Lithium-ion battery pouch cells offer superior packaging efficiency and significant design flexibility. This lightweight battery design directly boosts performance. It enables a high energy density, a critical factor for a modern lithium-ion battery. The flexible pouch cell design supports innovative, slim products like consumer electronics and electric vehicles. The overall density and efficiency of this battery contribute to its wide adoption.

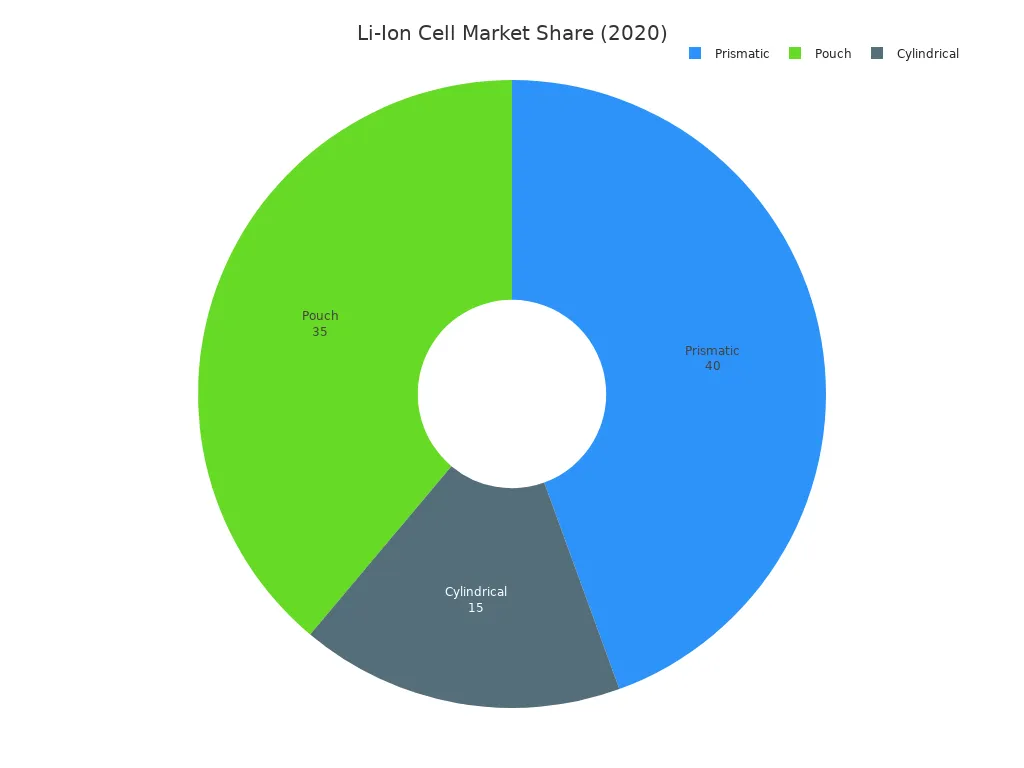

The pouch cell is a major competitor in the market for lithium-ion batteries, holding a significant share in the passenger vehicle sector.

Design Advantages of Lithium-Ion Battery Pouch Cells

The unique construction of lithium-ion battery pouch cells provides distinct advantages in modern applications. The core benefits stem from a smart and efficient design that prioritizes space, weight, and adaptability. These characteristics make the lithium pouch cell a leading choice for engineers and product designers.

Packaging Efficiency

Packaging efficiency refers to how much of a battery’s total volume contains active, energy-storing materials. Pouch cells excel in this area. They do not have a rigid metal can like cylindrical or prismatic cells. This absence of a heavy, space-consuming enclosure allows the cell design to maximize internal volume for active materials. The result is a higher energy density for the available space.

A lithium pouch cell achieves the highest packaging efficiency among common battery form factors. The flexible foil seal allows for more compact designs and better use of the battery’s internal volume.

This superior efficiency means that for a given size, a pouch battery can store more energy, a critical factor in portable electronics and electric vehicles where space is a premium.

Lightweight Construction

The materials used in a pouch battery contribute directly to its lightweight nature. The outer casing is not metal but a thin, durable aluminum-laminated film. This material is known for its light weight, high formability, and excellent safety barrier properties. This construction significantly reduces the overall weight of the battery.

The laminated film itself is a multi-layer composite. A typical structure includes:

- An outer Polyamide layer for puncture resistance.

- An adhesive layer.

- A central Aluminum foil layer that acts as a moisture barrier.

- Another adhesive layer.

- An inner Polypropylene layer that seals the battery.

This layered approach creates a robust yet lightweight enclosure, boosting the battery’s gravimetric energy density (energy per unit of mass).

Flexibilität des Formfaktors

Perhaps the most significant advantage of this cell design is its flexibility. The soft, pliable pouch allows manufacturers to create a battery in various shapes and sizes. This flexible form factor is a major departure from the fixed dimensions of rigid cells. This adaptability allows the battery to conform to the unique contours of a device.

This design flexibility enables thinner, lighter, and more ergonomic products. Engineers can utilize unconventional or limited spaces within a product’s chassis, optimizing the overall design.

| Application Area | Benefit of Form Factor Flexibility |

|---|---|

| Smartphones & Tablets | Creates ultra-slim device profiles. |

| Wearable Technology | Allows the battery to fit into curved or small spaces. |

| Electric Vehicles (EVs) | Enables large, flat battery packs that improve vehicle layout. |

This freedom in design makes lithium-ion batteries highly attractive for next-generation technology where every millimeter of space counts.

Performance Characteristics Analysis

The design of lithium-ion battery pouch cells directly influences their performance characteristics. A deep analysis of these characteristics reveals why this battery format is chosen for demanding applications. Key metrics like energy density, safety, and durability define the practical value of a lithium pouch cell.

Energy and Power Density

Energy density measures the amount of energy a battery can store for its size (volumetric) or weight (gravimetric). Power density indicates how quickly a battery can deliver that energy. The lithium pouch cell excels in both areas, making it ideal for high-performance applications.

Die flexible casing of a lithium pouch cell provides the highest packaging efficiency. This design allows more active material to fit inside, boosting the system-level energy density. While battery chemistry is the primary factor for cell-level density, efficient packing significantly enhances the overall capacity of a battery pack.

- Pouch cells offer superior packaging efficiency due to their non-rigid casing.

- This flexibility allows them to fit into unconventional spaces in devices.

- System-level energy density improves when cells are packed efficiently.

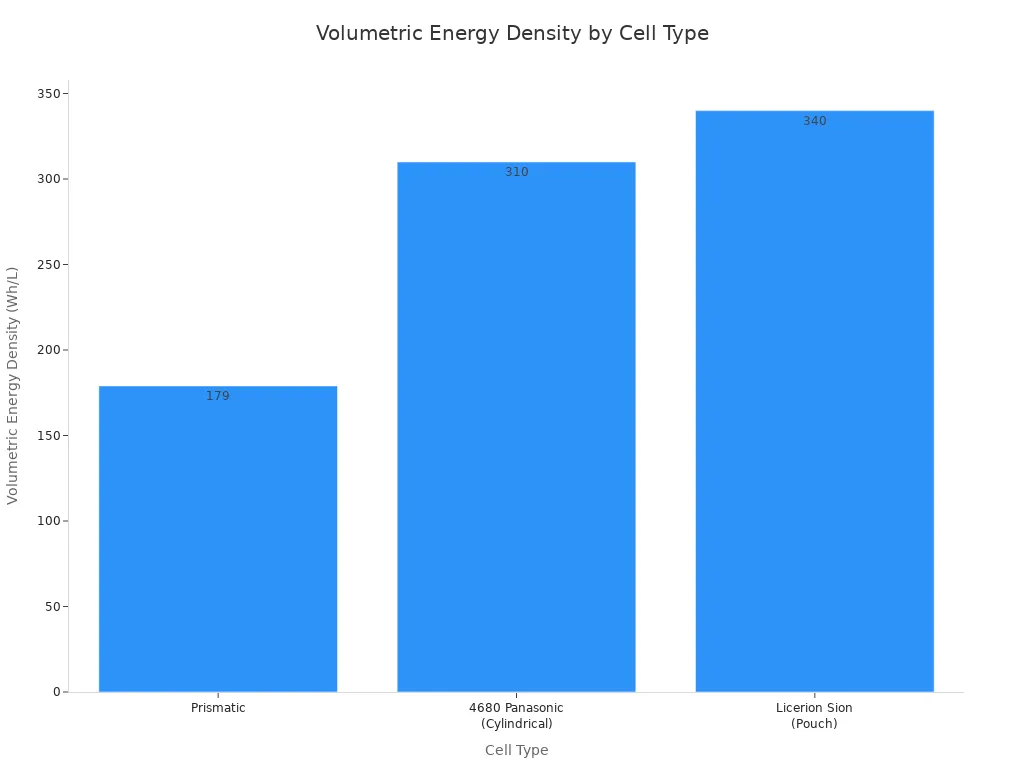

Recent advancements show that pouch cells achieve a higher energy density than other formats. For a given capacity, pouch cell systems can be smaller and lighter, a key advantage for electric vehicles and consumer electronics.

| Cell Type | Capacity (kWh) | Volume (L) | Volumetric Energy Density (Wh/L) |

|---|---|---|---|

| Prismatisch | 82 | 458 | ~179 |

| 2170 Panasonic (Cylindrical) | 82 | Lower than Prismatic | Higher than Prismatic |

| Ultium GM (Pouch) | 82 | Lower than Prismatic | Higher than Prismatic |

| 4680 Panasonic (Cylindrical) | 100.9 (82 * 1.23) | 325 | ~310 |

| Licerion Sion (Pouch) | 104.4 (82 * 1.272) | 307 | ~340 |

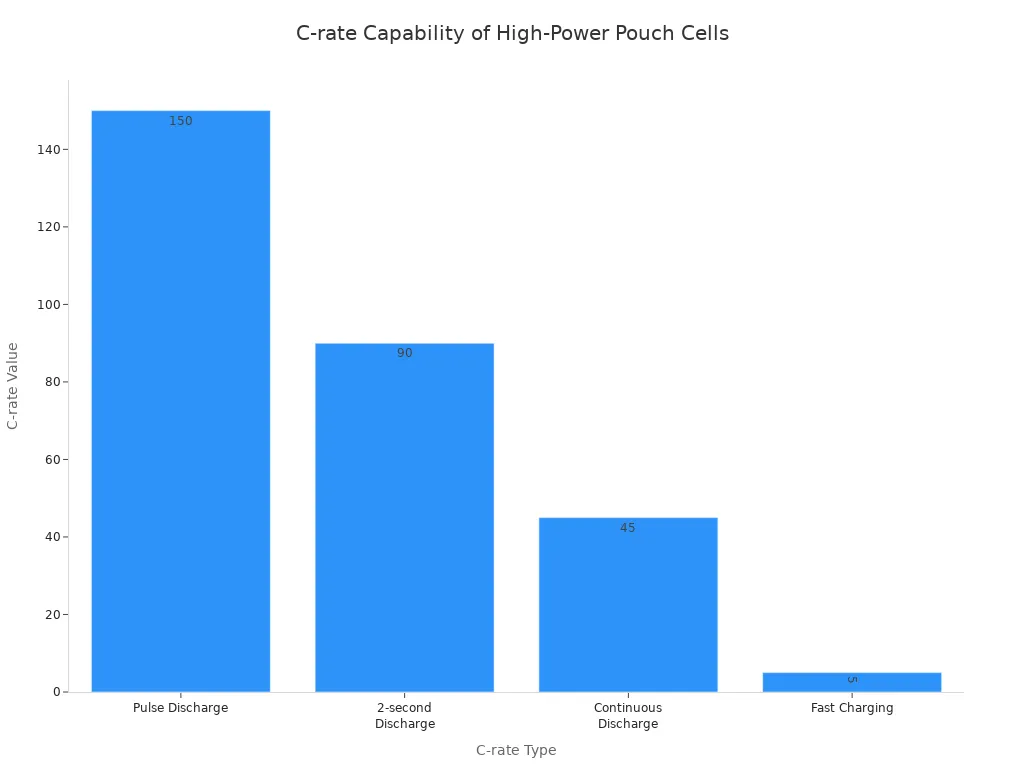

Power density is equally important, especially for high-performance EVs. The C-rate measures the charge and discharge rate relative to the battery’s capacity. High-power pouch cells can tolerate very high discharge rates. Some designs handle continuous discharge rates up to 45C and pulse rates over 100C. This capability enables rapid acceleration in electric vehicles and supports fast charging.

| C-rate Type | Value |

|---|---|

| Pulse Discharge | 150C |

| 2-second Discharge | 90C |

| Continuous Discharge | 45C |

| Fast Charging | 5C |

Lithium Pouch Cell Safety Profile

Safety is a primary concern for all lithium-ion batteries. The soft casing of a pouch cell presents unique challenges and requires specific safety solutions. The main issues are swelling from gas generation and vulnerability to punctures.

Swelling is a known issue for pouch cells. It occurs when gas is generated during charging and discharging. This pressure can damage the device housing or internal electronics.

Several factors can cause a battery to swell:

- Faulty manufacturing processes.

- Overcharging or over-discharging the battery.

- Excessive current during operation.

- Exposure to high temperatures.

At a chemical level, failure often starts at the lithium metal anode. Processes like uneven lithium deposition and volume changes during cycling can damage the protective Solid Electrolyte Interphase (SEI) layer. This damage leads to the formation of “dead Li,” which reduces capacity and contributes to gas generation, compromising long-term performance and safety.

To counter these risks, manufacturers integrate multiple safety mechanisms into the battery design and the overall system. These features work together to ensure thermal stability and prevent catastrophic failures.

- Robust Separators: These withstand high temperatures to prevent internal short circuits.

- Thermal Barriers: Insulation materials are placed between cells to stop heat from spreading.

- Pressure Relief Vents: These vents open to release gas and pressure during a failure, preventing an explosion.

- Battery Management Systems (BMS): A BMS constantly monitors the battery’s temperature, voltage, and state of charge. It prevents conditions that could lead to thermal runaway.

- Advanced Electrolytes: The development of non-flammable or solid-state electrolytes is a key area of research to improve the safety of lithium-ion batteries.

These integrated safety features are essential for the reliable operation of pouch cells in demanding applications like energy storage systems.

Cycle Life and Durability

The cycle life of a battery refers to the number of charge-discharge cycles it can endure before its capacity falls significantly. The durability of a lithium pouch cell is closely tied to managing the mechanical stress caused by swelling.

Gas generation is a continuous process as a battery ages. This gas causes the cell to swell and contract with each cycle. This repeated mechanical fatigue can accelerate capacity fade and shorten the battery’s life. Irreversible swelling from SEI growth and gas formation permanently reduces the amount of active material, which degrades performance.

Excessive swelling can cause internal structural damage, lithium plating, and even electrolyte leakage. Optimizing the operating conditions and external support is crucial for extending the battery’s life.

Applying external pressure is a common practice to improve the cycle life and durability of pouch cells. This pressure helps maintain good contact between internal components and prevents delamination. However, the amount of pressure must be carefully controlled. Too much pressure can shorten the battery’s life by accelerating mechanical damage.

Engineers use specialized fixtures to enhance durability in battery packs.

- Cell Fixtures: These fixtures use rigid plates, often made of aluminum or stainless steel, to apply uniform pressure across the cell surface.

- Pressure Control: Springs are often used with bolts to apply a specific, calibrated amount of pressure. This method is effective for maintaining optimal contact without causing damage.

- Accurate Measurement: Technicians use flat pressure sensors for precise calibration. This ensures the pressure is distributed evenly, which is vital for maximizing the battery’s life and performance.

Proper mechanical support is essential for managing the unique characteristics of pouch cells. This support helps unlock their high energy density and long cycle life for modern applications.

Comparative Analysis: Pouch vs. Other Formats

Choosing the right battery form factor is critical for product design and performance. Lithium-ion battery pouch cells offer unique benefits, but they compete directly with established cylindrical and prismatic formats. Each type presents a different set of trade-offs.

Pouch vs. Cylindrical Cells

Cylindrical cells, like the common 18650 and 21700 types, are known for their excellent mechanical strength. Their rigid metal casing provides superior resistance to physical stress and vibration. This durability makes them a reliable choice for many applications. In contrast, the flexible lithium pouch cell is more delicate and susceptible to punctures. Cylindrical battery manufacturing is highly automated and standardized. This efficiency often results in lower production costs compared to the more customized pouch format.

Pouch vs. Prismatic Cells

Prismatic cells use a rigid, rectangular metal can. This design gives them strong structural integrity, unlike the soft casing of a lithium pouch cell. While prismatic cells are durable, they generally have a lower energy density than pouch cells. A key advantage of the pouch design is its ability to achieve a high energy density by maximizing active material in a lightweight package. However, this comes with a trade-off. Prismatic cells can offer better thermal management because their metal casing helps dissipate heat. Die poor thermal conductivity of a pouch battery can be a challenge in tightly packed configurations.

Key Metrics Comparison

The ideal battery choice depends on the specific priorities of an application, such as maximizing capacity or ensuring structural safety. The following table compares the three main formats of lithium-ion batteries across key metrics.

| Metric | Pouch Cell | Cylindrical Cell | Prismatic Cell |

|---|---|---|---|

| Die Energiedichte | Highest (250-300 Wh/kg) | High (150-280 Wh/kg) | Good (160-255 Wh/kg) |

| Kosten | Höher | Lowest | Low to Moderate |

| Sicherheit | Vulnerable to puncture/swelling | High (mechanically stable) | High (rigid case) |

| Thermal Management | Poor | Ausgezeichnet | Good |

| Mechanical Robustness | Low (requires external support) | Ausgezeichnet | Hoch |

This comparison shows that while the pouch battery leads in energy density, it requires careful system design to manage its mechanical and thermal weaknesses.

Lithium-ion battery pouch cells provide a lightweight and flexible design. This design boosts the battery capacity and density. The efficient pouch cell structure leads to a high energy density.

A lithium pouch cell requires careful system integration. The soft battery needs external support to manage swelling and protect against punctures, ensuring both high capacity and safety for lithium-ion batteries.

FAQ

What is the main advantage of a pouch cell?

The primary advantage of a pouch cell is its high energy density. The lightweight, flexible design maximizes the amount of active material. This allows the battery to store more energy for its size and weight compared to other formats.

Why do pouch cells swell?

Pouch cells swell due to gas generation inside the cell. This process occurs naturally during charging and discharging cycles. Over time, the buildup of gas causes the soft pouch to expand, which requires management in product design.

Are pouch cells safe?

Pouch cells are safe when integrated into a well-designed system. Manufacturers use a Battery Management System (BMS) to monitor temperature and voltage. External mechanical support also protects the cell from punctures and controls swelling, ensuring safe operation.

Which applications use pouch cells most often?

Many modern electronics use pouch cells. Their slim and flexible shape is ideal for smartphones, tablets, and drones. Electric vehicle (EV) manufacturers also favor them for building large, high-capacity battery packs that fit a vehicle’s chassis.