If you fly FPV, race RC, build robots, or spec packs for products, LiPo discharge is where performance, safety, and longevity collide. This guide gives you a practical, 2025-current playbook: the math you actually use, conservative defaults that protect packs, how to set LVC with real telemetry, what to do when a pack swells, and the standards that now shape shipping and compliance.

Quick promise: you’ll leave with ready-to-use tables, checklists, and settings that work in the field.

Executive summary: the five do’s and don’ts

Do:

- Size current by math:

I (A) = Capacity (Ah) × C-rateper the industry-standard C-rate definition in the educational summary from Ossila — What is battery C‑rate. - Set conservative LVC: start near 3.2–3.3 V/cell under load; warn earlier around 3.5 V/cell; then tune from telemetry. Hobby ESC/FC defaults sit in this range, for example the 3.4/3.0/2.8 V modes in the Hobbywing Skywalker V2 manual (2023 PDF) and Betaflight’s 3.5/3.3 V thresholds in its CLI reference.

- Respect temperature: best performance is around 15–35°C; high heat accelerates aging, and cold raises IR and sag, as summarized by Battery University’s testing overview (BU‑907b) and manufacturer FAQs like Ufine’s temperature ranges.

- Store at ~3.7–3.85 V/cell in a cool, dry place; avoid trickle/float charging, which Li‑ion chemistries do not accept per Battery University’s charge method tables.

- Ship and travel legally: airlines and logistics increasingly enforce ≤30% SoC and other rules; see the IATA Lithium Battery Guidance Document (2025) and passenger rules in IATA’s traveler advisory (2025).

Don’t:

- Believe every C number printed on a shrink wrap. Vendor C-ratings vary; confirm with reputable sources or your own measurements (see IR section) and the practical cautions echoed by industry summaries such as Ufine’s C‑rate guide.

- Run to 3.0 V/cell regularly. That’s the hard floor; habitual deep discharge shortens life and risks damage, a point reinforced by manufacturer voltage guides like Grepow’s LiPo voltage overview.

- Charge a hot pack or in freezing conditions. Let it cool to ambient and keep charge temps in ~0–45°C.

- Ignore swelling, odor, or heat. Treat as a hazard; government advisories recommend isolating and disposing properly, e.g., the New Jersey Division of Fire Safety (2023).

- Parallel packs with large voltage deltas. Equalize within ~0.1 V per cell first and follow safe connection practices like those in Oscar Liang’s parallel charging guide.

1) LiPo discharge basics: what C-rate really means

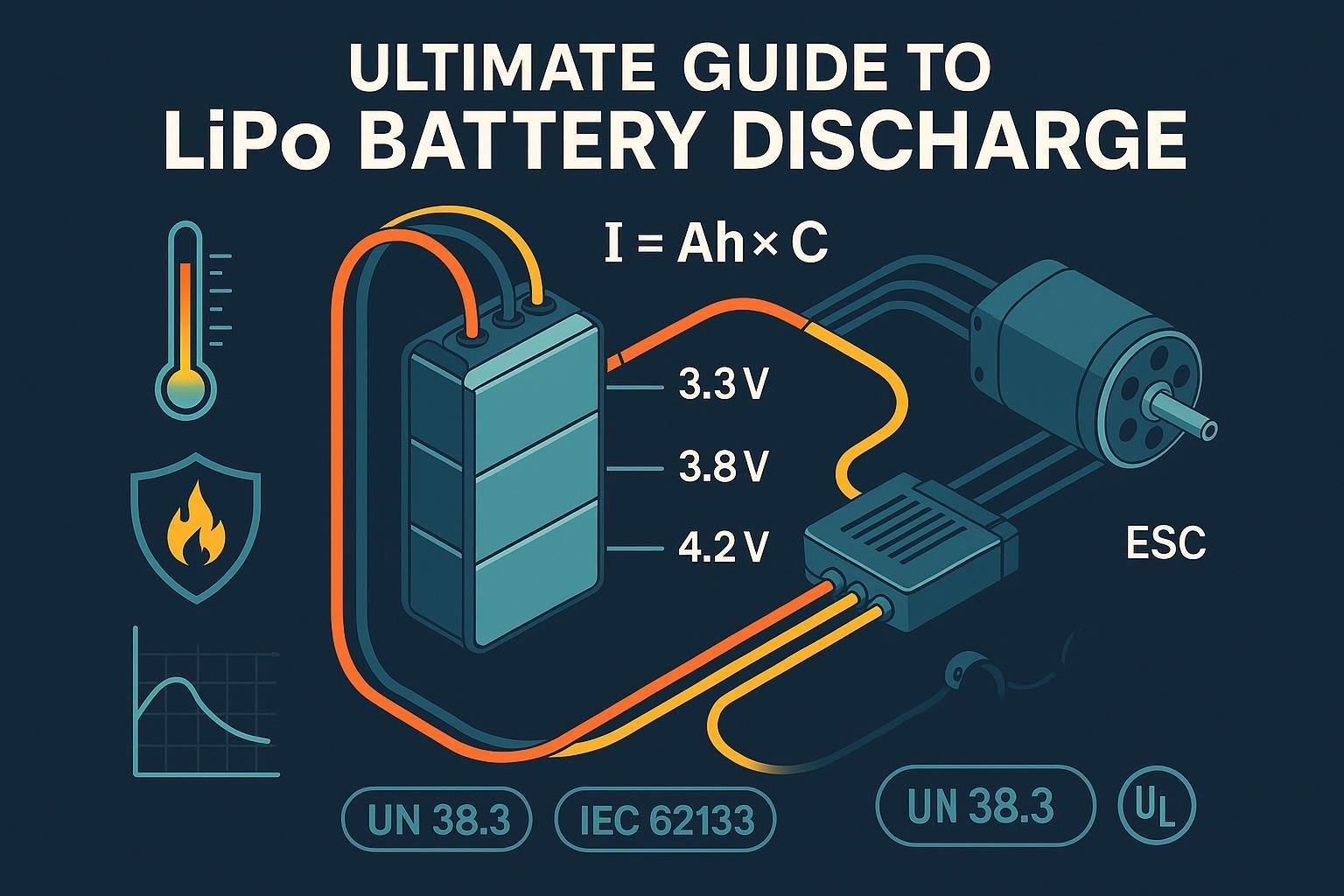

C-rate is simply a multiplier for current relative to capacity. The core formula is your go-to:

- Discharge current:

I (A) = Capacity (Ah) × C-rate - Example: a 2.2 Ah (2200 mAh) pack at 25C → 2.2 × 25 = 55 A continuous. This is the standard industry interpretation as explained by Ossila’s C‑rate definition.

Continuous vs. burst:

- Many packs specify “continuous” and a short “burst” rating (often 5–10 seconds). Burst capability can be 1.5–2× the continuous value but raises heat and accelerates wear, a practical caution echoed across manufacturer and integrator guides, e.g., Ufine’s C‑rate overview.

Three realities to keep in mind:

- C-ratings aren’t standardized across brands. Consider them a starting point, not a guarantee.

- Temperature and internal resistance (IR) determine how much sag and heat you’ll see at a given C.

- Higher C for longer = faster aging. If you want longevity, size for lower average C and keep temps controlled.

Quick reference: capacity × C-rate to amps

| Kapazität | 20C | 25C | 30C | 60C |

|---|---|---|---|---|

| 650 mAh (0.65 Ah) | 13 A | 16.3 A | 19.5 A | 39 A |

| 1300 mAh (1.3 Ah) | 26 A | 32.5 A | 39 A | 78 A |

| 2200 mAh (2.2 Ah) | 44 A | 55 A | 66 A | 132 A |

| 5000 mAh (5.0 Ah) | 100 A | 125 A | 150 A | 300 A |

Tip: When in doubt, size the pack so your typical continuous draw is ≤50% of the rated continuous current. You’ll get cooler operation and longer life.

2) How low can you go? Cutoff voltages under load vs. at rest

There are two voltages you care about:

- Under load: The pack sags due to IR; this is where ESC/BMS cutoffs work.

- At rest: After a short recovery, the voltage rebounds a bit—this is where you measure for storage or health checks.

Conservative, field-proven defaults:

- Warnings: ~3.5 V/cell (under load)

- Cutoff/critical: ~3.2–3.3 V/cell (under load)

- Absolute floor: ~3.0 V/cell (under load) — avoid reaching this routinely. Manufacturer and hobby literature consistently advise staying above 3.0 V/cell; see Grepow’s LiPo voltage overview.

These align with common controller defaults. For example, the Hobbywing Skywalker V2 offers modes around 2.8/3.0/3.4 V per cell (multiply by S-count) per the Hobbywing manual (2023 PDF). Betaflight’s default warnings are 3.5 V per cell (warn) and 3.3 V per cell (min) per its CLI documentation, and it includes “VBat Sag Compensation” to stabilize readings across throttle per the Betaflight docs.

Storage voltage (at rest): ~3.7–3.85 V/cell. This aligns with common manufacturer guidance and the safety rationale behind reduced state of charge for transport—around 30% SoC corresponds to ~3.70 V/cell per Battery University’s 2025 shipping note (BU‑704a) and manufacturer summaries such as Grepow’s voltage guide.

Quick reference: LVC totals by S-count (choose one per-cell target and multiply)

| Cells (S) | 3.1 V/cell | 3.2 V/cell | 3.3 V/cell |

|---|---|---|---|

| 2S | 6.2 V | 6.4 V | 6.6 V |

| 3S | 9.3 V | 9.6 V | 9.9 V |

| 4S | 12.4 V | 12.8 V | 13.2 V |

| 5S | 15.5 V | 16.0 V | 16.5 V |

| 6S | 18.6 V | 19.2 V | 19.8 V |

Anmerkungen:

- For high-sag setups (cold weather, high IR, thin wiring), start higher (e.g., 3.3 V/cell) to avoid abrupt cutoffs.

- For endurance builds with gentle loads, you can sometimes set warning lower (3.4–3.5 V/cell warn, 3.2–3.3 V/cell critical) and rely on telemetry to land with margin.

3) Temperature and discharge: what changes and why it matters

Temperature reshapes IR, sag, and safety.

- Cold: IR rises, so the same current causes more voltage drop and less usable capacity. You’ll hit LVC earlier under load. Manufacturer FAQs report steep performance loss below 0°C and substantial IR increases in cold, consistent with lab evidence summarized by Battery University (BU‑907b, 2025) and range notes like Ufine’s operating temperatures.

- Hot: High temperatures accelerate aging and can push the cell toward hazardous reactions. Separator materials soften/melt around ~130°C as a shutdown mechanism noted in Battery University’s protection circuits overview (BU‑304); detailed calorimetry shows SEI decomposition and self-heating onsets near ~98°C and ~128°C, respectively, in ARC tests reported by Baakes et al., Chemical Science (2023).

Operating guidance you can trust:

- Discharge: roughly −20°C to 60°C possible for many LiPo packs, with best performance ~15–35°C, echoing manufacturer specs such as Ufine’s range summary.

- Charge: keep it ~0–45°C; let packs cool before charging. Float/trickle is not used on Li‑ion chemistries per Battery University’s charge tables.

Temperature cheat sheet

| Situation | What to do | Why |

|---|---|---|

| ≤0°C (32°F) and flying | Pre‑warm pack to ~20°C; lower LVC target (warn sooner); avoid full-throttle sags early | Cold raises IR and sag; early LVC prevents deep dips |

| Hot day >35°C (95°F) | Increase airflow; reduce average current; consider a lower full charge if longevity matters | Heat accelerates aging and risk |

| After a hard run | Let the pack cool to near ambient before charging | Charging hot packs stresses chemistry |

| Lagerung | Leave at ~3.7–3.85 V/cell in a cool, dry place | Mid‑SoC is more stable over time |

4) The LiPo Safety Playbook (field‑ready)

Recognize hazards early

- Swelling/puffing, strong odor/chemical smell, unusual heat, hissing, or discoloration are all red flags. Public safety advisories (e.g., the New Jersey Division of Fire Safety, 2023) advise moving the device to a non‑flammable area and contacting professionals if a fire risk exists.

Prevent problems up front

- Use a pack with headroom: size for lower average C and keep temps in check.

- Balance-charge with a reputable charger; avoid makeshift adapters.

- No trickle/float; charge only within recommended temperatures as reflected in Battery University’s charge method tables.

- Don’t leave charging unattended. Use fire‑resistant bags/containers on non‑combustible surfaces.

- Inspect packs each session (mechanical damage, puffing, cable stress, connector discoloration).

If you see swelling or damage (mini‑case: “Swelling and Save”)

- Scenario: After a hot summer run, a 4S pack is warm and slightly puffy. What now?

- Stop using it immediately; disconnect safely.

- Move it to a fire‑resistant, ventilated area away from combustibles.

- Do not puncture or compress. Let it cool. Do not attempt to “reform” the pack.

- Place in a LiPo‑safe container and contact a battery recycling/hazardous waste facility. Public advisories like the NJ Fire Safety bulletin (2023) emphasize proper disposal.

- Review your telemetry logs for peak current and temperatures; derate your setup (prop size, gearing, ESC timing) or choose a higher‑C/larger pack.

Storage and transport

- Storage: ~3.7–3.85 V/cell, cool and dry. Check monthly.

- Air travel (spares): Carry‑on only, terminals insulated, observe Wh limits (≤100 Wh standard; 101–160 Wh with airline approval). See the IATA passenger advisory (2025).

- Shipping: Many lanes now require ≤30% SoC; see the IATA 2025 Lithium Battery Guidance Document and note the 2026 mandate tightening SoC for more consignments.

Entsorgung

- Do not throw LiPos in trash. Use certified e‑waste or municipal hazardous waste programs. Isolate damaged packs until recycled, per public safety guidance such as the New Jersey Division of Fire Safety (2023).

Safety checklist (printable)

- Before use: Inspect pack, check balance, confirm connectors, verify LVC settings, confirm pack temperature is safe.

- During use: Watch voltage telemetry, avoid sustained full‑throttle if temps climb, heed early warnings.

- After use: Let cool to ambient before charging; log peak current and min voltage; store at mid‑SoC if resting >24 hours.

5) Tuning LVC with telemetry: a step‑by‑step workflow

Goal: Avoid deep discharge while minimizing nuisance cutoffs from transient sag. You’ll combine per‑cell targets with real flight/drive data.

Preparation

- Start with conservative defaults: warn ~3.5 V/cell; critical/cutoff ~3.2–3.3 V/cell. These align with popular firmware defaults (e.g., Betaflight CLI thresholds) and ESC modes such as the 2.8/3.0/3.4 V options in the Hobbywing Skywalker V2 manual (2023).

- Enable telemetry: voltage (pack and per cell if available), current, and temperature.

Workflow

- Baseline run: Fly/drive a normal session. Note the lowest observed per‑cell under load and the resting voltage 2–3 minutes after landing.

- Correlate sag to current: If your FC supports it, review logs for voltage vs. current. Betaflight’s “VBat Sag Compensation” aims to stabilize the OSD reading across throttle per its documentation.

- Adjust warnings: If you routinely hit the warning too early (e.g., 30–40% capacity remains), you can lower warn slightly (e.g., 3.45 → 3.40 V/cell). If you see hard cutoffs at throttle punches, raise the critical value (e.g., 3.2 → 3.3 V/cell) or reduce current draw.

- Validate with logs: The resting voltage after landing should be near 3.7–3.8 V/cell when you intend to store. If it rebounds much higher, you were too conservative; if it rebounds only to ~3.5 V/cell, you’re cutting it close.

- Application presets:

- FPV freestyle/racing: Higher sag from pulses—use higher cutoff (3.3 V/cell) and a clear audible warning; tune sag compensation.

- Fixed‑wing endurance: Lower average C—warn lower (3.45–3.5), cutoff ~3.2–3.3 V/cell; prioritize capacity measurement (mAh consumed) when you can.

- Ground RC: Good airflow but high bursts—watch temps; choose 3.2–3.3 V/cell cutoff; log IR over time.

- For autopilots: ArduPilot uses pack‑level thresholds (BATT_LOW_VOLT, BATT_CRT_VOLT) with time filters; set per‑cell × S‑count and validate failsafe behavior per ArduPilot’s battery failsafe docs.

Mini‑case: “Unexpected LVC at half pack”

- Symptom: Your quad drops power after a few hard punches at only 50% used.

- Diagnosis flow: Check ambient temps (cold?), measure pack IR (has it increased?), inspect wiring/connectors for resistance, review logs for peak current. High IR or cold can cause deep transient dips. Raise cutoff slightly (e.g., 3.2 → 3.3 V/cell), reduce peak current (prop/gear), or replace an aging pack whose IR has doubled compared to new (see IR section).

6) Special scenarios: LiHV and series/parallel packs

LiHV (4.35 V/cell) specifics

- Voltages: Nominal ~3.8 V/cell; full charge 4.35 V/cell. See manufacturer and hobby summaries such as Grepow’s LiHV page und Oscar Liang’s LiHV overview.

- Cutoff: Similar under‑load cutoffs work (e.g., ~3.4–3.5 V/cell for longevity), with ~3.0 V/cell as the hard floor. Many users accept slightly higher cutoffs to reduce stress.

- Trade‑off: Charging to 4.35 V yields more runtime but can shorten life; some charge LiHV to 4.2 V for longevity.

Series/parallel packs: practical rules

- Only parallel packs of the same S‑count and close voltage. Equalize within ≤0.1 V per cell before connecting; otherwise, inrush current can be large, risking damage. See the field‑tested practices in Oscar Liang’s parallel charging guide.

- Match capacity, age, brand/model, and similar IR for best current sharing.

- Use proper connectors rated for your current; avoid long, thin leads that add unnecessary resistance (and heat).

- For series assemblies (custom packs), a BMS with balancing and protection is strongly recommended to manage over/under‑voltage, over‑current, and temperature.

Parallel charging basics (if you do it at all)

- Balance leads connected, same S‑count only, voltages matched, charge rate based on combined capacity (1C of total is safest), and never unattended. Follow detailed steps as outlined in Oscar Liang’s guide.

7) Diagnostics and optimization: internal resistance, sag, and heat

Internal resistance (IR) is the bridge between “specs” and what your pack actually delivers.

How to measure IR

- Charger IR function: Many quality chargers measure per‑cell IR via a small load pulse. Accuracy varies.

- ESR meters: Purpose‑built milliohm meters provide better repeatability.

- DC load step: Measure ΔV across a known current step and compute

R = ΔV / I. - Avoid multimeters for IR—they aren’t precise in the milliohm range. Practical methods and ranges are summarized in manufacturer tech articles like Ufine’s IR measurement overview.

Interpreting IR (ballparks; size‑dependent)

- Small FPV cells (~500–850 mAh): often 10–20 mΩ per cell when new.

- Mid‑size (~1300–2200 mAh): roughly 5–10 mΩ per cell.

- Larger (~4000–6000 mAh): roughly 2–5 mΩ per cell.

- Replace a pack when IR rises to ~2–3× its new value or when sag/heat becomes excessive under your use.

Use IR to predict sag and heat (Ohm’s law)

- Voltage drop:

V_drop = I × R - Heat:

P_heat = I² × R - Example: If a cell’s IR is 10 mΩ (0.010 Ω) and the current is 50 A, the per‑cell drop is 0.5 V and heat is 25 W—multiplied across cells, that’s a lot of sag and temperature rise. This is why cold or aged packs (higher IR) trigger early LVC.

Ways to reduce sag and heat

- Choose packs with lower IR (newer, higher‑quality, and right‑sized for current).

- Optimize wiring: Shorter, thicker leads; high‑quality connectors; clean solder joints.

- Manage temperature: Pre‑warm in cold; improve airflow in hot weather.

- Tune the powertrain: Smaller prop/gear ratio; soft‑start/curves; ESC timing; current limits.

8) Standards and compliance (2025 snapshot)

Why this matters: If you ship, integrate into products, or travel with LiPos, you’re on the hook for test, safety, and transport rules. Here’s a fast, practical summary to keep you safe and compliant.

- UN 38.3: Transport safety tests (altitude, thermal, vibration, shock, external short, impact, overcharge, forced discharge) for Li‑ion/LiPo cells and batteries. It’s the baseline for global transport acceptance and referenced throughout logistics rules (e.g., in the IATA guidance below).

- IEC 62133‑2: The worldwide portable battery safety standard for rechargeable lithium cells and batteries (≤100 V packs). It covers electrical, mechanical, and environmental safety; widely used for product compliance.

- UL 1642 (cells) and UL 2054 (packs): North American safety standards often recognized by regulators (e.g., FDA for medical devices). Summaries clarifying the split and regulatory recognition include JJR Lab’s UL 1642 vs. UL 2054 explanation and a note on recognition in Medical Design Briefs (FDA, 2012 recognition; still relevant today).

- IATA/ICAO air transport rules (2025): The IATA Lithium Battery Guidance Document (2025) reiterates the ≤30% SoC requirement for UN 3480 (batteries shipped alone) and notes tightening rules for more consignments from January 1, 2026. For passengers, carry‑on rules and watt‑hour limits are summarized in IATA’s passenger advisory (2025).

How to use this:

- Hobby use: Know airline passenger limits; keep spares in carry‑on; insulate terminals.

- Product teams: Specify cells/packs certified to relevant standards (UN 38.3, IEC 62133‑2, UL 1642/2054) and maintain documentation.

- Shipping: Keep SoC ≤30% where required; use proper packaging/marks per IATA/ICAO.

9) FAQs

What’s the difference between “under load” and “at rest” voltage?

- Under load includes instantaneous sag from IR. At rest is the rebound voltage after the load is removed. LVC acts on under‑load readings; storage checks use at‑rest values.

Is 3.0 V/cell ever okay?

- It’s the emergency floor under load. Don’t plan to hit it regularly; staying at or above 3.2–3.3 V/cell under load improves longevity, consistent with voltage guidance from sources like Grepow (manufacturer).

Does C‑rating tell the whole story?

- No. It’s a guide. Temperature, IR, and wiring determine real‑world performance. Measure IR and use telemetry to validate.

Should I balance every charge?

- For best results and safety, yes—especially as packs age.

What storage voltage should I pick?

- Aim for ~3.7–3.85 V/cell at rest. The transport rationale for mid‑SoC is reflected by Battery University’s 30% SoC ≈ 3.70 V/cell shipping note (2025) and manufacturer storage guidance such as Grepow’s voltage guide.

How do I know when a pack is “done”?

- Rising IR (2–3× new), heat under modest loads, imbalance during charge, puffing, or frequent early LVC all point to end‑of‑life. Replace it.

Can I mix packs in parallel?

- Only if they’re same S‑count, similar age/IR, and within ≤0.1 V per cell of each other before connecting. See parallel charging best practices.

Is trickle charging safe for LiPo?

- No. Li‑ion chemistries do not use float/trickle like lead‑acid; see the charge method tables in Battery University (BU‑409b).

What about Betaflight/ArduPilot defaults?

- Betaflight: warn ~3.5 V/cell, minimum ~3.3 V/cell per the CLI docs and sag compensation discussed in the Betaflight documentation. ArduPilot: set pack‑level thresholds (multiply per‑cell by S‑count), with two‑level failsafes per ArduPilot’s battery failsafe page.

10) Glossary (fast)

- C‑rate: Current multiplier relative to capacity;

I = Ah × C. - LVC (Low Voltage Cutoff): Controller threshold to prevent over‑discharge under load.

- IR (Internal Resistance): The effective resistance inside the cell; higher IR → more sag/heat.

- LiHV: High‑voltage LiPo able to charge to 4.35 V/cell.

- SoC (State of Charge): Percent of capacity; mid‑SoC is more stable for storage/transport.

11) Ready‑to‑use reference tables and checklists

C‑rate to current (duplicate of Section 1 table for printing)

| Kapazität | 20C | 25C | 30C | 60C |

|---|---|---|---|---|

| 650 mAh (0.65 Ah) | 13 A | 16.3 A | 19.5 A | 39 A |

| 1300 mAh (1.3 Ah) | 26 A | 32.5 A | 39 A | 78 A |

| 2200 mAh (2.2 Ah) | 44 A | 55 A | 66 A | 132 A |

| 5000 mAh (5.0 Ah) | 100 A | 125 A | 150 A | 300 A |

LVC totals by S‑count (choose per‑cell target appropriate for your sag/temps)

| Cells (S) | 3.1 V/cell | 3.2 V/cell | 3.3 V/cell |

|---|---|---|---|

| 2S | 6.2 V | 6.4 V | 6.6 V |

| 3S | 9.3 V | 9.6 V | 9.9 V |

| 4S | 12.4 V | 12.8 V | 13.2 V |

| 5S | 15.5 V | 16.0 V | 16.5 V |

| 6S | 18.6 V | 19.2 V | 19.8 V |

Charge/temperature quick guidance

- Discharge window: about −20°C to 60°C for many LiPos; best power ~15–35°C, per manufacturer ranges like Ufine’s.

- Charge window: ~0–45°C; no float/trickle for Li‑ion types per Battery University’s table (BU‑409b).

- Thermal caution: Elevated temps accelerate aging; SEI decomposition and self‑heating begin well below 150°C as shown by Chemical Science (2023) calorimetry.

Field safety checklist (duplicate for printing)

- Inspect → Balance → Confirm LVC → Safe temp → Safe surface/container for charging.

- Monitor telemetry (volts, amps, temp). Heed early warnings.

- Cool down before charging. Store at ~3.7–3.85 V/cell if resting.

- Handle swelling/damage as hazardous; isolate and recycle per local rules and public advisories like NJ Fire Safety 2023.

12) Final notes on longevity

- Run cooler, not just faster: keep average C low, improve airflow, and avoid sun‑baking packs on the bench.

- Stop chasing the last 5%: landing with margin increases cycle life.

- Keep logs: track mAh used, min voltage under load, temps, and IR over time. These trends catch aging early.

- Follow the datasheet first: if a manufacturer specifies different charge/discharge/temperature limits for your exact cells, those override rule‑of‑thumb values in this guide.

-

Acknowledgments and sources

- C‑rate definition, formula: Ossila — What is battery C‑rate (Zugriff 2025).

- Voltage and storage ranges: Grepow — LiPo voltage overview (manufacturer, 2023–2025 content).

- ESC/FC LVC examples: Hobbywing Skywalker V2 manual, 2023 PDF; Betaflight CLI/Docs (2025) und VBat Sag Compensation description; ArduPilot battery failsafe doc.

- Temperature, IR, and charging notes: Battery University BU‑907b; Battery University BU‑409b charging table; Battery University BU‑304; Ufine temperature range; Chemical Science 2023 calorimetry.

- LiHV: Grepow LiHV page; Oscar Liang — LiHV overview.

- IR measurement: Ufine — Ways to measure internal resistance.

- Parallel charging: Oscar Liang — Parallel charging best practices.

- Safety advisory: New Jersey Division of Fire Safety — Lithium‑ion advisory (2023).

- Transport/standards: IATA Lithium Battery Guidance Document, 2025; IATA passenger advisory (2025); UL 1642 vs. UL 2054 summary — JJR Lab; Medical Design Briefs — FDA recognition of UL standards.