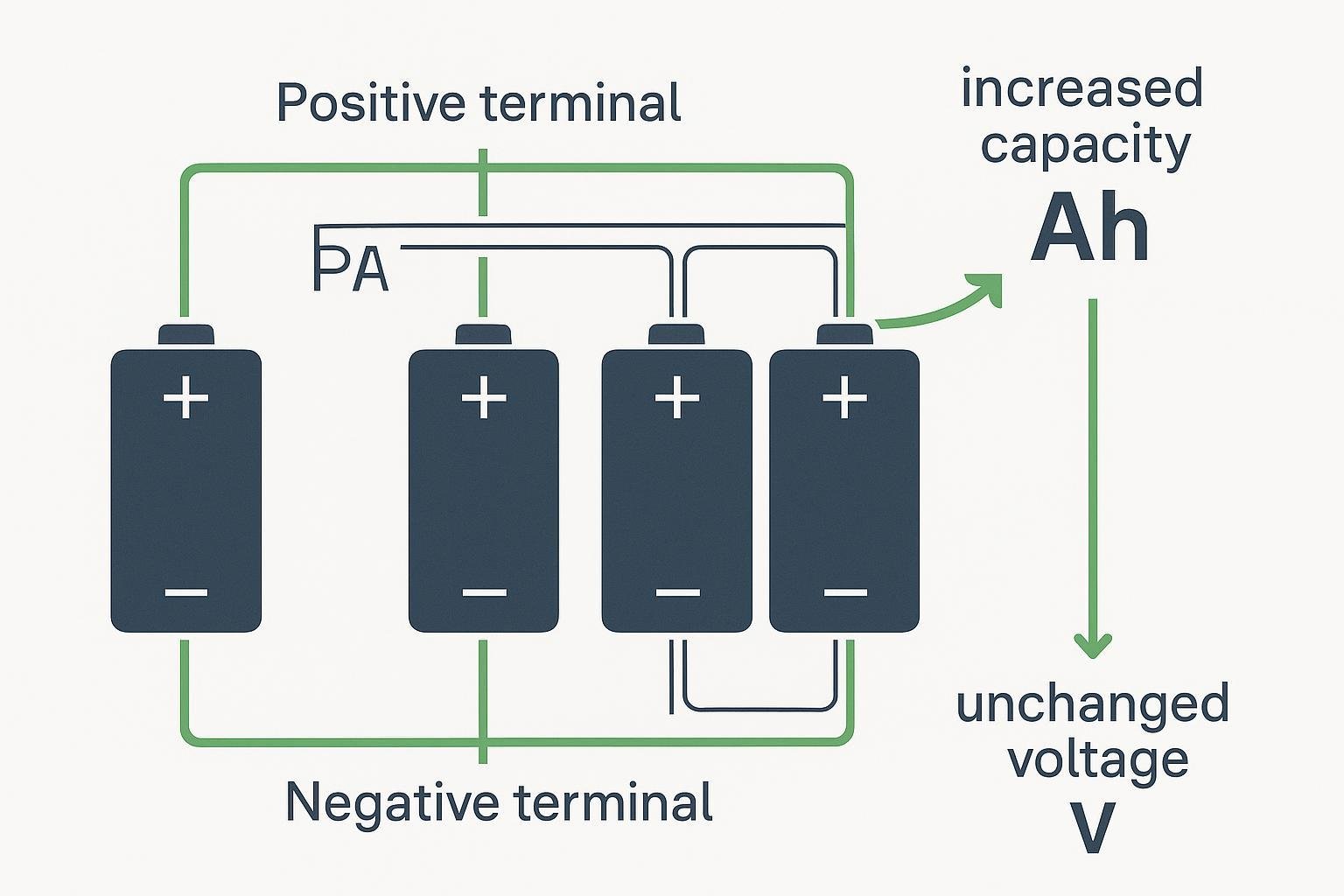

A parallel connection (P) in lithium battery systems involves wiring the positive terminals of multiple cells together and the negative terminals together—resulting in increased total capacity (ampere-hours, Ah) while maintaining the same voltage as a single cell.

Explicación detallada

In battery pack design, connecting cells in parallel means that each cell’s voltage remains constant across the pack, but their capacities are combined. For example, if each cell provides 3.6V and 2Ah, three parallel-connected cells still provide 3.6V but now offer 6Ah total capacity. This enables longer runtimes and higher peak current delivery, which is why parallel configuration is common in applications needing extended energy supply and power stability.

It’s critical in lithium battery systems to ensure that all cells are closely matched in voltage and state of charge before wiring them in parallel. Mismatched cells can lead to large balancing currents, overheating, or even risk of thermal runaway. Proper parallel connection demands precise engineering and often involves pre-balancing cells or using active balancing circuits.

Key Components and Considerations

- Capacity (Ah) Increase: Total capacity is the sum of individual cell capacities.

- Constant Voltage (V): The pack’s voltage remains the same as a single cell.

- Current Sharing: Current drawn from the battery divides across all parallel cells, reducing stress on any one cell and enabling higher peak draw.

- Balancing Needs: Lithium cell voltages must be closely aligned; in larger packs, active or passive balancing circuits are essential.

- Battery Management System (BMS): Especially for lithium batteries, a BMS monitors each parallel group to ensure safe charging, discharging, and balancing (learn more).

Aplicaciones reales

- Consumer Electronics: Laptop batteries often use parallel connection to boost runtime.

- Electric Vehicles & E-bikes: High-capacity battery packs for EVs and e-bikes combine many cells in parallel for greater range.

- Solar Energy Storage: Home or industrial storage systems frequently parallel several cells or modules to meet long-duration power needs.

- Uninterruptible Power Supplies (UPS): Data centers and industrial facilities rely on large parallel-connected battery banks for reliable backup.

Safety and Best Practices

- Always use matched and pre-balanced lithium cells when building parallel packs.

- Integrate fuses or current-protection devices to limit failure risks.

- Employ a robust BMS to monitor all cells and manage balancing, overcharge, and discharge safety.

Related Terms

- Series Connection (S): Increases total voltage while keeping capacity constant. Series and parallel connections are often combined (series-parallel) in advanced battery packs.

- Sistema de gestión de baterías (BMS): Electronic circuitry that oversees charging, discharging, and balancing of cells in both series and parallel groups.

- Battery Pack: A combination of cells (in series, parallel, or both) assembled as a functional energy unit.

- Capacity (Ah): The total energy storage available, additive across parallel cells.

- Voltage (V): The electrical potential, which remains unchanged in parallel connection.

Conclusión

A parallel connection (P) is fundamental in lithium battery engineering for increasing system capacity and supporting higher current applications. Safe design mandates voltage matching, balancing, and use of a qualified BMS—especially as pack complexity and scale grow in industrial and OEM contexts. For more detailed technical guidelines, consult Battery University’s article on series and parallel battery configurations.