You want safe and reliable charging for your lithium polymer battery. The right battery charger connectors help you protect your lipo battery and extend its life. Not all lipo battery connectors work with every charger. Using lipo compatible chargers and connectors made for lithium polymer battery cells prevents damage and fire risks. Always match your battery connector to your lipo battery for the best results. Choose a charger that supports lithium polymer battery packs and uses safe battery charger connectors.

Key Factors for Battery Charger Connectors

Compatibility Basics

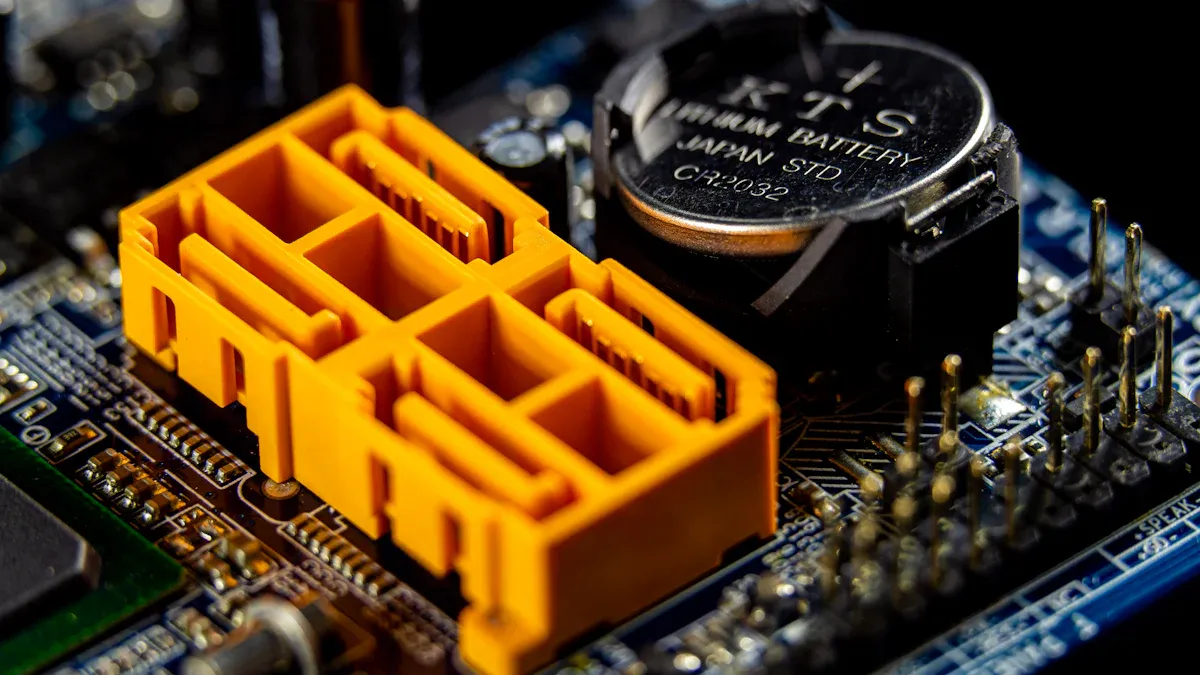

You need to make sure your battery charger connectors match your lithium polymer battery and charger. Compatibility problems often cause charging issues or even damage. Here are some common problems you might face:

- Hardware charging current limits can be too low for larger lithium polymer battery packs. You may need to change hardware settings or parts to charge bigger batteries safely.

- Charging indicator lights may not work right if your device goes into deep sleep mode. This can make it hard to know if your lithium polymer battery is charging.

- Using the wrong connector type or mixing up polarity can stop your battery from charging or even cause damage. For example, using a JST PH2.0 connector instead of the correct VIN/GND can prevent power flow.

- Some USB ports or cables do not support the right charging signals or current. This can lead to slow or failed charging.

- If you use solar power or other sources that turn on and off, the charging timer may not reset correctly. This can affect how your lithium polymer battery charges.

Tip: Always check the connector type, polarity, and cable quality before you start charging your lipo battery.

Manufacturers help you avoid these problems by listing compatibility requirements. They tell you which connectors fit your battery and charger, what voltage and current they support, and how to match polarity. You should always follow these guidelines to keep your lithium polymer battery safe and working well.

Current and Voltage Needs

Your lithium polymer battery and charger must handle the right amount of current and voltage. If you use battery charger connectors that cannot handle the power, you risk overheating or damaging your battery. Manufacturers rate connectors by how much current they can carry. For example, XT60 connectors work for smaller batteries, while XT90 or EC8 connectors handle high-current applications.

| Connector Type | Typical Current Rating | Common Use Case |

|---|---|---|

| JST-PH | Up to 2A | Small RC models, toys |

| XT60 | Up to 60A | Medium drones, RC cars |

| XT90 | Up to 90A | Large drones, e-bikes |

| EC5/EC8 | 120A/200A+ | High-current applications |

You should always match the connector rating to your battery and charger. If you use a connector with a lower rating, it can get hot and fail. If you use a connector with a higher rating than needed, it will still work, but it may be bigger and heavier.

Note: Always check the voltage and current ratings for both your battery and charger before connecting them. This helps prevent accidents and keeps your lithium polymer battery healthy.

Safety Essentials

Safety matters most when you charge a lithium polymer battery. You need battery charger connectors with good safety features. Look for connectors with secure locking mechanisms, strong materials, and correct polarity markings. These features help prevent short circuits, loose connections, and overheating.

- Use connectors with locking clips or latches if your device moves or vibrates.

- Choose high-quality connectors made from durable materials to avoid wear and tear.

- Make sure the connector fits tightly and does not wiggle or slip out.

- Always double-check polarity before connecting your charger to your lipo battery.

Warning: Never leave your lithium polymer battery charging unattended. Always use lipo compatible chargers and charge on a fireproof surface.

By following these steps, you protect your battery, charger, and yourself. Good battery charger connectors and safe charging practices help your lithium polymer battery last longer and work better. You also lower the risk of fire or damage during charging and discharging.

Why Connector Choice Matters

Performance Impact

Choosing the right connector for your lithium polymer battery system makes a big difference in how well your devices work. When you use a connector that matches your battery and charger, you get safe, efficient, and reliable power. The connector type, size, and quality all play a role in how much current and voltage your system can handle. If you pick a connector that cannot handle the power, you may see voltage drops, heat buildup, or even a shorter battery life.

1. Identify your device’s voltage and current needs before picking a connector. 2. Make sure the connector can handle the power without getting hot. 3. Choose a connector type that fits both your lithium polymer battery and charger, like JST or XT60. 4. Check that the connector fits your device and has the right polarity. 5. Use connectors with locking mechanisms if your device moves or shakes. 6. Pick high-quality connectors for better reliability and longer life.

A good connector helps your lithium polymer battery deliver power with less resistance. This means your lipo battery will last longer and work better during charging and discharging.

Safety Risks

Connector choice also affects safety during charging. Poor or loose connectors can cause power loss, sparks, or even short circuits. These problems can damage your lithium polymer battery or start a fire. Always use connectors that fit tightly and have clear polarity markings. High-quality connectors with gold-plated contacts and locking clips help prevent accidents.

- Never use a connector that feels loose or gets hot during charging.

- Always double-check the fit and polarity before you start charging your lipo battery.

- Use connectors made from strong materials to avoid wear and tear.

Safety starts with the right connector. Protect your lithium polymer battery, charger, and yourself by making smart choices.

LiPo Battery Connector Types

Common Low-Voltage Connectors

You will find several lipo battery connector types designed for low-voltage and small lithium polymer battery packs. These connectors work well for lightweight devices and small RC models. The most common connectors of lithium polymer battery in this group include JST-PH, Molex Picoblade, Micro JST, and PH 2.0. These low-voltage lipo battery connectors handle less current and fit thin wires. You often see them in toys, micro drones, and wearable electronics.

| Connector Type | Typical Current Rating | Typical Cable Size | Common Usage / Notes |

|---|---|---|---|

| JST-PH | Up to 2A | 26-28 AWG | Micro drones, toys |

| Molex Picoblade | Up to 1A | 28-30 AWG | Small electronics |

| Micro JST | Up to 1.5A | 28 AWG | Wearables, sensors |

| PH 2.0 | Up to 2A | 26-28 AWG | Mini RC, LED strips |

You can also find JST-XH and JST-RCY connectors for balance leads or low current needs. These types of lipo battery connectors keep your lithium polymer battery safe in small devices.

High-Current Connectors

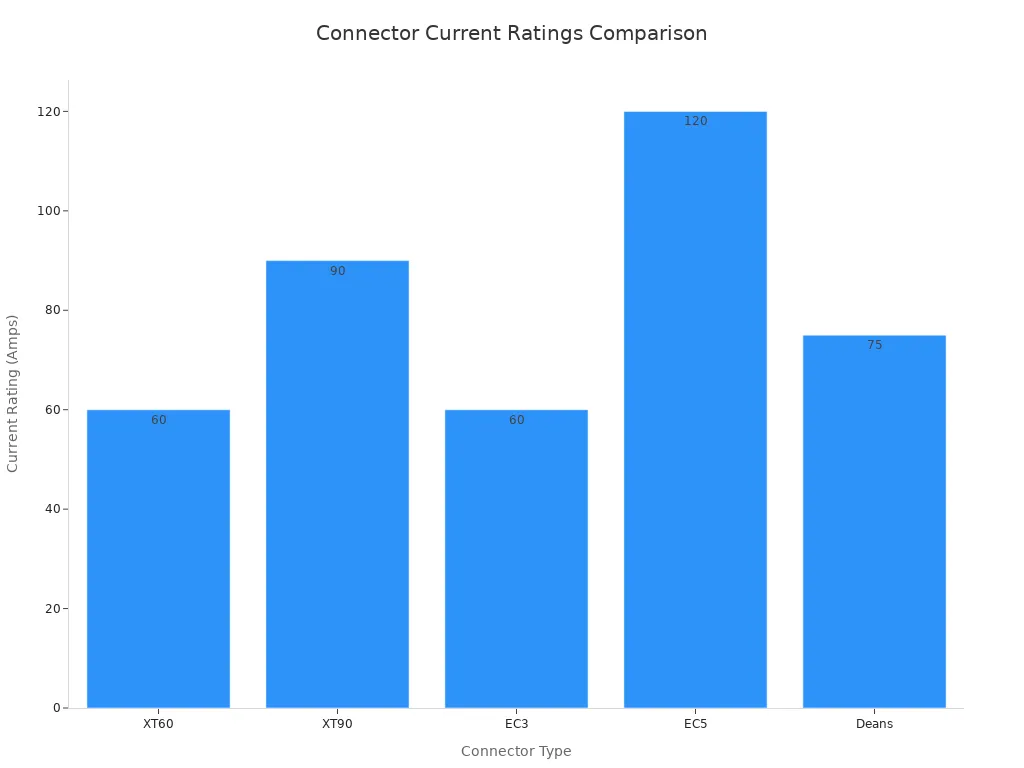

When you use a lipo battery for high-current applications, you need strong connectors. High-current power connectors like XT60 connectors, XT90 connectors, EC3, EC5, Deans, and Bullet connectors support large lithium polymer battery packs. These lipo battery connector types handle more current and thicker wires. You often see them in RC cars, drones, and e-bikes.

| Connector | Current Rating (Amps) | Physical Characteristics | Advantages | Disadvantages | Common Usage |

|---|---|---|---|---|---|

| XT60 | Up to 60 | Yellow nylon, bullet pins | Easy to solder, secure | Slightly bulky | RC cars, drones |

| XT90 | Up to 90 | Larger, robust nylon | High current, safe | Heavy, large | Large drones, e-bikes |

| EC3 | Up to 60 | Blue, 3mm bullets | Easy assembly | Bulky | RC planes, cars |

| EC5 | Up to 120 | Blue, 5mm bullets | High current | Heavy, large | High-power RC |

| Deans | 60-75 | Small, spring terminals | Tight fit, compact | Hard to solder | 1/10 RC cars |

XT60 connectors and XT90 connectors have become very popular for lithium polymer battery packs. You get a secure fit and strong current handling. Always match the connector to your battery and device needs.

Balance Charging Connectors

Balance connectors play a key role in safe charging for multi-cell lithium polymer battery packs. When you connect the balance lead to your charger, you allow the charger to check and control the voltage of each cell. This stops any cell from overcharging. You protect your lipo battery from damage and lower the risk of fire. Most chargers use JST-XH as the standard balance connector.

Tip: Always use the balance connector when charging multi-cell lipo batteries. This keeps all cells at the same voltage and extends battery life.

Balance charging connectors help you spot problems early. You can see if one cell has a lower voltage than the others. The charger will stop charging when all cells reach the right voltage. This feature keeps your lithium polymer battery safe and healthy.

Ensuring Compatibility

Matching Connectors

You need to match the connectors on your lithium polymer battery, charger, and device. This step prevents charging errors and keeps your system safe. When you use the wrong connector, you risk poor connections, charging interruptions, or even damage to your lithium polymer battery. Many users face problems because of loose or damaged plugs, dirt on contacts, or using non-original chargers. These issues can cause connection errors and even fire hazards.

- Poor or loose connections in main power or balance plugs, such as XT60 or EC5, often cause errors.

- Dirt or oxidation on battery contacts leads to poor connectivity.

- Using third-party chargers can create firmware or protocol mismatches.

- Incorrect voltage or cell count recognition by the charger interrupts charging.

- Physical damage, like burnt or loose plugs, affects connection stability.

- Charging at rates above the recommended 1C increases the risk of battery swelling or failure.

- Improper power input, such as AC/DC incompatibility, can stop the charger from working.

- Firmware incompatibility between smart batteries and chargers causes errors.

You can avoid most of these problems by using original cables and chargers from the same brand. Regularly clean your battery contacts and check for damage. Always use charge leads that fit your battery connector. Before you buy a new lithium polymer battery or charger, identify the connector type on both. Common types include XT60, Deans, EC3, and mid-range voltage lipo battery connectors.

Tip: Using batteries and chargers from the same brand, like HobbyKing, helps reduce errors because they use matched calibration and protocols.

Polarity and Wire Gauge

Polarity means the direction of current flow. You must connect the positive and negative terminals correctly. If you reverse polarity, you can cause a short circuit, damage your lithium polymer battery, or even start a fire. Always check the polarity markings on your battery cable and charger lead. Red wires usually mean positive, and black wires mean negative. If you are unsure, use a voltage meter to check before connecting.

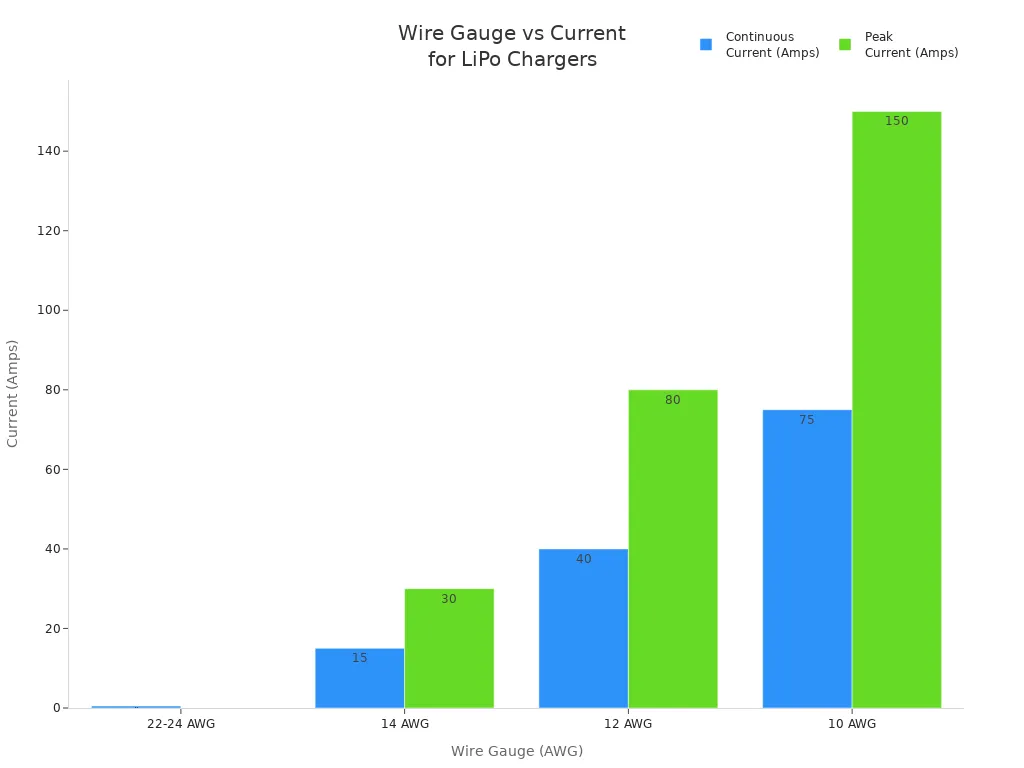

Wire gauge is also important for safe charging. The wire gauge tells you how much current the wire can handle. Using wires that are too thin for your lithium polymer battery can cause overheating and fire hazards. Here is a table to help you choose the right wire gauge for your lipo battery connectors:

| Wire Gauge (AWG) | Continuous Current (Amps) | Peak Current (Amps) | Notes |

|---|---|---|---|

| 22-24 AWG | ~0.5 (balance charging) | N/A | Good for balance charging at low current (~0.5A max) |

| 14 AWG | 15+ | 30 | Minimum for moderate currents |

| 12 AWG | 40+ | 80 | Good for 15-20 amp kits |

| 10 AWG | 75+ | 150 | Best for high current (around 140A peak) |

| 8 AWG | N/A | >140 | Use for very high peak currents |

Balance charging uses low current, so thin wires like 22-24 AWG work well. For high discharge currents, use thicker wires such as 14 AWG to 8 AWG. This keeps your lithium polymer battery safe and prevents fire hazards.

Note: Double-check charger settings, such as cell count and charging mode, before you start charging. This step helps prevent mistakes and keeps your battery healthy.

Physical Fit

Physical fit matters for both safety and performance. Your battery connector must fit tightly into the charger and device. A loose fit can cause power loss, sparks, or even short circuits. Always check that your lipo battery connectors do not wiggle or slip out during use. If you notice any damage or wear, replace the connector right away.

Some users try to solve connector mismatches by using adapters. While adapters seem convenient, they can create new risks:

- Adapters increase electrical resistance, which leads to heat buildup and efficiency loss.

- Overheating can melt plastic adapters and damage your lithium polymer battery.

- Adapters may bypass built-in safety features, raising the chance of accidents.

- Using third-party adapters can void your battery warranty.

- Adapters may lack overcharge protection, increasing hazards.

Warning: Avoid using adapters in high-powered applications. Directly solder compatible connectors to your battery and charger for the safest connection.

A secure and proper fit ensures your lithium polymer battery charges safely and delivers power efficiently. Always inspect your connectors before each use. Clean contacts and check for signs of wear or damage. By following these steps, you protect your battery, charger, and yourself from common charging problems.

Safety for LiPo Battery Charging

Anti-Spark Features

When you connect a lithium polymer battery, sparks can happen if the current rushes in too quickly. Anti-spark technology helps you avoid this problem. Many connectors, like the QS8-S and XT90S, have built-in anti-spark features. These connectors can handle high current and stop sparks and loud snaps during charging. Some anti-spark connectors use precharge resistors to slowly fill up the capacitors before making a full connection. This keeps your charger and battery safe from sudden surges.

- QS8-S connectors handle over 300 amps and work well for high-power charging.

- XT90S connectors offer anti-spark protection but have lower power limits.

- HXT connectors help when you connect several lithium polymer battery packs together.

- Waterproofing, like silicone seals, protects your connectors from water and dust.

| Feature | Description |

|---|---|

| Current Handling | 110A continuous, 300A+ peak |

| Voltage Rating | 600V DC |

| Material | Plated brass, durable nylon composite |

| Anti-Spark Effectiveness | Eliminates sparks and audible snaps |

| Application | High-voltage, high-power LiPo battery connectors |

Locking Mechanisms

Locking mechanisms keep your connectors secure during charging. You do not want your lithium polymer battery to disconnect by accident. Lever locks, push-pull latches, and screw locks all help prevent unplugging from bumps or vibration. For example, a lever lock clamps the connector halves together with a click. Push-pull locks need you to squeeze and pull to disconnect. These safety features make sure your charger stays connected until charging finishes. This reduces the risk of sparks, arcing, or damage to your battery and charger.

Material Quality

You should always choose connectors made from strong, flame-retardant materials. Good connectors use plated brass and nylon composites that resist heat and wear. These materials help your lithium polymer battery system last longer and work safely. High-quality connectors also handle high temperatures and keep their shape during charging and discharging.

Safe Charging Practices

You must follow safe charging steps every time you use your lipo battery. Always inspect your battery for swelling or damage before charging. Never charge a damaged battery. Use a digital voltmeter to check cell voltage. Do not charge if any cell is below 3.3V. Always charge on a fireproof surface and never leave your battery unattended. Use balance charging mode with the correct connector. Set the charger to match the battery’s cell count and voltage. Keep the charging current at or below 1C. Let your battery cool before charging again.

Tip: Use a battery management system (BMS) and a smart charger with safety features. These systems monitor voltage, temperature, and current. They stop charging if anything goes wrong. This keeps your lithium polymer battery safe and improves safety and efficiency for every charging and discharging cycle.

Step-by-Step Connector Selection

Assess Application

Start by looking at how you plan to use your lithium polymer battery. Think about the current your device needs, the type of connection, and where you will use it. For example, a small RC toy needs a different connector than a high-power drone. Use this table to compare connector types and their key points:

| Connector Type | Current Rating | Key Considerations |

|---|---|---|

| JST | Up to 5A | Good for small packs, lightweight, not for high current motors |

| Deans Ultra Plugs | Up to 100A | Light, strong, great for high current |

| Deans Micro Plugs | Up to 15A | Gold-plated, for lower power |

| Anderson Powerpole | 15-180A | Many sizes, easy to handle, good for different wire gauges |

| Multiplex 6-pin | Up to 50A | Multi-pin, can connect power and control signals |

You should also check if the connector can handle vibration, moisture, or heat. Always match the connector to your battery’s needs and follow the manufacturer’s advice.

Check Compatibility

You must make sure your charger, lithium polymer battery, and connector all work together. Follow these steps:

- Find out your battery’s cell count and voltage.

- Pick a charger that matches your battery’s voltage and shape.

- Check that the charger’s connector fits your battery’s connector.

- Use adapters only if needed, and always check polarity.

- Connect both the main power and balance cables.

- Set the charger to the right voltage and charge time.

- Start charging at a low rate and watch the battery temperature.

- Stop charging when the battery is full.

Tip: Always use industry-standard plugs like JST-XH for balance charging. Never force connectors together.

Review Safety Features

Look for safety features when you choose connectors for your lithium polymer battery. Good connectors protect against over-voltage, over-current, and short circuits. Some connectors have anti-spark designs to stop sparks during charging. Make sure your connectors are rated higher than your battery’s peak current. Clean and tight connections help prevent overheating. Watch for signs of damage, like melted plastic or a burning smell.

- Overcharge and short circuit protection keep your battery safe.

- Temperature sensors help stop overheating.

- International safety certifications show the charger meets high standards.

Plan for Future Needs

Think about how new technology might change your needs. Future lithium polymer battery trends include higher energy, faster charging, and smart features. Choose connectors that meet new safety rules and work with smart chargers. Look for connectors made from eco-friendly materials. Modular and flexible designs will help you adapt to new battery shapes and uses.

Note: Picking the right connector now helps your lipo battery system stay safe and ready for future upgrades.

Quick Checklist

You want to make sure your LiPo battery system stays safe and works well. Use this checklist before you start charging or choose a new connector. This table gives you a quick way to check the most important points:

| Checklist Item | Description | Examples / Notes |

|---|---|---|

| Connector Types | Check for both discharge and balance connectors on your battery. | Discharge connectors deliver power. Balance connectors keep cell voltages equal. |

| Common Discharge Connectors | Pick the right type for your battery and device. | Deans (T-Plug), XT30, XT60, XT90, EC3, EC5, EC8, JR, JST subtypes |

| Current Capacity | Match the connector to your device’s current needs. | XT30 (~30A), XT60 (30-60A), XT90 (>90A), EC3 (60-80A), EC5 (80-120A), EC8 (>150A) |

| Size and Compatibility | Make sure the connector fits your battery pack and charger. | JST connectors for small batteries, JR for larger models |

| Application Considerations | Choose based on your model’s size and power requirements. | Small models use JST or XT30. Large models use XT60, XT90, or EC series. |

✅ Always double-check polarity before charging.

✅ Inspect connectors for damage or dirt before every charging session.

✅ Use balance charging for multi-cell LiPo batteries to keep all cells healthy.

✅ Never leave your battery unattended while charging.

✅ Select connectors that match your device’s current and voltage needs.

You can print this checklist or keep it on your workbench. Following these steps helps you avoid mistakes and keeps your LiPo battery safe during every charging cycle.

When you choose connectors for your lithium polymer battery, always focus on compatibility, current rating, and safety. Use dedicated connectors and chargers designed for your lipo battery to prevent overheating and extend battery life. Follow these steps for reliable charging:

- Connect batteries with the correct polarity and use balancing chargers.

- Monitor charging and store batteries at safe voltages in cool places.

- Inspect batteries for swelling or damage before each use.

Stay informed about new connector technologies and safety standards to keep your battery system safe and efficient.

FAQ

What connector should I use for my LiPo battery?

You should choose a connector that matches your battery’s current and voltage needs. XT60 and Deans work well for most RC models. Always check your device’s manual for the recommended connector type.

Can I mix different connector types on one system?

You should not mix connector types. Mixing connectors can cause poor connections or safety risks. Always use the same connector type for your battery, charger, and device to keep your system safe.

How do I know if my connector is safe for charging?

Check for tight fit, no damage, and correct polarity. Use connectors with locking features and strong materials. If you see sparks or feel heat, stop charging and inspect your connector.

Why do commercial drone battery connectors look different from hobby connectors?

Commercial drone battery connectors often handle higher currents and offer extra safety features. These connectors use stronger materials and advanced locking systems to meet strict industry standards.

Can I use adapters to connect my battery and charger?

You can use adapters, but only for low-power setups. Adapters may increase resistance and heat. For high-power systems, always solder the correct connector directly to your battery and charger.