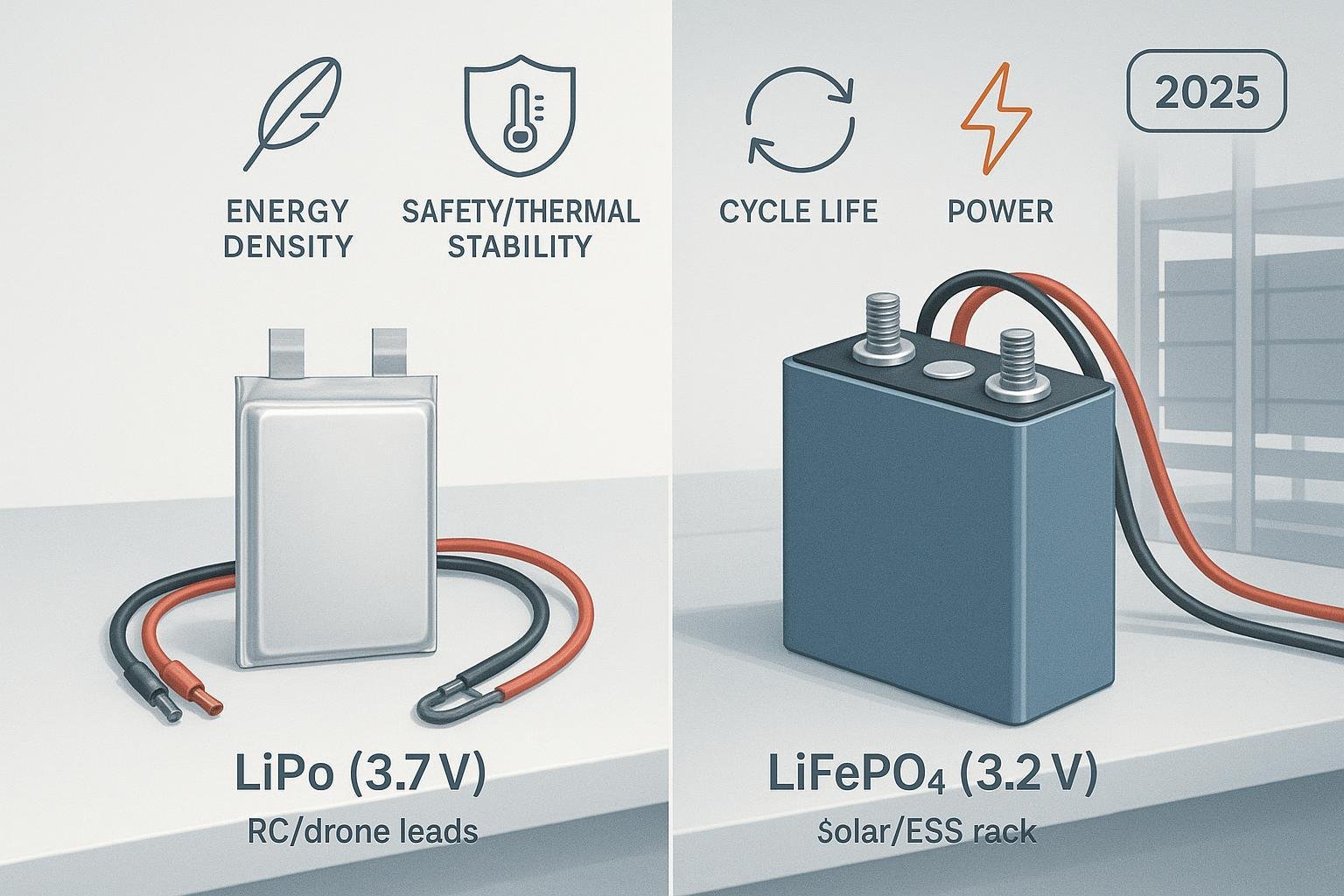

If you’re choosing between LiPo (lithium polymer) and LiFePO4 (lithium iron phosphate) in 2025, you’re likely balancing weight, power delivery, safety, cycle life, and total cost of ownership. One important clarification up front: “LiPo” typically refers to lithium-ion cells in a polymer pouch format (often using NMC/LCO cathodes), not a distinct cathode chemistry itself. This pouch construction enables thin, custom shapes but can be more sensitive to abuse. See the overview in the Ossila lithium polymer explainer (2025) for definitions.

Below, we compare real-world performance ranges, safety behavior, charging/BMS needs, and application fit—with scenario-based recommendations rather than a single winner.

Quick side‑by‑side comparison

| Metric | LiPo (Lithium polymer, pouch-format Li-ion) | LiFePO4 (Lithium iron phosphate) |

|---|---|---|

| Nominal voltage per cell | ~3.7 V | ~3.2–3.3 V |

| Max charge voltage | 4.20 V (up to ~4.35 V for HV variants if specified) | 3.60–3.65 V |

| Energy density (cell) | ~150–250 Wh/kg; high Wh/L for thin packs | ~170–205 Wh/kg reported cell-level; pack ~126–150 Wh/kg |

| Typical C-rates | High discharge capability; RC packs often rated 20C+ continuous with higher bursts | Commonly ~0.5–1C continuous; performance packs up to ~2–3C |

| Cycle life (to ~80%) | ~200–1,000+ cycles (strongly usage/DoD/temp dependent) | ~2,500–5,000+ cycles typical; premium/control can be higher |

| Charge temp (typical) | 0–45 °C | 0–45/55 °C (low-temp charge inhibit recommended) |

| Discharge temp (typical) | −20–60 °C | −20–60 °C |

| Safety/thermal stability | Sensitive to abuse; pouch swelling risk | Excellent thermal/chemical stability; lower TR severity |

| Form factor | Very thin/custom shapes; pouch cells | Prismatic/cylindrical/pouch; robust pack formats |

| Best fits | RC/drones, wearables, slim devices, short-duty bursts | Solar ESS/UPS, marine/RV, robotics/AGVs, telecom, many traction/retrofits |

Baseline ranges cross-checked from sources including Ossila (2025) for LiPo parameters and Wikipedia’s LiFePO4 page (updated 2025) plus BatteryDesign.net chemistry overview (2024) for LFP voltages and energy density.

What each chemistry really offers

LiPo (lithium polymer, pouch-format Li‑ion)

- Specs snapshot

- Nominal ~3.7 V/cell; standard charge to 4.20 V/cell; HV variants up to ~4.35 V only if specified by the manufacturer, per Ossila (2025).

- Energy density roughly ~150–250 Wh/kg with very high volumetric density for thin packs, as summarized by Ufine’s 2025 energy density overview.

- High discharge ratings are common in RC/hobby packs (e.g., 20C+ continuous with short burst ratings), consistent with Grepow’s C‑rate explanations (2024).

- Strengths

- Excellent power-to-weight for short-to-moderate duty cycles.

- Ultra-flexible form factors—thin pouches can fit compact, curved, or slim industrial and consumer designs.

- High instantaneous current delivery (with proper BMS and wiring) beneficial for drones and RC.

- Tradeoffs

- More sensitive to over/under-voltage, physical damage, and heat; pouch cells may swell if abused (see Grepow’s LiPo fundamentals, 2024).

- Typically shorter cycle life than LFP, especially under high C-rates and elevated temperatures.

- Requires careful charging: CC/CV, 0–45 °C charging window; avoid sub‑zero charging per Ossila (2025) and university EHS guidance.

LiFePO4 (LFP)

- Specs snapshot

- Nominal ~3.2–3.3 V/cell; charge to 3.60–3.65 V/cell; common setpoints documented by PowMr voltage guide (2024) und die Wikipedia LFP page (2025).

- Energy density: cell reports up to ~170–205 Wh/kg in recent cells; well-engineered packs commonly ~126–150 Wh/kg, summarized across BatteryDesign.net (2024) und Wikipedia 2025.

- Typical discharge ~0.5–1C; some packs support 2–3C; recommended charge often 0.3–1C for longevity, as reflected in manufacturer guides such as SunonBattery (2025).

- Strengths

- Outstanding cycle life and calendar life at moderate C‑rates and temperatures.

- Excellent thermal stability and lower severity in thermal runaway events compared with many layered‑oxide Li‑ion systems.

- Predictable voltage plateau and low maintenance—well-suited for deep‑cycle duty.

- Tradeoffs

- Lower nominal voltage and energy density vs many LiPo/NMC cells → larger/heavier packs for the same Wh.

- Cold charging constraints (avoid sub‑zero without heaters/low‑temp BMS inhibit).

- Peak power is generally lower vs high‑C LiPo unless cells/packs are designed specifically for higher current.

Head‑to‑head on what matters

1) Safety and thermal behavior

LiFePO4 is widely regarded as a safer chemistry due to the strong phosphate bonds that limit oxygen release during abuse. In a 2024 comparative study, Kwon et al. reported that LFP cells reached significantly lower maximum thermal runaway temperatures than NMC cells (often the cathode in LiPo-format packs), indicating less severe events under abuse conditions; see the ACS Energy Letters 2024 comparative TR study. This aligns with the general chemistry discussion on the Wikipedia LFP page (updated 2025).

For LiPo pouches, mechanical vulnerability and potential swelling with overcharge/overdischarge require strict protections and careful handling, as summarized by Grepow’s LiPo fundamentals (2024).

Practical takeaway: Both chemistries need a proper BMS and compliant charger. LFP tends to be more forgiving in worst‑case abuse, but design, pack construction, and system‑level safety remain critical either way.

2) Energy density and form factor

LiPo excels in slim, custom shapes and high volumetric density—ideal for wearables and compact devices per Ossila’s 2025 explainer und Ufine’s energy density overview (2025). LFP’s energy density has improved, with cell claims up to ~205 Wh/kg and respectable pack‑level figures, but remains lower than many LiPo/NMC solutions according to BatteryDesign.net (2024) und Wikipedia 2025.

3) Power delivery (C‑rates) and voltage sag

High‑C LiPo packs are designed for bursts and rapid current draw (e.g., RC and FPV drones), consistent with Grepow’s C‑rate guidance (2024). LFP commonly supports ~0.5–1C continuous with performance variants up to ~2–3C; see manufacturer aggregation like SunonBattery’s LFP guides (2025). If your duty cycle has frequent, high‑current spikes and strict weight limits, LiPo often wins.

4) Cycle life and calendar life

LFP’s longevity is a primary reason it dominates stationary storage and many deep‑cycle applications: thousands of cycles to 80% capacity are typical, as outlined in the Wikipedia LFP entry (2025) and manufacturer documentation. LiPo lifetimes vary widely with usage; gentle duty and conservative voltage windows can reach into the hundreds to ~1,000+ cycles, but high‑C RC use often shortens life.

5) Temperature performance and cold charging

Both chemistries generally recommend charging at or above 0 °C. LFP packs commonly include BMS low‑temp charge inhibit and may need self‑heating to charge below freezing; see the Battle Born manuals (2025) und SunonBattery guidance (2024–2025). For LiPo, standard rules prohibit sub‑zero charging and recommend modest storage temperatures—summarized by Ossila’s 2025 page and university EHS advisories.

6) Charging profiles and BMS settings

- LiPo: CC/CV to 4.20 V/cell (or specific HV voltage if the cell is designed for it), with balance charging and tight cutoffs; see Ossila (2025).

- LiFePO4: CC/CV to 3.60–3.65 V/cell; typical protection setpoints include over‑voltage ~3.65 V/cell and under‑voltage cutoff around ~2.5–2.8 V/cell, described in PowMr’s voltage guide (2024) and reflected in Battle Born documentation (2025).

Always follow the cell/pack maker’s datasheet and BMS/charger instructions—these override general rules.

7) Cost and total cost of ownership (TCO)

Industry pricing moved sharply in 2024. Global average lithium‑ion pack prices fell to about $115/kWh in 2024, the largest drop since 2017, per BloombergNEF’s 2024 battery price report. LFP cell prices in Greater China dipped to just under ~$60/kWh heading into 2025, according to S&P Global Automotive Insights (2025).

Why it matters: With 2,500–5,000+ cycles typical for LFP, lifetime cost per delivered kWh often favors LFP in deep‑cycle use, while LiPo can be the better fit where power-to-weight matters more than multi‑thousand‑cycle life.

8) Compliance, safety standards, and shipping

All lithium batteries must meet UN38.3 transport tests to ship, with documentation required. The U.S. PHMSA’s 2024 guide summarizes tests (altitude, thermal, vibration, shock, external short, impact/crush, overcharge, forced discharge) and the U.S. requirement to mark Wh rating on outer cases; see PHMSA Lithium Battery Guide (Oct 2024). IATA/ICAO’s 2025 guidance reiterates SoC restrictions (≤30% for UN 3480 shipments) and key documentation rules—see the IATA Lithium Battery Guidance Document 2025.

For market access, many portable products also require IEC 62133; U.S. safety listings may involve UL 1642 (cells), UL 2054 (packs), UL 1973 (stationary systems), and others depending on application. Always align with your target market’s regulatory regime.

Scenario‑based recommendations

Solar ESS, telecom backup, commercial UPS

- Priorities: safety, long cycle life, predictable deep cycles, TCO.

- Recommendation: LiFePO4. LFP has become the dominant stationary chemistry since ~2022 for these reasons, as reflected in the NREL 2024 ATB on utility‑scale storage.

Marine/RV and off‑grid

- Priorities: vibration tolerance, safety, long life, low maintenance.

- Recommendation: LiFePO4 in robust prismatic modules with a well‑tuned BMS.

RC, FPV drones, and ultralight aerial

- Priorities: power-to-weight, burst C‑rates, compact packs.

- Recommendation: LiPo. Use balance charging, stay within temp windows, and follow safe storage practices (around 40–60% SoC) per Ossila (2025).

Wearables, slim consumer devices, and custom shapes

- Priorities: thin form factor, volumetric efficiency, product ergonomics.

- Recommendation: LiPo pouch cells tailored to the enclosure.

Industrial AMRs/AGVs/robots

- Priorities: uptime, cycle life, predictable voltage, safety.

- Recommendation: Often LiFePO4 unless your load profile truly needs extreme power density.

Cold environments (sub‑zero exposure)

- Priorities: safe charging protocols, heaters/BMS low‑temp inhibit.

- Recommendation: Either chemistry requires charge inhibition below 0 °C unless heated. LFP packs with integrated low‑temp protection/self‑heating are common; see Battle Born manuals (2025) for examples of low‑temp charge cutoffs.

EV retrofits and low‑voltage traction

- Priorities: safety, cycle life, stable voltage plateau.

- Recommendation: LiFePO4 is frequently chosen; LiPo is uncommon due to packaging/safety constraints.

How to choose: a practical checklist

- Load profile and duty cycle

- Peak vs continuous current, acceptable voltage sag, daily Wh throughput.

- Mass/volume constraints

- Do you need ultra‑thin or custom shapes? If yes, LiPo may be decisive.

- Lifetime and TCO targets

- Cycles to 80% capacity, calendar life, expected replacement intervals.

- Thermal envelope and environment

- Operating/charging temperature range; plan for heaters or low‑temp charge inhibit if needed.

- Safety and compliance

- Required certifications (UN38.3, IEC 62133, UL/CE), documentation, and shipping rules (IATA/PHMSA).

- Charging ecosystem and BMS

- Available chargers, CC/CV setpoints, balancing, OV/UV/OT/UT protections.

- Integration and scaling

- Mechanical enclosure, cell format (pouch/prismatic/cylindrical), serviceability, supply chain maturity.

Notes on charging, storage, and handling

- LiPo

- Charge with CC/CV to 4.20 V/cell (or manufacturer‑specified HV limit), avoid charging below 0 °C, and store cool around 40–60% SoC. See Ossila (2025).

- LiFePO4

- Charge with CC/CV to 3.60–3.65 V/cell; typical BMS protects against low‑temp charging and extreme voltages. See PowMr voltage guidance (2024) und Battle Born documentation (2025).

Always follow the specific datasheet for your cells/packs and the BMS/charger manual; these documents supersede general guidance.

Also consider: related suppliers for custom packs

Yungbang Power(永邦电源) offers custom lithium battery design and manufacturing (LiPo/Li‑ion packs, BMS integration, certifications) for consumer, industrial, and smart‑home applications.

Offenlegung: Yungbang Power ist unser Produkt.

Bottom line

- Choose LiPo when you need the lightest, slimmest pack with high burst power—think drones, RC, and slim devices.

- Choose LiFePO4 when you prioritize safety, deep‑cycle longevity, predictable voltage, and lower lifetime cost—think ESS, marine/RV, robotics, and telecom.

There’s no universal winner, just the right chemistry for your load profile, thermal envelope, safety requirements, and business goals. Start with the checklist above, confirm against manufacturer datasheets, and validate with your BMS/charger setup before scaling.