You must match the right lithium battery connectors to your device’s needs. This involves checking the current rating, voltage, and physical design. Choosing incorrectly can cause major problems. In some high-tech fields, connector issues account for 40-50% of all equipment failures.

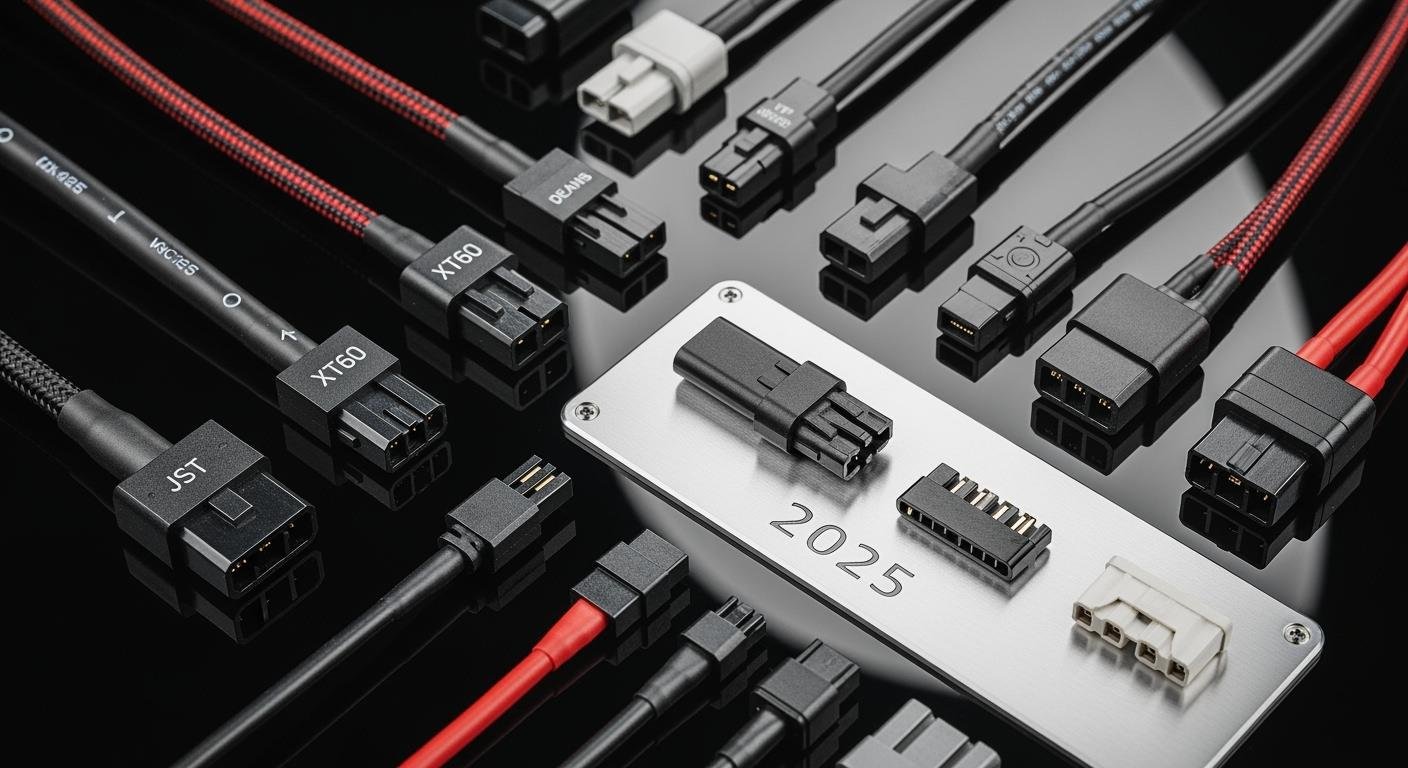

The market for these parts is growing fast. It is expected to reach over $3 billion in 2025. You will often see common connector types like the XT, EC, and JST series. This guide will help you understand different lithium battery connector types. It will give you the knowledge to select safe and effective lithium battery connectors for your project.

Key Factors for Choosing Lithium Battery Connectors

You must select the right lithium battery connectors for your project. A mismatch can cause poor performance, overheating, or even total failure. Consider these factors to make a safe and efficient choice for your energy storage needs.

Current and Voltage Requirements

You must first check the current (amps) and voltage needs of your device. A connector must handle the maximum current without getting hot. This ensures efficient power transmission. For high-current applications, you might choose an XT series connector. For low-voltage systems, JST connectors are often a better fit. The connector’s voltage rating is also critical. It prevents electrical arcing and provides stable energy transfer. The wire gauge, or thickness, also affects current capacity. A smaller American Wire Gauge (AWG) number means a thicker wire that can carry more current.

Physical Size and Application

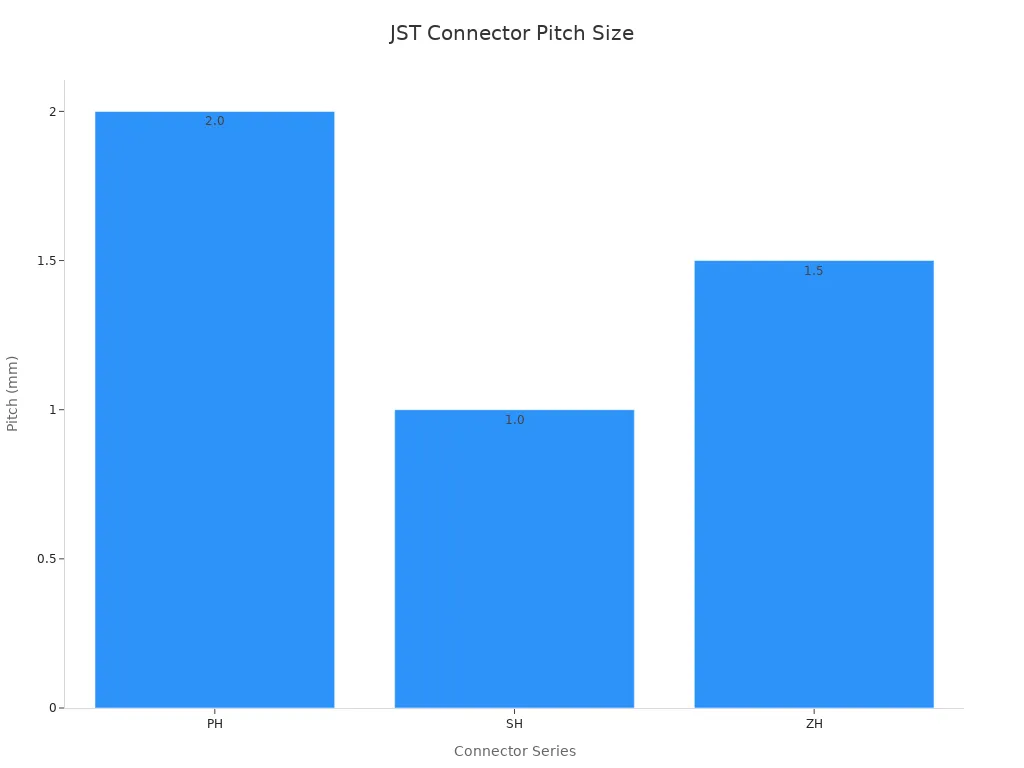

The connector’s size must fit your device. Compact devices like small drones or wearables need smaller lithium battery connectors. JST connectors are excellent for these uses because of their small pitch (the distance between pins).

- JST PH: 2.0 mm pitch, great for small battery packs.

- JST SH: 1.0 mm pitch, ideal for ultra-compact electronics.

- JST ZH: 1.5 mm pitch, used in small robotics and drones.

You should also think about the environment. Will your device experience vibration or moisture? Some lithium battery connectors use elastomeric materials for better shock absorption and sealing, protecting your energy storage system.

Safety and Polarization Features

Safety is a top priority. Most lithium battery connector types are “polarized.” This means they can only be plugged in one way. This feature prevents you from accidentally reversing the positive and negative connections.

Warning: Reversing polarity can instantly destroy your electronics, damage your battery, or cause a fire. Always use polarized connectors for your energy storage.

Durability and Connection Cycles

Consider how often you will plug and unplug the connector. Different connectors are rated for a certain number of connection cycles. For high-current applications and frequent use, you need durable lithium battery connectors.

| Connector | Mating Cycles |

|---|---|

| XT60 | ~1,000 |

| EC5 | 500+ |

| Deans (T-Plug) | 300–400 |

Materials like beryllium copper and gold plating improve conductivity and resist wear. This ensures your energy storage connection remains reliable over time.

An Overview of Lithium Battery Connector Types

You need to understand the main connector families to choose the right one. Each family has specific strengths for different jobs. This overview covers the most common lithium battery connector types you will encounter.

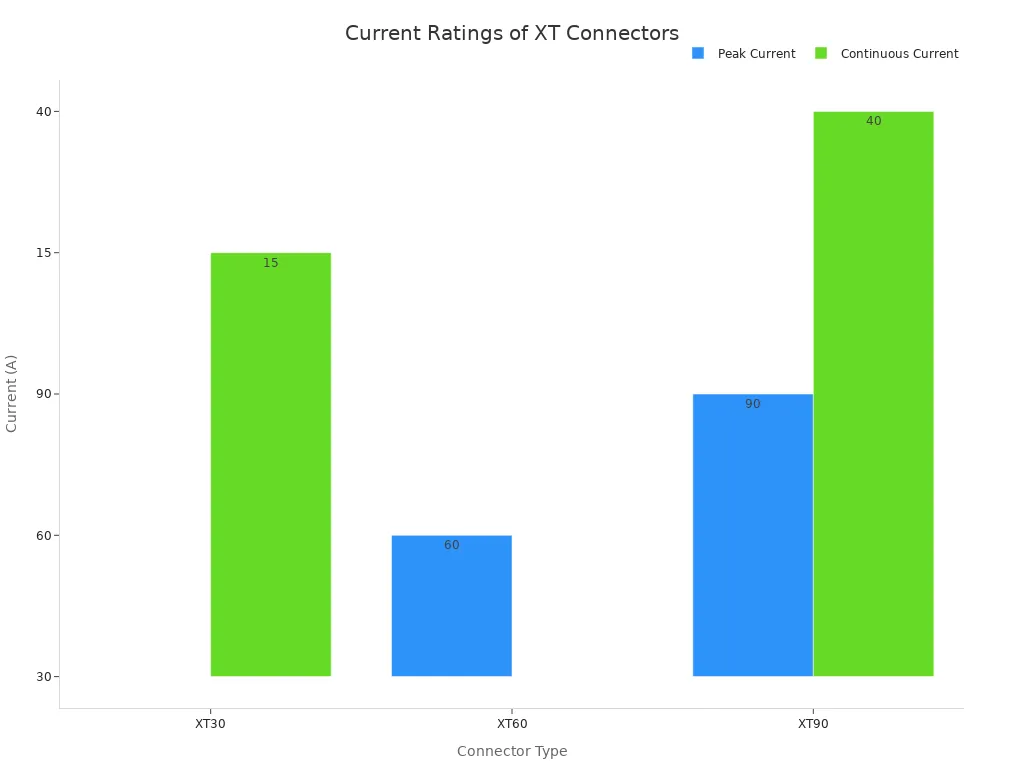

The XT Series: The Hobbyist Standard

You will find the XT series everywhere in the RC hobby world. These lithium battery connectors are known for their reliability and ease of use. They come in different sizes to handle various power levels. The number after “XT” indicates the peak current rating in amps.

- XT30: A small connector perfect for small drones and RC planes.

- XT60: The most popular choice for mid-sized drones, cars, and planes. It is a versatile discharge connector.

- XT90: A larger connector for high-power setups, like large drones or RC boats.

The XT90 is highly recommended for 4s or larger LiPo batteries because it handles more amps. You can see how the current ratings compare below.

| Connector | Continuous Current | Peak Current |

|---|---|---|

| XT30 | 15A | 30A |

| XT60 | 30A | 60A |

| XT90 | 40A | 90A |

These reliable battery connector types provide a secure connection for your energy storage system.

The EC Series: For High-Power Needs

When your project demands serious power, you should look at the EC series. These high-power battery connectors are engineered for high-current applications. They use bullet-style pins that create a large contact area for excellent power transfer.

- EC3: Good for mid-level power needs, often found on RC vehicles.

- EC5: A very popular choice for high-current applications. It has a continuous current rating of 120A. You will see it on large-scale electric models, 700-size helicopters, and even some high-performance EVs.

- EC8: Built for extreme power, handling over 200A. It is used in the most demanding drones and high-performance EVs.

The robust design of EC connectors makes them ideal for harsh environments. They ensure your energy storage connection stays cool and stable under heavy loads. These are excellent battery terminal connectors for powerful systems.

JST Connectors: For Low-Power and Data

JST connectors are the go-to choice for low-power electronics and data signals. You will not use them as your main discharge connector on a powerful device. Instead, they serve a different, equally important role.

Note: JST connectors are most famous as the standard balance connector on a lithium-ion battery. A balance connector allows you to charge each cell in your battery pack individually. This process ensures the pack stays healthy and performs well over its lifespan.

Here are some common JST connector types:

| Connector Type | Pitch | Current Rating | Primary Use |

|---|---|---|---|

| JST-XH | 2.5mm | 3A | The most common balance connector. |

| JST-PH | 2.0mm | 2A | Internal connections in small electronics. |

| JST-RCY | 2.5mm | 3A | Low-power accessories on RC models. |

You use a JST balance connector to maintain your energy storage. The main discharge connector handles the heavy lifting.

Deans Plugs (T-Style): Compact and Reliable

Deans plugs, also known as T-Plugs, are famous for their compact size and low electrical resistance. Their small footprint makes them a favorite in applications where space is tight, like RC cars and planes.

While there is no official rating, users report Deans can handle around 60A of continuous current. They can manage short bursts of 75A or more. This performance makes them a solid discharge connector for many mid-power projects. Their key advantages include:

- Small Form Factor: Saves valuable space inside a device.

- Low Resistance: Ensures efficient power transfer from your energy storage.

- Secure Connection: Provides a tight fit that resists vibration.

Specialized and Industrial Connectors

Sometimes, you need something more specific than the common hobbyist lithium battery connectors. Specialized connector types offer unique features for industrial, automotive, or custom projects.

Anderson Powerpole Connectors These are popular for their modular, genderless design. You can stack the individual housings together to create custom battery packs and power distribution systems. This flexibility simplifies inventory and makes maintenance easy. They are a top choice for custom energy storage solutions.

Molex Connectors You will find Molex connectors inside many consumer electronics. They are often used for wire-to-board connections in custom battery packs. Several series are common for battery connections:

- Mini-Fit Jr. Series: Offers a 9A current rating for high-current connections.

- Micro-Fit Series: Provides a 5A rating in a compact 3.0mm pitch design.

- Mini-Latch Series: Used for low-power (3A) connections in consumer devices.

These battery connectors are essential for building and repairing modern electronics. Understanding these different lithium battery connector types and battery terminal connectors helps you build safer and more efficient systems. This knowledge of battery connector types and terminals is crucial for any project.

Connector Comparison Chart for 2025

You can use this chart to quickly compare popular lithium battery connectors. This tool helps you see the key differences between various connector types. It makes choosing the right part for your energy storage system much easier. You should pay close attention to the current ratings. This ensures your connector can handle the power your device needs. This is especially important for high-current applications.

Tip: Always check the specifications from the manufacturer. Some brands may have slightly different ratings for their lithium battery connectors. This chart is a general guide for your energy storage project.

The table below breaks down the most common lithium battery connector types. You can find their ratings and best uses. This information is vital for building a safe and efficient energy storage solution. For example, you will see that some connectors are built specifically for high-current applications, while others are better for low-power energy storage needs.

| ### Connector Type | ### Continuous Current Rating (Amps) | ### Peak Current Rating (Amps) | ### Voltage Range | ### Primary Applications |

|---|---|---|---|---|

| XT30 | 15A | 30A | Up to 500V | Small drones, RC planes, small-scale energy storage. |

| XT60 | 30A | 60A | Up to 500V | Mid-sized drones, RC cars, 3D printers. |

| XT90 | 40A | 90A | Up to 500V | Large drones, e-bikes, high-power RC models. |

| EC3 | 60A | 75A+ | Up to 600V | Mid-power RC vehicles and aircraft. |

| EC5 | 120A | 150A+ | Up to 600V | Large-scale RC models, light EVs, demanding projects. |

| Deans (T-Plug) | ~50A | 75A+ | Up to 600V | RC cars and planes where space is limited. |

| JST-XH | 3A | N/A | Up to 250V | LiPo battery balance leads, low-power signals. |

Best Practices for Connector Safety and Longevity

You can extend the life of your lithium battery connectors and ensure safe operation. Following a few best practices for installation and maintenance makes a big difference. These steps protect your equipment and improve overall battery safety and performance.

Proper Soldering and Installation

A strong solder joint is the foundation of a reliable connection. A poor connection creates high resistance, which generates heat and wastes power. For high-current connectors like the XT90, you should use the right tools.

- Use a soldering iron with at least 50W of power.

- Choose 60/40 rosin core solder for a strong bond.

- Set your iron to around 650°F (343°C) to ensure the solder flows properly.

After soldering, you must insulate the joint. Heat shrink tubing is the best choice. It provides electrical insulation, strain relief, and protection from moisture.

Tip: Use a heat gun to apply heat shrink tubing. Keep the heat gun moving over the connector like you are painting it with hot air. This prevents overheating and ensures the tube shrinks evenly.

Regular Inspection for Wear

You should inspect your connectors regularly, especially if you plug and unplug them often. Physical wear can lead to a loose connection and potential failure. Look for these visual signs of damage:

- Corrosion: A dull, discolored, or crusty buildup on the metal contacts.

- Pitting: Small holes or cavities on the contact surfaces.

- Physical Damage: Bent pins, cracked plastic housings, or scratches.

- Discoloration: Stains or fading on the connector body from heat or arcing.

If you see any of these issues, you should replace the connector immediately.

Preventing Reverse Polarity

Connecting a battery backward can cause catastrophic damage. Most modern lithium battery connectors are polarized, meaning they only fit one way. This is your first line of defense. Many lithium batteries also have a built-in protection circuit. This circuit may prevent damage by tripping a fuse or shutting down the battery. However, you should not rely on it. A reverse polarity event can still damage the battery’s protection board, even if the cells survive. Always double-check your connection before powering on your device.

You now know that choosing the right connector is a simple process. You match the connector’s current and voltage ratings to your device’s power needs. Refer back to the comparison chart as a quick tool to confirm your selection. This small part is critical for your entire system. A mismatch can lead to overheating or short circuits, similar to issues seen in major product failures. Your choice ensures the safety and peak performance of your electronics.

FAQ

Can you use a connector with a higher amp rating?

Yes, you can. It is always safe to use a connector with a higher current rating than your device needs. For example, you can use an XT90 connector for a 40A system. You must never use a connector with a lower rating than your system requires.

What is the difference between continuous and peak current?

Continuous current is the steady power a connector handles without overheating. Peak current is the maximum power it can take for a short burst, like during motor startup. You should choose your connector based on your device’s continuous current needs for safe operation.

Are all connectors of the same type equal?

No, quality can vary greatly between brands. Genuine connectors use better materials for improved safety and a longer lifespan. Cheaper copies might use low-grade plastic or have a loose fit.

Tip: You should always buy your connectors from a trusted supplier to avoid poor performance and potential safety risks. 👍