If LiPo packs are the “fuel tanks” of RC and FPV, the C rating is the diameter of the fuel hose. It tells you how quickly the battery can safely deliver energy. Here’s how C rating actually works, how to translate it into amps, and how to choose the right pack for your RC car, drone, boat, plane, or any high‑power device—with 2024–2025 best practices.

What the C rating really means

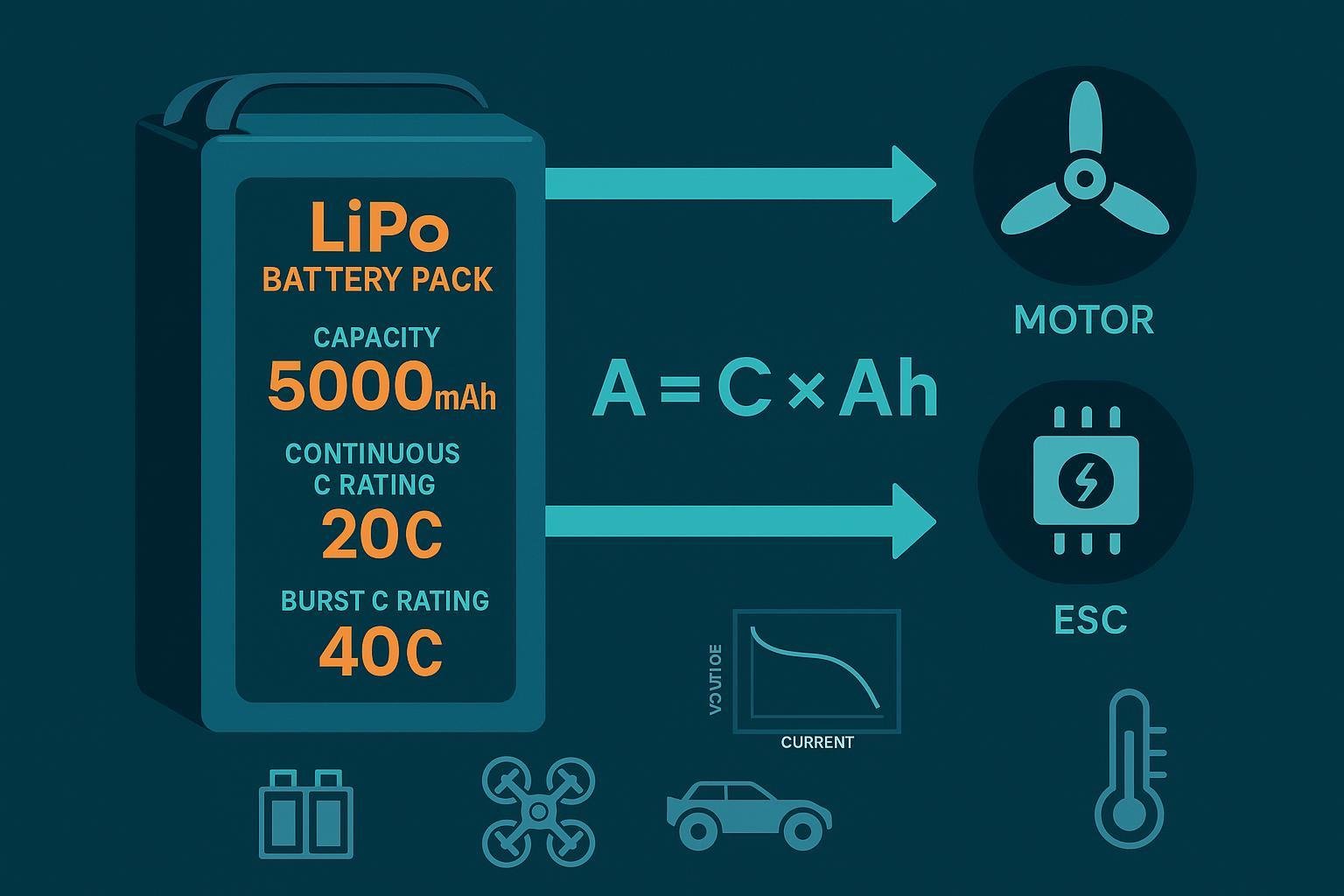

- Core idea: C rate expresses discharge current relative to capacity. The simple math: Max current (A) ≈ Capacity (Ah) × C. A 5 Ah pack at 30C claims 150 A continuous. See the foundational definition in Battery University — “BU‑101: What is C‑rate”.

- Continuous vs. burst: “Continuous C” is what the pack claims it can sustain; “burst C” is a short spike—often on the order of a few seconds for punch‑outs or hard launches. Vendors define burst differently; as a typical rule of thumb in RC, burst windows are around seconds, not minutes, as discussed in HobbyKing’s “Battery burst rating explained”.

Two immediate caveats:

- C ratings are not standardized. Two “60C” packs from different brands can perform very differently; many labels are optimistic. Hobby guides frequently warn about marketing inflation, e.g., OscarLiang’s LiPo battery guide and the HobbyKing articles above.

- C applies to charging too (e.g., 1C charge = charge in one hour), but charge C is a separate spec. See Battery University — BU‑101.

Why C matters in the real world

- Performance: Higher usable C reduces voltage sag under throttle, improving punch and consistency.

- Heat: Drawing more current than the pack can comfortably supply converts energy into heat, aging the pack faster.

- Safety: Excessive sag and heat can trigger cutoffs, puffing, or in worst cases, failure.

Voltage sag is largely ohmic: under load, V_drop ≈ I × R. Lower internal resistance (IR) means less sag and heat for the same current. See Battery University — “How does internal resistance affect performance”.

A simple selection workflow (with examples)

- Estimate your current needs

- FPV/drone: Use motor + prop data, or telemetry logs. Punch‑outs often exceed average current.

- RC cars/boats: Motor Kv, gearing/prop, ESC logs, and race conditions inform sustained vs. burst.

- Choose capacity for runtime

- Convert desired runtime into capacity (Ah). Example: If you average 20 A for ~15 minutes, you need ~5 Ah (because 20 A × 0.25 h ≈ 5 Ah), plus headroom.

- Compute the required continuous C

- Required C ≈ Sustained current (A) ÷ Capacity (Ah).

- Add headroom for bursts and label inflation

- Plan at least 30–50% headroom over expected sustained current. Because labels can be optimistic, assume only part of the printed continuous C is truly usable unless validated by testing.

- Verify with real‑world checks

- Check pack IR, observe voltage sag during a hard pull, and monitor temperature after a run. Adjust capacity or brand if results are marginal.

Examples

- FPV drone (6S): You expect 90 A peak, ~45–60 A sustained. If you pick 6S 1100 mAh (1.1 Ah), the printed continuous for “100C” is 110 A, but the real usable may be much lower. If sag/heat are high, move to 1300 mAh (1.3 Ah) to raise available amps for the same C and reduce stress.

- RC car (2S): Your setup bursts to ~150 A and sustains ~90 A. A 2S 5000 mAh (5.0 Ah) pack labeled 50C “claims” 250 A continuous. In practice, expect less; test temps and sag. If the pack finishes a heat above ~warm‑to‑hot and sags hard on acceleration, consider higher‑quality cells, higher capacity, or a more robust connector.

Quick sag estimate: If the pack’s measured IR sums to 12 mΩ, a 100 A punch drops about 1.2 V (I × R). On a 6S (~22.2 V nominal), that’s ~0.2 V per cell.

Reality check: labels vs. physics

- Non‑standard labels: There’s no universal test that enforces what “60C” means across brands. Community guides note that headline C can be marketing‑inflated; see OscarLiang’s LiPo battery guide.

- Practical derating: Until you have data, treat printed continuous C conservatively (e.g., assume only a portion is truly sustainable). Validate with IR, sag, and temperature.

How to test a pack (and decide if it’s “good enough”)

- Measure IR per cell and total: Many chargers show per‑cell IR. Lower IR generally means less sag and heat. See Battery University — “How does internal resistance affect performance”.

- Watch voltage under load: Log voltage during a full‑throttle climb or launch. For FPV, a pragmatic target is to avoid deep dips much below the low‑3.3 V/cell range under load, and aim to land with cells rebounding to mid‑3.5–3.7 V after rest, per the practices outlined in OscarLiang’s LiPo battery guide.

- Track temperature: End a flight/run and immediately touch the pack; ideally, keep it warm but not uncomfortably hot. Elevated temperature accelerates aging; managing heat is key to cycle life, as discussed in Battery University — “BU‑808: How to Prolong Lithium‑based Batteries”. Many Li‑ion datasheets list 60 °C near the upper end of discharge operating temperature; staying well below that improves longevity.

- Sanity‑check weight and size: Extremely light packs boasting very high C are suspect—energy and power density have trade‑offs.

Tip: If two packs have similar capacity but one consistently finishes cooler with less sag in your setup, that pack effectively has a higher usable C for you.

Continuous vs. burst C, demystified

- Continuous C should reflect what the pack can supply indefinitely within its thermal limits.

- Burst C is a short pulse rating, often on the order of 5–10 seconds, depending on brand definition, as noted in HobbyKing’s “Battery burst rating explained”.

- Don’t plan your build around burst; design for sustained current and treat burst as occasional headroom.

Safety and longevity checklist (2024–2025 practices)

- Voltage targets: For RC/FPV, avoid running packs into deep depletion. A conservative practice is to avoid heavy under‑load dips much below ~3.3 V/cell and land so resting voltage rebounds to ~3.5–3.7 V/cell; see OscarLiang’s LiPo battery guide.

- Storage: Store at partial state‑of‑charge (~40–60%, about 3.7–3.8 V per cell) to slow aging, per Battery University — “BU‑808: How to Prolong Lithium‑based Batteries”.

- Charging: Follow the pack manufacturer; if unspecified, 1C is a safe default. Remember that “C” for charging is separate from discharge C; definition in Battery University — BU‑101.

- Connectors and wiring: Ensure connectors and wire gauge match your current. For example, the original AMASS XT60’s official datasheet lists 30 A rated current with 60 A short‑duration max; see Changzhou AMASS XT60 datasheet (PDF). If you routinely draw higher sustained current, consider larger connectors (e.g., XT90) and thicker wire.

- Physical care: Avoid puffed or damaged packs; stop using any pack that smells sweet/solvent‑like, swells significantly, or runs unusually hot.

- Compliance context: Commercial shipping and many product certifications require lithium battery safety testing. See the UN transport test suite in UNECE — Manual of Tests and Criteria, Section 38.3 and the portable battery safety standard IEC — IEC 62133 overview.

FAQs

- Is a higher C always better? Not necessarily. Higher‑C packs can be heavier and costlier. For endurance builds, extra weight may hurt more than the added punch helps.

- Why does my “100C” pack still sag? Label C isn’t standardized; your pack’s real continuous capability may be lower. Validate with IR and temperature, and consider higher capacity or a better cell brand.

- What’s the difference between charge C and discharge C? Both use the same “C” concept, but charge C is about how fast you can safely charge, and is typically much lower than the discharge C. Definitions in Battery University — BU‑101.

Quick rules of thumb

- Convert in seconds: Amps ≈ Ah × C.

- Design for sustained current; treat burst as short‑term headroom.

- Start with printed C, then derate unless you have test data.

- Avoid deep sag: throttle back if cells dip toward the low‑3.3 V/cell range under load.

- Finish cool: cooler packs live longer; watch temps and keep airflow where possible.

- Store around 3.7–3.8 V/cell.

- Size connectors and wire to your real current, not the label.

A little math plus a reality check goes a long way. Use C to get into the right ballpark, then verify with IR, sag, and temperature in your own setup. That’s how you choose LiPos that punch hard, run cooler, and last longer.