

- The application requires specific power delivery to handle peak loads.

- Advanced battery management is needed for remote monitoring.

A custom battery can integrate a smart BMS with telematics systems. This allows for sophisticated battery data management, giving fleet operators real-time insights into battery health. This proactive approach to battery management helps predict failures and optimize device performance.

For applications demanding reliability and long-term value, LiFePO4 lithium batteries are the definitive choice. The stable lithium chemistry directly addresses operational challenges. It provides a superior battery lifespan and resilience in extreme temperatures. This lithium battery technology ensures a long lifespan. The extended battery lifespan is a key factor for telematics.

When selecting your next battery, prioritize LiFePO4. Verify its key specifications and certifications to ensure optimal performance and peace of mind.

PREGUNTAS FRECUENTES

Can you use a standard lithium-ion battery instead of LiFePO4?

While other lithium batteries work, LiFePO4 chemistry provides superior safety and a much longer lifespan. These benefits make it the professional choice for vehicle telematics. Its stability is essential for components installed inside a car or truck.

What happens if a LiFePO4 battery is charged below freezing?

Charging below 0°C (32°F) can cause permanent damage. This process, called lithium plating, reduces the battery’s total capacity and compromises its safety. A quality Battery Management System (BMS) prevents charging in these unsafe conditions.

Is a higher Ah rating always better?

Not always. A higher Amp-hour (Ah) rating provides longer runtime but results in a larger, heavier battery. Fleet managers must balance the device’s power needs and available space. The optimal choice fits both the physical and electrical requirements of the application.

Why is IATF 16949 certification important for a battery?

IATF 16949 is a strict automotive quality standard. A certified manufacturer uses processes that focus on defect prevention. This certification signals a high-quality, reliable battery built specifically for the demands of in-vehicle use, ensuring consistent performance and safety.