The common causes of battery fires include internal defects, physical damage, and improper charging. Experts predict a sharp rise in battery fire risks for 2025, with electric scooter fires becoming a significant concern. A damaged battery increases the danger of sudden fires. This guide provides essential information for prevention and emergency response.

A single battery failure can lead to devastating fires. Understanding your battery is the first step toward better safety. Effective fire safety and user safety practices are not optional; they are necessary.

Understanding E-Mobility Battery Failure

A lithium-ion battery can experience a dangerous process called embalamiento térmico. This is a self-sustaining chain reaction where the battery generates heat faster than it can release it. The process of thermal runaway creates an uncontrollable cycle of rising temperatures, which can cause fires or explosions. Once thermal runaway begins, it is nearly impossible to stop. This issue is becoming more common as e-mobility adoption grows, increasing battery fire risks. Understanding the causes is key to improving safety and performance.

Internal Contamination and Defects

Many cases of battery failure start during manufacturing. The battery cell manufacturing process is complex. Tiny metal particles, often copper, can become trapped inside a lithium-ion battery. These particles can puncture the thin separator that keeps the positive and negative sides apart. This damage creates an internal short circuit, which can lead to thermal runaway and fires. The quality of manufacturing is critical for the battery’s long-term efficiency and safety. Poor quality control during electric vehicle production can introduce these defects.

Physical Damage and Impacts

A battery does not need a manufacturing defect to fail. Physical impacts from drops or crashes can damage the internal structure of the lithium-ion battery. A puncture to the battery casing can cause an immediate and severe short circuit. This creates high-risk scenarios where a seemingly minor accident leads to a major fire. Any physical damage compromises the battery’s integrity and can trigger thermal runaway.

Improper Charging and Uncertified Gear

Utilizar el cargador equivocado is a common mistake that leads to fires. Uncertified chargers often lack the technology to communicate with the battery. This can cause the battery to overcharge, which damages the cells and can initiate thermal runaway. Low-quality chargers also may not have protections against overheating or overcurrent, making them a significant fire hazard. The quality of the charger directly impacts battery performance and safety.

Environmental Stress and Extreme Temperatures

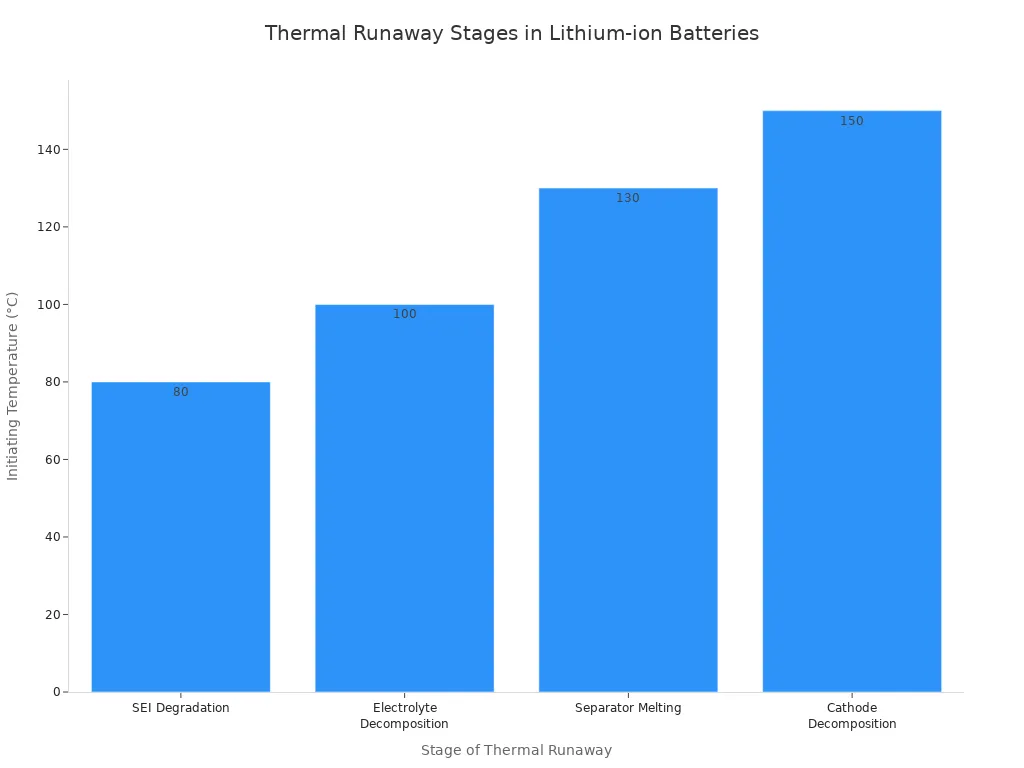

A lithium-ion battery is sensitive to its environment. Extreme heat or cold affects its performance and efficiency. The ideal storage temperature for a lithium battery is around 15°C (59°F). Charging a battery below 0°C (32°F) can cause permanent damage. High heat accelerates chemical reactions, increasing the risk of thermal runaway. High humidity can also cause corrosion and degrade internal components, reducing battery efficiency. The stages of thermal runaway are directly linked to temperature increases.

Essential Prevention Strategies and Solutions

Understanding the risks is only the first step. Active prevention is the most effective way to ensure safety. These essential prevention strategies and solutions help users minimize the danger of battery failure. Good habits and informed choices are crucial for protecting people and property. The quality of both the product and its handling determines its safety.

Safe Charging and Storage Habits

Proper battery management begins with safe daily routines. Users can significantly reduce fire risks by adopting correct charging and storage habits. The quality of these habits directly impacts battery longevity and safety.

For safe charging, users should follow several key practices.

- Utilice siempre UL-certified chargers and devices. New laws in places like New York City now require e-mobility products to meet UL safety standards.

- Avoid plugging chargers into overloaded sockets. This can damage building wiring and create a fire hazard.

- Never charge a device where it might block a fire exit.

- Do not leave a battery on the charger unattended for long periods, especially overnight. Grouping chargers together also increases heat and risk.

Proper storage also offers critical protection for a lithium-ion battery.

- Store the battery in a clean, dry location with a stable temperature, ideally between 40°F and 70°F.

- Keep the battery away from flammable materials, heat sources, and direct sunlight.

- For long-term storage, maintain the lithium battery at approximately 50% charge. Leaving a lithium battery fully charged or completely empty for months can degrade its performance and efficiency.

- Never attempt to open a faulty battery. The lithium powder inside is combustible, and only a professional should handle repairs.

Choosing a Certified Battery and Device

The market is filled with e-mobility options, but not all are created equal. The product quality of a battery and its charger is paramount. High-quality manufacturing processes are essential for safety. Consumers must choose devices certified by recognized organizations. This ensures the product meets strict safety and performance standards. The quality of manufacturing is a top priority.

Certifications like UL (Underwriters Laboratories), CE (Conformité Européenne), and IEC (International Electrotechnical Commission) indicate that a product has undergone rigorous testing. The quality of a device is often proven by these marks.

| Certificación | Origin | Alcance | Applicability |

|---|---|---|---|

| UL | Estados Unidos | Product safety testing for electrical devices | North America |

| IEC | Switzerland | International standards for electronics | Global |

| CE | Unión Europea | Meets EU health, safety, and environmental rules | Unión Europea |

Consumers can verify a product’s certification. Organizations like UL, TÜV Rheinlandy Intertek offer testing services and maintain databases of certified products. A genuine certification mark from a reputable manufacturing source confirms the product quality and its adherence to safety protocols. The difference in quality between a certified and a counterfeit battery is significant. Poor manufacturing choices lead to dangerous products. High-quality manufacturing focuses on safety.

| Característica | Certified Batteries | Counterfeit Batteries |

|---|---|---|

| Internal Protection | Includes devices like PTCs and CIDs | Often absent |

| Battery Management | Properly designed and integrated system | Lacks proper design or expertise |

| Calidad del material | High-quality materials and proper welds | Poor-quality materials and welds |

| Safety Standards | Tested and certified for safety | Not tested or certified |

The battery cell manufacturing process for a certified lithium ion battery is complex and precise. This level of quality and manufacturing detail is absent in counterfeit products, making them a serious risk. The overall product quality is a direct result of the manufacturing process.

Routine Inspection for Damage

Regular inspection is a simple yet powerful tool for prevention. Physical damage can compromise a battery’s internal structure and lead to failure. Users should perform routine visual checks to catch problems early.

A step-by-step inspection can identify potential hazards.

- Inspect the Battery Exterior: Look for cracks, dents, or fluid leaks on the battery housing. Any swelling, bulging, or discoloration is a major warning sign of internal gas buildup.

- Check Cables and Connectors: Examine all cables for fraying, splits, or burn marks. Ensure connectors are firmly attached and free of corrosion.

- Examine Mounting Hardware: Check that all screws and bolts securing the battery are tight. A loose battery can suffer damage from vibrations.

Subtle signs of damage can indicate a serious risk. Corrosion on terminals suggests moisture exposure, while small cracks can allow electrolyte to leak. Even minor physical changes can signal a problem.

A battery that is ‘bent like a taco‘ is a subtle sign of damage that would disqualify it from use, even if voltage and resistance appear normal.

This shows that any physical deformation makes the battery unsafe. The quality of the external case reflects the potential safety inside.

The Role of Advanced Battery Technology

Technology offers powerful solutions to improve battery safety and efficiency. Innovations in battery design and management systems are creating safer e-mobility products. These advanced fire protection solutions are key to future safety.

Solid-state batteries represent a major leap forward. These batteries replace the flammable liquid electrolyte in a traditional lithium-ion battery with a solid material.

- The solid electrolyte is not flammable, which eliminates the primary cause of thermal runaway.

- This design improves safety, performance, and efficiency.

- It allows for mayor densidad energética, meaning a lighter battery can provide a longer range.

Another critical technology is the Battery Management System (BMS). A smart BMS acts as the brain of the battery pack. Its management function is vital for safe operation.

- Voltage and Current Monitoring: The BMS prevents overcharging and over-discharging by tracking each lithium ion cell.

- Temperature Sensing: It uses multiple sensors to monitor the battery’s temperature, cutting off power if it gets too hot or too cold.

- Equilibrio celular: The system ensures all lithium ion cells maintain a similar charge, which improves battery performance and lifespan.

These technological solutions, combined with high-quality manufacturing, are essential for building a safer e-mobility ecosystem. The focus on quality in manufacturing and technology provides the best path forward for battery efficiency and safety.

Emergency Protocol: Responding to a Failing Battery

Knowing how to react during a battery emergency is critical for fire safety. Quick, correct actions can prevent catastrophic fires and protect lives. These immediate action steps provide a clear guide for responding to a failing battery.

Reconocer las señales de alarma

Users must learn the early warning signs of battery failure. A battery often signals a problem before it enters thermal runaway. These signs require immediate attention to prevent dangerous fires. A swollen or bulging casing is a major red flag. It indicates internal gas buildup, creating pressure that can rupture the cell and lead to high-risk scenarios. Other distinct warnings include:

- Unusual Sounds: Hissing, popping, or crackling noises suggest internal pressure release.

- Strange Odors: A sweet, metallic, or chemical smell indicates that the battery is venting flammable gases.

Immediate Safety Steps

If a battery shows any signs of failure, the first priority is safety. Do not attempt to extinguish the fire. Many people do not realize that using water on these fires can increase the output of toxic gases like hydrogen fluoride and carbon monoxide. Traditional extinguishers are also not effective.

Call 911 immediately. Professionals use special encapsulator agents, like F-500, to cool the cells and stop the chemical reaction that fuels these intense fires.

After calling for help, evacuate the area. The toxic smoke and risk of explosion create a serious hazard. Maintain a safe distance from the device.

| Scenario | Recommended Safe Distance |

|---|---|

| Electric Vehicles (EVs) | At least 30 meters |

| Damaged EVs | At least 15 meters |

| Damaged Residential BESS | At least 3 meters |

| Fire/Smoke-damaged batteries | At least 3 meters |

Professional Disposal Requirements

A damaged lithium-ion battery is considered hazardous waste. Never throw it in the regular trash. Improper disposal can cause fires in sanitation trucks and waste management facilities. The toxic chemicals inside, like cobalt and nickel, can also leak into the soil and groundwater.

Federal and state laws regulate the handling of a damaged battery. Proper management is essential. Consumers can find certified disposal locations through several resources:

- Call2Recycle.org: This nonprofit program offers a search tool to find local drop-off sites.

- Earth911: This website provides a recycling search to find businesses that accept electronics.

- Local Retailers: Many electronics stores offer in-store recycling programs.

Contacting these resources ensures the battery is handled correctly, protecting both people and the environment.

Manufacturing defects, physical damage, and improper use cause battery failure. These issues lead to devastating fires. In New York City alone, such fires cost over $500 million in damages and injuries. Users can prevent battery failure by choosing certified products and practicing safe charging. Recognizing warning signs and calling 911 immediately are critical emergency steps. Ultimately, personal responsibility for battery safety is the best defense. It protects both individuals and the community from the growing threat of these fires and improves overall fire safety.

PREGUNTAS FRECUENTES

How can users charge a lithium battery safely?

Users should always use the manufacturer’s certified charger. The quality of the charger is important. They must avoid overcharging the lithium-ion battery. Good charging habits are simple solutions for safety. The quality of these habits protects the lithium battery.

What does a “certified” battery mean?

A certified battery meets strict safety standards. Organizations test its product quality and internal components. This certification confirms the manufacturing quality. High quality is essential for a safe lithium-ion battery. The product quality of a certified lithium battery is reliable.

Can a damaged lithium battery be thrown away?

No. A damaged lithium battery is hazardous waste. People must take it to a special recycling center. Proper disposal is one of the key solutions for community safety. The quality of disposal methods protects the environment from the lithium and ion components.

Important Note: Never put a lithium battery in household trash or recycling bins. The risk of fire is very high. The quality of community safety depends on correct disposal.

Why is temperature control important for a lithium ion battery?

Extreme temperatures damage a lithium ion battery. Heat can trigger dangerous chemical reactions. Cold weather reduces the battery’s efficiency and lifespan. Maintaining a stable temperature is a simple solution. The quality of storage conditions affects the battery’s overall quality and safety.