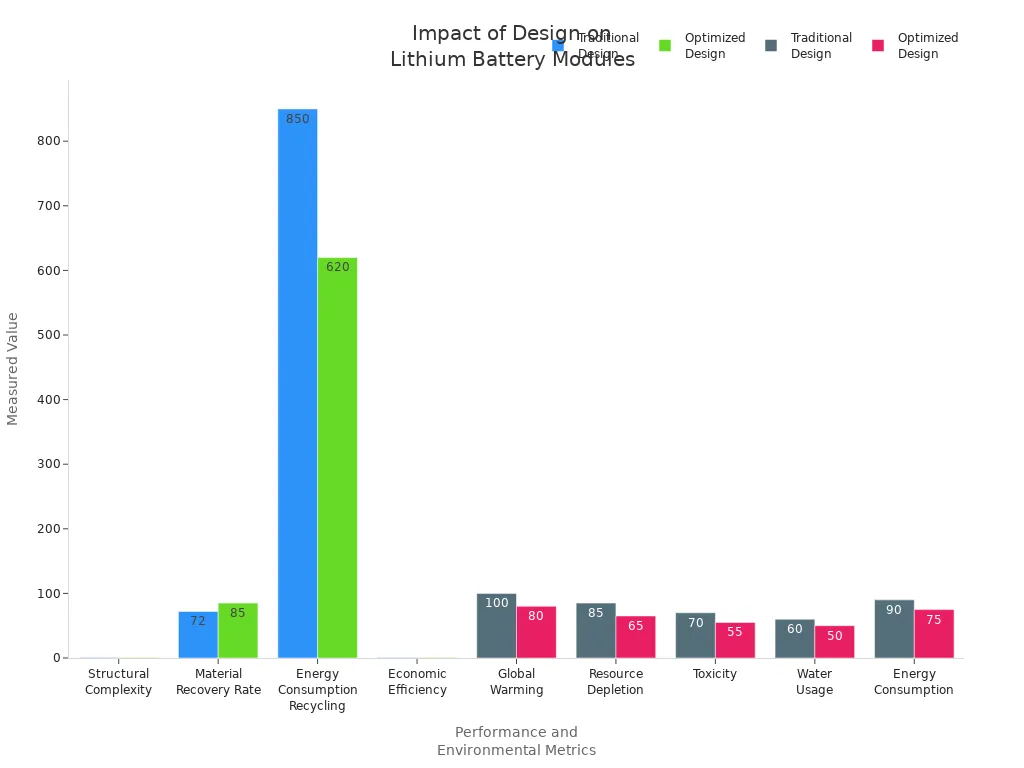

Lithium battery modules power electric vehicles, smartphones, and renewable energy systems. Their battery design shapes safety, performance, and application in every modern device. Over 300 gigafactories worldwide reflect the surge in lithium battery demand, with Asia-Pacific producing over 80% of today’s supply. Studies show that optimized battery design reduces structural complexity and environmental impact while boosting recycling efficiency, as seen below:

Optimization, modeling, and smart management systems now drive safer, more efficient lithium battery modules.

Lithium Battery Modules Overview

Definition and Structure

Lithium battery modules serve as the building blocks for many modern energy systems. Each module consists of several lithium-ion battery cells connected in series or parallel. This arrangement allows the module to deliver the required voltage and current for different devices. The cells inside a module come in three main shapes: cylindrical, prismatic, and pouch. These shapes influence the module’s size, weight, and performance.

A typical lithium-ion battery cell contains five main parts:

- Positive electrode (cathode), often made from lithium cobalt oxide, nickel-cobalt-manganese, or lithium iron phosphate.

- Negative electrode (anode), usually graphite.

- Electrolyte, which lets lithium ions move between electrodes.

- Separator, which keeps the electrodes apart but allows ion flow.

- Casing, which protects the cell and keeps it sealed.

Modules also include terminals and a protective casing. Multiple modules connect together to form a battery pack, which powers everything from cars to backup power systems.

Note: The structure of lithium battery modules affects their safety, energy density, and how well they fit into different applications.

Key Applications

Lithium battery modules power a wide range of industries and devices. Their main applications include:

- Residential Use

- Home energy storage with solar panels

- Backup power during outages

- Energy self-sufficiency

- Commercial and Industrial Use

- Reducing demand charges

- Load shifting and energy arbitrage

- Power quality stabilization

- Integration with on-site renewables

- Utility-Scale Deployment

- Supporting renewable energy generation

- Frequency regulation and load balancing

- Emergency backup for critical infrastructure

Other important applications include new energy vehicles, military equipment, rail transit, and UPS energy storage. The high energy density, long cycle life, and safety of lithium battery modules make them ideal for these uses.

| Aspecto | Detalles |

|---|---|

| Growth Rate | 15-18% CAGR over the past decade |

| Main Market Segments | Electric vehicles, consumer electronics, energy storage systems |

| Regional Dominance | Asia-Pacific leads with over 70% of global output |

| Key Drivers | EV expansion, renewable storage demand, tech advances, government policy |

These trends show that lithium battery modules will continue to play a key role in future energy applications.

Core Components of Lithium Ion Batteries

Cells and Electrodes

Cells form the foundation of all lithium batteries. Each cell contains two electrodes: the anode and the cathode. The anode, usually made from graphite, stores lithium ions during charging. The cathode, often made from lithium-based compounds like nickel manganese cobalt oxide or lithium iron phosphate, releases lithium ions during discharge. These electrodes enable the battery to store and deliver energy through reversible chemical reactions.

| Cell/Electrode Type | Material del cátodo | Anode Material | Key Performance Metrics | Impact on Performance |

|---|---|---|---|---|

| NMC | Nickel, Manganese, Cobalt | Grafito | Voltage ~3.6-3.7V, Specific Energy 150-220 Wh/kg, Cycle Life 1000-2000 | High energy, good stability, used in EVs |

| LCO | Cobalt dominant | Grafito | Voltage ~3.6V, Specific Energy 150-200 Wh/kg, Cycle Life 500-1000 | High energy, shorter life, used in phones |

| LMO | Manganese spinel | Grafito | Lower energy, high current, good safety | Used in power tools, hybrid vehicles |

| Silicon-based Anode | N/A | Silicon + Graphite | Capacity up to 4000mAh, lower cycle life | Higher capacity, mechanical challenges |

Electrode design, thickness, and processing methods like calendering affect battery performance, cycle life, and safety. Advances in recycling now allow recovery of high-quality cathode materials, supporting sustainability and reliable supply.

Electrolyte and Separator

The electrolyte in lithium batteries acts as a medium for lithium ions to move between the anode and cathode. Most electrolytes use lithium salts dissolved in organic solvents. The separator, a thin porous membrane, keeps the electrodes apart while allowing ions to pass through. This design prevents short circuits and ensures safe operation.

- Separators serve as physical barriers and reservoirs for electrolytes, enabling ionic transport.

- They provide critical safety by shutting down ion flow at high temperatures, preventing thermal runaway.

- Materials like polyethylene and polypropylene offer thermal and mechanical stability.

- Ceramic-coated separators improve safety and electrolyte wettability.

Tip: Advances in separator technology, such as ultrathin and ceramic-coated designs, increase both energy density and safety in lithium batteries.

Sistema de gestión de baterías

A battery management system (BMS) monitors and controls the operation of lithium batteries. The BMS tracks each cell’s voltage, current, and temperature to keep the battery within safe limits. It prevents overcharging, over-discharging, and overheating, which can damage the battery or cause safety hazards.

- The BMS balances the state of charge across all cells, ensuring even aging and maximum usable capacity.

- It manages thermal conditions by controlling heating and cooling elements.

- Protection features guard against short circuits, overcurrent, and extreme temperatures.

- The BMS estimates the state of charge and health, enabling better maintenance and fault detection.

- Communication interfaces allow the BMS to report status and integrate with external systems.

A well-designed BMS extends battery life, improves reliability, and enhances safety for all lithium battery modules.

Design Principles

Densidad energética

Maximizing energy density stands as a primary goal in lithium battery design. Engineers use two main approaches to achieve this: materials-based design and parameter-based optimization. Materials-based design focuses on selecting and modifying cathode, anode, electrolyte, and separator materials. These choices directly impact how much energy a battery can store. Parameter-based optimization involves adjusting cell geometry, structure, and internal parameters through modeling and simulation.

- Advanced materials selection and modification increase cell-level energy density.

- Separator and electrolyte design enable higher energy density and better battery performance.

- Engineering teams aim for cell-level energy densities of 350 Wh/kg or more to extend electric vehicle range.

- Organizations such as USABC set system-level targets to guide industry progress.

- Historical trends show that cost reduction and material innovation drive future improvements.

Combining advanced materials with optimized cell structure forms the foundation of high-performance lithium battery modules.

Seguridad

Safety remains a critical aspect of battery design. Modern lithium battery modules use advanced Battery Management Systems (BMS) to monitor cell voltage, temperature, and state of charge. These systems prevent thermal runaway and extend battery lifespan. Modular and flexible pack designs allow safer customization and scalability. Integrated sensors and wireless connectivity enable real-time monitoring and predictive maintenance.

Recent research highlights the importance of understanding thermal runaway stages and associated hazards, such as venting gases and fire risks. Engineers now use improved fire suppression strategies and active suppression techniques to address these dangers. Enhanced cooling and management systems maintain safety even as energy density increases.

Note: Good safety performance depends on continuous monitoring, robust design, and effective suppression mechanisms.

Ciclo de vida

Cycle life measures how many times a lithium battery can charge and discharge before its capacity drops below a usable level. Battery design, manufacturing qualityy operational conditions all influence cycle life. Different lithium chemistries show varying lifespans. For example, LiFePO4 batteries offer longer cycle life, making them ideal for solar energy storage.

| Factor | Descripción |

|---|---|

| Electrode Batching | Uniform dispersion of materials ensures consistent performance and longer lifespan. |

| Coating Process | Optimized electrode thickness and density reduce decay and internal resistance. |

| Winding Process | Proper tightness balances resistance and wetting, preventing capacity loss. |

| Aging and Side Reactions | Minimizing side reactions extends cycle life and improves battery stability. |

| Environmental Conditions | Extreme temperatures and mechanical shocks shorten lifespan and degrade components. |

| Charge/Discharge System | Correct charging protocols tailored to chemistry prevent premature degradation. |

Manufacturers use high-grade materials and precise processes to extend battery lifespan. Proper charging, temperature control, and usage patterns also play key roles in maximizing cycle life and overall battery performance.

Material Compatibility

Material compatibility issues present significant challenges in lithium battery module design. Flammable liquid electrolytes pose safety risks, especially in high energy density batteries. Engineers address this by using solid-state electrolytes and non-combustible alternatives, such as ionic liquids and phosphate esters, to improve chemical stability.

| Material Compatibility Issue | Descripción | Addressing Approach |

|---|---|---|

| Flammability of electrolytes | High fire risk in traditional designs | Use solid-state or non-combustible electrolytes |

| Brittleness of inorganic electrolytes | Poor interface contact | Develop composite solid electrolytes for better stability |

| Limited strength of polymer electrolytes | Reduced mechanical robustness | Optimize polymer design for strength and conductivity |

| Interface stability in composites | Need for balanced properties | Control composition and structure for optimal performance |

| Safety challenges | Inefficient traditional protection | Integrate smart safety materials (PCMs, PTCs, STPs, SMMs) |

| Interfacial reactions | Degraded performance and safety | Use interface engineering to improve stability |

Smart safety materials, such as phase change materials and shape memory polymers, respond to temperature changes and help prevent thermal runaway. Interface engineering further enhances stability and safety analysis. These innovations ensure that lithium battery modules deliver reliable performance and long lifespan in demanding applications.

Structural and Thermal Optimization

Mechanical Layout

Engineers focus on mechanical layout to ensure the structural integrity of every battery module. Mechanical testing plays a key role. Vibration tests simulate the stresses of transport and operation. Shock and impact tests check resistance to sudden forces. Crush tests show how the module behaves under extreme compression. These tests confirm that the battery can withstand real-world conditions and maintain safety.

Best practices in design account for cell swelling and breathing effects. Engineers must control deformation and stress so that the structure does not exceed its yield strength. Limiting deformation prevents cells from touching each other, which could cause short circuits. Reliability-based design optimization frameworks help address uncertainties in material properties and operating conditions. Some modules use a 3D metal lattice splint. This structure, optimized through simulation, improves mechanical uniformity and reduces pressure and temperature differences between cells. The result is better stability, longer battery life, and improved safety.

Gestión térmica

Thermal management keeps battery modules within safe temperature ranges. Several techniques help prevent overheating:

- Thermal barriers between cells contain heat and stop thermal runaway from spreading.

- Physical separation allows heat to dissipate and lowers the risk of heat transfer.

- Active cooling systems, such as liquid cooling and forced air, remove excess heat. Liquid cooling works best for high-power applications.

- Venting mechanisms safely release gases and heat, preventing casing rupture.

- Fire suppression systems detect thermal runaway and release agents to smother flames.

- Battery management systems monitor temperatures and activate safety protocols.

- Thermal insulation materials, like phase change materials, absorb and release heat to stabilize temperature.

These strategies work together to improve safety and extend battery life.

Cell Arrangement

Cell arrangement affects both cooling efficiency and safety. Engineers use different layouts, such as rectangular, diamond, and staggered. The staggered arrangement provides the best airflow and heat dissipation. This layout lowers the maximum temperature and improves temperature uniformity, which increases safety.

| Cell Arrangement | Cooling Efficiency Impact | Safety Impact | Optimal Spacing (mm) | Temperature Metrics (°C) |

|---|---|---|---|---|

| Rectangular | Moderate airflow | Higher max temperature, uneven cooling | Δh: 3.86, Δv: 3.96 | N/A |

| Diamond | Blocked airflow in back rows | Increased temperatures | Δh: 3, Δv: 4 | N/A |

| Staggered | Best airflow, enhanced heat dissipation | Lower max temperature, better uniformity | Δh: 4, Δv: 4 | Avg: 27.78, Max: 28.27, Min: 25.2 |

Engineers use optimization algorithms to find the best arrangement and spacing. Good cell arrangement ensures even cooling, reduces temperature differences, and improves battery safety and efficiency.

Performance Optimization Strategies

Electrical Configuration

Electrical configuration forms the backbone of lithium battery module performance. Most modules use series-parallel topologies. In these systems, engineers connect cells in parallel to form groups, then link these groups in series to reach the desired voltage. The battery management system (BMS) monitors each group as a single unit. However, differences in cell capacity, internal resistance, and heat generation can cause uneven current flow and temperature changes. These imbalances lead to faster aging, reduced lifespan, and safety risks such as thermal runaway.

The placement of system terminals and the use of cross-connectors play a major role in performance optimization. Modules with cross-connecting terminals show better current and temperature balance. This design can extend cycle life by more than four times compared to standard layouts. Reducing connector resistance and balancing cell currents help prevent aging differences and improve safety. Both manufacturing inconsistencies and connector design affect how well the battery performs. Engineers use multiphysics electro-thermal-aging models to simulate these effects and guide better battery modeling and design optimization.

Tip: Optimized electrical configurations not only boost battery performance but also increase safety and extend lifespan.

Reliability-Based Design

Reliability-based design focuses on making lithium battery modules last longer and work more safely. This approach uses redundancia, adding extra cells and equalization circuits to handle temperature differences and cell aging. By including redundant cells, the module can keep working even if some cells degrade faster than others. This method addresses the “Buckets effect,” where the weakest cell limits the whole pack’s lifespan.

Engineers use advanced modeling techniques to predict how each cell will age and how the pack will perform over time. These models consider electric, chemical, thermal, and flow factors. They help find the best balance between cost, redundancy, and reliability. The table below summarizes key aspects of reliability-based design:

| Aspecto | Explicación |

|---|---|

| Redundant Cells | Extra cells extend lifespan and reduce the need for early replacement, improving safety. |

| State of Health (SoH) | Reliability calculations use the health and aging of each cell to predict overall reliability. |

| Modeling Techniques | Universal Generating Function (UGF) and Multi-State System (MSS) models optimize reliability. |

| Tradeoff Consideration | Balances cost, redundancy, and reliability for safer, longer-lasting modules. |

| Safety Impact | Prevents aged cells from overloading others, reducing risk and improving safety. |

| Application Context | Used in electric vehicles to address real-world issues like heat and cell degradation. |

Reliability-based design ensures that battery modules deliver consistent performance and a longer lifespan, even under tough conditions.

Computational Tools

Computational tools have become essential for performance optimization in lithium battery modules. Engineers use a range of models to predict and improve battery behavior:

- Electrochemical models simulate how ions move and react inside cells.

- Mechanical models study how the battery structure responds to stress and vibration.

- Thermal management system models predict temperature changes and cooling needs.

- Multiphysics models combine electrical, thermal, and mechanical effects for a complete view.

Popular software tools include COMSOL® Multiphysics, which integrates electrical, thermal, and electrochemical simulations, and ANSYS Fluent CFD, which models fluid flow and temperature distribution. Electrical equivalent circuit models use simple components to predict voltage, current, and capacity under different conditions. Digital twin technology creates a virtual copy of the battery system, allowing engineers to test and optimize performance without building physical prototypes.

Note: Virtual prototyping with these tools reduces development time and cost while improving battery safety and performance.

AI-driven workflows now accelerate battery design. In the exploration phase, engineers define problems, generate hypotheses, and test them using computational models. The exploitation phase filters and ranks solutions, then validates them with advanced calculations and lab tests. AI models trained on battery data can quickly identify new materials and manufacturing methods that improve battery performance and sustainability. Generative AI models even create new electrode microstructures, helping engineers find the best manufacturing settings for higher energy density and longer lifespan.

Engineers also use advanced cooling strategies, such as immersion cooling and phase change materials, to manage heat. Computational fluid dynamics (CFD) and thermal simulations help predict hot spots and optimize cooling designs. These tools, combined with smart battery management systems and careful cell arrangement, ensure that lithium battery modules achieve top performance and safety.

Application and Selection

Requirements by Use Case

Selecting the right battery module depends on the specific needs of each application. Engineers consider factors such as energy density, safety, cycle life, and compliance. For electric vehicles, battery modules must deliver high energy density to reduce weight and maximize driving range. In contrast, stationary energy storage systems focus on safety, long cycle life, and reliability. The table below highlights the main differences between battery modules for electric vehicles and stationary storage:

| Requirement Aspect | Electric Vehicle Battery Modules (NMC) | Stationary Energy Storage Battery Modules (LFP) |

|---|---|---|

| Cathode Chemistry | Nickel Manganese Cobalt (NMC) for high energy density | Lithium Iron Phosphate (LFP) for stability and safety |

| Densidad energética | High energy density to minimize weight for vehicle propulsion | Lower energy density, weight less critical |

| Operating Voltage | Approximately 3.7 volts per cell | Approximately 3.2 volts per cell |

| Seguridad | Higher risk of thermal runaway due to looser oxygen bonds and reactive electrolyte | Lower risk of thermal runaway due to stronger oxygen bonds and more stable chemistry |

| Longevity and Cycle Life | Shorter lifespan due to higher voltage and reactive chemistry | Longer lifespan with thousands of charge-discharge cycles |

| Molecular Structure | Smaller molecules, less expansion/contraction during cycling | Larger molecules allowing easier expansion/contraction, enhancing durability |

| Primary Focus | Maximizing energy density and power for propulsion | Emphasizing safety, cycle life, and reliability for repeated daily use |

Application-specific requirements also influence the choice of battery chemistry, form factor, and management system. For example, renewable energy storage systems need battery modules that can handle frequent charge and discharge cycles, withstand harsh outdoor conditions, and integrate with solar or wind power. Medical devices require battery modules with high safety and compliance standards. Custom battery packs help optimize power, size, and runtime for each use case.

Tip: Partnering with experienced manufacturers ensures that battery modules meet electrical, mechanical, and regulatory needs for each application.

Industry Standards

Industry standards guide the design, manufacturing, and certification of every battery module. These standards ensure safety, performance, and regulatory compliance across different sectors:

- UL standards:

- UL 1642: Safety for lithium primary and rechargeable cells and batteries.

- UL 2271: Batteries for light electric vehicles.

- UL 2580: Batteries for industrial and automotive applications.

- International Electrotechnical Commission (IEC) standards:

- IEC 62133: Safety and performance for portable lithium-ion batteries.

- IEC 62619: Safety for secondary lithium cells in industrial and stationary applications.

- IEC 62620: Performance requirements for industrial batteries.

- IEC 62281: Safety during transport of lithium batteries.

- UN Manual of Tests 38.3: Required for global transportation safety.

- ANSI and IEEE standards:

- ANSI C18 series for portable lithium batteries.

- IEEE 1725 and 1625 for mobile devices.

- SAE standards: Automotive and aerospace battery applications.

- FDA regulations: Medical device battery compliance.

- Fire protection and storage:

- NFPA 855: Fire protection for energy storage systems.

- FM Global Data Sheet 8-1: Fire protection for battery storage.

- International Fire Code (IFC) Chapter 12: Energy storage system installations.

- CE Marking: Compliance for the European market.

Standards such as IEC 62660 and UL 2580 set strict safety and testing benchmarks for automotive battery modules. Compliance with these standards is essential for certification and market access. These guidelines help manufacturers deliver battery modules that meet the highest safety and performance requirements worldwide.

Lithium battery modules rely on strong design principles to deliver safety and high performance. Engineers now use parametric optimization, advanced materials, and artificial intelligence to improve energy density and reliability. Nano-coating and new conductive materials help extend lifespan and reduce costs. Readers should apply these strategies and continue learning as technology and best practices evolve.

PREGUNTAS FRECUENTES

What is the main advantage of lithium battery modules over traditional batteries?

Lithium battery modules offer higher energy density and longer cycle life. They weigh less and store more power than traditional batteries. Many industries choose them for their reliability and efficiency.

How does a Battery Management System (BMS) improve safety?

A BMS monitors voltage, current, and temperature for each cell. It prevents overcharging, overheating, and short circuits. This system helps extend battery life and reduces safety risks.

Why is thermal management important in lithium battery modules?

Thermal management keeps battery temperatures stable. It prevents overheating and thermal runaway. Good thermal control improves safety and extends the lifespan of the battery module.

Can lithium battery modules be recycled?

Yes, recycling processes recover valuable materials like lithium, cobalt, and nickel. Recycling reduces environmental impact and supports a sustainable battery supply chain.

What factors affect the lifespan of a lithium battery module?

Several factors influence lifespan: cell chemistry, charging habits, temperature control, and mechanical design. Proper use and regular maintenance help maximize battery life.