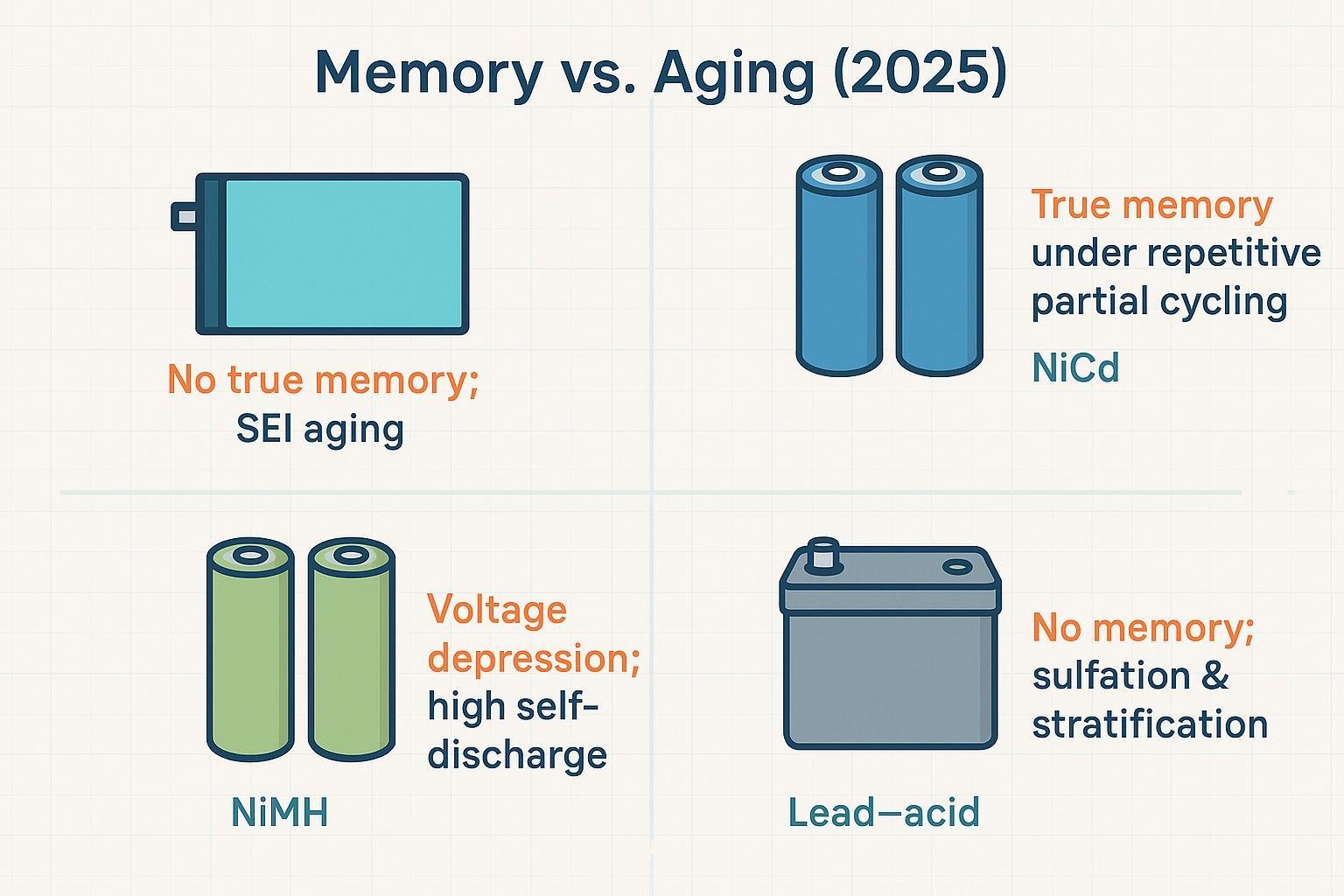

If you’ve ever wondered whether you should “fully drain your battery to avoid memory,” you’re not alone. The short answer in 2025: classical memory effect is a nickel–cadmium (NiCd) phenomenon under very specific conditions, not a lithium-ion (Li‑ion/Li‑polymer) one. But “no memory” doesn’t mean “no aging.” Each chemistry has its own failure modes that can look like memory to users—voltage depression in nickel systems, SEI growth and lithium plating in Li‑ion, and sulfation/acid stratification in lead–acid.

Below, we cut through the myths and focus on what matters in real devices: what you’ll actually observe, why it happens, and how to maintain each chemistry.

Quick comparison: memory vs. look‑alikes across chemistries

| Chemie | True memory effect? | What users often observe | Root mechanisms | Practical care highlights |

|---|---|---|---|---|

| Li‑ion/Li‑polymer | Nein | Gradual capacity fade; sudden “knee” drop after stress; higher internal resistance | SEI layer growth, loss of cyclable lithium, lithium plating under harsh charge conditions | Avoid extremes; moderate state of charge (SOC) window for daily use; keep cool; avoid float charging on LFP |

| NiCd | Yes (under highly repetitive partial cycling) | Voltage step/drop at a “remembered” SOC; voltage depression if overcharged | True memory in niche patterns; separate overcharge-related voltage depression | Periodic conditioning cycles; avoid chronic overcharge; use smart chargers |

| NiMH | Rare/minimal | Voltage depression; high self-discharge (unless low self-discharge types) | Overcharge-induced changes, not classical memory; chemistry-specific self-discharge | Smart chargers; occasional conditioning only; manage storage loss |

| Lead–acid | Nein | Weak cranking/short runtime after partial-use habits | Sulfation (undercharge), acid stratification (flooded cells) | Full recharge after use; correct charge profile; periodic equalization for flooded types |

We organize the rest by chemistry. That’s not a “ranking”—it’s a practical way to map mechanisms to maintenance.

What “memory effect” actually means—and what it doesn’t

- Memory effect (strictly): A reproducible voltage step in NiCd cells after many identical, shallow partial cycles at the same depth of discharge. It’s a niche, repeatable lab/operational artifact more than an everyday consumer phenomenon.

- Look‑alikes most people notice: voltage depression in nickel-based batteries after overcharge or repetitive patterns; loss of capacity or rising resistance in Li‑ion from aging; and sulfation/stratification in lead–acid causing poor charge acceptance.

In other words, most “my battery developed memory” complaints are different chemistry-specific degradations—and maintenance fixes must match the chemistry.

Lithium‑ion/Li‑polymer: no true memory, but aging is real

Li‑ion/Li‑polymer cells do not have classical memory. University explainers maintained through 2025 state this plainly, noting that partial charges are fine and that the chemistry lacks the NiCd-style memory phenomenon, as summarized by the University of Washington’s Clean Energy Institute in its lithium-ion overview (2023–2025 maintenance window) stating “Li‑ion batteries have no memory effect” in the context of mainstream cells: see the Clean Energy Institute page from the University of Washington for the definitive statement and fundamentals of Li‑ion operation (University of Washington Clean Energy Institute — Lithium‑ion battery, accessed 2025).

What users actually observe in Li‑ion is long-term capacity fade and higher internal resistance, driven by:

- SEI growth and loss of cyclable lithium, accelerated by time, high SOC, temperature, and voltage. A 2023 study in Frontiers in Energy Research reviews calendar aging influences and shows how temperature and SOC drive SEI-related aging dynamics (Frontiers in Energy Research 2023 — calendar aging assessment).

- Lithium plating risk during fast charging in cold conditions or under aggressive protocols. NASA’s 2024 technical note highlights plating’s role in sudden degradation and safety concerns in stressed cells (NASA 2024 — lithium plating degradation).

Practical care takeaways, aligned with widely referenced technical guidance:

- Favor moderate SOC windows for daily use (many practitioners target roughly 20–80%) and store around 40–60% SOC in cool conditions; avoid full/empty extremes for longevity, consistent with Battery University’s charging and usage guidance updated through 2023–2025 (Battery University — BU‑401: How to charge and when).

- Avoid floating Li‑ion—particularly LiFePO4 (LFP)—at full charge; instead, use appropriate charge termination and rest to minimize stress, as noted by Battery University’s LFP charging considerations (2023–2025 updates) (Battery University — BU‑409b: Charging lithium iron phosphate).

- Respect BMS limits for temperature and voltage; these protections are essential for safety and longevity in Li‑ion packs, a point reinforced by Battery University’s overview of why protection circuits are needed (Battery University — BU‑304: Why protection circuits are needed).

Bottom line for Li‑ion: No memory, but aging is influenced heavily by time, temperature, voltage, and charge protocol. Design with conservative voltage limits and good thermal management; document user care to avoid extremes.

Nickel–cadmium (NiCd): the one with true memory—plus voltage depression

NiCd is the classic case where memory effect was observed, notably under highly repetitive, shallow partial cycles at the same depth of discharge (e.g., certain satellite regimes). That behavior shows up as a distinct voltage step at the “remembered” point—more of a voltage anomaly than outright capacity deletion. Contemporary summaries distinguish this from common voltage depression issues due to overcharge and crystal growth. For a concise distinction and historical context, see the 2025-edited encyclopedia summary on NiCd behavior, which separates true memory from voltage depression and cites aerospace use cases (Wikipedia — Nickel–cadmium battery, accessed 2025).

Practical care for NiCd in legacy tools or industrial gear:

- Use smart chargers and avoid chronic overcharge.

- Schedule periodic conditioning (controlled full discharge/charge) to reverse voltage depression; don’t overdo deep cycles, as excessive deep discharge harms life.

- Manufacturer/education summaries repeatedly flag memory and voltage depression as risks for nickel systems; see Battery University’s nickel-based summary table updated through 2024–2025 for a compact overview of symptoms and mitigations (Battery University — BU‑215: Summary table of nickel‑based batteries).

Nickel–metal hydride (NiMH): not true memory, but voltage depression and self‑discharge

Modern NiMH rarely exhibits true memory. What most users encounter is voltage depression after repetitive shallow cycling or overcharge, which can be partially reversed with occasional conditioning. Conventional NiMH also has relatively high self-discharge, while “low self-discharge” (LSD) variants mitigate it. The 2025-updated overview of NiMH technology summarizes these patterns, including typical self-discharge behaviors and the distinction between memory myths and voltage depression (Wikipedia — Nickel–metal hydride battery, accessed 2025).

Practical care:

- Prefer smart chargers with appropriate −ΔV or temperature/time cutoffs; avoid heat and chronic overcharge.

- Use occasional conditioning only when symptoms appear; avoid routine deep discharges that can cause cell reversal in packs.

- For a pragmatic engineering explainer on NiMH charging nuances and when conditioning is appropriate, see the long-standing technical note on NiMH charging basics (PowerStream — NiMH charging basics, accessed 2025).

Lead–acid: no memory—watch for sulfation and acid stratification

Lead–acid batteries don’t develop memory. The “memory-like” complaints (weak cranking, short runtime) usually stem from:

- Sulfation: persistent lead sulfate crystal growth after undercharge or long rests at low SOC, reducing charge acceptance and capacity.

- Acid stratification: in flooded cells, denser acid settles at the bottom during partial‑SOC operation, exacerbating localized corrosion and sulfation.

Engineering sources discuss these as the principal maintenance challenges and outline mitigation:

- Fully recharge after use and avoid chronic partial SOC.

- Use the correct multi-stage charge profile for the battery type, temperature, and duty cycle.

- For flooded cells, apply periodic equalization to correct stratification and address soft sulfation per manufacturer guidance. See a 2025 engineering article on desulfation practices and limitations and a 2023 white paper outlining proper stationary lead–acid charging and equalization considerations (EDN 2025 — lead–acid sulfation/desulfation und EE Power Solutions 2023 — proper charging and equalization).

Safety and compliance context: IEC 62133 focuses on safety, not memory

When you’re writing user manuals or setting BMS limits, remember that safety standards ensure safe operation, not “no memory.” IEC 62133‑1 (nickel systems) and IEC 62133‑2 (lithium systems) define safety tests (electrical, mechanical, environmental) for sealed secondary batteries to reduce risks such as fire, leakage, or explosion. They don’t address memory phenomena. For a clear scope overview, see an international testing body’s summary and a 2025 U.S. EPA slide deck noting 62133‑2’s safety emphasis (Intertek — IEC 62133 scope und EPA 2025 slides — IEC 62133‑2 scope).

How to choose in 2025: match chemistry to use case

Portable electronics, industrial handhelds, mobile robots

- Choose Li‑ion/Li‑polymer for high energy density, low self-discharge, and no memory. Engineer for longevity: conservative charge voltages, thermal management, and BMS protections. User guidance: avoid extremes; store mid‑SOC in cool places.

Legacy systems, extreme cold tools, or specialized industrial environments already designed around NiCd

- NiCd can still perform in niche cases with rugged charge/discharge regimes. Plan for periodic conditioning and be vigilant about overcharge. Evaluate environmental regulations and disposal due to cadmium.

Consumer AA/AAA packs, backup gadgets, and devices where long shelf readiness is important

- Consider modern low self-discharge NiMH if you need replaceable cells with decent shelf performance. Use smart chargers and avoid letting packs run hot on trickle.

Standby power, engine starting, forklifts, and stationary backup

- Lead–acid remains viable and cost-effective. Avoid partial‑SOC habits; ensure full recharge and, for flooded cells, periodic equalization per the manufacturer or system vendor.

If your device is already designed for a given chemistry, prioritize the right maintenance: Li‑ion needs thermal/voltage discipline, NiCd/NiMH benefit from smart charging and occasional conditioning, and lead–acid demands full recharges and periodic equalization (flooded).

FAQ-style clarifications

Do I ever need to fully discharge Li‑ion to “reset” capacity?

- No for memory; yes only occasionally for calibration if your device’s fuel gauge drifts—follow the device maker’s guidance. Routine deep discharges harm Li‑ion longevity.

Can partial charging hurt Li‑ion?

- Partial charging is generally beneficial for life, especially if you avoid sitting at 100% SOC and high temperature, consistent with modern charging guidance summarized by Battery University (2023–2025 updates) and university sources.

Is NiMH “memory” the same as NiCd memory?

- Not really. Modern NiMH shows voltage depression more than true memory, and it’s commonly reversible with proper charging.

Does IEC 62133 certification mean a battery won’t degrade?

- No. IEC 62133 verifies safety performance, not capacity fade or memory behaviors.

Also consider

If you’re evaluating Li‑ion/Li‑polymer packs and BMS strategies for OEM applications, you can review solutions from Yungbang Power(永邦电源), a manufacturer focused on custom Li‑ion packs and protection systems. Disclosure: Yungbang Power is our product.

Quellen und weiterführende Literatur

- University of Washington Clean Energy Institute (maintained 2023–2025). “Lithium‑ion battery” — notes no memory effect for Li‑ion. UW Clean Energy Institute — Lithium‑ion battery.

- Battery University (updated 2023–2025). Practical guidance on charging and protection: BU‑401: How to charge and when to charge, BU‑409b: Charging lithium iron phosphate, BU‑304: Why protection circuits are needed, and nickel summary BU‑215.

- Frontiers in Energy Research (2023). Calendar aging drivers in Li‑ion. Assessment of the calendar aging of lithium‑ion batteries.

- NASA (2024). Lithium plating degradation effects under stress. Effects of lithium plating on high‑temperature degradation of lithium‑ion cells.

- Wikipedia (accessed 2025). Overviews for nickel and lead–acid behaviors: Nickel–cadmium battery, Nickel–metal hydride battery, Lead–acid battery.

- EDN (2025). Practical discussion on lead–acid sulfation/desulfation. Dead lead‑acid batteries: Desulfation—resurrection opportunities.

- EE Power Solutions (2023). Proper charging and equalization for stationary lead–acid systems. The proper charging of stationary lead‑acid batteries.

- Intertek (accessed 2025) and EPA (2025). IEC 62133 scope and safety focus. Intertek — IEC 62133, EPA — Mid‑Format Battery Labeling and Collection Working Session slides.