Balanced charging is the single most reliable way to keep multi‑cell LiPo packs safe, predictable, and long‑lived. Standards emphasize outcomes—preventing any cell from exceeding voltage and temperature limits—rather than prescribing a specific method; in practice, balancing is how engineers keep individual cells in bounds during charge. See the outcomes focus in the official landing pages for IEC 62133‑2:2017 + A1:2021 (IEC Webstore) und UL 2054 (UL Standards Catalog), and the transport controls in UN 38.3 (UNECE, Part III).

What’s new and useful in 2025

- Low‑millivolt visibility is now practical. Modern battery monitoring AFEs deliver per‑cell measurement accuracy on the order of single millivolts, enabling tighter balance control—see Analog Devices ADBMS1818 datasheet (2024).

- Smarter storage modes and balancing windows are common in system‑level BMS/chargers, which helps maintain packs near partial‑SOC in storage; operational guidance is documented in Victron Lithium NG operation notes (2024).

- Hobby/industrial smart chargers increasingly automate storage SOC and balance routines; see feature examples in Grepow’s G‑Tech charger pages (2023–2024).

Step‑by‑step: Balanced charging workflow

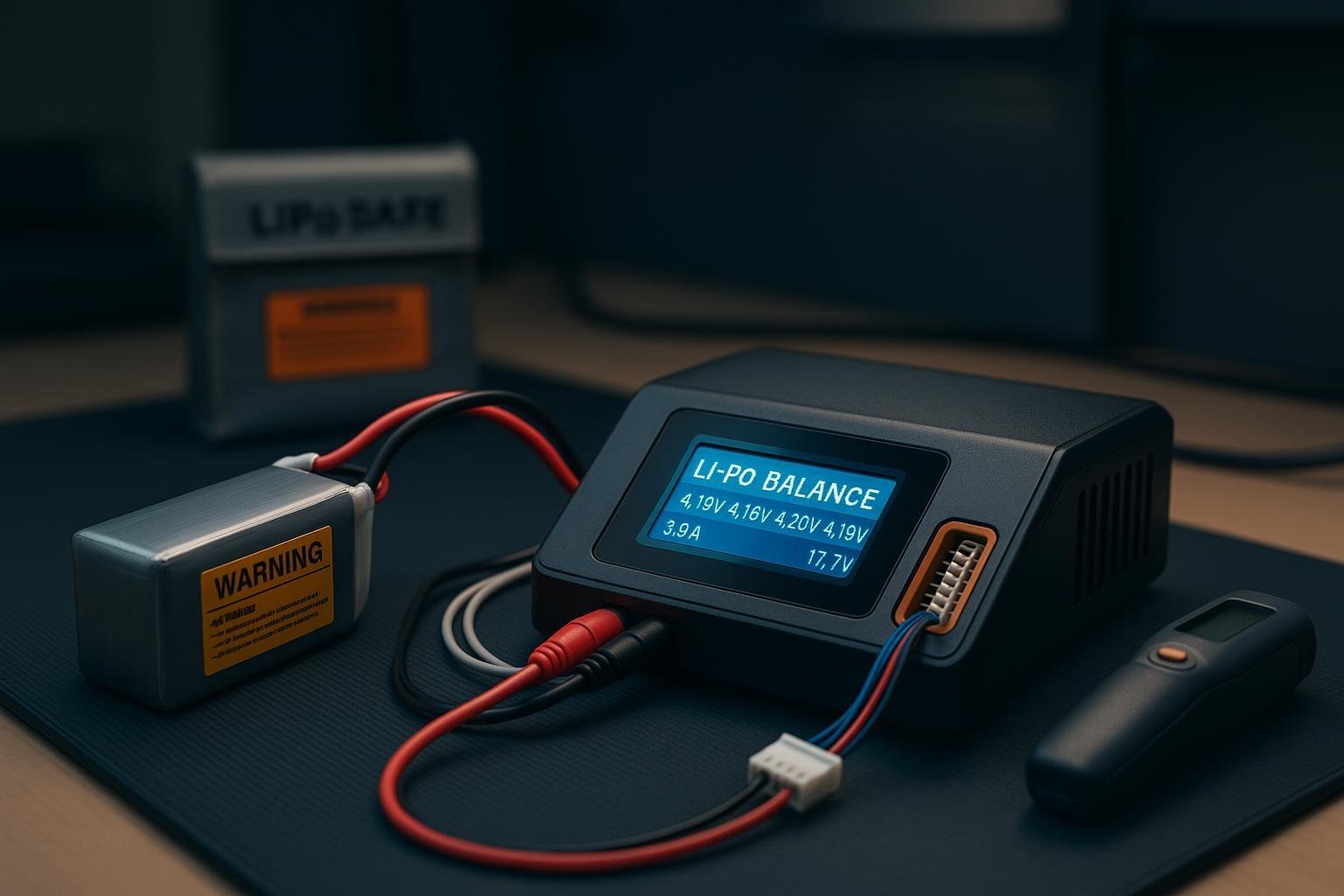

This workflow assumes a 2S–6S LiPo pack with JST‑XH balance lead and a balance‑capable charger. Always defer to the specific cell/pack datasheet and charger manual.

- Inspect

- Look for swelling, punctures, delamination, or odor. Do not charge damaged packs.

- Check harnesses: main leads, balance connector strain relief, correct pinout.

- Prepare environment

- Use a nonflammable surface, LiPo‑safe bag or metal container, and nearby Class D/ABC extinguisher. Keep a temperature probe handy.

- Ensure ambient 15–25°C; avoid charging below 0°C or above 45°C as general practice; confirm model‑specific limits. Panasonic guidance (indicative for Li‑ion) lists 10–45°C charge windows and modest C‑rates; see the Panasonic NCR18650BD datasheet (rev.) for representative policy.

- Connect correctly

- First connect the balance lead to the charger’s balance port; then connect main leads. Verify cell count auto‑detection matches your pack.

- Configure charger

- Chemistry/profile: LiPo (4.20 V/cell). Some packs are LiHV (4.35 V/cell)—confirm label/datasheet.

- Charge current: start at 0.5C for longevity unless the pack explicitly allows higher. Many OEM specs allow up to 1C when temperature is controlled.

- End‑of‑charge: enable balance mode and per‑cell cutoff at the nominal max (e.g., 4.20 V). Set safety timeout.

- Monitor actively

- Observe per‑cell voltages and pack temperature. If any cell races ahead to cutoff early, expect extended balancing near end of charge.

- Keep the area attended. Do not leave balancing cycles unattended.

- Verify and log

- Post‑charge, record pack voltage, per‑cell spread, time‑to‑balance, and any errors.

- Practical target: a post‑balance spread in the low millivolt range is achievable given AFE accuracy capabilities; see Analog Devices ADBMS1818 accuracy figures (2024) and TI’s discussion on voltage accuracy impacts in TI application note SLUAAR1.

Settings that matter (and why)

- Spannung pro Zelle

- Standard LiPo: 4.20 V/cell; LiHV variants: 4.35 V/cell. Exceeding these risks lithium plating and swelling.

- Current (C‑rate)

- 0.5C is a conservative baseline for longevity; up to 1C if the datasheet permits and temperature is controlled. Datasheet examples for lithium‑ion cells commonly specify 0–45°C charge with modest C‑rates; see Panasonic’s indicative values in the NCR18650BD datasheet.

- Temperature window

- Keep charge within manufacturer limits, typically around 0–45°C. Avoid charging below freezing; most chargers/BMS will refuse or alarm.

- Balance threshold and exit criteria

- Aim for a tight per‑cell delta at end of charge; low‑mV is realistic with modern measurement. The tighter the control, the less capacity is lost to early high‑cell cutoff.

Troubleshooting quick‑reference

Typical charger/BMS alerts and what to do. For exact error codes, consult your model manual.

- Cell count mismatch

- Check balance lead seating and pinout; count cells via per‑cell readout.

- Balance port error

- Inspect connector damage; clean contacts; verify harness continuity.

- Cell voltage out of range

- If a cell is <3.0 V, many chargers refuse to start; pre‑charge at a very low current under supervision or retire the pack if IR is excessive.

- Charge timeout

- Often indicates weak cell or high resistance; reduce current and let balancing finish; evaluate pack health.

- Temperature sensor error

- Confirm probe placement and sensor integrity; ensure ambient within spec.

Brand support hubs summarize common alerts—see ISDT support center (accessed 2024–2025) and the B80 manual remark that unbalance mode triggers alarms without the balance port connected in ISDT B80 manual.

Storage and maintenance that extend life

- Store at partial SOC: 40–60% (about 3.7–3.85 V/cell). This aligns with longevity principles cited in the NASA State‑of‑the‑Art 2023 power report.

- Temperature: cool, dry, ventilated—ideally 15–25°C. Avoid prolonged high heat.

- Cadence: check every 1–3 months; run storage‑mode cycles to return to target SOC. System‑level guidance on storage behavior and periodic balancing appears in Victron Lithium NG operations (2024).

Recommended balancing chargers and BMS tools (neutral toolbox)

Disclosure: The following includes a mention of our brand alongside peers for context.

- Yungbang Power(永邦电源): Custom LiPo packs with integrated BMS and balancing options for consumer/industrial designs; ISO9001/14001 facilities and global supply capabilities. This mention is part of a comparative toolbox and may represent a commercial interest.

- Grepow smart chargers: G‑Tech ecosystem with automated storage/balance features and model recognition.

- Ufine Battery balancer guide: Clear primer and safety practices; useful for onboarding technicians.

- Junda BMS tech notes: Process/BMS updates helpful for pack designers seeking balancing strategies.

(Keep selection criteria objective: required cell count support, measurement accuracy, thermal sensing, data logging, and storage mode automation.)

Example: Balancing a Yungbang LiPo pack (micro‑procedure)

Using a custom 4S LiPo pack on a lab charger: Inspect for swelling and verify harness integrity. Connect the JST‑XH balance lead first, then main leads. Set LiPo 4.20 V/cell, 0.5C current, balance mode on, safety timeout enabled. Monitor per‑cell voltages and surface temperature; allow the charger to taper and balance until the per‑cell delta is in the low‑mV range. Log time‑to‑balance and per‑cell readings before disconnecting.

Safety you should never skip

- Charge in a fire‑resistant area with a LiPo bag or metal container; keep an extinguisher nearby.

- Never charge unattended. Avoid charging damaged or swollen packs.

- Keep within temperature specs and use calibrated probes.

- Ensure BMS/charger firmware is up‑to‑date; review protection parameters periodically.

- For installations, ensure monitoring and suppression meet outcomes aligned with NFPA 855 (2023 Edition).

Post‑charge verification checklist

- Pack voltage at spec; per‑cell within tight delta (low mV target)

- No abnormal temperature rise near end of charge

- Reasonable time‑to‑balance (compare to historical logs)

- No charger error codes; balance lead and main lead intact

- Update maintenance log with IR/voltage readings and ambient temperature

Quick safety and maintenance checklist

- Workspace: nonflammable surface, containment, extinguisher

- Charger: correct chemistry profile, balance mode on, timeout set

- Connections: balance lead first, then main leads; verify cell count

- Monitoring: per‑cell voltages and temperature; do not leave unattended

- Storage: 40–60% SOC at 15–25°C; recheck every 1–3 months

Final notes on compliance and SOPs

Balanced charging is an engineering control that helps you meet the outcome requirements embedded in safety and transport frameworks such as IEC 62133‑2:2017+A1:2021, UL 2054und UN 38.3. Always align charger settings and maintenance procedures with the specific cell/pack datasheet and your model’s manual. For additional primers and field tips, practitioner guides like Oscar Liang’s LiPo battery guide (2024) provide accessible context; combine such guidance with your internal test logs for a robust SOP.