When you select lithium battery connector types, you directly affect battery safety and performance. Connectors join wires, boards, or devices, while terminals form the contact points for electrical flow. Reliable battery connector types, such as wire-to-board, pin, blade, and socket connectors, appear in many industries because they match lithium battery connectors and terminals for secure, efficient connections. Terminals keep current stable and prevent energy loss. The importance of battery connectors grows as advanced terminals with anti-looseness and insulating features protect your devices.

Connector Type Common Applications Wire-to-Board Consumer electronics, industrial Pin Connectors Automotive, industrial equipment Blade Connectors Energy storage, portable devices Socket Connectors Telecommunications, healthcare

Lithium Battery Connector Types

When you work with lithium batteries, you need to understand the different lithium battery connector types. These connectors and terminals help you safely connect, charge, and use your batteries. The right battery connector types keep your devices running smoothly and protect your equipment from damage.

Discharge Connectors

A discharge connector is the main path for power to leave your lipo battery and reach your device. You use this connector when you want to power your RC car, drone, or electric bike. Discharge connectors handle high-current applications, so they must be strong and reliable. The wires on a discharge connector are thick, usually red for positive and black for negative. This design lets you draw a lot of current quickly, which is important for devices that need bursts of power.

You also use the discharge connector for fast charging. It connects directly to the battery, giving you a quick and efficient way to recharge. Unlike a charging connector with extra safety features, the discharge connector focuses on delivering power fast and efficiently. This makes it a key part of many lithium battery connector types.

Balance Connectors

A balance connector is just as important as the discharge connector. You find this connector on every lipo battery pack with more than one cell. The balance connector has several thin wires, one for each cell in the battery. These wires let your charger check the voltage of each cell and make sure they all charge evenly.

When you use a balance connector, you help your battery last longer. The charger can adjust the charge to each cell, so no cell gets overcharged or undercharged. This process, called balancing, keeps your battery safe and healthy. If you skip using the balance connector, your battery could fail early or even become dangerous. Always connect the balance lead when charging your lipo battery to protect your investment.

Tip: Always use the balance connector during charging. This step helps prevent cell damage and extends the life of your lipo battery.

Common Battery Connector Types

You will see many types of battery connectors in lithium and lipo battery packs. Each connector type has its own strengths and best uses. Here are some of the most common types of battery connectors you will find:

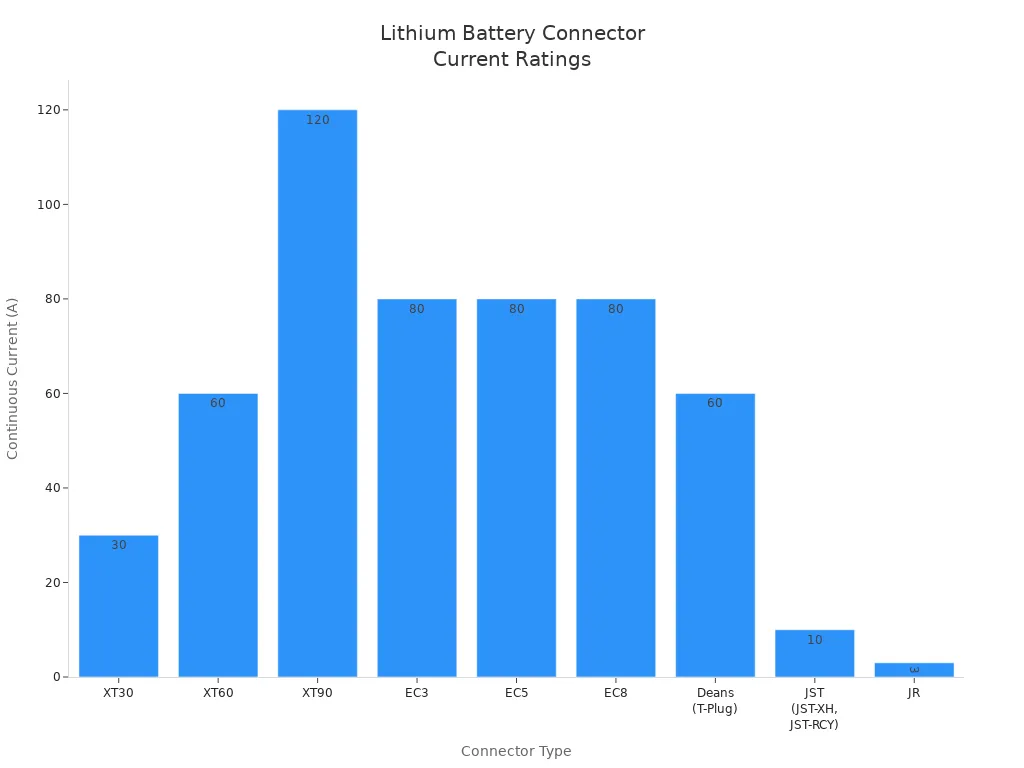

- XT Series (XT30, XT60, XT90): These connectors are popular in the RC hobby world. XT30 works for small devices, XT60 handles up to 60 amps, and XT90 is for high-current applications like electric bikes. They are easy to solder and provide a secure fit.

- EC Series (EC3, EC5, EC8): EC connectors are strong and reliable. EC3 is good for medium power, while EC5 and EC8 are for high-current applications. You often see these in drones and large RC vehicles.

- Deans (T-Plug): Deans connectors are compact and have low resistance. They support high current and are common in RC cars and planes.

- JST Connectors: JST connectors are small and used for low-current applications. You find them in small electronics and as balance connectors on lipo batteries.

- Molex and Hirose: These connectors are tiny and lightweight. They work well in compact devices where space is tight.

- Bullet Connectors: Bullet connectors are simple and allow quick connections. You see them in high-current applications and custom battery builds.

- Anderson Powerpole: These connectors are versatile and used in power distribution systems, especially for 12V setups.

Here is a table to help you compare the most common types of lipo battery connectors:

| Connector Type | Typical Current Capacity | Typical Applications | Distinguishing Features |

|---|---|---|---|

| XT30 | Up to ~30A | Small RC models, micro drones | Small size, low current rating |

| XT60 | 30-60A | RC cars, planes, drones | Moderate current, widely used |

| XT90 | >90A | Large RC models, electric bikes | High current, larger size |

| EC3 | Up to 60-80A | RC helicopters, drones, some cars | Medium size, moderate current |

| EC5 | 80-120A | Electric cars, boats, larger aircraft | Larger size, higher current |

| EC8 | 150A+ | Large-scale RC models, high-performance EVs | Largest size, highest current |

| Deans (T-Plug) | High current | High-performance RC applications | Low resistance, reliable connection |

| JST | Low current | Micro RC models, small electronics | Small size, low-power use |

| Molex, Hirose | Low current | Micro RC models, compact devices | Very small, lightweight |

| Anderson Powerpole | Variable | Power distribution, 12V systems | Versatile, widely used |

You need to match lithium battery connectors and terminals to your device’s needs. For high-current applications, choose connectors like XT60, XT90, EC5, or EC8. For small electronics, JST, Molex, or Hirose connectors work best. Always check the current and voltage ratings before you pick a connector.

Note: The importance of battery connectors goes beyond just making a connection. Certified connectors and terminals meet strict safety standards like UL, IEC, and automotive-specific rules. These standards make sure your connectors can handle the required current, resist vibration, and protect against dust and water.

When you select the right lithium battery connector types and terminals, you keep your devices safe and running at their best. You also help your lipo battery last longer and avoid problems like overheating or poor performance. Always pay attention to the types of battery connectors and match lithium battery connectors and terminals to your application.

Types of Lithium Battery Terminals

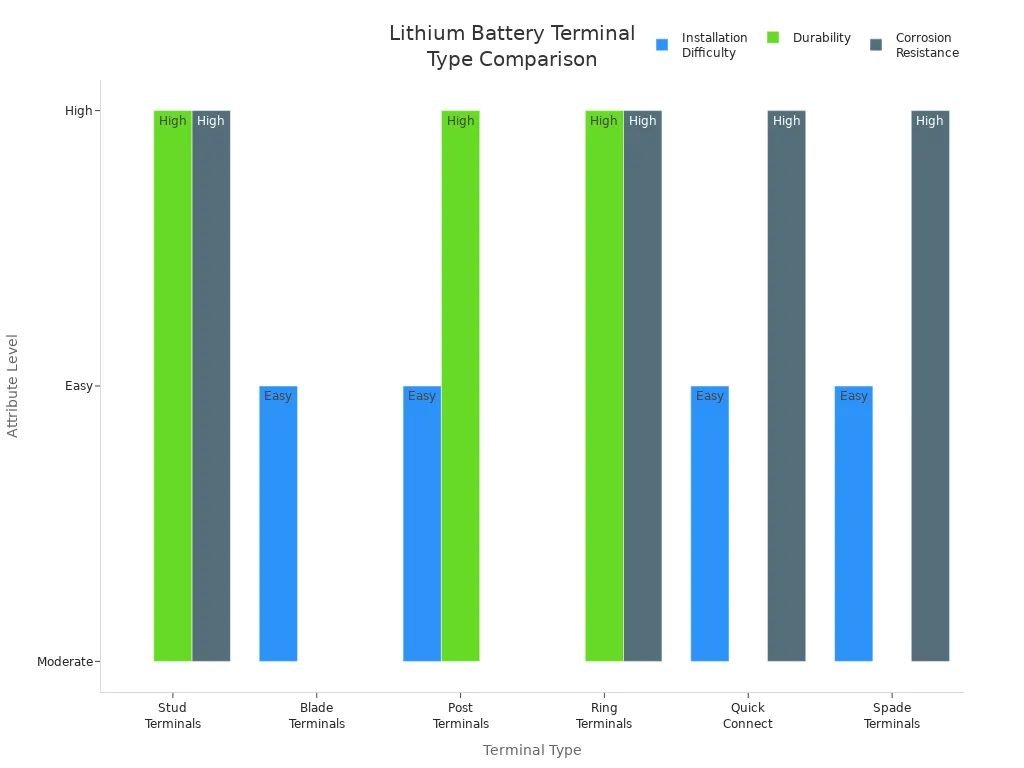

When you work with lithium battery systems, you need to identify lithium battery terminals that match your application. The types of lithium battery terminals you choose affect safety, performance, and how long your battery lasts. Each type of terminal has a unique design and works best in certain situations. You will see these terminals in cars, boats, solar panels, and even DIY projects.

| Terminal Type | Connection Method | Typical Current Rating | Common Applications | Installation Difficulty | Durability | Corrosion Resistance |

|---|---|---|---|---|---|---|

| Stud Terminals | Bolt-On | High (100-200A) | Power, Marine, Telecommunications | Moderate | High | High |

| Blade Terminals | Slide-On | Moderate (50-100A) | Electronics, Automotive | Easy | Moderate | Moderate |

| Post Terminals | Top/Side Mount | High (100-200A) | Automotive, Heavy Machinery | Easy | High | Moderate |

| Ring Terminals | Bolt-On | Moderate (50-100A) | Marine, Manufacturing | Moderate | High | High |

| Quick Connect | Plug-In | Low (<50A) | Electronics | Easy | Moderate | High |

| Spade Terminals | Slide-On | Low (<50A) | Household Appliances, Electronics | Easy | Moderate | High |

Button and Flat Terminals

You often see button and flat terminals in small lithium battery packs. These terminals save space and cost less than other types. You can connect them by soldering, welding, or using simple hardware. Button and flat terminals work best in low-drain batteries where you do not need high current. They have a small contact area, so they can heat up if you use them for high-power devices. If you want a compact and budget-friendly solution, these terminals are a good choice, but you trade off some conductivity and strength.

- Button and flat terminals are easy to install and fit in tight spaces.

- They are not ideal for high-current loads because they can get hot.

- You will find them in portable electronics and backup battery packs.

Stud and Bolt Terminals

Stud and bolt terminals give you a strong, secure connection. You attach cables using nuts and washers, which keeps the connection tight even if your device vibrates. These terminals use durable materials like brass or stainless steel, so they resist corrosion and last a long time. Stud and bolt terminals handle high current, making them perfect for electric vehicles, marine batteries, and solar power systems. You can trust these terminals for smooth charging and discharging, even after thousands of cycles.

- Stud terminals use a threaded post for a tight, adjustable fit.

- Bolt terminals create a rugged, vibration-resistant connection.

- These terminals reduce the risk of loose connections and overheating.

Ring, Blade, and Flag Terminals

Ring terminals have a circular shape that fits over a stud or bolt. You see them in automotive and marine wiring because they give a stable, long-lasting connection. Blade and flag terminals are flat and rectangular. They fit into tight spaces like fuse boxes and relay panels. Blade terminals are easy to slide on and off, which helps with quick repairs. Flag terminals work well in compact battery setups, but they have lower current ratings. Always match the ring terminal hole size to your fastener for the best fit.

Tip: Use ring terminals for high-reliability connections and blade or flag terminals when you need to save space.

Clamp, Lug, and Splice Terminals

Clamp terminals, like alligator clips, let you make quick, secure connections. Lug terminals have a U-shape and give you a strong mechanical hold. Splice terminals join wires together using twist-on, crimp-on, or heat-shrink methods. These types of lithium battery terminals use materials like copper, brass, or aluminum for good conductivity. You should always pick the right terminal for your power needs, wire size, and environment. Loose or dirty battery terminals can cause heat, power loss, or even battery failure. Clean, tight connections keep your lithium battery terminals safe and reliable.

- Clamp terminals are great for temporary setups or testing.

- Lug and splice terminals provide strong, stable connections for permanent wiring.

- High-quality terminals resist corrosion and vibration, which is important for positive and negative lithium battery terminals.

Remember: Secure and clean battery terminals help prevent overheating and extend battery life. Always check your positive and negative lithium battery terminals for tightness and cleanliness.

Lipo Battery Connector Overview

When you choose a lipo battery connector, you decide how safely and efficiently your lipo battery delivers power. The common types of lipo battery connectors each serve a unique purpose. You need to match the connector to your device’s current needs and size.

XT Series (XT30, XT60, XT90)

XT connectors are some of the most popular choices for lipo battery users. You see XT30, XT60, and XT90 in many RC models and drones. XT30 handles up to 30 amps, making it perfect for small drones and mini quads. XT60 supports up to 60 amps, which fits mid-range voltage lipo battery connectors in RC cars and planes. XT90 steps up to 90 amps or more, so you use it for high-voltage lipo battery connectors in large RC vehicles and high-current applications.

| Connector | Max Current Rating (A) | Typical LiPo Battery Application |

|---|---|---|

| XT30 | ~30A | Small drones, FPV racers, mini quads (3S LiPo) |

| XT60 | ~60A | Drones, RC planes, 1/10 scale RC cars (3S LiPo) |

| XT90 | ~90A | Large RC cars, 1/8 scale RC vehicles |

XT connectors use gold-plated bullet terminals and strong nylon housings. You get a secure, one-way fit every time.

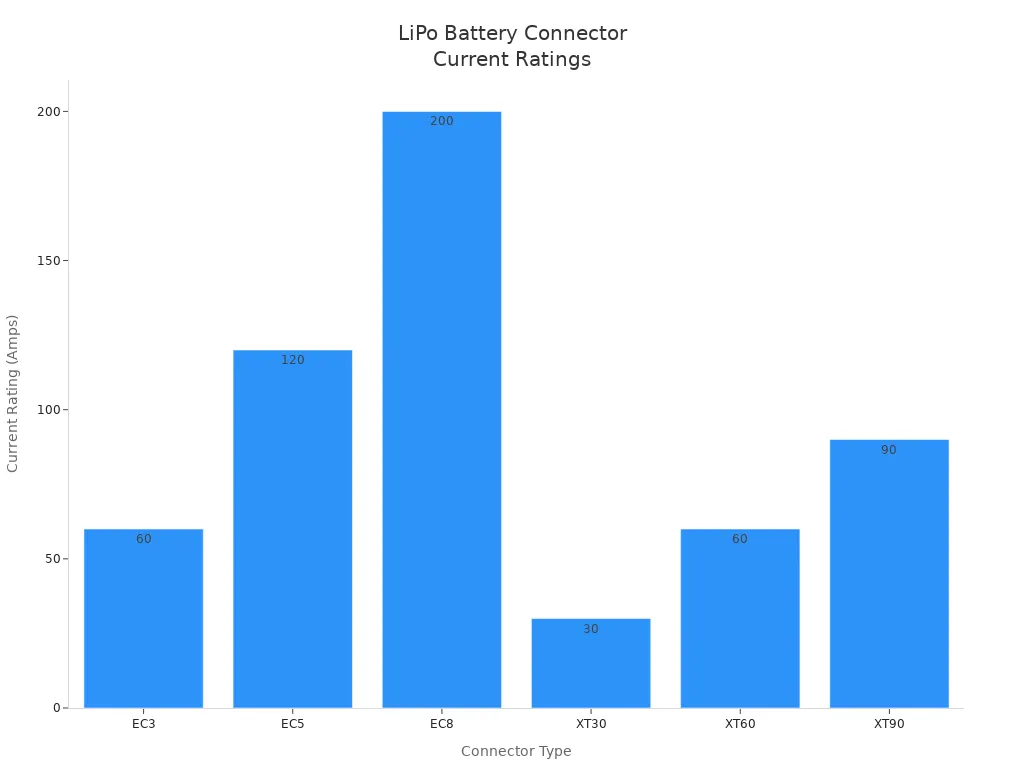

EC Series (EC3, EC5, EC8)

The EC series gives you reliable battery connectors for different power levels. EC3 supports up to 60 amps, which works well for lower current lipo battery setups. EC5 handles up to 120 amps, so you use it for larger electric helicopters and cars. EC8 goes beyond 200 amps, making it the best choice for high-power lipo battery systems.

| Connector | Current Handling Capacity | Typical Use Cases |

|---|---|---|

| EC3 | Around 60A | Lower current lipo battery applications |

| EC5 | Up to 120A | Large scale electrics, 700 size helicopters |

| EC8 | Over 200A | High-power needs, very high current handling |

You find EC connectors easy to solder. The bullet-style pins give you a large contact area for safe, efficient power transfer.

JST, Molex, Hirose, and Bullet Connectors

JST connector types are small and lightweight. You use them for low-voltage lipo battery connectors in micro drones and small electronics. Molex and Hirose connectors also fit compact devices where space matters. Bullet connectors come in many sizes, from 3.5mm to 8.0mm, and handle currents from 35A to 200A. You often see bullet connectors between ESCs and motors, but some use them for custom lipo battery builds.

Tip: Always match the connector’s current rating to your lipo battery’s needs. Using the wrong size can cause overheating or power loss.

Deans T-Connectors and JR Connectors

Deans t-connector is a classic choice for lipo battery connector setups. It has a compact design and gives you a secure fit. Many RC hobbyists trust it for high-current applications, but it can be tricky to solder. JR connector types are common in RC receivers and servos. You use them for moderate current, but they are larger than JST connectors and not ideal for very low-power devices.

| Connector Type | Advantages | Limitations |

|---|---|---|

| JR Connector | Reliable, handles moderate current well | Larger than JST, not for very low-power |

| Deans T-Connector | Compact, secure connection | Can be difficult to solder |

You should always check the current rating and fit before choosing battery connectors for your lipo battery. The right lipo battery connector keeps your device safe and running at its best.

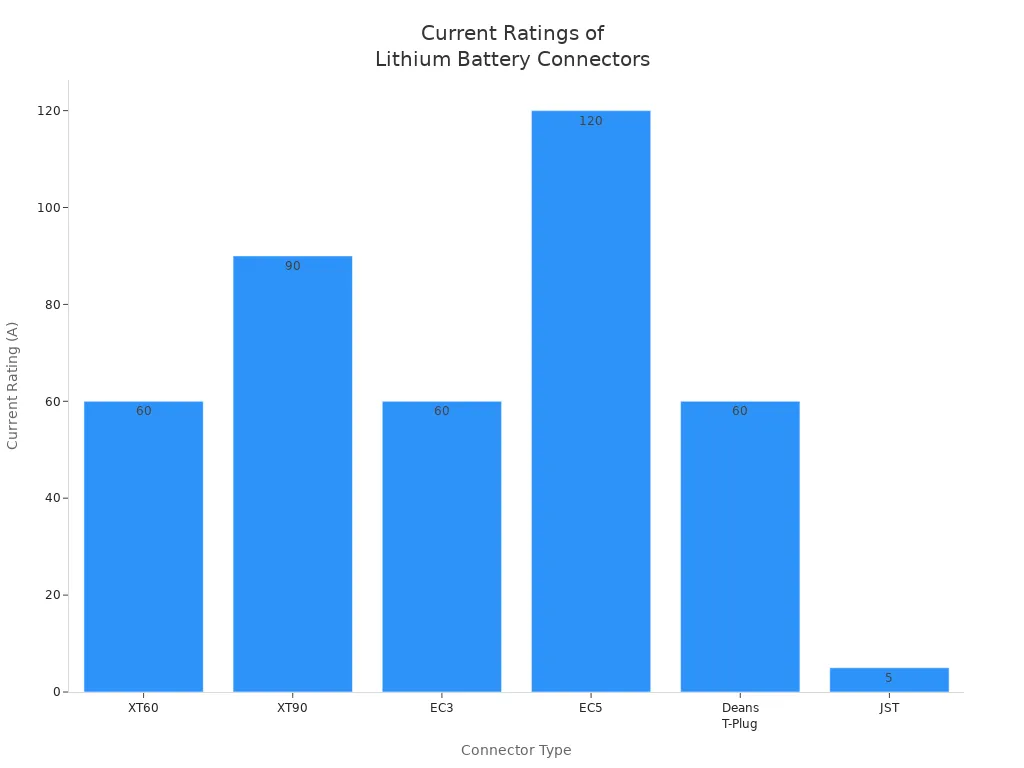

Comparing Battery Connector Types

Performance and Safety

When you choose a lithium battery connector, you must think about both performance and safety. Each connector type has a different current and voltage rating. For example, XT60 connectors handle up to 60 amps, while XT90 connectors support 90 amps or more. EC5 connectors can go up to 120 amps. You should always match the connector’s rating to your device’s needs.

Most connectors use quality materials like copper or gold plating. These materials help prevent corrosion and keep the connection strong. Many connectors are polarized, which means you cannot plug them in the wrong way. This feature protects your battery from short circuits and overheating. You should always check for a secure fit. Loose connections can cause heat buildup and power loss.

Tip: Use connectors with keyed shapes or color codes to avoid reverse polarity and make installation easier.

Application Suitability

You need to pick the right connector for your application. High-drain devices like electric vehicles or large RC models need connectors such as EC5, XT90, or even larger types. These connectors handle high current and stay cool under heavy loads. For small electronics or micro drones, JST or Molex connectors work best because they are lightweight and compact.

Environmental factors also matter. High temperatures can cause connectors to loosen or corrode. Humidity increases the risk of oxidation. You should choose connectors with protective coatings and strong seals if you use them outdoors or in harsh conditions. Regular inspection and cleaning help keep your connectors safe and reliable.

- Use high-current connectors for powerful devices.

- Choose compact connectors for small gadgets.

- Pick corrosion-resistant materials for wet or hot environments.

Summary Table of Key Differences

Here is a quick comparison of popular lithium battery connector types:

| Connector Type | Current Rating | Ease of Use | Safety Features | Best For |

|---|---|---|---|---|

| XT60 | 60A | Moderate, polarized | Good fit, quality materials | Drones, RC vehicles |

| XT90 | 90A | Large, polarized | Secure, prevents overheating | High-performance RC, e-bikes |

| EC3 | 60A | Secure, moderate | Polarized, reliable contact | RC airplanes, helicopters |

| EC5 | 120A | Large, easy handle | Robust, high current, fireproof plastic | High-current, harsh environments |

| Deans T-Plug | Up to 60A | Compact, polarized | Low resistance, reduces misconnection | RC vehicles |

| JST | Low current | Small, lightweight | Polarized, safe for low current | Small electronics, micro drones |

Note: Always match the connector’s current rating and safety features to your device’s needs for the best performance and protection.

How to Choose Battery Connector Types

Application and Compatibility

You need to match your connector and battery terminals to your device’s needs. Start by thinking about what you want your battery to do. High-current devices like electric vehicles or large RC models need strong connectors and heavy-duty terminals. Small electronics, such as drones or portable gadgets, work best with compact connectors and smaller battery terminals.

- Identify your application: automotive, marine, robotics, or small electronics.

- Check if the battery terminals fit your battery design and wiring.

- Choose reputable brands for safety and reliability.

- Make sure the connector matches your device’s port. Adapters can cause problems.

- Look for terminals that resist corrosion and fit your environment.

Tip: Always consult your device’s manual or manufacturer’s specifications before you select the right lipo battery connector or terminals.

Current and Voltage Ratings

You must check the current and voltage ratings for both connectors and battery terminals. If you use a connector that cannot handle your device’s power, you risk overheating or even fire. Always pick terminals that match or exceed your device’s maximum current.

| Connector Type | Max Current (A) | Typical Use |

|---|---|---|

| XT60 | 60 | RC vehicles, drones |

| EC5 | 120 | Electric cars, heavy-duty |

| JST | <10 | Small electronics, sensors |

- Match the connector’s rating to your battery and device.

- Use certified connectors and battery terminals for better safety.

- Consider the size and material of the terminals for a secure fit.

Note: High-quality battery terminals last longer and keep your connections safe.

Safety and Installation Tips

Proper installation and maintenance of battery terminals keep your system safe and reliable. Always make sure your terminals are clean and tight. Loose or dirty battery terminals can cause power loss or even damage your battery.

- Inspect battery terminals for corrosion or damage before use.

- Clean terminals with a safe solution if you see any buildup.

- Tighten connections using the right tools, but do not overtighten.

- Use protective covers to keep dust and moisture away from battery terminals.

- Apply dielectric grease to terminals to prevent corrosion.

- Replace damaged terminals right away to avoid safety risks.

- For high-vibration environments, check battery terminals more often.

Remember: Secure and clean battery terminals help your battery last longer and work better.

You need to understand both connectors and terminals to keep your lithium batteries safe and long-lasting. The right terminals help you avoid power loss, overheating, and short circuits. When you select and install terminals properly, you improve energy transfer and reduce risks. Always check that your terminals fit your battery and device. Use corrosion-resistant terminals and keep them clean. Follow these tips for better results:

- Choose terminals with the correct current rating and thermal stability.

- Use terminals with anti-corrosion coatings for longer life.

- Tighten terminals securely and avoid over- or under-tightening.

- Pick terminals from trusted brands for reliable performance.

- Protect terminals with covers to prevent shorting.

- Store batteries in cool, dry places to help terminals last longer.

- Clean terminals with baking soda and water if you see corrosion.

- Avoid grease or lubricants on terminals.

- Check cables and terminals for damage or corrosion often.

- Use the right size wires and proper crimping for all terminals.

| Terminal Type | Application | Maintenance Tip |

|---|---|---|

| Auto Male Terminal | Cars | Keep terminals clean; avoid grease; proper torque |

| Hairpin Terminal | Secure connections | Check for corrosion; ensure proper crimping/soldering |

| Double Post Terminal | Marine, automotive | Use ring terminal; avoid over-tightening |

| Terminal Button | UPS, emergency systems | Use correct bolt size; keep terminals clean |

| Terminal AT | Heavy-duty, solar panels | Maintain secure, corrosion-free terminals |

Remember: The right terminals and good care help your battery work better and last longer. Always match your terminals to your needs and follow safe installation steps.

FAQ

What happens if you use the wrong battery connector?

If you use the wrong connector, your device may overheat or stop working. You risk damaging your battery or causing a fire. Always match the connector type and current rating to your device.

How do you know which connector your lithium battery needs?

Check your device manual or battery label. Look for the current and voltage ratings. Match these to the connector’s specifications. If unsure, ask the manufacturer or a battery expert.

Can you mix different connector types with adapters?

You can use adapters, but this may cause power loss or loose connections. Adapters add resistance and may not fit securely. For best results, use the correct connector for your device.

How often should you check your battery terminals and connectors?

Inspect your connectors and terminals before each use. Look for dirt, corrosion, or loose parts. Clean and tighten them as needed. Regular checks help prevent problems and keep your battery safe.

Why do some connectors have gold plating?

Gold plating resists corrosion and improves electrical contact. You get a stronger, more reliable connection. This helps your battery deliver power safely and efficiently.

Tip: Always choose connectors with quality materials for better performance and longer life.