The future of energy storage is not just about battery chemistries; it is about plastic. Key innovations in battery plastics are revolutionizing how batteries work. These breakthroughs include advanced polymer separators, thermally conductive casings, and solid-state polymer electrolytes. Such materials are vital for improving the safety and performance of a battery.

Did You Know? Light vehicle batteries now incorporate 50% more plastic than a decade ago. These plastic battery components help build lighter and more efficient battery systems that meet modern safety requirements for energy storage.

These advanced components are changing the landscape for all types of batteries.

The Essential Role of Plastics in a Modern Battery

Plastics are fundamental to the function and safety of modern batteries. These materials serve multiple critical purposes inside every battery, from providing electrical insulation to ensuring structural stability. The quality and design of plastic battery components directly impact the overall performance and longevity of energy storage solutions.

Electrical Insulation

Preventing Short Circuits

A primary function of plastic in a battery is to prevent electrical shorts. Conductive parts inside a battery must remain separate to operate safely. Plastic materials excel at this job due to their high dielectric strength.

How Insulation Works Materials like flame-retardant polypropylene and polycarbonate are excellent insulators. They stop electrical arcing between sensitive components. This property is essential for high-voltage battery systems, where safety is a top priority.

These plastic battery components, such as cell spacers and busbar insulation, effectively isolate electrical pathways. This insulation is a key defense against short circuits that could lead to battery failure or fire.

Structural Integrity and Protection

Housing Sensitive Cells

A battery contains delicate internal parts. Plastic battery housings provide a tough, protective shell. These enclosures safeguard the sensitive cells from mechanical shock, road vibration, and impact. Engineered plastics offer excellent cushioning and energy absorption. Designers create robust battery housings with features like internal ribs that lock components in place, increasing durability. This protection is vital for the demanding environments of electric vehicles and portable electronics.

Reducing Weight

Weight is a critical factor in battery design, especially for electric vehicles. Lighter battery systems improve vehicle efficiency and range. Plastic offers a lightweight alternative to metal for many components. Using high-performance resins for housings and internal structures reduces the overall weight of the battery pack. This weight reduction helps create more efficient and powerful batteries without compromising strength or safety.

Chemical and Corrosion Resistance

Withstanding Electrolytes

The internal environment of a battery is chemically aggressive. The electrolyte, a key part of the battery, can be highly corrosive. Plastic is naturally resistant to chemical corrosion.

- Protective Coatings: Certain battery plastics, like polyvinylidene fluoride (PVDF), are used as protective coatings and binders for electrodes.

- Separators: Polypropylene (PP) and polyethylene (PE) films act as separators between electrodes. They allow ions to flow but stop electrons, preventing shorts while resisting the electrolyte.

This chemical resistance ensures the long-term reliability of all storage components, protecting them from degradation over thousands of cycles.

An Overview of Core Battery Plastics

Different types of battery plastics serve specific functions within modern battery systems. Manufacturers select these materials for their unique properties, ensuring each part performs its job correctly. The quality of these plastic battery components is essential for the overall safety and efficiency of the battery.

Polyolefins as Separators

Polyolefins are a family of plastic widely used for battery separators. These materials are popular due to their excellent stability and low cost. They form a micro-porous barrier between the anode and cathode.

Polypropylene (PP)

Polypropylene is a top choice for separators and casings. It has great chemical resistance and mechanical strength. This plastic performs well at high temperatures, which helps reduce the risk of thermal runaway. Multi-layer separators often use PP to improve heat resistance in battery systems.

Polyethylene (PE)

Polyethylene is another common material for battery separators. It provides excellent electrical insulation, preventing short circuits. At the same time, its porous structure allows ions to flow freely. This property is critical for battery performance.

Advanced Separators Some advanced separators use a three-layer PP-PE-PP structure. This design combines the shutdown feature of PE with the mechanical strength of PP, creating safer and more reliable components.

Engineering Plastics for Protective Battery Components

Engineering plastics provide the strength and protection a battery needs. These high-performance resins form the tough outer shell and internal structures that shield sensitive cells.

Polycarbonate (PC) Casings

Polycarbonate is used for battery housings because of its high impact strength and heat resistance. Some PC resins are transparent. This clarity allows for easy visual inspection of internal components, which is useful for monitoring the battery’s health.

Polyamide (PA) Structures

Polyamide (PA), also known as nylon, is valued for its toughness and durability. Manufacturers use this plastic for structural components inside the battery pack, including connectors and support frames. These plastic battery components must withstand vibration and impact, and PA is strong enough for the job.

Fluoropolymers as Binders

Fluoropolymers play a vital role inside the battery electrodes. They act as a special kind of glue, holding everything together.

PVDF in Electrodes

Polyvinylidene fluoride (PVDF) is a popular binder material. It connects the active electrode materials to the metal current collectors.

- Adhesion: PVDF has excellent bonding performance, ensuring the electrode materials do not flake off during charging and discharging.

- Stability: This plastic is chemically stable and resists corrosion from the electrolyte. This resistance helps extend the life of the battery.

- Strength: PVDF provides the mechanical strength needed to prevent the electrode from cracking as the battery operates.

These plastic battery components are crucial for the long-term stability and function of lithium-ion batteries.

Breakthroughs Shaping the Future of Battery Plastics

Innovations in battery plastics are pushing the boundaries of what is possible in energy storage. Scientists are developing new materials that make batteries safer, more powerful, and longer-lasting. These advanced plastic battery components are at the heart of next-generation battery systems.

Advanced Polymer Separators

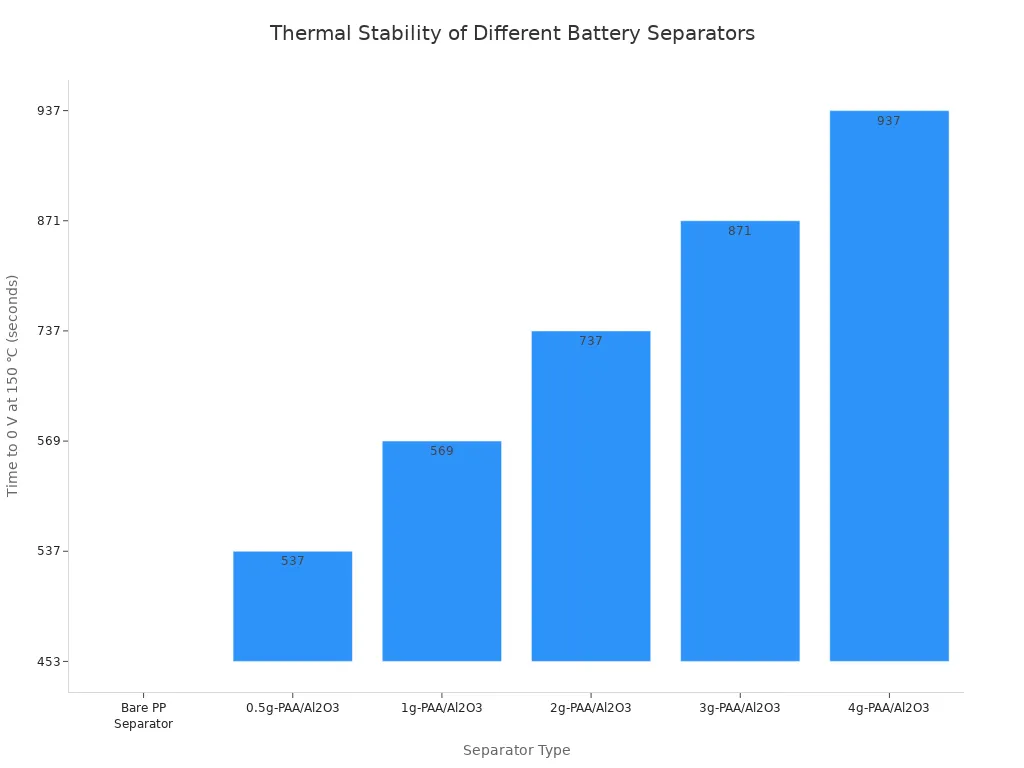

The separator is a thin plastic film that prevents the anode and cathode from touching. New separator technologies are dramatically improving battery safety and performance. The quality of these components is critical for modern batteries.

Ceramic-Coated Films

Standard polymer separators can shrink or melt at high temperatures. This failure can cause a short circuit and lead to a dangerous event called thermal runaway. Researchers now apply a thin layer of ceramic material to the plastic separator. This ceramic coating creates a rigid framework. It prevents the separator from shrinking, even when the battery gets very hot. Materials like high-purity alumina are excellent for this purpose. A lithium iron phosphate (LFP)-coated separator showed only 1.1% shrinkage at 140 °C, a temperature that would melt a normal separator. This improved thermal stability is a key defense against battery fires.

Dendrite Growth Prevention

Lithium-ion batteries can form tiny, needle-like structures called dendrites during charging. These dendrites can pierce the separator, causing a short circuit. New plastic battery components are designed to stop this from happening.

- Increased Strength: Advanced separators have greater mechanical strength to resist being punctured by dendrites.

- Ion-Selective Polymers: Some new separators use an ion-selective plastic. This material allows lithium ions to pass through but blocks other particles that contribute to dendrite formation.

- Uniform Deposition: These advanced materials also help regulate the uniform deposition of lithium ions, which prevents the initial formation of dendrites.

Solid-State Polymer Electrolytes

Traditional lithium-ion batteries use a flammable liquid electrolyte. This liquid can leak and catch fire if the battery is damaged. Solid-state polymer electrolytes replace this liquid with a solid, flexible plastic film, revolutionizing battery safety and design.

Eliminating Flammability

A solid polymer electrolyte is not flammable. This change dramatically improves the safety of a battery. It removes the risk of leakage and fire, which is a major concern for electric vehicles and consumer electronics. One recent breakthrough involves an additive that makes the electrolyte solidify on impact. This “oobleck-like” material, made of silica particles, turns solid under pressure. It prevents electrodes from touching if the battery is damaged, stopping a fire before it can start.

Increasing Energy Density

Solid electrolytes allow for new battery designs that can store more energy in a smaller space. They enable the use of high-energy lithium metal anodes, which are not compatible with liquid electrolytes. This advancement leads to lighter, more powerful battery systems. Researchers are exploring several polymers for this purpose:

- Poly(ethylene oxide) (PEO): A non-toxic material that has been a reference in the field for years.

- Polycarbonate (PC): A non-toxic polymer that shows improved lithium-ion conductivity.

- Polyacrylonitrile (PAN): A material with high thermal stability and strength.

Thermally Conductive Plastics

Heat is a major enemy of battery performance and lifespan. Too much heat can reduce efficiency and cause damage. New thermally conductive plastic resins help manage this heat effectively.

Integrated Heat Dissipation

Engineers are adding special fillers to plastic battery components to help them dissipate heat. These fillers create pathways for heat to escape from the battery cells. This turns the plastic housings into an active part of the thermal management system. Conductive fillers include:

- Ceramic Fillers: Materials like aluminum oxide and boron nitride are excellent at conducting heat away from its source.

- Metallic Fillers: Small particles of aluminum, copper, or silver can also be mixed into the plastic to improve thermal conductivity.

These advanced storage components help keep the battery at its optimal operating temperature.

Improved Performance and Lifespan

Better heat management leads to a longer-lasting and better-performing battery. When cells stay cool, they can be charged faster and can deliver power more efficiently. The improved durability of these components ensures the battery can withstand thousands of charge and discharge cycles without degrading. This innovation in storage technology is crucial for demanding applications like electric vehicles and grid-scale battery systems.

Sustainable and Recyclable Materials

The battery industry is moving toward a greener future. A key part of this shift involves creating sustainable plastic battery components. Researchers are developing new materials that come from renewable sources and are easier to recycle. This focus helps reduce waste and lowers the environmental impact of battery production.

Bio-Based Polymers

Scientists are exploring polymers made from natural sources instead of fossil fuels. These bio-based plastics can perform essential jobs inside a battery. They offer a way to make batteries more environmentally friendly without losing performance. Many of these natural materials are abundant and biodegradable.

From Nature to Batteries Using polymers from living organisms can reduce the carbon footprint of battery manufacturing. These materials are often non-toxic and can be sourced sustainably.

Some promising bio-based polymers include:

- Cellulose and Chitosan: Derived from plants and crustacean shells, these polymers can function as separators or binders in lithium-ion and zinc-based batteries.

- Agarose: This polymer, which comes from seaweed, is used as a separator and a protective coating for anodes.

- Polylactic Acid (PLA): PLA is a popular bioplastic often made from corn starch. Engineers use it to 3D-print custom battery electrodes, creating a more sustainable manufacturing process.

- Silk and Keratin: Proteins like silk and keratin are being tested for use in electrodes and electrolytes due to their unique structural properties.

Design for Disassembly

Recycling a battery is complex. Many components are glued together permanently, making them hard to separate. “Design for Disassembly” is a new approach to solve this problem. Engineers are creating plastic battery components that are easy to take apart at the end of their life.

This method allows for the clean recovery of valuable materials. Instead of shredding the entire battery pack, workers can separate the plastic casings, metal foils, and active chemicals. This makes recycling more efficient and less costly. Designers achieve this using clever techniques like:

- Reversible Adhesives: Special glues that can be “un-stuck” with a specific trigger, like heat or a chemical solvent.

- Mechanical Fasteners: Using clips, snaps, or screws instead of permanent bonds allows for simple manual or robotic disassembly.

This smart design philosophy ensures that the plastic materials in a battery can be recovered and reused, closing the loop on a circular economy.

Applications: Revolutionizing Energy Storage

Innovations in battery plastics are creating powerful new applications for energy storage. These advanced materials are improving battery systems across major industries. The applications range from electric vehicles to large-scale grid storage. These developments show how better plastic components lead to better battery performance.

Electric Vehicles (EVs)

Plastic is a key material in modern EV battery systems. These applications demand lightweight and safe components for optimal performance.

Lighter and Safer Packs

Advanced plastic resins significantly reduce the weight of an EV battery pack. Polymers have a much lower density than metals. This property helps create lighter and more efficient batteries. Lighter battery enclosures improve a vehicle’s range and acceleration.

- Glass Fiber Reinforced Plastics (GFRP): These composites offer a high strength-to-weight ratio. Manufacturers use them for strong battery enclosures.

- Carbon Fiber Reinforced Plastics (CFRP): These materials are extremely lightweight and rigid. They are used for critical structural parts in high-performance applications.

Faster Charging Support

Thermally conductive plastics are essential for fast-charging applications. They help manage the intense heat generated during high-power charging. These plastic battery components are integrated into cooled cable systems. They help dissipate heat from the charging cable to the socket. This efficient thermal management allows for higher currents, which significantly reduces charging times for an EV battery.

Consumer Electronics

New polymer materials are changing the design of consumer electronics. These applications benefit from thinner and safer battery systems.

Thinner, Power-Dense Devices

Smart polymers enable the creation of flexible and power-dense devices. These materials respond to stimuli like heat or electric fields. This adaptability allows for lighter and more integrated electronic components.

Flexible Power Conductive polymers like PEDOT:PSS and dielectric polymers like PVDF allow for the creation of printed batteries and flexible capacitors. These components can conform to non-planar surfaces, enabling new designs for wearable technology and low-profile electronics.

Enhanced Safety

The move toward solid-state polymer electrolytes greatly improves the safety of a battery. Replacing flammable liquid electrolytes with a solid plastic film eliminates the risk of leaks and fires. This is a major safety upgrade for devices people carry every day, like smartphones and laptops.

Grid-Scale Energy Storage

Plastic innovations are vital for large-scale energy storage solutions. These applications support the stability of the power grid.

Durable BESS Components

Battery Energy Storage Systems (BESS) are large installations that store massive amounts of energy. The plastic battery components in these systems must be extremely durable. High-performance plastic provides the necessary durability and resistance to corrosion for long-term outdoor storage applications.

Cost-Effective Systems

Plastic offers a cost-effective alternative to metal for many large components in BESS. The lower material cost and easier manufacturing of plastic parts help reduce the overall expense of these massive storage projects. This makes grid-scale energy storage more accessible.

Supporting Renewable Energy

Durable and thermally stable plastic components are vital for BESS. These battery systems help manage the intermittent nature of renewable energy sources like wind and solar. By providing grid services and frequency regulation, BESS ensures a stable power supply. This makes large-scale storage a cornerstone of a modern, green energy infrastructure.

Innovation in battery plastics is a critical driver for better battery systems. Advanced plastic battery components, like solid-state electrolytes and thermally conductive plastic, make each battery fundamentally safer, a key goal for any battery. These improved components create powerful and sustainable battery systems for all types of storage. The future of energy storage will see materials science and AI combine, creating the next generation of batteries and storage solutions. This synergy ensures the evolution of these materials continues to improve every battery and its storage capabilities, building safer battery systems.

FAQ

Why are plastics essential in batteries?

Plastics serve many critical roles. They provide electrical insulation to prevent short circuits. They also create strong, lightweight housings that protect sensitive internal components from damage and reduce overall weight.

What is a battery separator?

A separator is a thin, porous plastic film. It sits between the anode and cathode. This film stops the electrodes from touching but allows ions to flow through, which is essential for the battery to function correctly.

How do new plastics improve battery safety? 🛡️

Advanced plastics enhance safety in several ways:

- Ceramic-coated separators prevent melting at high temperatures.

- Solid-state electrolytes replace flammable liquids, removing fire risk.

- Stronger polymers resist puncture from dendrite growth.

What is a solid-state polymer electrolyte?

It is a solid plastic film that replaces the flammable liquid electrolyte in traditional batteries. This innovation eliminates leakage risk, boosts energy density, and makes energy storage systems much safer.

Can battery plastics be recycled? ♻️

Yes, new designs focus on recycling. The “Design for Disassembly” approach uses reversible glues and mechanical clips. This method makes it easier to separate and recover plastic components for reuse, promoting a circular economy.

How do plastics help with faster charging?

Thermally conductive plastics help manage heat. These materials draw heat away from the cells during fast charging. Better heat dissipation allows the system to handle higher currents safely, reducing charging times.