You’re here because you want to charge 4S LiPo packs correctly—safely, efficiently, and without shortening their life. This guide distills the electrical principles, the must-have charger features, the exact safety parameters that matter, and the everyday workflows that prevent accidents. Whether you build RC rigs or design products that ship worldwide, this is the one-stop resource to choose the right 4S charger, use it well, and sleep better at night.

At a glance, the 80/20 of safe, long-lived charging looks like this:

- Use a real LiPo balance charger with per‑cell monitoring.

- Keep peak voltage at or below 4.20 V per cell (16.8 V for 4S).

- Charge conservatively, typically 0.5C–1C.

- Store around 3.7–3.85 V per cell (~14.8–15.4 V for 4S).

- Charge between roughly 0°C and 45°C, ideally near room temperature.

- Inspect packs and never charge swollen, damaged, or smelly packs.

- Don’t leave charging unattended.

These aren’t opinions—they’re anchored in widely cited lithium‑ion fundamentals and safety guidance. We’ll link primary sources inline as we go and keep the jargon friendly.

1) 4S LiPo Fundamentals You Need to Know

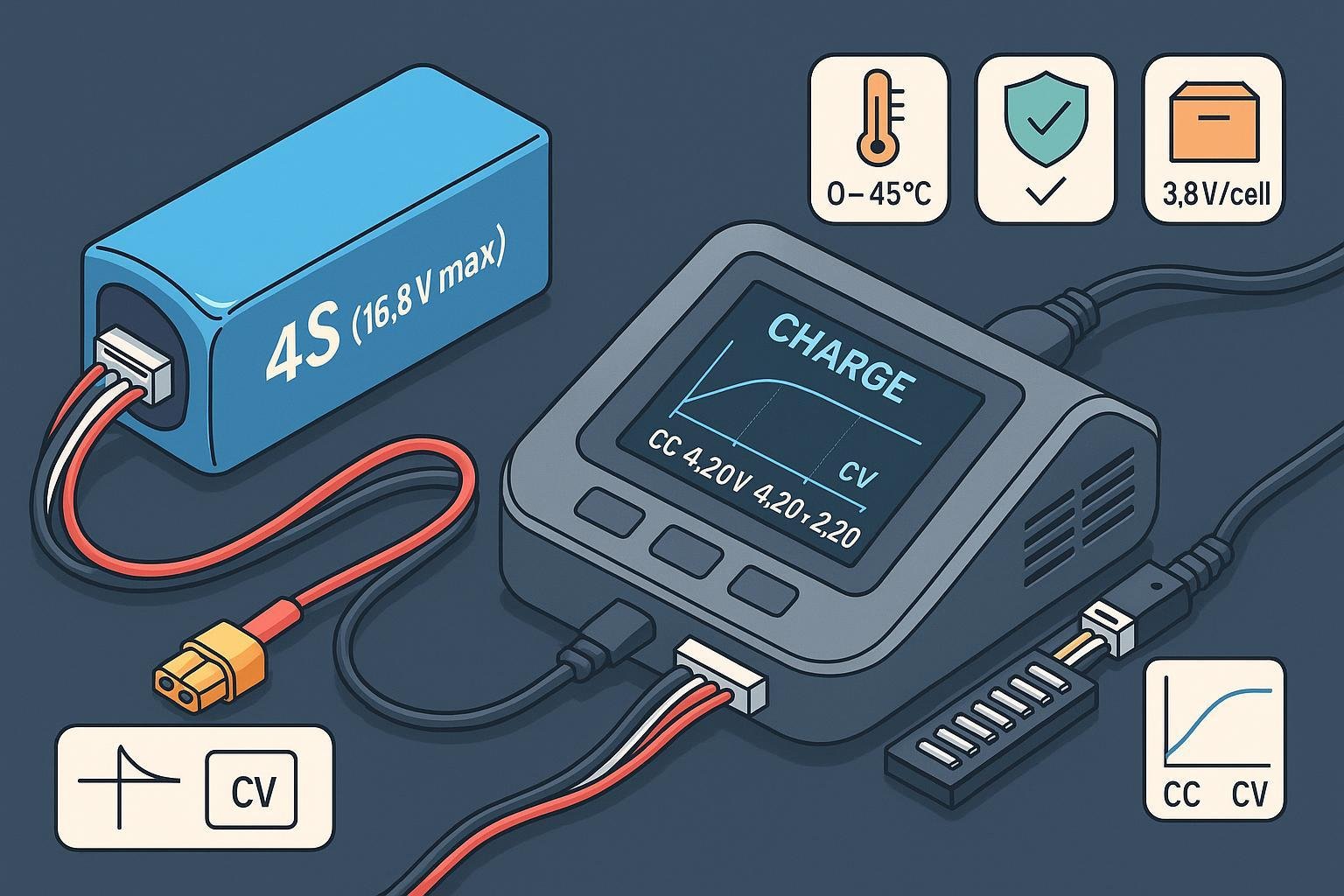

A 4S LiPo pack is four lithium‑ion polymer cells in series. In standard LiPo chemistry, the full‑charge limit is 4.20 V per cell, so a 4S pack tops out at 16.8 V. The mainstream charging method is two‑stage constant current/constant voltage (CC/CV): current is held steady until the per‑cell voltage reaches 4.20 V, then voltage is held steady while the current tapers down to a termination threshold. This isn’t lore—it’s the method documented by Battery University’s overview of CC/CV charging and limits in the 2024 edition of the resource, see the explanations in Battery University BU‑409, Charging Lithium‑ion and the per‑cell voltage context in Battery University BU‑303, Confusion with Voltages.

- Typical termination current in the CV phase lands around 0.05C–0.1C, per the 2024 guidance in Battery University BU‑409.

- Charging faster than 1C increases stress and may shorten cycle life; conservative practice for energy cells is 0.5C–1C, discussed in Battery University BU‑409 with C‑rate definitions in Battery University BU‑402 (What is the C‑rate?).

- Temperature matters: charging below 0°C risks lithium plating, and high temperatures cut charge acceptance. Battery University’s 2024 article on temperature effects notes degrading acceptance at elevated temps (e.g., at 45°C, capacity acceptance drops markedly), see Battery University BU‑410, Charging at High and Low Temperatures.

- For storage, holding cells around 40–60% state of charge—about 3.7–3.85 V per cell—reduces long‑term stress. See the 2024 storage guidance in Battery University BU‑808, How to Prolong Lithium‑based Batteries and the summary in BU‑409.

Balancing: Why Per‑Cell Control Matters

In 4S packs, the individual cells aren’t perfectly matched. Over time, slight differences in capacity/internal resistance create imbalances. Balancing is how the charger levels per‑cell voltages near the top of charge.

- Passive balancing bleeds charge from higher cells through resistors. It’s simple and common, but wastes heat and is limited by low bleed currents. Active balancing transfers charge between cells with inductive/capacitive/DC‑DC methods—more complex and efficient. See engineering overviews from Analog Devices in Analog Dialogue on battery backup and balancing concepts and TI application notes such as TI SLUAA81 (BQ769x2 cell balancing settings).

- Typical passive balancing currents in monitoring ICs are on the order of tens of milliamps (for example, around 35–65 mA depending on design), per TI notes like SLUAA81/related app notes. Many hobby chargers advertise higher “balance current” at the charger level—for instance, ISDT lists up to 1.5–2.0 A per cell in some models, see the ISDT Q8 Max manual, “Balance current 1.5A/Cell” und ISDT B80 manual page, “Balance current 2A/Cell”.

- Practically, balancing adds time if the pack is significantly out of whack. Expect minutes to tens of minutes depending on imbalance magnitude and the (often modest) bleed capability. TI’s balancing notes outline how delta thresholds and bleed limits govern speed in real packs; see TI SLUAA81 (Cell Balance Min Delta, Stop Delta).

The takeaway: Always connect the balance harness for 4S charging, and expect extra time if cells start far apart.

2) How 4S LiPo Chargers Work (CC/CV + Balance + Protections)

A proper 4S LiPo charger implements:

- Chemistry‑specific CC/CV control to 4.20 V/cell with CV taper and termination.

- Per‑cell monitoring via the balance port to prevent any cell from exceeding the limit.

- Safety protections such as reverse polarity, time/capacity limits, over‑temperature cutoff, abnormal voltage alarms, and “connection break” detection.

Examples from mainstream charger families:

- SkyRC B6 series manuals describe Balance Charge, Storage mode targeting ~3.8 V/cell, and safety options including temperature thresholds. See the product documentation for the iMAX B6AC V2 (EN V3.10 manual) and storage voltage details in SkyRC iMAX B6AC V2 with mirrored manual references such as EN V3.10 PDF. A more recent compact unit, SkyRC B6neo, publishes balance current up to 500 mA.

- ISDT’s smart chargers advertise higher balance currents and robust alarm systems (e.g., abnormal voltage, incorrect cell count). See the ISDT Q8 Max manual und die ISDT B80 manual page.

Combine these device‑level features with the chemistry truths from Battery University BU‑409 and you’ve got the playbook for how a “real” LiPo charger behaves.

3) Choosing a 4S LiPo Charger: Power, Current, Features, and Fit

Let’s walk the selection workflow you can use for any 4S pack.

Step 1: Determine Current and Power Requirements

- Charge current Icharge (A) = Capacity (Ah) × C‑rate. For longevity, start with 0.5C–1C for energy cells (e.g., a 2200 mAh pack at 1C = 2.2 A), consistent with the advice in Battery University BU‑409 (2024) and C‑rate definitions in BU‑402.

- For a 4S pack, Vmax ≈ 16.8 V. Required charger power P ≈ V × I × headroom. Use 1.1–1.2 headroom to cover CV taper losses and balancing overhead.

Examples using 20% headroom:

- 1300 mAh (1.3 Ah) at 1C: 1.3 A → P ≈ 16.8 × 1.3 × 1.2 ≈ 26.2 W

- 1300 mAh at 0.5C: 0.65 A → ≈ 13.1 W

- 2200 mAh (2.2 Ah) at 1C: 2.2 A → ≈ 44.4 W

- 2200 mAh at 0.5C: 1.1 A → ≈ 22.2 W

- 5000 mAh (5 Ah) at 1C: 5 A → ≈ 100.8 W; at 0.5C: 2.5 A → ≈ 50.4 W

Rule of thumb: If you plan to parallel charge or run dual channels, multiply accordingly—charger wattage is often the bottleneck.

Step 2: Decide on AC vs. DC and Channel Count

- AC/DC all‑in‑one: Convenient bench option; typically lower max power per dollar.

- DC‑only: Higher power density; pair with a quality DC supply for bench use or field packs in the field.

- Single vs. dual channel: Duals dramatically increase throughput when cycling many packs.

Step 3: Prioritize Features That Actually Matter

- Balance charge mode with robust per‑cell monitoring and a meaningful balance current. For spec context, SkyRC’s B6neo lists 500 mA balance current, while ISDT’s Q8 Max and B80 list up to 1.5–2.0 A/cell; see SkyRC B6neo specs, ISDT Q8 Max manualund ISDT B80 manual page.

- Storage mode targeting ~3.8 V per cell. SkyRC explicitly documents 3.8 V/cell storage, aligning with storage guidance summarized by Battery University BU‑808 (2024) and the B6AC V2 materials above.

- Temperature sensing and cutoff. Many chargers accept an external thermistor probe and can stop if temps exceed a threshold; see examples in SkyRC/ISDT manuals (SkyRC iMAX B6AC V2, ISDT Q8 Max manual).

- Safety limits and alarms: capacity/time caps, abnormal voltage alarms, incorrect cell count detection, “connection break” stop.

- Firmware and UI: updatable firmware, clear per‑cell readouts, error logs.

Step 4: Connector and Harness Compatibility

- Main leads: match your ecosystem (e.g., XT60 common in RC). Ensure good‑quality, low‑resistance adapters if you must convert.

- Balance harness: most 4S LiPos use a JST‑XH balance plug. Confirm your charger’s balance board/port matches 4‑pin JST‑XH for 4S.

Step 5: Quality and Compliance Signals

- Prefer reputable brands with thorough manuals, published specifications (including balance current and error handling), and safety cutoffs. As a cautionary example, in 2024 the U.S. Consumer Product Safety Commission warned consumers to stop using HTRC C240 chargers due to fire and burn hazards, reinforcing the need for certified, reputable devices—see the official notice in CPSC warning on HTRC C240 (2024).

- For OEMs and serious hobbyists, check the charger’s conformity documentation; and ensure your battery packs meet pack/cell safety standards (more on that below) to reduce system‑level risk.

4) Safety and Compliance Essentials (What Not to Compromise)

Let’s anchor the hard limits and good habits with evidence:

- Max per‑cell voltage: 4.20 V standard LiPo; 4S total 16.8 V. See Battery University BU‑303 (2024) und BU‑409 (2024).

- Typical charge rate: 0.5C–1C for energy cells for longevity; higher rates increase stress. See Battery University BU‑409 (2024) und BU‑402.

- Storage voltage: target ~3.7–3.85 V per cell (≈14.8–15.4 V for 4S). See Battery University BU‑808 (2024) and the storage function in SkyRC B6AC V2 docs.

- Temperature window: charge roughly 0°C to 45°C; avoid sub‑zero charging and high‑heat environments. See Battery University BU‑410 (2024).

- Visual/olfactory inspection before charging: retire packs with swelling, mechanical damage, electrolyte odor, or voltage anomalies. This aligns with practical safety guidance summarized by fire safety bodies like the NFPA Lithium‑ion Battery Safety Tip Sheet (2024).

Standards and Regulatory Sidebar (2025 Snapshot)

If you design products or need compliance documentation, these are the common pillars:

- UL 2054: Household and commercial batteries (pack‑level safety for standalone batteries). See the UL 2054 catalog page (2022 edition).

- IEC/UL 62133‑2: Safety for sealed secondary Li‑ion cells and batteries used in portable applications. See the UL adoption page UL 62133‑2 catalog und die IEC 62133‑2 overview.

- UN 38.3: Transport testing (altitude, thermal, vibration, shock, short circuit, impact, overcharge, forced discharge)—required for shipments. See the UNECE UN 38.3 amendment document (June 2025).

- IATA Lithium Battery Guidance (2025): Air transport packaging/SOC limits/markings. See the IATA 2025 Guidance Document.

- CPSC: Safety advisories, recalls, and education for U.S. consumers and products. See ongoing listings at the CPSC Recalls portal and the 2024 warning on a defective charger above.

The standards don’t replace good charging discipline; they augment it and set a baseline for hazard reduction.

5) Operational Workflows You Can Reuse

The right charger makes correct operation easier. These repeatable workflows keep you consistent.

A) First Charge on a New 4S Pack

- Inspect the pack for any swelling, dents, torn laminate, electrolyte odor, or damaged wiring. If any red flags appear, do not charge.

- Measure open‑circuit voltage and per‑cell voltages if your charger reads them with the balance harness. Expect ~3.7–3.85 V per cell from the factory.

- Place the pack in a fire‑resistant location (non‑flammable surface, LiPo safety bag or enclosure) with ventilation.

- Connect the main leads and the 4S JST‑XH balance plug to the charger.

- Select LiPo Balance Charge, 4S, and set current ≤1C (0.5C if you’re cautious or if ambient temps are elevated).

- Confirm temperature is near room temperature; avoid charging below 0°C or in hot, enclosed spaces per Battery University BU‑410 (2024).

- Start the charge. Monitor the first cycle end‑to‑end. The charger should change from CC to CV near the end, taper current, and stop at 4.20 V/cell.

- After completion, let the pack rest and cool to ambient before use.

B) Routine Balance Charge (Daily Use)

- Quick visual check and sniff test; verify wires and balance plug integrity.

- Connect main + balance; select Balance Charge at your chosen current (0.5C–1C typical per BU‑409, 2024).

- Keep the pack in a fire‑safe area; keep an eye on cell deltas—well‑matched packs should converge within a few tens of mV by the end.

- If the charger reports high imbalance repeatedly, consider retiring the pack.

C) Storage Prep (If Not Using the Pack for a Week+)

- If the pack is near full, run Storage mode on the charger; it should discharge to about 3.8 V/cell (4S ≈ 15.2 V). SkyRC documents this target in B6AC V2 manuals; see SkyRC B6AC V2 docs. This aligns with Battery University BU‑808 (2024).

- Let the pack cool, then store in a cool, dry place away from flammables.

- Check every 1–3 months; top up to storage voltage if it drifted.

D) Field Charging Setup (RC/Robotics in the Wild)

- Power source: If you use a DC‑only charger, bring a known‑good DC supply or a larger field battery with appropriate voltage/current capacity.

- Ventilation and safety: Elevate the charger, keep air moving, and use a fire‑safe mat or container.

- Cables: Carry spares for main leads and balance extensions—many “connection break” errors stem from cable wear.

E) When to Retire a Pack

- Repeated swelling after charge/discharge, persistent high cell delta at end of charge, abnormal heat at modest currents, or physical damage are strong retirement signals. This aligns with general safety education like the NFPA tip sheet (2024). Safely discharge and dispose per local regulations.

6) Troubleshooting Matrix: Fix It or Stop Immediately

| Symptom | Likely Causes | What to Do (Stepwise) |

|---|---|---|

| “Cell imbalance” warning or high cell delta | Natural mismatch/aging; loose/damaged balance plug; one weak cell | 1) Stop the charge if any cell exceeds limits or the pack heats. 2) Re‑seat the balance plug and inspect for broken wires. 3) Run Balance Charge at a moderate current and watch deltas. 4) If the same cell lags or deltas stay high, retire the pack. TI notes show delta thresholds and the limits of bleed current; see TI SLUAA81 (balancing thresholds, 2023–2024). |

| “Connection Break” or “Cell not detected” | Worn/bad main leads; broken balance lead; charger port wear | 1) Inspect and replace suspect leads/adapters. 2) Try another port/board if available. 3) Verify on a second charger. 4) If a cell reads open intermittently, retire the pack. Error types like “connection break” appear in SkyRC B6 series materials; see SkyRC iMAX B6AC V2 docs (2023–2024). |

| Pack running hot during charge | Current set too high; high ambient; failing cell; poor ventilation | 1) Stop and let cool. 2) Reduce current (≤0.5C) and improve airflow. 3) Charge near room temp; avoid <0°C or hot spaces per Battery University BU‑410 (2024). 4) If heat persists, retire the pack. |

| Storage mode takes “forever” | Large imbalance; low discharge capability; aggressive safety limits | 1) Ensure balance plug is connected. 2) Consider a partial discharge to near storage manually, then run Storage mode to fine‑tune. 3) Patience: passive balancing/discharge currents can be small; specs like SkyRC B6neo balance 500 mA hint at practical speed limits. |

| “Abnormal voltage” or “Incorrect cell count” alarm | Mis‑set chemistry/cell count; faulty harness; damaged cell | 1) Confirm chemistry set to LiPo and 4S detected. 2) Re‑seat harnesses and verify continuity. 3) Try measuring per‑cell voltages with a meter or the charger’s readout. 4) If a cell is out of range, retire the pack. ISDT manuals document these alarms; see ISDT Q8 Max manual (2023–2024). |

| Swollen pouch | Overcharge, aging, abuse, or internal gas formation | 1) Stop using/charging immediately. 2) Isolate in a fire‑safe area. 3) Follow local disposal guidance. Consumer safety groups emphasize retiring swollen Li‑ion batteries; see the NFPA lithium‑ion safety tip sheet (2024). |

If in doubt, stop and reassess. A “saved” pack is never worth a fire.

7) OEM and Procurement Perspective: Validation and Documentation

If you’re integrating 4S LiPo packs into products, you’ll want a structured validation workflow and clean compliance evidence. Here’s a pragmatic approach:

Certification alignment

- Cell/battery: IEC/UL 62133‑2 compliance for cells/packs, verify current certificate and test report. See UL 62133‑2 catalog page und IEC 62133‑2 overview.

- Pack safety (as standalone battery): UL 2054 if applicable—see UL 2054 catalog.

- Transport: UN 38.3 test report and IATA 2025 conformance; see UNECE UN 38.3 (June 2025 amendment) und IATA 2025 Lithium Battery Guidance.

Charger/pack matching

- Confirm charger CC/CV parameters and terminations match the pack spec (4.20 V/cell standard LiPo; termination ~0.05C–0.1C). See the fundamentals in Battery University BU‑409 (2024).

- Verify balance current and delta thresholds are appropriate for your pack’s capacity and expected imbalance.

DOE and acceptance tests

- Charge‑rate DOE across ambient temperatures; measure pack temperature rise and time to balance.

- Fault handling: reverse polarity, connection break, incorrect cell count, abnormal voltage, over‑temperature cutoff.

- End‑of‑charge accuracy: verify per‑cell reaching 4.20 V within tolerance; measure storage mode setpoint accuracy (~3.8 V/cell per SkyRC B6AC V2 docs).

- Acceptance criteria: maximum cell delta at end of charge, maximum skin temperature at 1C, and cutoff behavior on fault.

Documentation set

- IEC/UL certificates, UN 38.3 report, IATA packaging/SOC procedures.

- Charger manuals/specs, test protocols, and qualification reports.

8) Coordinating with Your Battery Supplier

If you’re speccing a charger for a specific pack, share your intended charge current, connector types, and any BMS limits with your battery provider—they can help you avoid mismatches (for example, connectors, balance pinouts, or protective cutoffs) that waste time or cause faults.

A manufacturer’s perspective can be valuable when matching charger behavior to pack chemistry and BMS settings. For example, Yungbang Power(永邦电源) can advise on pack specifications, connector standards, and validation checklists when you’re selecting chargers for their packs. Disclosure: Yungbang Power is our product.

This is not a sales pitch—coordination simply reduces risk and helps you validate faster.

9) Quick‑Reference: Parameters and Checklists

A) 4S LiPo Charging Parameters Cheat Sheet

| Parameter | Evidence‑backed Value | Anmerkungen |

|---|---|---|

| Full‑charge per cell | 4.20 V | Standard LiPo; see Battery University BU‑303/BU‑409 (2024) |

| 4S max pack voltage | 16.8 V | 4 × 4.20 V |

| Typical charge rate | 0,5C-1C | Longevity‑friendly; see Battery University BU‑409 (2024) |

| Termination current | ~0.05C–0.1C | CV taper; see BU‑409 (2024) |

| Storage voltage per cell | ~3.7–3.85 V | Storage mode ~3.8 V/cell; see SkyRC B6AC V2 docs und BU‑808 (2024) |

| Charging temp window | ~0°C to 45°C | Ideal around 25°C; see BU‑410 (2024) |

| Balance connection | Mandatory for 4S | Enables per‑cell protection and top‑balance |

B) Charger Sizing Helper (4S)

- Formula: Pcharger (W) ≈ 16.8 × Icharge × 1.1–1.2

- Examples: 2.2 A → ~44–45 W; 5.0 A → ~92–101 W.

- If you plan dual‑channel or parallel workflows, multiply by the number of simultaneous packs.

C) Safe Charging Checklist (Print‑worthy)

- Before charging

- Inspect for swelling/damage/odor; verify wiring/insulation.

- Confirm ambient temp is within ~0–45°C (prefer ~25°C).

- Place pack on a non‑flammable surface in a ventilated, supervised area.

- Einrichtung

- Connect main leads and the 4S balance plug (JST‑XH) to the charger.

- Set LiPo chemistry, 4S, Balance Charge, and current ≤1C.

- Enable safety limits (time, capacity, temperature cutoff if available).

- During

- Stay nearby; watch per‑cell readouts for anomalies.

- Stop if the pack gets unusually hot or starts to swell.

- After

- Let the pack cool before use or storage.

- If not using for a week or more, run Storage mode to ~3.8 V/cell.

10) Frequently Asked Questions (Fast Answers)

- Can I charge a 4S LiPo without the balance plug? You shouldn’t. Per‑cell monitoring is how the charger prevents any one cell from exceeding 4.20 V—a core safety function.

- What current should I use for a 2200 mAh 4S? 1C equals 2.2 A. For longevity, 1.1–1.6 A (0.5C–0.75C) is even gentler, per guidance summarized in Battery University BU‑409 (2024).

- What’s “storage voltage” for 4S? Around 14.8–15.4 V total (3.7–3.85 V/cell). Many chargers’ Storage mode targets ~3.8 V/cell; see SkyRC B6AC V2 docs (2023–2024) und BU‑808 (2024).

- Is faster than 1C okay? Some high‑rate cells are rated for it, but it shortens life and raises risk if misapplied. Check your specific pack’s datasheet and remember the general trade‑offs explained in BU‑409 (2024).

- How hot is too hot during charging? Keep well below 45°C, and stop for any unusual warmth or swelling. See temperature cautions in BU‑410 (2024).

11) Putting It All Together

If you take nothing else away, take this: a proper balance charger, conservative charge rates, correct storage voltage, and good temperature discipline eliminate most avoidable failures. Add a reputable charger brand (with clear manuals and safeguards), keep an eye on standards if you ship products, and coordinate early with your battery provider to avoid mismatches.

With those habits, your 4S LiPos will charge safely, perform consistently, and last longer—without anxiety.